An Automation Positioning Measurement System Based on

Multi-measurement Equipment

Hongli He

1

, Jie Zhang

1,2

, Quanbo Ge and Zhongcheng Ma

3

1

Institute of testing, Chinese Flight Test Establishment, Xi'an, China

2

School of Aviation, Beijing University of Areonautics and Astronautics, Beijing, China

3

School of Automation, Hangzhou Dianzi University, Hangzhou, China

Keywords: Three-dimensional model, Automation measurement, Simulation, Flight test.

Abstract: According to the requirement of flight test, The high precision Automation positioning measurement system

is designed and implemented for obtaining three-dimensional points, lines or polygons of measured object.

The system can be satisfied with the needs of future weapons development. The system functions include

simulation, online measurement, fast processing, real-time monitoring etc. The system structures,

framework and composition are given. The key technical problems are analyzed in order to know of the

system feasibility. A feasible platform are set up by total station instrument, light pen, image measuring

system equipment in the laboratory. The interface performance, real time guide, coordinate transforming,

adjustment of observation are verified. The algorithm accuracy is verified. The system construction thought

is overall being planned. The system will effectively boost the development in flight test, It is very

important to improve testing precision, speed or saving manpower and material resources.

1 INTRODUCTION

Space positioning measurement for Flight test is

surveying the aviation aircraft position and other

parameters of the target in the real test environment,

which mainly is used for the establishment of Spatial

reference Information and the value transfer,

installation and calibration for weapons, the plane

deformation test and three-dimensional

model[1,2].The improving of the aviation weapon

performance put forward higher requirements for

measurement. Measurement object is becoming

more and more complex, it is not only to measure

the position of aircraft and weapons, but also to

measure the relationship between weapons and

aircraft. The accuracy requirements for attitude

angle arc seconds, positioning requirements are

millimeter. The measurement tests get more and

more. The measurement items are more than one

type measured with high frequency which measure

hundreds of sorties every year; the original static

measurement is converted for static and dynamic

binding; The automation technology research must

be conducted in order to improve the accuracy and

reliability and the test efficiency[3].

At present, digitalization and detection

technology are becoming more and more mature.

Model-based detection technology has become the

main detection method for engineering,and Model-

based detection technology effectively improve the

detection capability and efficiency[4].

Model-Based Systems Engineering is regarded

as the "revolution" of system engineering, "the

future of system engineering ","transformation of

system engineering" and so on. China Aviation

Industry Group has also carried out related research

and application[5,6].

According to the requirement of flight test, the

high precision automation engineering positioning

measurement system for flight test is designed and

implemented for obtaining 3D points, lines or

polygons integration of measured object in greater

scope. The system should be satisfied with the needs

of future weapons development. The system

functions include simulation ,online measurement,

fast processing, real-time monitoring etc. The

system can realize the plane model building,

installation process online test for weapon system on

the aircraft ,the complex body positioning

monitoring, monitoring of the test site ,which can

provide the basis for on-the-spot decisions.

This subject provides new methods and new

ideas for online monitoring ,provides technical

support for the research of distributed large-scale

measurement, and also provides online error

correction of industrial robots, online space

positioning and reverse engineering, which is

widely used for flight test.

2 THE SYSTEM FRAMEWORK

2.1 Basic Framework

According to the requirement of flight test, using the

advanced digital measurement equipment such as

total station instrument, light pen, image measuring

system equipment ,3D scanners, GPS, laser tracker,

etc. based on 3D digital-analog measuring system

composed of a set of automation measurement

system, through the computer and automatic control

technology to achieve integration measurement

7

.

Through offline programming device layout and

mission planning system after the completion of

online testing in the field of data processing,

shortening the processing cycle, improves the

effectiveness and accuracy of the measured data .In

the measurement platform building process, we

should fully consider the system's advanced nature

that system construction should not only have data

processing and control functions, but to be able to

optimize the layout of measurement equipment, In

the measurement task trace route planning, ensure

the accuracy of automated measurement. The

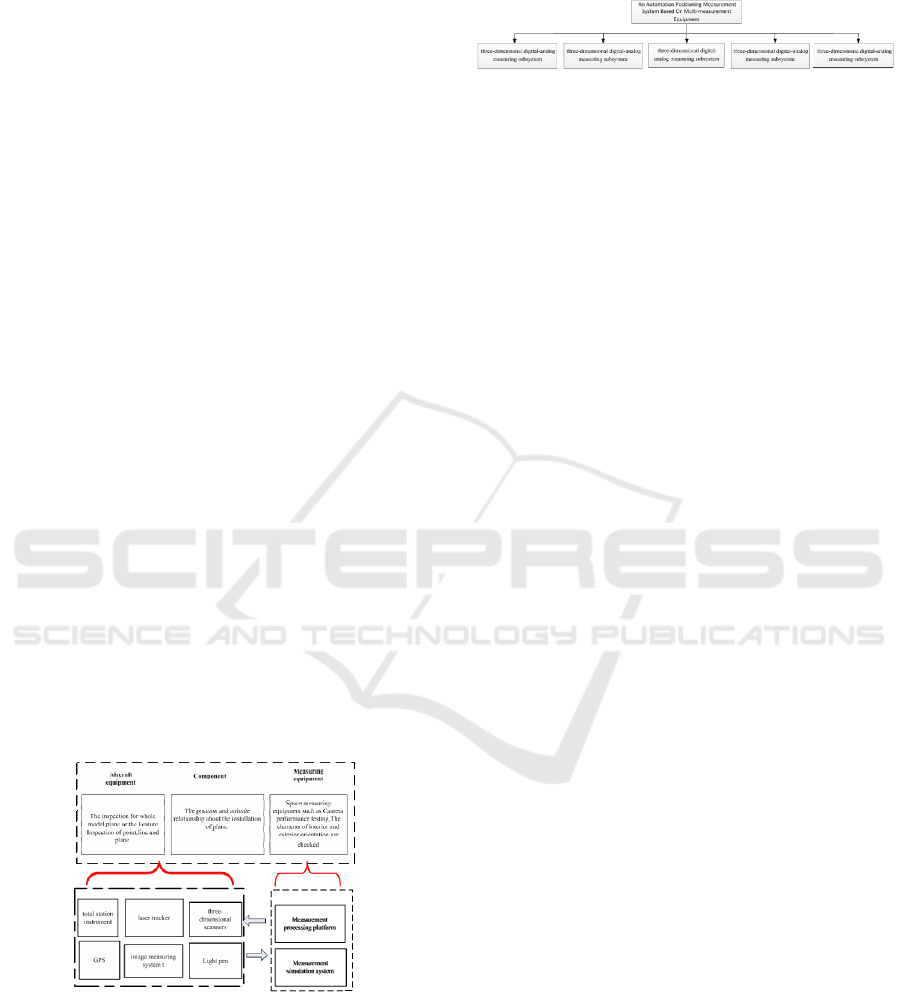

framework of the system is shown in figure 1.

Figure 1: System frame of multi-measurement equipment

diagram.

2.2 System Components

Figure 2: An Automation Positioning Measurement

System composition.

According to the characteristics of flight test,

automation high-precision measurement system are

set up, which can achieve fast automated collection

for feature point, line, polygon data, recording,

computing and other functions. Automation

measurement system is mainly composed of the

following parts: accurate point measurement

subsystem, image measurement subsystem, three-

dimensional digital-analog measuring subsystem,

measurement and control center subsystem,

measurement simulation subsystem. The system

composition is shown in figure 2.System equipment

composition is shown in figure 3.In which precise

point measurement subsystems, 3D modeling

subsystems, image measurement subsystem achieve

information collection and access. measurement and

control system is the core of the whole system that is

responsible for data processing, control, guidance,

analysis, display function; measurement simulation

mainly completes the measurement equipment

layout, composition and measuring path planning,

which is key to optimize the allocation of system,

but also automatic measurement of foundation. The

specific composition is as follows:

1) Accurate point measurement subsystem:

which is made up of the total station, light pen,

Laser tracker and other equipment, which can obtain

3d measurement information about the main point

features.

2) Image measurement subsystem: which is

composed of camera, lens, analytical software, The

key point coordinates were obtained using digital

close-range photogram metry principle, The static

or dynamic measuring process target point

coordinates can be given through calculating.

3) Three-dimensional digital-analog measuring

subsystem: including 3D scanner, hand held scanner,

model building tools, etc., is mainly used for model

construction or the measurement about Surface

target and the attitude datas of the object.

4) Measurement and control center subsystem:

mainly achieve the system camera, 3D laser scanner

and total station and other equipment background

operation control and real time information

collection, guide transmitted, the processing,

evaluation, display, with image processing, data

processing, and analytical parameters adjustment

calculation and other functions.

5) Measurement simulation subsystem: the

simulation model is established according to the

measurement task requirements and site

environmental knowledge, through simulation and

calculation on measurement characteristics, through

the simulation is given a specific task in measuring

device configuration, layout and measurement task

planning is key to optimal allocation of system. The

main task is to prepare for the simulation of the

field, the equipment layout, equipment interference,

measurement of the trajectory of the simulation, the

test quantity schemes and plans to confirm.

Figure 3: System equipment composition.

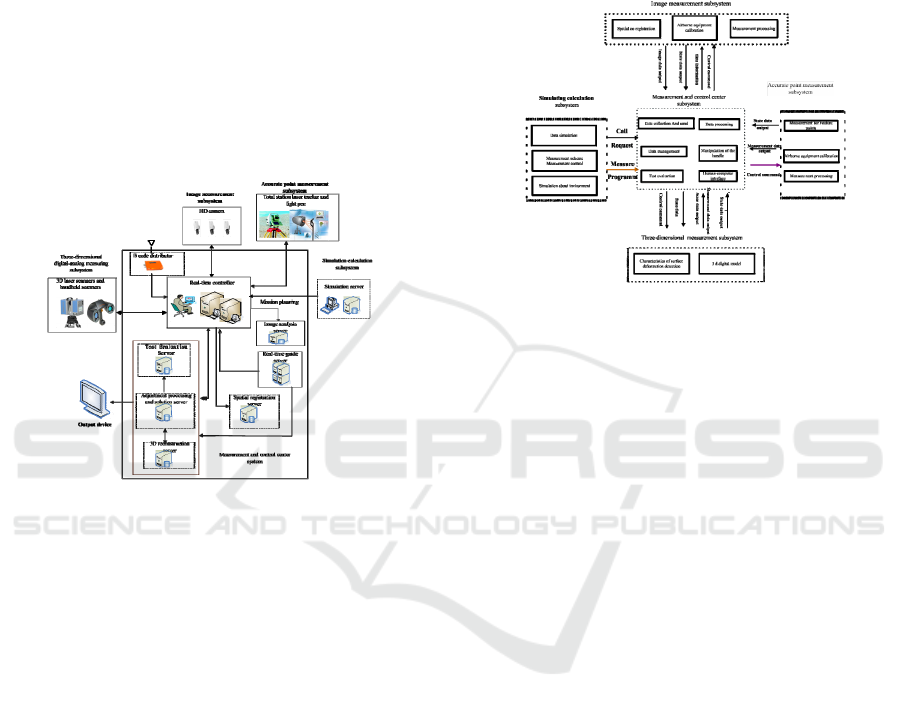

2.3 Second Section

For a test, it is necessary to carry out automation

measurement, first of all, according to the

requirements of the task We measure the field

simulation environment and get the measurement

plan. This subsystem transfers the measurements

related to the planning, equipment status information

to the control center, which is based on the original

digital to analog information into the coordinate

conversion, converts data into the value of the

respective equipment coordinate measuring system

and controls the equipment in accordance with the

requirements for automatic measurement. Other

precise measuring system, image measuring system,

3D modeling system are based on the control center

issued the control instructions ,then take the

respective measurement data back (transfer) to the

monitoring and control center for the integrated

treatment, carrying out after the process is

completed testing and evaluation, and save all the

measured data, the data results in accordance with

the statements of the model output; model formation

through the model viewer access. All measurements

according to the measurement plan under control of

Control Center automatic completion of the

measurement. According to the above planning, the

information exchange between the system and the

measurement system is given as shown in figure4.

Figure 4: Information exchange.

2.4 Software Framework

The system software is based on operating software,

supporting software.

Different kinds of measuring instruments often

use different communication interface standards,

which makes data communication and integration

difficult. For point, line and polygons Object,

different measuring devices are adopted, Unified

standard interface is designed to control all data in

the same control center , Three dimensional CAD

software (such as CATIA and UG) has been

developed. Based on the unified measurement

kernel, information such as geometric information,

dimensional tolerance, inspection plan, simulation

and measurement results are shared seamlessly

between the same or different platforms. All data are

managed to achieve information integration and

closed loop feedback[4,8]. Application software is

the key to intelligent measurement of the system. Its

composition and functions are as follows.

The application software contains the following

functions:

1) The collected data is mainly from the total

station ,laser tracker and three-dimensional scanning

instrument, some data is from the manual input

parameter information or the model data

information. The data and images of all the

measuring devices can be unified into the network

interface for data transmission, which is in order to

send data efficiently . the hardware interface must

be extensible.

2) Mage data, model construction can be

processed in the data processing center and the data

of multi - measuring equipment can be combined

adjustment. many kinds of data from various

measurement devices can be processed, including

original measured data, the data generated to show

on the device and the data to guide.

3) It is mainly used for the preparation of the

measurement task, Simulated measurement site, The

purpose of simulation is to plan the layout of

equipment, to know interact with each other and

gain the planed path.

4) The software are decomposed and analyzed

to the task. The software can be automatically

measured according to the data of the model

database, and the various instructions can be

manipulated.

5) The Man-machine interface is mainly

convenient for information interaction. It is

responsible for the display of plane and table

information on the display console the software

receives various intervention commands and manual

input data, and can read the three-dimensional

model.

3 KEY TECHNOLOGIES

3.1 The Reasonable Design,

Arrangement and Measurement of

the Control Standard

A comprehensive measurement system composed of

multi measurement equipment to obtain high

accuracy of the measurement results, firstly we must

determine the structure of observation and how to

layout, according to the measurement conditions and

the characteristics. In design process, a variety of

measurement equipment is needed to identify a

common characteristics of the measurement symbols,

we must think of the size scale of the measurement

object, the structure characteristics of the mark

points. According to the task of designing a common

identity, public signs are shown in Figure 5. Each

different mark represents a different point, and

different measuring equipment must identify the

center of each mark, Only in this way the data from

multi - measurement can be spliced or be fused.

Figure 5: Public sign.

To improve the measurement accuracy, it is

necessary to obtain diversity of observation data in

the layout process. Diversity observation data will

be the basis for an accurate adjustment model. We

need to consider measurement datas of blind

distribution, spatial distribution of the optical unit

can be used, The space of light coverage and the

light source arrangement of Optical measurement

system should be considered. when above all

problem are solved Enter the actual measurement.

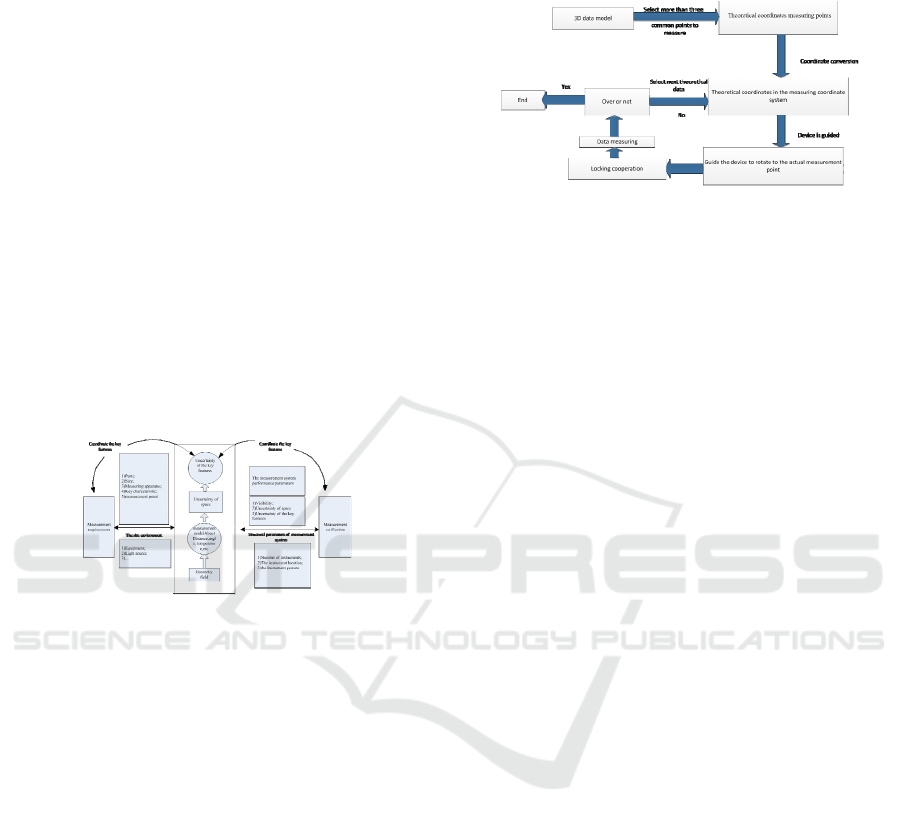

3.2 Based on the Model of Automation

Measurement Process Design

Automation measurement process model is

designed based on digital three-dimensional

simulation model[9,10], The task demand is

analyzed and simulated. measurement instruction is

generated ,according to the relevant test

requirements, The selection, combination and layout

of the measurement equipment are carried out by

simulation measurement, according to the site

environment; Based on the integrated control and

automatic measurement of the measured plan

generated by the simulation, All measurement data

are collected and calculated in the measurement and

control center, Building a unified coordinate system

for data solver to complete the on-line analysis.

Finally, the result of measurement is given.

Automated measurement procedures are as follows.

Figure 6: Based on the model of automation measurement

process design.

3.3 Measurement Simulation

Measurement simulation is the most important

condition to realize Automation measurement, and

establishing a reasonable measuring field model is

the base and key of the measurement planning and

system optimization in the field of complex aviation

experiment[11,12]. Overall, the field measurement

model should establish in accordance with the

measurement task requirements and site

environment model, which should include work

space, spare parts, obstacles, measurement,

measuring instruments, environmental factors of

measuring space etc. measurement system combined

with a different layout or configuration scheme, the

simulation will form different field measurement

results, the performance parameters of the

measurement system can be obtained before the

implementation of the actual measurement through

simulation. which can be in the evaluation of the

performance parameters of the measurement system

and the optimization of structural parameters to

verify the measurement field model and testing

requirements match, in the simulation process focus

on visibility and accuracy characteristics. The

simulation process is shown in figure 7.

Figure 7: Measurement simulation processn.

3.4 Automatic Measurement Process

Sample

The equipment used for automatic measurement

includes the tracking devices (tracker, total station),

and automatic aiming measurement is realized by

adopting the mode of coordinate value conversion -

equipment automatic driving - automatic point

finding -- Data collection. First , the theoretical

position of each measuring points under the design

coordinate system is obtained based on based on 3D

model, the conversion relationship between the

design coordinate system and the measurement

coordinate system is calculated, the theoretical

coordinate values of each measuring point under the

measurement coordinate system under the current

actual state are obtained, the measuring equipment is

automatically positioned near the measuring point to

be acquired through a program control, so that the

tracker automatically and accurately find a target

bull's-eye ball, complete the measurement. then

enter the next desired point of the search and

measurement. The process is shown in figure8.

Figure 8: Automatic measurement sample.

4 APPLICATION VERIFICATION

Using a combination of total station instrument,

lightpen, image measuring system equipment into an

integrated measurement platform. Through

measurement platform, Interface interoperability,

real-time guidance, coordinate transformation and

adjustment function can be verified. we can use the

software to develop stable controling equipment for

measuring, integrate precision accuracy is better

than a separate device; measurement range is

expanded,1+1>2 function can be realized. At the

same time, in the process of testing a number of

models, we test the combination of automated

measurement mode, achieve an online measurement;

improve the efficiency and reliability of

measurement.

5 CONCLUSIONS

Using total station instrument, light pen, image

measuring system can be composed of Automation

engineering measurement system; after the

completion of the Automation measurement system

can achieve routine tasks online measurement and

improve measurement speed and work efficiency.

To achieve the Automation test target requires

overall planning, the gradual implementation of the

construction line up at the facets, we are building

Automation test work progresses follow this idea.

The system will give a strong boost to the

development of flight test of Automation testing

technology, improving test accuracy and

measurement speed, saving manpower, material

resources.

REFERENCES

1. Tingwu, Y., Zhengzhong Z., 2014. Optical-Electronic

Measurement Theory and Methods in Flight

Test,National Defence Industry Press,Beijing.

2. Puzhou, R., Hongli H., 2012. Application of

photoelectric test technology in flight test,2012

western conference paper on photonics,Xi’an.

3. Zhou, Z, Q., 2010. Flight test project,Aeronautical

Industry Press,Beijing.

4. Zhang, L., Shan CL., 2015. Inpection Technology of

Aero-Engine Parts Based on MDB

Model,Measurement and control technology.

5. Shan CL., Yang HY., 2014. Research on Digital

Inspection Technology of Profile,Aviation Precision

Manufacturing Technology.

6. Chen, JT., 2016. The basic principle of system -

Engine based on Model,Aerospace China.

7. Maxham, D., 2010. Practical Means of VEC Applied

in Calibration of Large-Scale Machine

Tool,Aeronautical Manufacturing Technology.

8. Luo, F., Zhou, W. ,Y., 2014. Motion Planning and

Precision Controlling in Component Automatic

Butt,Aeronautical Manufacturing Technology.

9. Li, G., L., Meng, Y., M., 2015. Assembly Measure

Process Planning based on the 3D Assembly Process

Model,Aeronautical Manufacturing Technology.

10. Jun, X., P., Yao, 2005. Study on a three-dimensional

digital assembly process planning system,Journal of

Harbin Institute of Technology.

11. Zhu, X., S., Zheng, L., Y., 2005. Multiple-objective

optimization algorithm based on key assembly

characteristics to posture best fit for large component

assembly,Acta Aeronautica et Astronautica Sinica.

12. Zheng, L., Y., Shao, J., 2012. Large-Scale

Measurement Software Integrated in

CATIA,Aeronautical Manufacturing Technology.