Effect of High Cetane Fuel Blended with Methanol on

Combustion Characteristics

L Mei

1, *

, R N Li

1

, S Liu

1

and P H Chen

2

1

School of Automotive and Traffic Engineering, Jiangsu University, Jiangsu 212013,

China

2

Nantong Shipping College, Jiangsu 226010, China

Corresponding author and e-mail: L Mei, zjml94@163.com

Abstract. The influence of high cetane number fuel blended with methanol on the

combustion characteristics of diesel engine is studied. Fuels of high cetane number with

different cetane number were compounded by FT diesel fuel and methanol. Bench tests were

performed on 186F diesel engine. The cylinder pressure and heat release rate of different high

cetane number fuels were measured. The change law of ignition delay period and the

combustion duration of different methanol blending ratio under and loads were analyzed. The

results show that under the rated condition, with the decrease of the mixed fuel cetane number,

the maximum combustion pressure and peak value of heat release rate increase, and the

corresponding crank angle is delayed. When the cetane number of the fuel reduces from 75 to

64 under constant load, the ignition delay period increases and the combustion duration

reduces. The changes of the ignition delay period and combustion duration vary most

obviously under 25% load, ranging from 2.8°CA to 6.1°CA, respectively. With the same

high cetane number fuel, as the load increases, the ignition delay period shortens and the

combustion duration increases.

1. Introduction

In our country, due to the energy structure feature of rich coal and poor oil, the development of coal-

based synthetic oil fuels to replace some petroleum-based fuels has great advantages [1]. F-T diesel

oil is a product of indirect coal liquefaction with high cetane number. Methanol has high oxygen

content and high latent heat of vaporization, which can be mass-produced by coal, and is a kind of

clean fuel with low price and huge output[2].

The combustion and emissions of diesel are closely related to the physicochemical properties of

the fuel. The cetane number of diesel ranges from 45 to 50 normally [3]. Fuel with cetane number

higher than 50 is called high cetane number fuel. Cetane number of FT diesel and methanol is 75 and

3, respectively. A small amount of methanol is blended with the FT diesel fuel to obtain the mixed

fuel, the cetane number of which still belongs to the high cetane number range. The FT diesel fuel is

mixed with methanol to study the effect of high cetane number fuel blended with methanol on the

combustion process.

Domestic and foreign scholars have done a lot of research work on the effect of fuel blended with

methanol on the combustion process. Han et al.[4] studied the effects of fuel properties such as

Mei, L., Li, R., Liu, S. and Chen, P.

Effect of High Cetane Fuel Blended with Methanol on Combustion Characteristics.

In Proceedings of the International Workshop on Environmental Management, Science and Engineering (IWEMSE 2018), pages 313-318

ISBN: 978-989-758-344-5

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

313

cetane number on low-temperature combustion of diesel engines. Cetane number is the most

important factor affecting ignition delay time and inversely proportional to ignition delay time.

Donkerbroek[5] et al. founds different cetane number of fuels cause ignition delay time to change,

affecting the flame structure and soot generation. Li[6] studied the effect of cetane number on the

combustion and emissions of diesel engines. The results show that the cetane number increased from

44 to 64, NOX decreased by 5%, and particulate emissions increased by 15%. Hou Shumei[7] of

Tianjin University studied the effects of fuel physicochemical properties on the combustion and

emissions of diesel engines. The cetane number is found to determine the time of combustion heat

release. After blended with iso-octane, the cetane number of mixed fuels decreases and the delayed

ignition period is prolonged, the proportion of premixed combustion increases and soot emissions are

reduced. Xie Fangxi[8] et al studied the effect of fuels with different cetane number on the emission

characteristics of diesel engines. The results show that: under steady state conditions, with the

increase of fuel cetane number, the delayed ignition period is shortened, and HC and NOX decrease.

High cetane number fuels with different cetane number were prepared by F-T diesel fuel blended

with methanol. Bench tests were performed on a 186F diesel engine. The cylinder pressure and heat

release rate of different high cetane number fuels were measured. The change of ignition delay period

and the duration of combustion were analyzed with different methanol mixing ratio at different loads.

2. Fuel, test equipment and scheme

2.1. Preparation and physicochemical properties 3

The F-T diesel used is obtained through the Fischer-Tropsch synthesis, hydrorefining, and cracking

reaction of coal. The main component is C9-C23 alkanes with a hydrocarbon content of more than

95%. With low sulfur content, no aromatics and good stability characteristics. The F-T

diesel/methanol fuels with different cetane number was prepared with methanol blending ratio of 0,

5%, 10% and 15%.

The parameters such as low heating value, cetane number, and oxygen content of mixed fuels are

complex to be tested but can be quickly obtained by using the formula. According to Kay's mixing

rule [9], the physicochemical properties of the mixed fuel are calculated by formula (1), and the

physical and chemical characteristics of the fuel are shown in Table 1.

(1)

In the formula, K

i

i

is the volume fraction of the

ith substance; K

i

is the physicochemical characteristic parameter of the ith substance; i is the number

of components.

Table1. Main physical and chemical properties of the test fuel.

Fuel

Composition (volume

fraction)%

Cetane

number

Low heat value /

(kJ·kg

-1

)

Density /

(g/cm

-3

)

Sulfurcontent /

(mm

2

/s)

F-T diesel

Methanol

F-T diesel (FM0)

100

0

75

47.35

0.76

2.25

Methanol

0

100

3

20.26

0.79

0.58

FM5

95

5

71

46.00

0.76

2.10

FM10

90

10

68

44.64

0.76

2.03

FM15

85

15

64

43.29

0.76

1.96

2.2. Test equipment

Four-stroke, naturally-aspirated, air-cooled ,direct-injection and non-road diesel engine 186FA was

used in the test. The main test equipment is: CWF25D eddy current dynamometer; EWE-5000DAQ

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

314

in-cylinder combustion pressure collection system produced; KSM071860 pressure sensor. Figure 1

shows the bench test.

Figure 1. Experimental setup.

2.3. Test scheme

The indicator diagram of different cetane number fuels under conditions of 3600r/min, 25%, 50%,

75%, 100% load were tested. The cylinder pressure, instantaneous heat release rate, the ignition

delay period and combustion duration were analyzed.

3. Analysis of combustion characteristics

3.1. Cylinder pressure

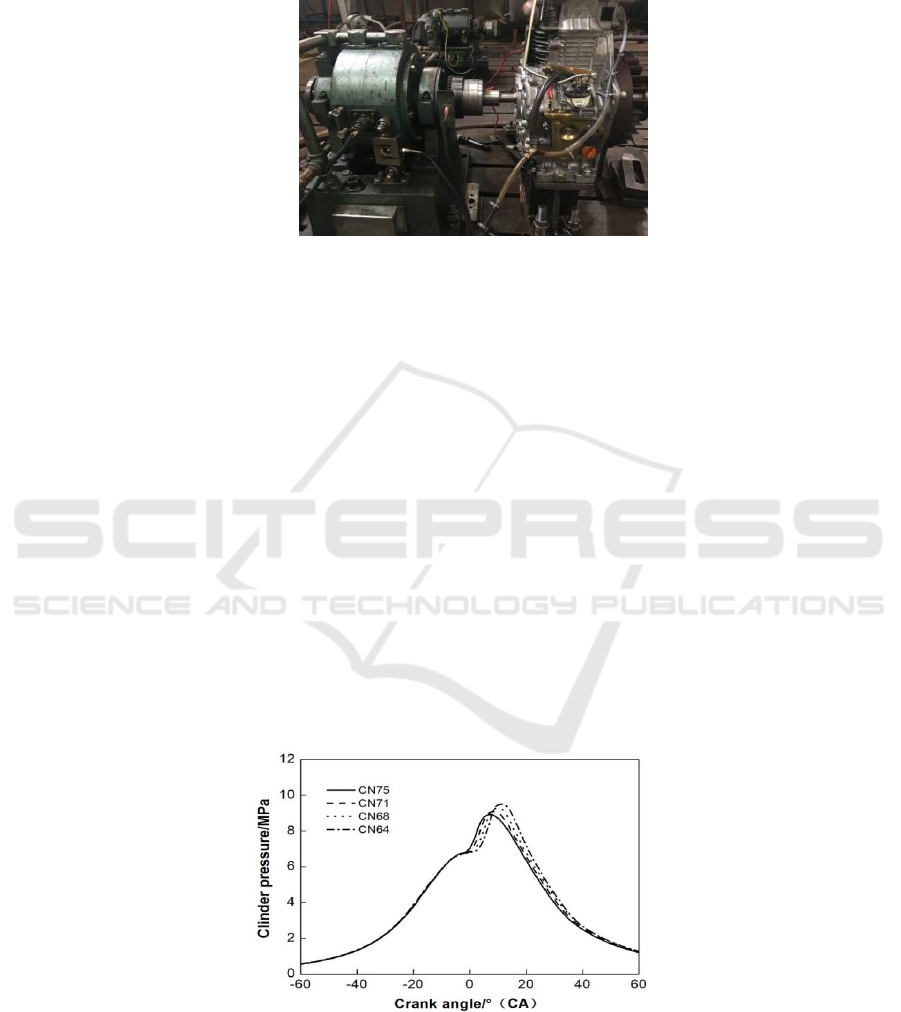

Figure 2 is the cylinder pressure curve of different high cetane number fuels under the rated

conditions (3600r/min, 100% load). As can be seen from the figure, with the cetane number

decreasing from 75 to 64, the maximum combustion pressure increased by 2.2%, 4.5%, and 6.7%,

and the corresponding crank angles lag behind by approximately 1° CA and 1° CA, 2 ° CA

respectively. The cetane number of F-T diesel is high, so it has high activity and ignition delay period

is short. With the increase of methanol blending ratio of mixed fuel, the cetane number decreases and

the ignition delay period increases, which leads to more mixture gas forming in the premixed

combustion stage and the increasing of the pressure peak.

Figure 2. Cylinder pressure curves of different cetane number fuels.

3.2. Instantaneous heat release rate

Figure 3 is the instantaneous heat release rate curve of different high cetane number fuels under the

rated conditions. As can be seen from the figure, when the fuel cetane number decreases from 75 to

Effect of High Cetane Fuel Blended with Methanol on Combustion Characteristics

315

64, the instantaneous peak heat release rate increases by 8.0 J (°CA)

-

-1

, 23.5 J

-1

, the corresponding crankshaft angles are shifted back by approximately 2°CA,

1°CA, and 2°CA, respectively. With the decrease of cetane number, the starting point of combustion

is postponed and the delayed ignition period is prolonged. The fuel injected during the ignition delay

period increases, and a large amount of flammable mixture is formed in the cylinder, which burns

rapidly in the period of fast burning. The viscosity of methanol is low, which leads to good effect of

atomization. The combustion rate is accelerated and the peak value of heat release rate increases.

Figure 3. Instantaneous heat release rate of different cetane number fuels.

3.3. The ignition delay period

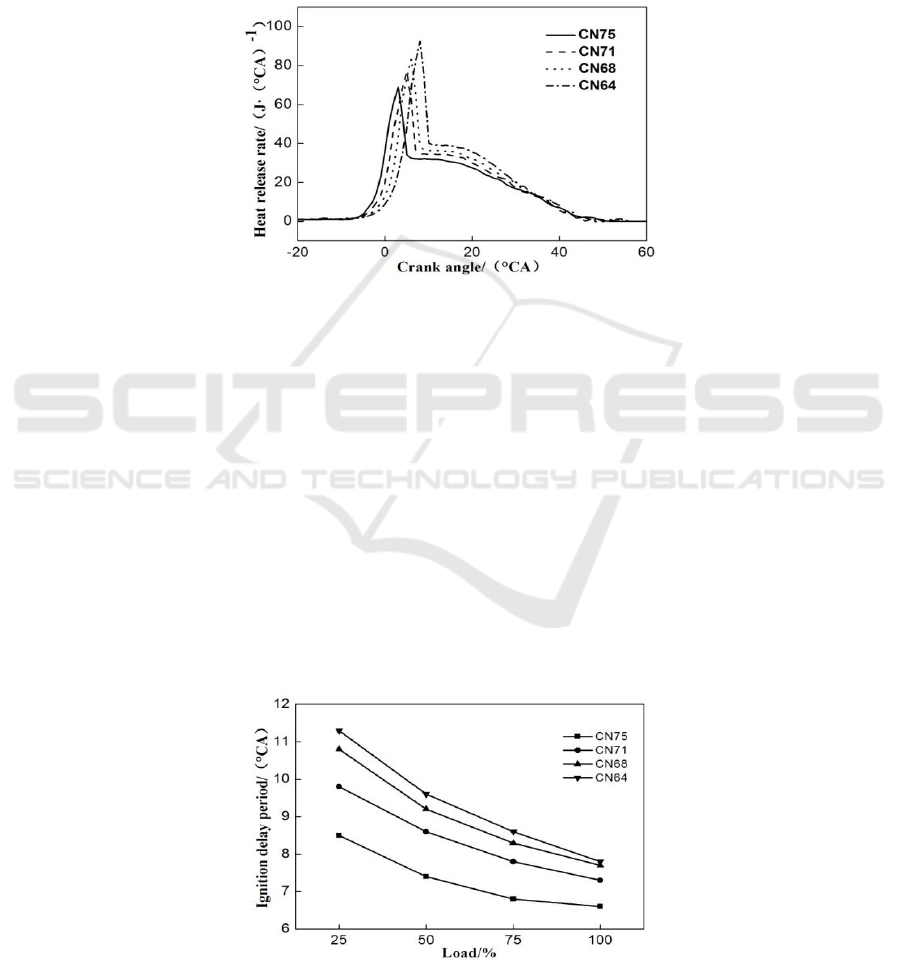

Figure 4 shows the change in the ignition delay time of different high cetane number fuels with

various loads at 3600 r/min. It can be seen from the figure that the ignition delay period is prolonged

with the decrease of cetane number. When the cetane number increases from 75 to 64, the increase of

the ignition delay period under 25% load is most obvious, increasing by 2.8°CA. F-T diesel is

mainly composed of straight chain n-alkanes with low aromatic hydrocarbons, so the carbon chain is

easy to break, and the cetane number is high. The cetane number of methanol is relatively low. As

the blending ratio increases, the cetane number of the mixed fuel decreases, the ignition property

deteriorates, and the ignition delay period prolongs. For the same high cetane fuel, when the loads

increases, the ignition delay period decreases. With the increasing load, the temperature and pressure

in the cylinder increase and the mixture gas ignites more easily. The ignition delay period is

shortened, and the combustion start point is advanced.

Figure 4. The ignition delay period of different cetane number fuels.

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

316

3.4. Combustion duration

Figure 5 shows the change in the combustion duration of different high cetane fuels under various

loads at 3600 r/min. It can be seen from the figure that the combustion duration decreases with

decreasing cetane number. When the cetane number decreases from 75 to 64, The combustion

duration is shortened most obviously under 25% load , decreasing by 6.1°CA. With the decrease of

cetane number, the ignition delay period is prolonged and the mixture of oil and gas becomes more

uniform. The premixed combustion period is prolonged but the diffusion combustion period is

shortened, so the combustion duration is shortened. For the same high cetane fuel, the combustion

duration increased with increasing load. As the diesel engine load increases, the amount of diesel

injected into the cylinder per cycle increases, the duration of combustion increases.

Figure 5. Combustion duration of different cetane fuels.

4. Conclusions

1) Under the rated condition, as the cetane number of mixed fuel increases from 75 to 64, the

maximum combustion pressure of the diesel engine increases by 6.7%, and the peak value of heat

release rate Increases

-1

. The corresponding crank angle of the both two are delayed

backwards.

2) The ignition delay period of high cetane fuels increases with cetane number decreases. When the

cetane number decreases from 75 to 64. The ignition delay period increases most obviously under

25% load, increasing by 2.8°CA. For the same high cetane fuel, the ignition delay decreases with the

load increasing,.

3) The combustion duration decreases as the cetane number decreases. When the cetane number

decreases from 75 to 64. The combustion duration decreases most obviously under 25%, decreasing

by 6.1°CA. With the same high cetane fuel, the combustion duration increases as the diesel engine

load increases.

References

[1] Cao Y S, Wang T, Yang T and et al 2016 Effects of Methanol/Biodiesel/F-T Diesel Coal-Based

Multi-Fuels on Engine Performance J. Chinese internal Combustion Engine Engineering

37(5):21-26

[2] Li R N, Wang Z, Li M D and et al 2014 Experimental study of cetane number on

metbanol/biodiesel emission of pollutant J. China Rnvironmental Science 34(7):1684-1689

[3] He X L, Zhan Y H, Meng X J and et al 1985 The effects of cetane number on the ignition and

combustion of diesel fuel in D.I. diesel engine J. Acta Petrolei Sinica(petroleum processing

section) (1):99-106

[4] Han M 2013 The effects of synthetically designed diesel fuel properties cetane number,

Effect of High Cetane Fuel Blended with Methanol on Combustion Characteristics

317

aromatic content, distillation temperature, on low-temperature diesel combustion J. Fuel

109(4):512-519

[5] Donkerbroek A J, Boot M D, Luijten C C M and et al 2011 Flame lift-off length and soot

production of oxygenated fuels in relation with ignition delay in a DI heavy-duty diesel engine J.

Combustion & Flame 158(3):525-538

[6] Li X, Chippior W L, Ömer L and Gülder 1996 Effects of Fuel Properties on Exhaust Emissions

of a Single Cylinder DI Diesel Engine[C]// Sae International Fall Fuels and Lubricants Meeting

and Exhibition

[7] Hou S M, Liu H F, Zheng Z Q and et al 2016 Effects of Fuel Properties on Diesel Combustion

and Emissions J. Transactions of CSICE (6):481-489

[8] Xie F X, Sun W C, Li G B and et al 2008 Effects of fuel cetane number on emission behavior

from a small diesel engine J. Journal of Jilin University (Engineering and Technology Edition )

38(5):1024-1028

[9] Li R N 2016 Study on the Atomization and Ignition Process ofMethanol/Biodiesel Blend Fuel D.

Jiangsu University

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

318