Study on the Frame Configuration and Optimization Design of

Miniature Foldable Electric Vehicle

Bo Jiang

1

, San chuan Zhang

1

and Ting ting Wang

1

1

College of Mechanical Engineering, Zhengzhou University, Science Avenue No.100, Zhengzhou, China

Keywords: Miniature electric vehicle; Foldable frame; Single-objective optimization design; Structure simulation.

Abstract: In order to solve the miniature foldable electric vehicle frame configuration and design problems, the key

dimensions and constraints of the frame has been extracted and a single objective optimization

mathematical model has been established and optimized by using MATLAB optimization tool kit, basing on

the design goals. The 3D model of the frame has been built by SOLIDWORKS and the ADAMS has been

used for kinematics simulation analysis. The results show that the optimized folding size of the vehicle has

increased by 18%, which meets the design requirements and the stability of the designed mechanism under

certain speed conditions is also verified.

1 INTRODUCTION

The concept of intercity vehicles has been proposed

to solve the increasingly serious urban traffic

problems in recent years. The Hiriko[1], a miniature

electric car with a folding frame developed by MIT

can realize such functions as shortening wheelbase

and zero radius steering. On the basis of Hiriko, EO

SCC 2[2-3], developed by DFKI, introduces the idea

of modular design, which lays a foundation for the

serialized development of the vehicle while realizing

the folding and high mobility of the vehicle.

A kind of electric vehicle folding mechanism

based on separating frame and rocker slider

mechanism is proposed and designed in this paper.

2 FRAME FOLDING

MECHANISM

CONFIGURATION DESIGN

2.1 Design Objective

According to GB1589-2016 and the same type of

vehicles, the goal of parking three electric vehicles

in folded state on the parking space of 5-5.5 meters

long compact car is realized by controlling the

external profile size of the vehicle.

2.2 Design Scheme

The frame is designed as a separate structure that

contains front frame, main frame and rear frame. A

folding mechanism with the principle of rocker

slider is used to lift the main frame, and the main

frame drives the front frame to shift, thus reducing

the length of the vehicle. Considering the cost and

structure interference, the front and rear frame adopt

the same frame and the rear frame is designed as the

inclined plane where the rear frame meets the main

frame. The frame folding scheme (side view) is

shown in Figure.1.

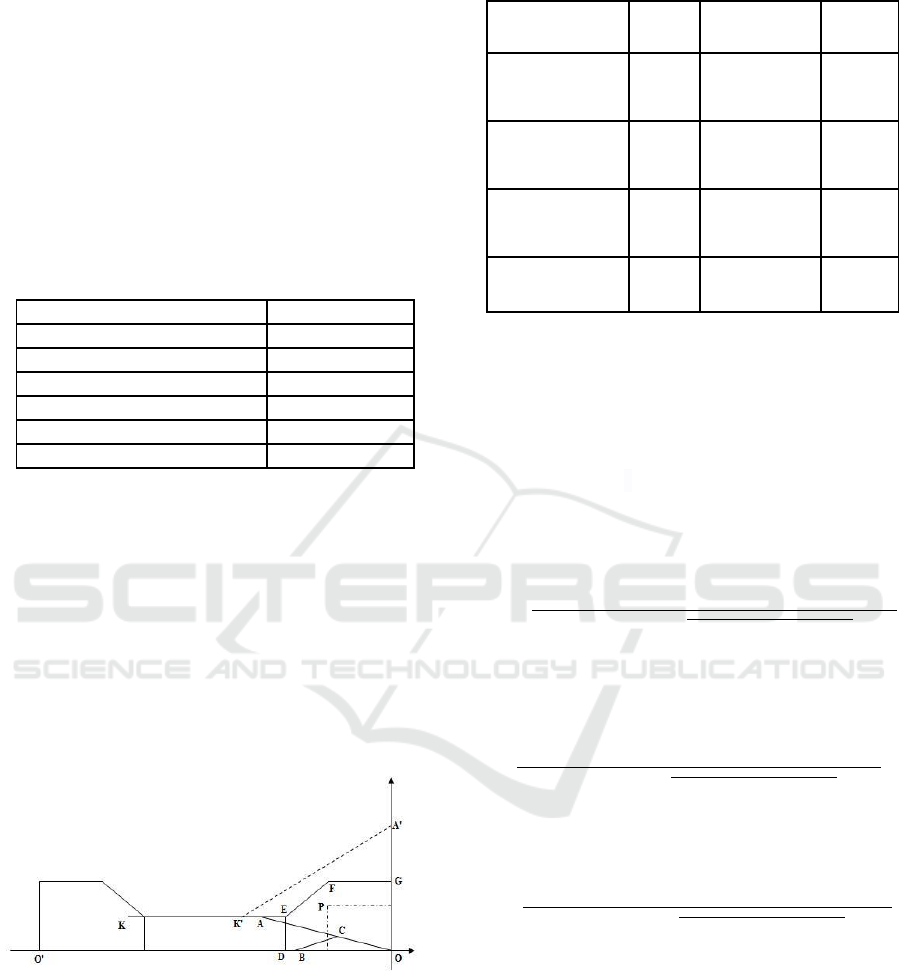

Figure.1: Scheme of foldable frame.

When the vehicle is stopping, the rear frame

wheels keep still and the bottom AK of the main

frame is parallel to the ground. When the vehicle is

folding, the electric servo cylinder BC pushes the

back of the main frame which is connected with the

rocker OA and then the front frame which is

connected with the hinge points K is shifted

backward to shorten the length of the vehicle.

2.3 Mathematical Modeling

2.3.1 Vehicle Parameters

On the basis of referring to the national standard for

the size of similar types of vehicles and vehicle

exterior profile, the main performance parameters of

the vehicle are summarized in Table.1.

Table.1: Vehicle parameters.

Category

Value

Vehicle length, mm

2000

Main frame length, mm

1300

Wheel base, mm

1500

Tread, mm

1100

Curb weight, kg

270

Maximum speed, km/h

80

2.3.2 Design Variable

As the frame is a complex structure, the main

structural interference factors should be considered

in the designing process, and the model should be

simplified.

The Cartesian coordinate system as shown in

Figure.2 is established at the hinge point O of the

rocker and the rear frame. The main dimensions

such as the vehicle exterior profile and the outline

of the battery pack of the external frame are

extracted, which are taken as design variables.

Figure.2: Simple diagram of the folding mechanism.

The value range of design variables are

determined by visual design and comparison of

vehicle size of the same type that are shown in

Table.2.

Table.2: Summary of designing variables.

Variable

Mark

Range

Initial

value

Front height

of rear frame

DE

X

1

0-400mm

150mm

Bevel length

of the rear

frame EF

X

2

0-400mm

290mm

Length of

upper side of

rear frame FG

X

3

0-400mm

290mm

Slope angle of

rear frame

X

4

30°-60°

45°

2.3.3 Objective Function

In order to reduce the parking space, the wheelbase

should be the minimum after folding. The maximum

displacement of the point K where the front frame is

hinged with the main frame is designed as the

objective function. It is assumed that the rocker OA

is in the vertical position when the vehicle folding

length reaches its maximum.

The projection length of the main frame bottom

face AK:

′

The maximum displacement of the hinged point

K of the main and front frame after folding:

The model objective function expression:

2.3.4 Constraint Conditions

1. Vehicle length constraint

To control the vehicle size, the total length of the

vehicle frame should be less than 2000mm. Design

variables should satisfy the relation:

After simplifying, the relation:

(1)

2. Limit point interference constraint

In the process of frame folding, there should be

no interference between the hinge point A of lifting

bar and the limit position point F of auxiliary frame,

and the length of lifting bar should be longer than

the length from point O to point F. The dimension

constraint relation:

(2)

3. Frame interference constraint

After folding, the front and rear frames should

not interfere. As the point K is not the limit position

of the front frame, when the frame reaches the limit

position, the clearance between the point K and the

rear frame is reserved for 120mm.The dimension

constraint relation:

After simplifying, the relation:

(3)

4. The battery interference constraint

Due to the use of hub motor drive technology,

the space of the front and rear frame is mainly

occupied by the battery pack, so the interference of

the battery pack should be considered in the design

of the frame.

The equation of the straight line EF can be get

from the point E(-

,

)and point

F(

,

).

The liner equation:

To ensure that the limit position point P (-520

,180)of the battery pack does not interfere with

the ramp of the auxiliary frame, point P should be

below the right of the linear EF in the coordinate.

The constraint relation can be obtained from the

position relation:

(4)

5. Front and rear frame size constraint

Considering the size of battery pack and folding

mechanism of vehicle size, the outer profile height

of auxiliary frame is preliminarily determined to be

300-500mm. Constraint relation:

and

(5)

The length of the front and rear frame is 400-

600mm.And the constraint relation:

and

(6)

6. Constraint of the lifting bar inclination

Rotation of the rocker plays a major role in

frame folding. In order to ensure that the pressure

angle of the rocker is not too large, its inclination

angle relative to the X-axis of the coordinate system

is set within 10-30°. The constraint relation:

°

and °

(7)

3. MATLAB OPTIMIZE DESIGN

AND MODELING SIMULATION

3.1 Multivariable Optimization

The mathematical model of frame folding

optimization belongs to the problem of single

objective multivariable optimization.

The normalized form[4]:

min F(X)

s.t

AX ≤b

AeqX = beq

C(x) ≤ 0

Ceq(X) = 0

lb≤ X ≤ub

The function fmincon is invoked to solve the

problem. The basic format of the function command

:

[x,fval,exitflag,output]=fmincon(@objfun,x0,A,b

,Aeq,beq,lb,ub,@confun)

By writing the M file of the objective function

and the constraint function, the optimization results

can be obtained by establishing the main program

solution:

x =149.2821 400.0000 226.7949 0.5236

fval = -778.9473

exitflag =1

The result (exitflag =1) shows that the first-order

optimality condition of variable satisfies the

tolerance range. According to the optimized result,

the folding length of the frame will reach

778.95mm, which will reach one-third of the length

of the whole vehicle. The summary results of design

variable optimization are shown in Table.3.

Table.3: Optimization results of designing variable.

Design

variable

Length, mm

Angle,°

X1

X2

X3

X4

Initial

value

150

290

290

45

Optimum

value

149

400

226

30

Range of

optimization,%

0.67

37.9

22.1

33.3

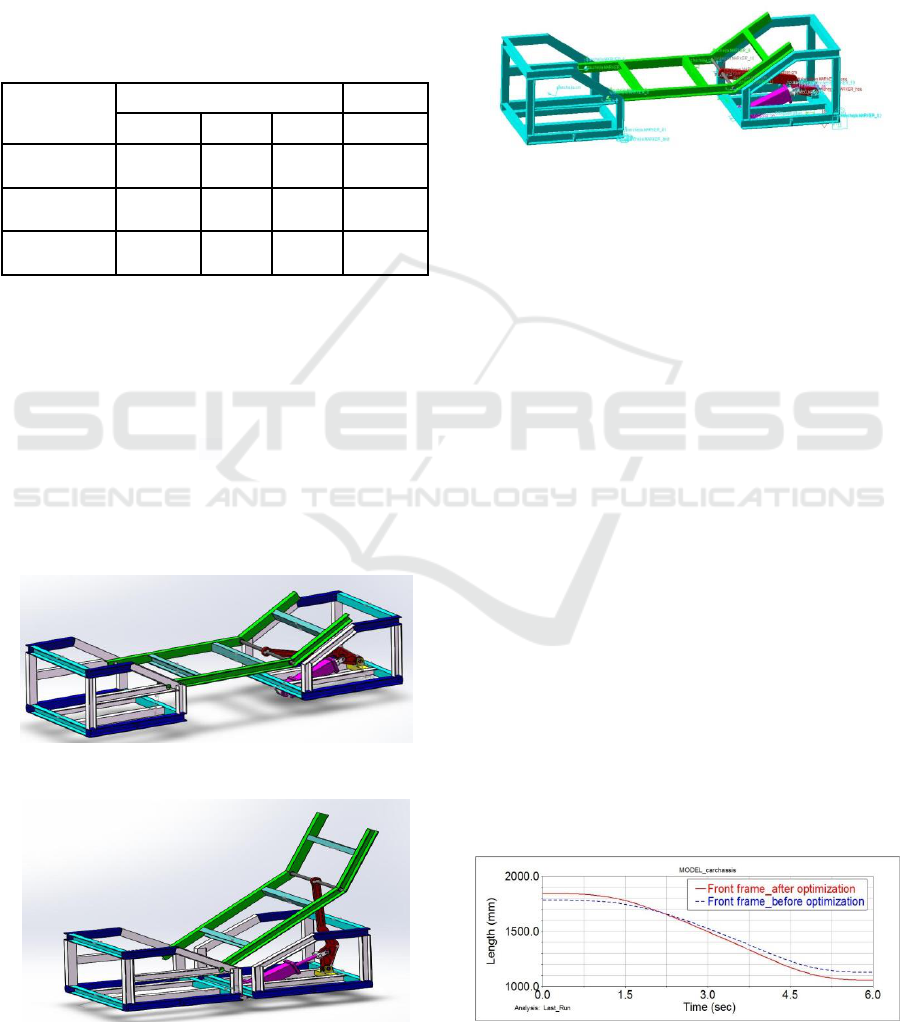

3.2 3D Modeling

According to the requirement of light weight and

strength of the frame, the standard channel steel is

adopted for the assembly modeling, and the rigid

point factor of the suspension is ignored in the

preliminary modeling. The virtual prototype

modeling of the whole frame of the frame is carried

out with SOLIDWORKS software, as shown in

Figure.3a and Figure.3b. The lifting of frame rocker

depends on the extension of actuator's pushing.

Figure. 3a: The working condition of the frame.

Figure.3b: The folded state of the frame when parking.

The 3D modeling of frame is imported into

ADAMS software and the source part model is

divided into front frame, main frame, rear frame,

connection, rod, linear actuator and connection first-

class parts by Boolean operation.

The ADAMS model in Figure.4 is obtained after

pre-processing.

Figure.4: ADAMS model of the car chassis.

3.3 Simulation Settings

In order to achieve the frame from acceleration start

to slow down the stillness of the folding process, the

ADAMS built-in STEP function is added in the

simulation of linear actuator and the connection to

simulate the movement speed. The movement

simulation time is set to 6 seconds.

The STEP function is shown below:

step(time,0,0,2,36.4)+step(time,2,0,4,0)+step(time,4,

0,6,-36.4)

The STEP Function meaning:The moving pair

accelerates from static to 36.4mm/s in 0-2s time,

moves at a constant speed of 36.4mm/s for 2-4s,and

the speed is reduced to 0 in 4-6s.

3.4 Simulation Results and Analysis

3.4.1 Frame Folding Analysis

The center of mass of the front frame is used to be

the reference point to measure its displacement in

the folding direction. The displacement of the front

frame under the initial size is compared with that of

the optimized front frame. The comparison results

are shown in Figure.5.

Figure.5 :Displacement of the front frame.

As can be seen from the Figure 6, the folding

length of the frame, that is, the displacement of the

front frame increases from 657mm to

775mm.Compared with the results of MATLAB

model, the error after optimization is less than 1%,

indicating that the virtual prototype modeling meets

the requirements.

3.4.2 Linear Actuator Motion Analysis

The linear actuator stroke, rocker rotation angle and

angular velocity images are shown in Figure.6.

Figure.6: The angular, velocity of the rocker and the

elongation of the line actuator.

As can be seen from the image, the maximum

displacement of the linear actuator S is 145mm,

which satisfies the maximum stroke of the selected

linear actuator of 152mm. The maximum rotation

angle of the rocker is 91, which is similar to the 90

rotation angle of the rocker in the mathematical

model. At the beginning and ending of the motion,

the displacement of the linear actuator changes

gently and the angular velocity of the rocker is not

accelerated or decelerated rapidly.

4 CONCLUSIONS

1. The folding length optimized by MATLAB has

increased by 18% compared with that before

optimization and is more than one third of the length

of frame. The folding effect of frame meets the

design requirements.

2. The comparison between MATLAB

calculation results and ADAMS simulation results

shows that the modeling error is less than 1%, which

reflects the reliability of this model.

3. The variation of motion parameters of key

components of folding mechanism shows the

stability of the designed mechanism at a certain

speed.

REFERENCES

1. Hiriko City Car.

http://praveens.mit.edu/portfolio/hiriko-city-car.

2. Birnschein T, Kirchner F, Girault B, etal. An

innovative, comprehensive concept for energy

efficient electric mobility - EO smart connecting

car[C]. Energy Conference and Exhibition. IEEE,

2012:1028-1033.

3. Yüksel M, Ahmed M, Girault B, et al. A Framework

for Design, Test, and Validation of Electric Car

Modules[M].Advanced Microsystems for Automotive

Applications 2014.Springer International Publishing,

2014:245-254.

4. Zhao Jijun. Optimization Technology and MATLAB

Optimization Tool [M]. China Machine Press, 2011

,

26-46.