Preparation of TiO2/RGO Composite and Application in

Photocatalytic Degradation of Unsymmetrical Dimethylhydrazine

Wastewater

Xiaomeng Lv

1

, Xuanjun Wang

1

, Ying Jia

1

, Zhiyong Huang

1

and Qilong Han

1

1

Rocket Force University Of Engineering

,

Xi

’

an

,

P.R. China

Keywords: TiO

2

/RGO, Preparation, UDMH wastewater, Photocatalytic Degradation.

Abstract: The TiO

2

/reduced graphene oxide composite was prepared with graphene oxide and titanium dioxide by

hydrothermal reduction method. Surface morphologies were collected by scanning electron microscopy and

ultraviolet-visible absorption performance was studied by ultraviolet-visible spectrophotometer. The

TiO

2

/RGO composites were used as catalysts for photocatalytic degradation of unsymmetrical

dimethylhydrazine wastewater with a concentration of 120 mgꞏl

-1

. The optimum condition of catalyst dosage,

pH value and reaction time were 1gꞏl

-1

, 7 and 120 min respectively and the optimum photocatalytic

degradation rate of UDMH wastewater was 72.1%.

1 INTRODUCTION

Unsymmetrical dimethylhydrazine (UDMH) is an

important liquid propellant used in aerospace and

military field. It is difficult to achieve completely

photocatalytic degradation of UDMH in wastewater

disposal with single catalyst owing to its

complicated molecular structure. Thus, searching for

composite catalytic materials for the photocatalytic

degradation of UDMH wastewater is important.

New carbon materials such as graphene and reduced

graphene oxide (RGO) et al. have a promising

application prospects in flexible graphite, thermal

energy storage materials, sorbents, conductive resin

composites and catalyst[1-2]. As a wide-band gap

semiconductor material, TiO2 particle has good

chemical stability, thermal conductivity, and

ultraviolet absorption that be applied in

photoelectron apparatus and photocatalyst[3-4].

Hybridization reaction of TiO2 particle and RGO

was conducted easily owing to a few oxygen-

containing function groups on the surface of RGO.

In the present study, TiO2/RGO composites were

prepared with graphene oxide and titanium dioxide

as raw materials by hydrothermal reduction method.

Then, TiO2/RGO applied in the photocatalytic

degradation experiment on UDMH wastewater was

carried out and the influence of reaction condition

on the optimum photocatalytic degradation rate was

also discussed.

2 EXPERIMENTAL

2.1 Preparation of TiO

2

/RGO

An appropriate amount of 50 mg (to the accuracy of

0.1 mg) graphene oxide (GO) sample was placed

into a with 50 ml NaOH solution of 10 mol•l-1.

After 2 hours dispersion treatment of the beaker in

ultrasonic processor, a certain amount of TiO2

particle was added and then another 2 hours

dispersion treatment was conducted. Dispersed

solution was placed into a high pressure resistant

reaction container, magnetic stirred in room

temperature for 4 hours, heated in 150 °C for 24

hours, removed and washed with dilute hydrochloric

acid and ultrapure water successively, and then

placed into a vacuum drier of 60 °C for 12 hours and

a vacuum tube furnace of 600 °C (pure nitrogen

environment) for 1 hour. Then, TiO2/RGO

composites were obtained.

2.2 Characterization

Surface morphologies of TiO2/RGO composites

were collected by scanning electron microscopy

(Czech, TESCAN, VEGA ІІ XMUINCN).

Ultraviolet-visible (UV-vis) absorption spectrum

was collected by UV-vis spectrophotometer (Japan,

SHIMADZU, UV-2700, 200 nm ~ 900 nm).

2.3 Photocatalytic Degradation of

UDMH Wastewater

TiO

2

particles and TiO

2

/RGO composites were used

as catalysts for photocatalytic degradation

experiment of 120 mg•l

-1

UDMH wastewater. A

self-made ultraviolet light photocatalytic device as

shown in Figure 1 was constituted of ultraviolet light

lamp, sealed wooded cases and strong magnetic

stirrer. The beaker containing UDMH wastewater

was placed under the UV lamp and the liquid level

of UDMH wastewater was 10 cm far away from the

UV lamp. The experiment of influence of catalyst

dosage, pH and reaction time on the photocatalytic

degradation rate was carried out.

Figure 1: A self-made UV light photocatalytic device.

3 RESULTS AND DISCUSSION

3.1 SEM Analysis

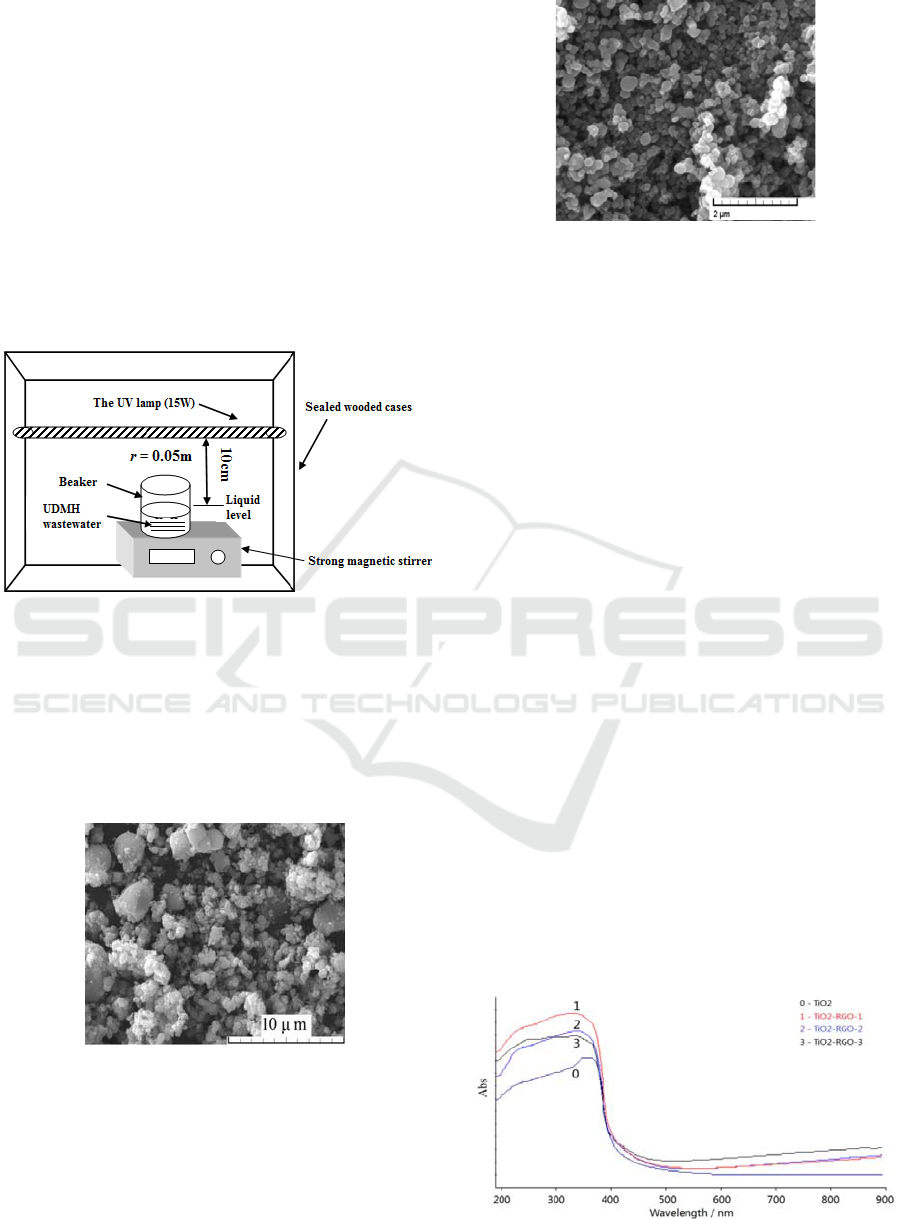

Figure 2: SEM images of TiO

2

/RGO.

Figure 2 shows SEM images of TiO

2

/RGO

composites prepared that with high purity have well-

proportioned size in the range from 5 μm to 30 μm.

Surface of TiO

2

/RGO composites appearing

spherical particles was covered with fold thin RGO

film. As shown in Figure 2, TiO

2

/RGO composites

with small agglomeration were clearly observed.

This result indicates that the oxygen-containing

function groups on the surface RGO attained

become fewer after reduction and the hydrophilicity

of RGO become lower. After Hybridization reaction

of TiO

2

particle and RGO, agglomeration of

TiO

2

/RGO could be restrained effectively owing to

its own nanostructure.

3.2 UV-vis Analysis

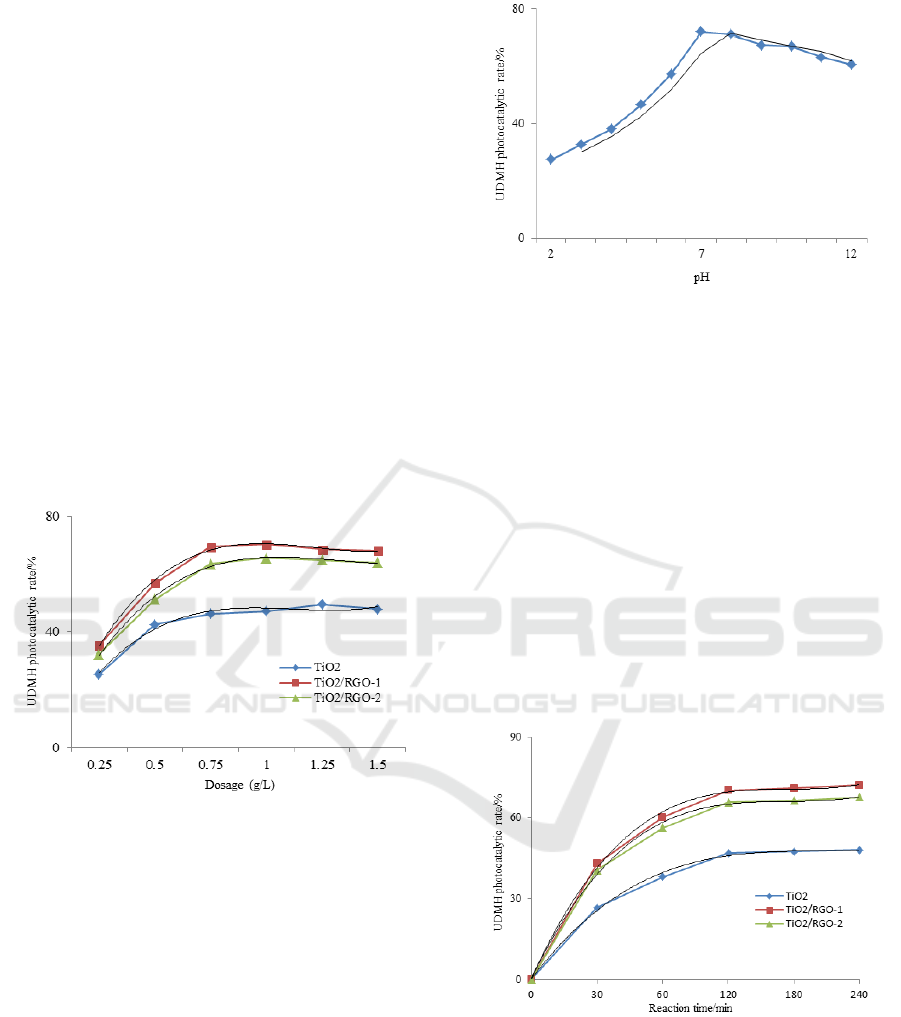

A comparative study of UV-vis absorption spectrum

analysis between TiO

2

particles and TiO

2

/RGO

composites were studied by UV-2700 ultraviolet-

visible spectrophotometer as shown in Figure 3. The

result shows a marked growing of UV-vis absorption

intensity of TiO

2

/RGO in the range from 200 nm to

400 nm. The UV-vis absorption intensity of

TiO

2

/RGO-1 was 80% stronger than that of TiO

2

.

Owning to sufficient electron transfer from valence

band to conduction band, most transfer electrons

were accepted by RGO and few electrons back was

recombined with hole. The more the electron holes

mount exist on the surface of TiO

2

/RGO, the

stronger the catalytic oxidation will be.

Figure 3: UV-vis absorption spectrum of TiO

2

/RGO.

3.3 Photocatalytic Property Analysis

Figure 4 shows the result of influence of catalyst

dosage on photocatalytic degradation rate of

120mg•l

-1

UDMH wastewater with TiO

2

and

TiO

2

/RGO samples. The increase in catalyst dosage

from 0.25 g•l

-1

to 0.75 g•l

-1

resulted in an accelerated

photocatalytic degradation rate of UDMH

wastewater. The photocatalytic degradation rate

increased to its maximum at about catalyst dosage of

1 g•l

-1

, and then decreased slowly because of more

catalyst dosage, possibly resulting in reducing UV-

vis absorption of TiO

2

and TiO

2

/RGO.

The degradation rate of UDMH wastewater with

TiO2/RGO catalyst can achieve 70.2% that was

approximately 50% higher than that of TiO2 particle.

This result indicates that Hybridization reaction is

advantageous to increase of the specific area and

absorption of TiO2/RGO. This condition could

result in improving surface chemical mobility and

broadening energy band gap of TiO2/RGO, and in

favor of the increase of degradation rate.

Figure 4: Influence of catalyst dosage on photocatalytic

degradation rates of UDMH wastewater.

The results of influence of pH value on

photocatalytic degradation rate of 120 mg•l

-1

UDMH

wastewater with TiO

2

and TiO

2

/RGO samples were

shown in Figure 5. The increase in pH value from 2

to 8 resulted in a gradual growing photocatalytic

degradation rate of UDMH wastewater from 27.5%

to 72.1%. The photocatalytic degradation rate

increased to its maximum at about pH value of 7,

and then decreased gradually.

Figure 5: Influence of pH value on photocatalytic

degradation rates of UDMH wastewater.

Because of physicochemical property of UDMH,

the solution pH value is a very important factor for

photocatalytic degradation experiment. A

neutralization reaction with unsymmetrical

dimethylhydrazine and hydrogen ion occurred and

UDMH-salt compounds were generated in acid

condition. TiO

2

/RGO was photocatalytic-insensitive

to UDMH-salt compounds, which resulting in a

lower photocatalytic degradation rate. In neutral and

alkalescent condition, UDMH existed in molecular

form that could be benefit to photocatalytic

degradation. The pH value above 9 is advantageous

for electron transfer due to high concentration of

hydroxide and the photocatalytic reaction with

TiO

2

/RGO and UMMH could be restrained partly

due to decrease of electron-hole pair amount.

Figure 6: Influence of reaction time on photocatalytic

degradation rates of UDMH wastewater.

Figure 6 shows the result of influence of reaction

time on photocatalytic degradation rate of 120 mg•l

-1

UDMH wastewater with TiO

2

and TiO

2

/RGO

samples. As the reaction time increased, the

photocatalytic degradation rate increased at the

initial reaction and became closer to its maximum

72.1% at 120 min. This result indicates that

photocatalytic reaction was completed after 120 min.

In the initial reaction time from 0 min to 60 min, a

significant increase of photocatalytic degradation

rate occurred owing to large specific area of

TiO

2

/RGO and rapidly absorption to UDMH

molecular that was benefit to photocatalytic reaction.

The reaction time longer than 120 min is

disadvantageous for the increase in photocatalytic

degradation rate because of absorption-degradation

saturation balance between TiO

2

/RGO and UDMH

molecular.

4 CONCLUSIONS

The TiO

2

/RGO composite was prepared with

graphene oxide and titanium dioxide as raw

materials by hydrothermal reduction method. The

TiO

2

/RGO composites were used as catalysts for

photocatalytic degradation of unsymmetrical

dimethylhydrazine wastewater with a concentration

of 120 mg•l

-1

. The optimum condition of catalyst

dosage, pH value and reaction time were 1g•l

-1

, 7

and 120 min respectively and the optimum

photocatalytic degradation rate of UDMH

wastewater was 72.1%.

REFERENCES

1. XIAO X Y, LI Y C, LIU Z P. Graphene

commercialization [J]. Nat Mater, 2016, 15: 697-698.

2. Li J H5 Li J Y, Li L F, et al. Flexible graphene fibers

prepared by chemical reduction induced self-assembly

[J]. Journal of Materials Chemistry A, 2014, 2(18):

6359-6362.

3. J.S. Lee, K.H. You, C.B. Park, Highly Photoactive,

Low Band gap TiO2 Nanoparticles Wrapped by

Graphene [J]. Advanced Materials 24 (2012): 1084-

1088.

4. Y.Y. Gao, X.P. Pu, D.F. Zhang, G.Q. Ding, X. Shao, J.

Ma, Combustion synthesis of grapheneoxide-TiO2

hybrid materials for photodegradation of methyl

orange, Carbon 50 (2012):4093-4101.