Effect of Meniran Extract (Phyllanthus niruri Linn.) to Alternate

Antibiotic Growth Promoter (AGP) on Egg Quality and Economics

Analysis of Layers Infected by Escherichia coli

Sri, H.,

1

, Rivienda, S.R.,

2

, Ika, A.A.,

2

, Emy, K.,

1

, Koesnoto, S.,

3

, Dika, F.L.,

4

1

Lecturer in Department of Animal Husbandry, Faculty of Veterinary Medicine, Universitas Airlangga, Surabaya,

Indonesia

2

Magister of Veterinary Agribusiness, Faculty of Veterinary Medicine, Universitas Airlangga, Surabaya, Indonesia

3

Profesor in Department of Animal Husbandry, Faculty of Veterinary Medicine, Universitas Airlangga, Surabaya,

Indonesia

4

Student of Veterinary Medicine, Faculty of Veterinary Medicine, Universitas Airlangga, Surabaya, Indonesia

Keywords: Meniran extract, AGP, Egg quality, Economic analysis, Layer infected by Escherichia coli

Abstract: The purpose of this study was to know the economics analysis in layers infected by Escherichia coli, which

used Meniran Extract (Phyllanthus niruri Linn.) as alternate Antibiotic Growth Promoter (AGP) to egg

quality. About 50 layers at 20 weeks of age were completely randomized into five treatments with two factors,

each treatment consisted of five replications with non-infectious factor and infectious factor. The treatments

were T0, T0+, T1, T2, and T3 containing standard feed, standard feed with 0,01 gram AGP/kg feed, standard

feed with 10% Meniran Extract/kg feed, standard feed with 20% Meniran Extract/kg feed, and standard feed

with 30% Meniran Extract/kg. The infection consisted of Escherichia coli 10

8

CFU/gram given to each layer

about 1 ml/kg of weight. The results in two ways Analysis of Variance (ANOVA) 5% showed that there were

insignificant differences among the treatments (P<0.05) and factors (P<0.05). In both factors, the lowest egg

quality was T3 which has 55.7 grams of weight, 76.24 of Haugh Unit Index, 0.36 of Yolk Index, 0.09 of

Albumen Index, and Yolk colour about 8.20. The highest egg quality was T2 which has 63.21 grams of

weight, 90.59 of Haugh Unit Index, 0.41 of Yolk Index, 0.11 of Albumen Index, and Yolk colour about 9.60.

All treatments showed good economics analysis, which had the best result in Benefit Cost Ratio, which has

a score about 1.51-1.60. It can be concluded that we can give 20% Meniran Extract/kg feed to get the best

egg quality and profit that can replace AGP.

1 INTRODUCTION

Eggs are a livestock product that contributes greatly

to the achievement of the nutritional adequacy of the

community. The price is relatively cheap compared to

other sources of animal protein and easily obtained

because the eggs have become public goods. Eggs are

one of the animal products derived from poultry and

are known as a food source of high quality protein

(Djaelani, 2016). Egg quality is a factor to be

considered, so that consumers get the nutritional

content of eggs intact. Combination of high ration

protein and linoleat content can produce eggs of

excellent quality. Quality of eggs will be guaranteed

if the quality of feed provided is sufficient according

to age and maintenance management (Djaelani,

2016).

Breeders generally use antibiotics to improve

quality and efficiency for feeding, as well as livestock

being healthier and more productive. Nowadays, the

use of antibiotics causes consumers anxiety about the

risk of antibiotic residues and they tend to avoid

livestock products containing residues.

Feed additives such as hormones and antibiotics

(Antibiotic Growth Promoter or AGP) are strictly

banned in developed countries including Indonesia

(Kompiang, 2006), related to the current global issue

of poultry farming, namely the safety of animal foods

Sri, H., Rivienda, S., Ika, A., Emy, K., Koesnoto, S. and Dika, F.

Effect of Meniran Extract (Phyllanthus niruri Linn.) to Alternate Antibiotic Growth Promoter (AGP) on Egg Quality and Economics Analysis of Layers Infected by Escherichia coli.

DOI: 10.5220/0007542503370342

In Proceedings of the 2nd International Conference Postgraduate School (ICPS 2018), pages 337-342

ISBN: 978-989-758-348-3

Copyright

c

2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

337

from contaminants and residues that are harmful to

consumers, certain bacterial resistance and

environmental issues (Akhadiarto, 2010). Feed

additives in poultry consist of vitamins, minerals,

antibiotics, and other factors such as growth hormone

used to improve poultry performance and improve the

nutrition of local raw materials used.

Khusnan (2012) states that feed additives have the

purpose of improving efficiency in breeding, by

accelerating the increase in body weight or increasing

livestock production so that maintenance costs can be

suppressed and profits can be obtained maximally.

Small doses of antibiotics in the diet to spur the

growth of livestock were used more than half a

century ago. The facts show that antibiotics in very

small doses can accelerate the growth of livestock,

thus causing leeway in obtaining antibiotics for use in

the field of livestock.

Some antibiotics that are widely used as AGP,

among others, include tetracyclin, penicillin,

macrolide, lincomysin and virginiamycin.

The activity of AGP as a growth promoter is

affected by antibiotic effects. There are several

theories that explain the mechanism of action of AGP.

These include antibiotics can help increase the

absorption of nutrients by making the wall barrier of

the small intestine become thin. Antibiotics can

reduce the production of toxins from the bacterial

gastrointestinal tract and reduce the incidence of

subclinical gastrointestinal infections (Feihgner and

Dashkevics, 1987 in Noor and Poeloengan, 2005).

The risk is of residual antibiotics becoming toxic to

consumers, as antibiotics can create resistant

microorganisms in the human body or livestock

especially pathogenic bacteria such as Salmonella,

Escherichia coli and Clostridium perfringens

(Sarwono, Yudiarti, and Suprijatna, 2012).

Escherichia coli belongs to gram negative

bacteria, facultative anaerob, rod-shaped, not spore-

forming, not acid-resistant and size 2-3 x 0.6 μm

(Gordon and Jordan, 1982). These bacteria live in the

animal's digestive tract. Physiological tests show a

positive reaction to indol and methyl red, negative to

Vogues-Proskauer, and do not use citrate as the only

carbon source (Krieg and Holt, 1984).

Innovation needs to be implemented in order to

find solutions to the problem and that is by providing

natural ingredients in the feed that can replace the

function of AGP. According to Bagalkotkar,

Sagineedu, Saad, and Stanslas (2006) in meniran

leaves there are various kinds of secondary

metabolites, including flavonoids, alkaloids, lignans,

tannins, and saponins. Almost all parts of the meniran

plant are medicinal.

Meniran plants (Phyllanthus niruri Linn.) grow in

tropical regions such as Indonesia. These plants are

often found growing wild in forests, in fields, and in

places where the soil is moist, sandy, by the river, on

the beach, and they even grow wild around the yard

of the house. Meniran can grow at an altitude of up to

1,000 meters above sea level (Ekasari, 2011).

Meniran herbal extract contains alkaloids, flavonoin,

saponin, steroid, tannin, and phenolic compounds

(Rivai, Septika, and Boestari, 2013).

The results suggest that meniran has

immunomodulatory activity that plays a role in

making the immune system more active in

performing its functions, strengthens the body's

immune system (immunostimulator) or suppresses

the immune system's excessive reaction

(immunosuppressant).

With the addition of meniran extract it is expected

to increase egg quality, thus reducing the production

cost in laying hens. Through business analysis with

total cost parameters, revenue, profit and loss, Benefit

Cost Ratio, will be analyzed regardingwhether the

provision of meniran extract on laying chicken feed

is more profitable or not. This study aims to

determine the financial analysis of infected chicken

farms (Escherichia coli) using meniran extract as a

substitute for Antibiotic Growth Promoter on the

quality of egg laying hens.

2 MATERIAL AND METHOD

2.1 Materials

The type of chicken used in this study was 50 egg

laying hens ISA-BROWN 20 weeks old with a

battery cage system length x wide x height front, rear

height = 40 cm x 40 cm x 37 cm, 30 cm.

Egg quality checking tools used: Egg yolk

separator used to separate egg yolks and egg whites,

yolk color Roche branded fans with 1-15 precision as

yolk color index (yolk index), glass as base with the

width of 20 cm and the length of 15 cm is used as the

base for measuring the egg white diameter, egg yolk

and its thickness, the sliding term is used to measure

the diameter of egg whites and egg yolk, the

spherometer is used to measure the thickness of the

egg white and the yolk, made of stainless steel, digital

scales Nakami weighing scales with gram scale with

a maximum limit of 5000 g to calculate egg weight.

ICPS 2018 - 2nd International Conference Postgraduate School

338

2.2 Method

The study was conducted in April 2018 in Ngrejo

village, Blitar regency, East Java. The day before the

research 20 weeks old chickens were taken and

separated in different cages. Chickens were adapted

for 5 days, fed commercial phase without antibiotics

layer and fed ad libitum. Chicken adapted and

weighed and weighed chicken feed for chicken needs

for 1 week. Data collection for egg quality was

performed in the last 1 week. On day 6 at the age of

21 weeks the chickens were infected with Escherichia

coli bacteria intramuscularly with concentration of

108 cells/kg weight as much as 1 ml then observed

clinical symptoms for 3 days. The meniran extract

was administered starting on the 9th day mixed in the

feed with different doses of each treatment group in

concentrations of 10%, 20%, and 30%.

2.3 The concentration of meniran

extract and AGP in the feed

2.3.1 Research on laying hens that are not

infected by Escherichia coli

Laying chickens were randomized into five

treatments, as follows:

o T0: Non-infected chickens Escherichia coli are

fed commercially

o T0 +: Non-infected chicken Escherichia coli fed

commercial with addition of 1% AGP

o T1: Non-infected chicken Escherichia coli fed

commercial with the addition of 10% concentrated

meniran extract of 1 ml / kgBW

o T2: Non-infected chicken Escherichia coli was

fed commercial with the addition of 20%

concentrated meniran extract of 1 ml / kgBW

o T3: Non-infected chicken Escherichia coli was

fed commercial with the addition of 30%

concentrated meniran extract of 1 ml / kgBW

2.3.2 Research on laying hens infected with

Escherichia coli

Laying chickens were randomized into five

treatments, as follows:

o T0: laying hens infected Escherichia coli 10

8

CFU / ml of 1 ml fed commercial

o T0 +: laying hens infected Escherichia coli 10

8

CFU / ml of 1 ml fed commercial with addition of 1%

AGP

o T1: laying hens infected with Escherichia coli

10

8

CFU / ml as much as 1 ml were fed with the

addition of 10% extract of meniran concentration of

1 ml / kgBW

o T2: laying hens infected Escherichia coli 10

8

CFU / ml as much as 1 ml fed with the addition of

extract of meniran concentration of 20% by 1 ml /

kgBW

o T3: laying hens infected Escherichia coli 10

8

CFU / ml of 1 ml fed with the addition of 30% extract

of meniran concentration of 1 ml / kgBW

2.4 Egg Quality

Looking at egg quality is done by breaking the egg

and spilling its contents on flat and smooth glass, then

measuring yolk index, egg white index, and Haugh

Unit. The Yellow Egg Index (IKT) is the high ratio of

egg yolk to the yolk center line (Koswara, 2009). The

standard for the yolk index is as follows: 0.22 = ugly;

0.39 = average, and 0.45 = high.

Egg White Index is a high ratio of egg white

(albumin) thick with an average diameter.

Measurements are performed after the egg yolks are

carefully separated. The new egg has an Egg White

Index between 0.050 - 0.174, but usually ranges

between 0.090 and 0.120. The Egg White Index

decreases during storage, due to the breakdown of

ovomucin that is accelerated by the rising pH.

Referring to the Badan Standardisasi Nasional

(2008) on SNI 3926: 2008, it is said that the egg white

index is a comparison between egg white height with

an average diameter of viscous egg white. Fresh egg

white index ranges between 0.050-0.174. The yolk

index is a comparison between the height of the egg

yolk and the yolk diameter. According to the Badan

Standardisasi Nasional (2008) on SNI 3926: 2008 the

index of fresh egg yolks ranged from 0.33 to 0.52.

Haugh unit was calculated using the formula

(Card and Nesheim, 1972), Haugh Units (%): 100 x

log(H+7.57 – 1.7W

0.37

), where H is the height of

albumen and W is the weight of the egg. Eggs with

good quality have a minimum HU of 72. Eggs that are

not worth consuming have less than 30 HU (Koswara,

2009).

a. Data Analysis

The experimental data of addition of meniran

extract on egg quality can be analyzed statistically

using analysis of variance (ANOVA) to know

whether there is real difference from treatment given.

If different or very different results are obtained then

it is continued with a Duncan Multiple Range Test.

Statistical analysis uses SPSS for Windows 21.0

program.

Effect of Meniran Extract (Phyllanthus niruri Linn.) to Alternate Antibiotic Growth Promoter (AGP) on Egg Quality and Economics

Analysis of Layers Infected by Escherichia coli

339

2.5 Business analysis

Production costs are all company expenditures to

obtain the factors of production that will be used to

produce goods produced by the company. Production

cost consists of two main parts, namely fixed cost and

variable cost.

2.5.1 Benefit Cost Ratio

Soepranianondo et al. (2013) states that the ratio

between the present value of the cash inflows and the

total present value of the outflow cash stream is called

the Benefit Cost Ratio (B / C), with the following

formula,

B/ C =

Sales Results

Production Fund

There are three possibilities: B / C> 1, B / C

= 1, B / C <1.

Criteria:

B / C Ratio > 1 means the business is feasible

B / C Ratio <1 means the business is not feasible

B / C Ratio = 1 means the business is break even

(BEP)

3. RESULTS

3.1 Egg Quality

3.1.1 Egg Yolk Index

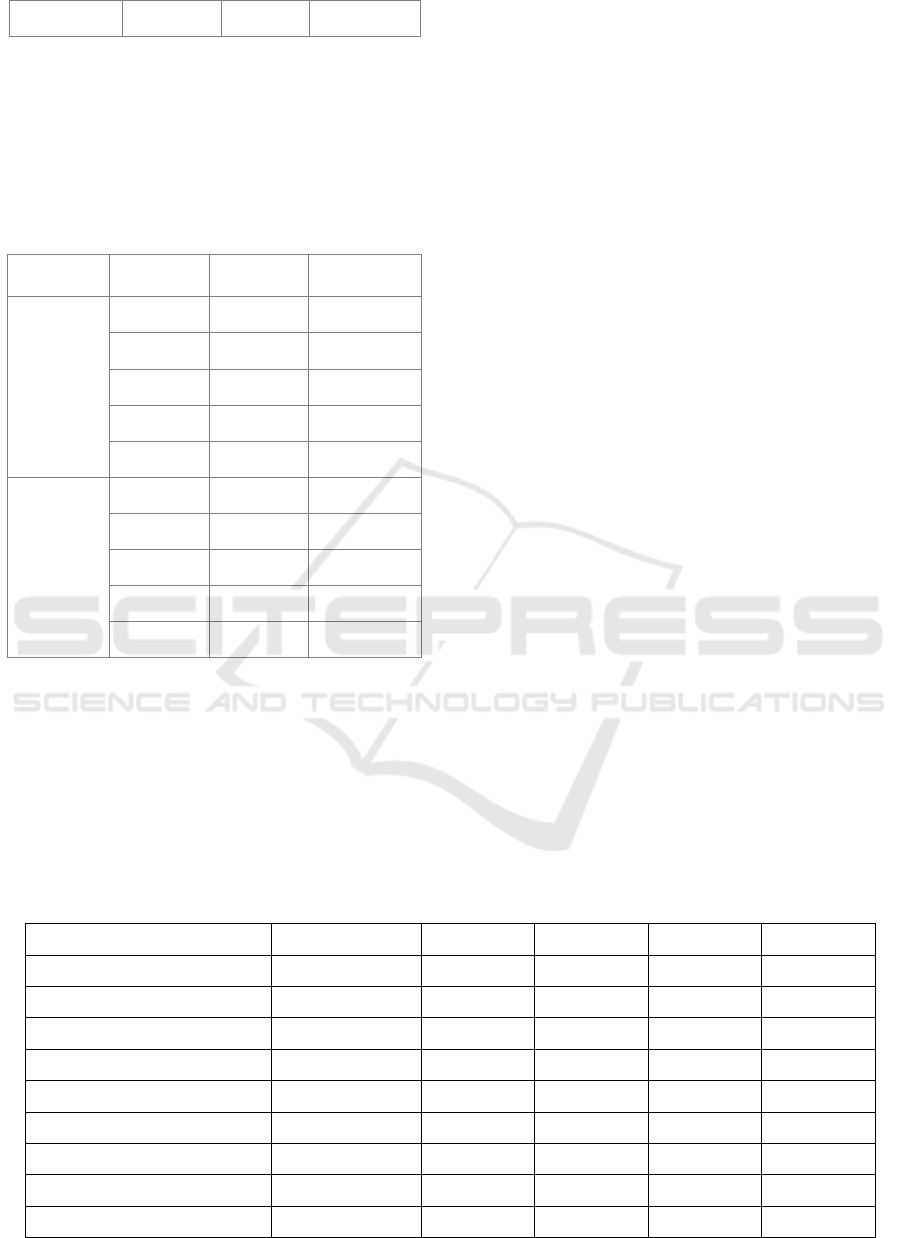

The mean value of the egg yolk index can be seen in

Table 1.

Table 1. The mean value and standard deviation of egg yolk

index.

FACTOR

GRO

UP

Mean

Std.

Deviation

NON

INFECTED

T0

0.3740

0.07092

T0+

0.3780

0.03421

T1

0.4120

0.02168

T2

0.4100

0.02000

T3

0.4060

0.00894

INFECTED

T0

0.3580

0.05167

T0+

0.4020

0.07950

T1

0.3900

0.02915

T2

0.4180

0.03347

T3

0.3180

0.17824

The results showed that among the treatments

that did not show any significant difference (p <0.05),

between the treatment of T0, T0 +, T1, T2 and T3 in

both factors there was no difference. The high yolk

egg index was found in T1 in uninfected and T2 factor

in infected factor of 0.412 and 0.418, respectively,

while the low egg yolk index was found in T0 in

uninfected and T3 factor in the infected factor,

respectively - range by 0.374 and 0.318.

The value of yolk index of each treatment

showed a moderate value, ranging from 0.31 to 0.41,

in accordance with the SNI 2008 stating the egg yolk

index ranged from 0.33 to 0.52.

3.1.2 Egg White Index

The mean value of the egg white index can be seen in

Table 2.

The results showed that among the treatments that

did not show any significant difference (p <0.05),

between the treatment of T0, T0 +, T1, T2 and T3 in

both factors there was no difference. The high egg

white index found in T2 in both factors is 0.118 and

0.116 respectively, while the low egg white index was

present in T0 in both factors respectively 0.092 and

0.078.

The egg white index value of each treatment

showed a moderate value, ranging from 0.07 - 0.11,

i.e. in accordance with SNI 2008 which states the egg

white index ranged from 0.05 - 0.174.

Table 2. The mean value and standard deviation of egg

white index

FACTOR

GROUP

Mean

Std.

Deviation

NON

INFECTED

T0

0.0920

0.02702

T0+

0.1140

0.03050

T1

0.1140

0.01517

T2

0.1180

0.03347

T3

0.0940

0.03130

INFECTE

D

T0

0.0780

0.01095

T0+

0.1080

0.03114

T1

0.1000

0.03742

T2

0.1160

0.04219

ICPS 2018 - 2nd International Conference Postgraduate School

340

T3

0.0880

0.05805

3.1.3 Haugh Unit Index

The mean value of the Haugh Unit index can be seen

in Table 3.

Table 3. The mean value and standard deviation of the

Haugh Unit Index.

FACTOR

GROUP

Mean

Std.

Deviation

NON

INFECTE

D

T0

92.4020

8.53913

T0+

90.8980

9.98262

T1

92.8680

3.75411

T2

92.4120

10.01690

T3

82.2720

12.36696

INFECTE

D

T0

76.4020

7.58204

T0+

87.6860

11.07991

T1

79.7720

26.55888

T2

88.7840

13.58453

T3

70.2120

40.49375

The results showed that among the treatments that

did not show any significant difference (p <0.05),

between the treatment of T0, T0 +, T1, T2 and T3 in

both factors there was no difference. The high Haugh

Unit index was found in T1 in uninfected and T2

factors in the infected factor of 92.868 and 88.784

respectively, while the low Haugh Unit index was in

T3 in both factors respectively 82.272 and 70.212.

Haugh Unit index value of each treatment shows

the value of the worst to the best, which ranges from

70 to 92, that is in accordance with Koswara (2009)

stating that the value of Haugh Unit has a minimum

value of 72.

With egg quality values that showed no

significant difference in treatment of addition of

meniran extract between control treatment and

treatment with addition of AGP it showed that

feeding innovation plus meniran extract could replace

AGP in feed.

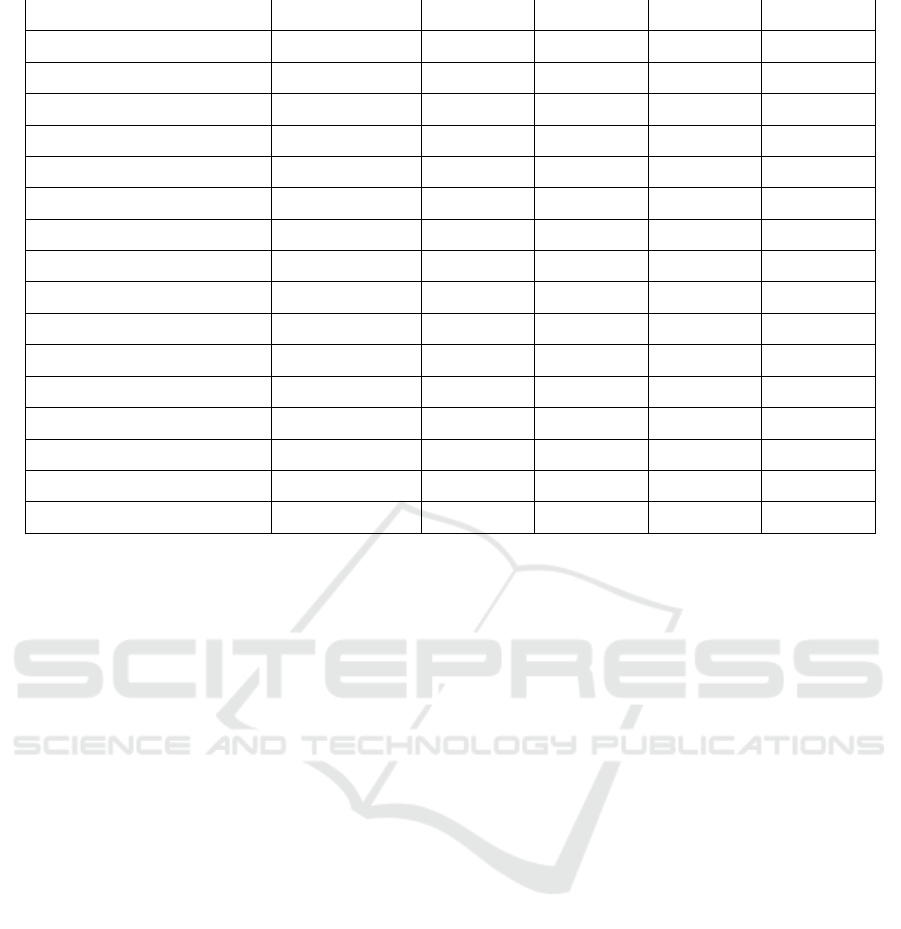

3.2 Business Analysis

Detailed calculation of business analysis can be seen

in Table 4.

Fixed costs are calculated from the multiplication

of fixed costs by the number of units. Fixed costs

consist of the cost of cage depreciation and

equipment, and employee salary. Fixed costs have the

same amount between treatments that is Rp 21,900.00

for 50 heads during 1 phase of production.

The variable cost is calculated from the

multiplication of variable costs by the number of

units. Variable costs consist of seeds, transportation,

feed and feed additive. Feed cost is calculated from

the average amount of feed consumption per

treatment.

Revenue is the selling price per unit of production

multiplied by the number of products sold.

Of the five treatments they showed no large

differences, each treatment shows the value of B / C>

1 which means the business is feasible. With the

provision of meniran extract on the diet it proved a

feasible effort to continue as a substitute AGP on

feed.

Table 4. Detailed calculation of business analysis (in Rupiah).

Description

T0

T0+

T1

T2

T3

Fixed Cost

Cage Depreciation

8000

8000

8000

8000

8000

Employee Salary

13500

13500

13500

13500

13500

Equipment Depreciation

400

400

400

400

400

Total Fixed Cost

21900

21900

21900

21900

21900

Variable Cost

Seeds

700000

700000

700000

700000

700000

Feed

1459213,34

1498751

1408170

1474958

1389095

Effect of Meniran Extract (Phyllanthus niruri Linn.) to Alternate Antibiotic Growth Promoter (AGP) on Egg Quality and Economics

Analysis of Layers Infected by Escherichia coli

341

Feed Additive

0

1924,56

2585,789

2708,43

2550,762

Transport

102939,4286

98912,57

99745,71

101597,1

99792

Total Variable Cost

2262152,768

2299588

2210502

2279263

2191438

Total Cost

2284052,768

2321488

2232402

2301163

2213338

Receipts

Egg

3088182,857

2967377

2992371

3047914

2993760

Chicken rejects

550000

550000

550000

550000

550000

Feces

2999,5

2999,5

2999,5

2999,5

2999,5

Total Receipts

3641182,357

3520377

3545371

3600914

3546760

Profit

1357129,589

1198888

1312969

1299750

1333422

Financial Analysis

BEP Price

13312,99075

14082,06

13428,56

13589,93

13307,71

B/C

1,59417611

1,516431

1,588142

1,564823

1,602448

4. CONCLUSION

The provision of meniran extract on feed proved able

to replace AGP function in the feed, with the best

result of egg quality at T2. With the calculation of

Benefit Cost Ratio each treatment also shows that the

meniran extract can replace AGP function in the feed

because it shows the result of feasible effort to be

continued.

REFERENCES

Akhadiarto, S. 2010. Pengaruh Pemberian Probiotik

Temban, Biovet, dan Biolacta Terhadap Persentase

Karkas, Bobot Lemak Abdomen dan Organ dalam

Ayam Broiler. Pusat Teknologi Produksi Pertanian,

BPPT, Jakarta.

Badan Standardisasi Nasional. 2008. Standar Nasional

Indonesia: Telur Ayam Konsumsi. SNI 3926:2008 ICS

67.120.20.

Bagalkotkar, G., S.R. Sagineedu, M.S. Saad, and J.

Stanslas. 2006. Phytochemicals from Phyllantus niruri

Linn. And their pharmacological properties: a review.

J. Pharm. Pharmac, vol. 58, no. 12, hh. 1559-1570.

Card L. E and M. C. Nesheim. 1972. Poultry Production,

Lea and Febiger, Philadelphia.

Djaelani, M.A. 2016. Kualitas Telur Ayam Ras (Gallus L)

setelah Penyimpanan yang dilakukan Pencelupan pada

Air Mendidih dan Air Kapur sebelum Penyimpanan.

Buletin Anatomi dan Fisiologi. vol. 24, n o . 1, hh.

122-127.

Ekasari, W. 2011. Sistem Informasi Tanaman Obat.

Universitas Airlangga, Surabaya.

Gordon, R.F. and Jordan F.T.W. 1982. Poultry Disease:

Second Edition. London: Bailliere Tindall.

Khusnan, Dwi Kusmanto and Mitra Slipranata. 2012.

Resistensi Antibiotik dan Deteksi Gen Pengode

Methicillin Resistant Staphylococcus aureus (MRSA)

Isolat Broiler di Wilayah Yogyakarta. Jurnal

Kedokteran Hewan, P-ISSN : 1978-225X; E-ISSN :

2502-5600.

Kompiang, I. P. 2006. Pemanfaatan Mikroorganisme

Sebagai Probiotik Untuk Meningkatkan Produksi

Ternak Unggas di Indonesia. Orasi Pengukuhan

Penelitian Utama Sebagai Profesor Riset Badan Pakan

dan Nutrisi Ternak. Balitnak, Bogor.

Koswara, S. 2009. Teknologi Pengolahan Telur (Teori dan

Praktek). eBookPangan.com

Krieg, N.R. and J.G. Holt. 1984. Bergey's Manual of

Systematic Bacteriology. Williams and Wilkins,

Baltimore, London.

Noor, M.P. and M. Poeloengan. 2005. Pemakaian

Antibiotika pada Ternak dan Dampaknya pada

Kesehatan Manusia. Lokakarya Nasional Keamanan

Pangan Produk Peternakan, hh. 56-64.

Rivai, Harrizul, Refilia Septika and Agusri Boestari. 2013.

Karakterisasi Ekstrak Herba Meniran (Phyllanthus

niruri Linn) dengan Analisa Flourensi. Jurnal Farmasi

Higea, vol. 5, no. 2, hh. 127-137.

Sarwono. S., R. Yudiarti and Suprijatna. 2012. Pengaruh

Pemberian Probiotik Terhadap Trigliserida Darah,

Lemak, Abdominal, Bobot dan Panjang Saluran

Pencernaan Ayam Kampung. Animal Agriculture

Journal, vol. 1, no. 2, hh. 157-167.

Soepranianondo, K., R. Sidik, D.S. Nazar, S. Hidanah,

Pratisto, S.H. Warsito, 2013. Buku Ajar

Kewirausahaan. Airlangga University Press, Surabaya,

hh. 192-197.

ICPS 2018 - 2nd International Conference Postgraduate School

342