Research on the

K

ey Technology for Robot Intelligent Welding of

Q235-Hydraulic Oil Tank

Hao Wang

1,2

,Junjian Lin

1

,Qingfang Qiu

1

,Xin Wei

2

and Fei Cao

1

1

Sinomach Intelligence Technology Co., Ltd

,

Guangzhou Guangdong, 510700

2

School of Electro-mechanical Engineering, Guangdong University of Technology

,

Guangzhou Guangdong, 510006

Keywords: Hydraulic oil tank; Robot arc welding; Process test; Flexible fixture.

Abstract: To solve the problems such as low welding efficiency, poor welding molding quality in manual welding of

hydraulic oil tank, this paper conducts a research on intelligent robot welding technology for hydraulic oil

tank. Aiming at these problems of various types and non-standard sizes of the tanks,this paper designs a

flexible fixture for the tanks, and studies the influence between the weld quality and the welding speed,

current, voltage, protective gas, and other process parameters through the welding experiment, finally a set

of robot welding technology of hydraulic oil tank which in the size of 1000mm×500mm×500mm is formed.

1 INTRODUCTION

The hydraulic oil tank as a key part of the hydraulic

system, played a crucial role in storage of hydraulic

oil, transmission and ensure the normal operation of

the hydraulic system. Therefore, the hydraulic oil

tank has a particularly high for welding quality

especially air tightness requirements after welding.

At present, the welding of hydraulic oil tank

mainly depends on the traditional manual arc

welding, some of which are introduced into robot

welding, and the welding material usually faces up

to 3mm thick plate. Due to the large thermal

influence zone in the process of arc welding, the

thermal deformation of the workpiece is large,

which can produce the complex residual stress,the

welding seam is poor and needs polishing after

welding. It is easy to form porosity, slag, unmelted

and unsoldered welding defects during the welding

process. In severe cases, minor cracks occur, causing

oil spills in the tank, which causes serious safety

problems to the stability of the hydraulic system.

Therefore, the research on high quality and high

efficiency welding technology of hydraulic oil tank

is very important to maintain the stability and safety

of hydraulic system.

Robot welding with its high speed, high quality,

good flexibility, easy to realize automation, is

widely used in shipbuilding, weapons and

equipment, marine engineering, automobile industry,

railway vehicle, hydraulic equipment manufacturing

and other fields, occupies a significant role in

manufacturing.Taking the hydraulic oil tank as

research object, this paper carried out the research

through the welding process, welding seam tracking

technology and flexible fixture design.

2 WELDING SYSTEM AND

MATERIAL

Figure 1.Robotic arc welding system.

Robotic arc welding system is mainly composed of

FANUC M-20i six joint robot, 500kg of two-axis

displacement machine, Lincoln R500 arc-welding

machine, STT advanced welding process module,

automatic wire feeding machine, ABIROB A500 air-

cooled welding torch and Torch Clean Station

cleaning equipmentas shown in Figure 1.At the same

time, it is equipped with J511 welding arc tracking

software, J536 starting point seeking software, J532

multi-layer welding software.

2.2 The Welding Object

Figure2. Hydraulic oil tank.

The welding object is a type of tire vulcanizing

machine oil tank and its size is

1000mm×500mm×500mm as shown in Figure 2.

The material is Q235-A steel, its chemical

composition is shown in Table 1.

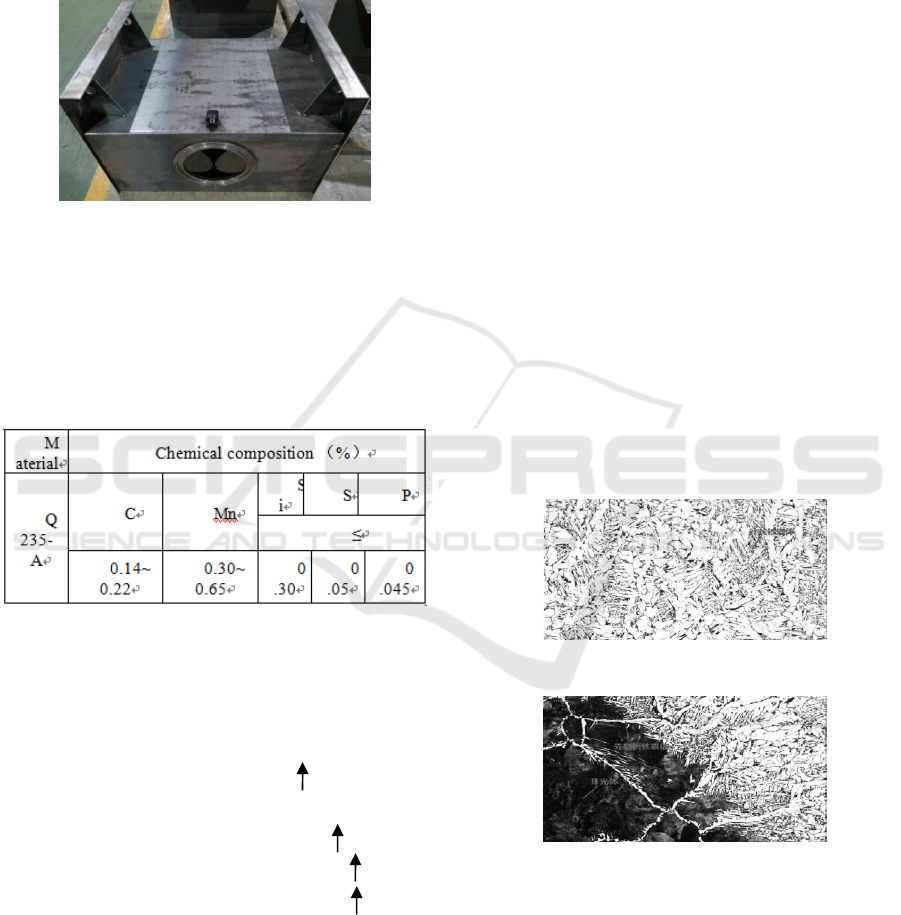

Table 1:The chemical composition of welding material.

The metallurgical reaction of welding material in

welding process is closely related to the formation of

welding porosity[1].When the carbon content in the

liquid weld is high and the deoxidation is deficient,

there are more FeO in the molten pool.When the

molten pool temperature drops, the following

reaction will occur[2]:

[ C ]+[ O ]= CO

[ FeO ]+[ C ]=[ Fe ]+CO

[ MnO ]+[ C ]=[ Mn ]+CO

[ SiO2 ]+2 [ C ]=[ SiO ]+CO

If the molten pool has started to crystallize, then

CO will be unable to escape and produce a CO

porosity. The higher the carbon content of the

welding material itself, the more likely it is to

produce a CO gas, thus forming a porosity.

The Si and Mn in the welding materials are

deoxidized elements which can effectively inhibit

the production of CO gases.But the contents of Si

and Mn in parent material are usually not

high.Therefore, the wire with high content of Si and

Mn, such as H08Mn2Si wire, can effectively

suppress the keyhole-induced porosity

[3].

3 EXPERIMENTAL STUDY ON

ROBOT WELDING PROCESS

The welding process test involves the influence of

parameters such as welding voltage, current,

welding speed, shielding gas (type and flow rate) on

the quality of welding seam. Huang Jiaqing[4], from

zhong che zhu zhou electric locomotive co., LTD,

has studied the welding process of the locomotive

bogie hollow shaft robot. The experimental results

show that it is better to use 80% Ar + 20% CO

2

mixture protective gas than the CO

2

protective gas in

welding process and the microstructure of the

welding joint consists of acicular ferrite as shown in

Figure 3.The microstructure of the overheat zone in

the thermal area of welding is obviously grown as

shown in Figure 4, and its tissue is consists of pre-

eutectoid ferrite, pearlite and a small number of

bainite.

Figure 3 The microstructure of weld seam[4].

Figure 4.The microstructure of the fusion area[4].

During the early stage of the welding process

test, the welding voltage, current, welding speed,

protective gas (type and velocity), arc starting and

stopping control parameters did not match properly,

which lead to welding quality is not ideal as shown

in Figures 5 and 6.The quality of the start and end

point of arc welding is poor, the surface of welding

seam is discontinuous and raised serious.

Figure 5.The weld molding under the immature process

parameter (1).

Figure 6.The weld molding under the immature process

parameter (2).

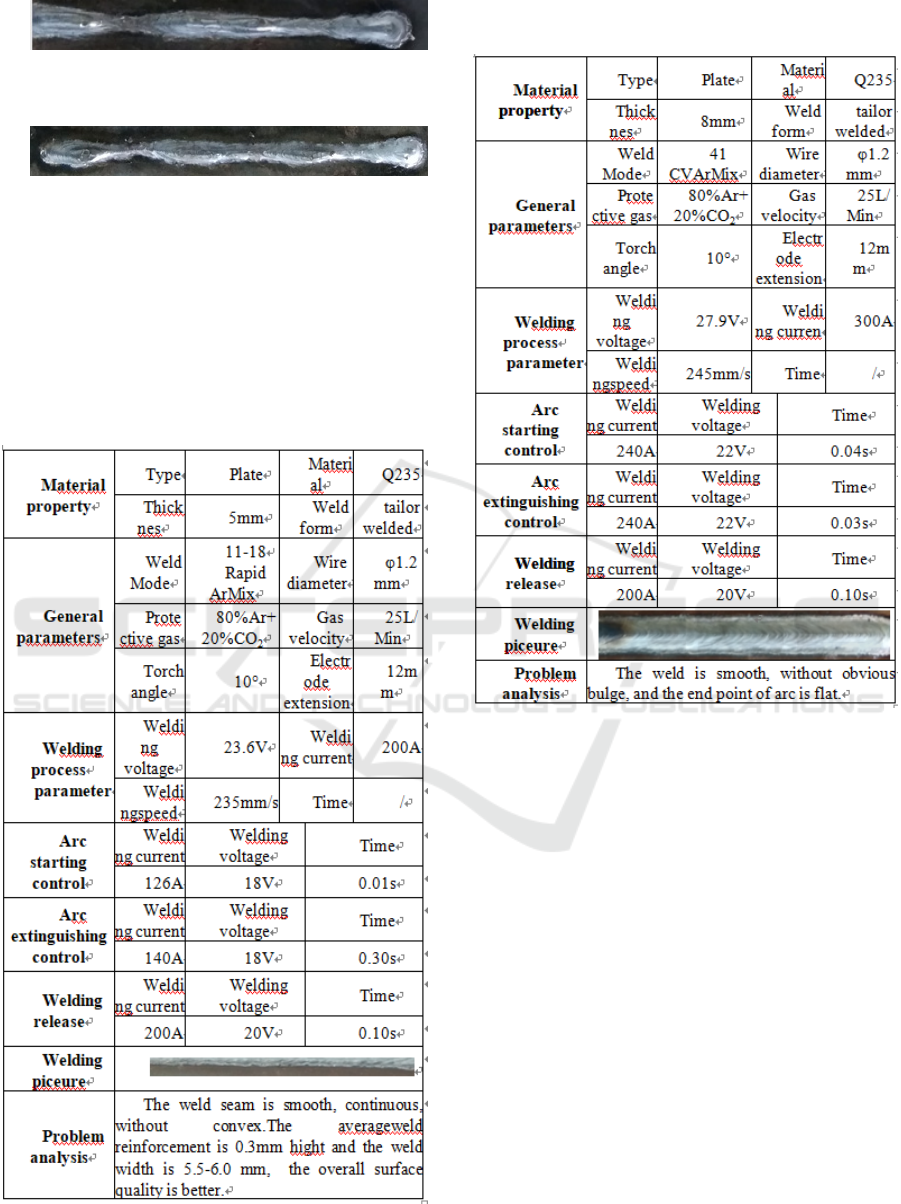

After a lot of process experiments and refer to the

relevant welding literature, the author finally

determined the better welding parameters of 5mm

and 8mm these two kinds of common plate thick

fuel tank as shown in table 2 and 3.

Table2: Welding process parameters of 5mm thick Q235

carbon steel plate.

Table3: Welding process parameters of 8mm thick Q235

carbon steel plate.

4 THE RESEARCH ON SEAM

TRACKING TECHNOLOGY

Because the processing error of the tank plate is

larger(about 1~3mm), the source of the error mainly

includes the followings: (1) The dimensional error

and deformation caused by the shearing process of

plate shearing machine;(2) The bending process

would produce dimensional error. Beside, because

the welding process would produce thermal

deformation, it causes current teaching programming

can not meet the requirements of real-time seam

tracking. Therefore, seam tracking technology

should be introduced.

In the research of seam tracking technology, Sun

Li, Lin Tao and others from Shanghai Jiao Tong

University[5], Gao Xiangdong, Ding Dukun and

others from Guangdong University of

Technology[6], have studied a seam tracking

technique based on machine vision, Zhang

Wenzeng, Chen Qiang and others from Tsinghua

University[7], Sun Mei,Du Jun and others from

Nantong University[8], have studied the trajectory

tracking technology of welding robot based on 3D

stereovision. Although the above scholars have

made many achievements, we consider the cost of

the program and the ease of implementation of the

technology, this article studied welding seam

tracking technology based on arc sensor( The

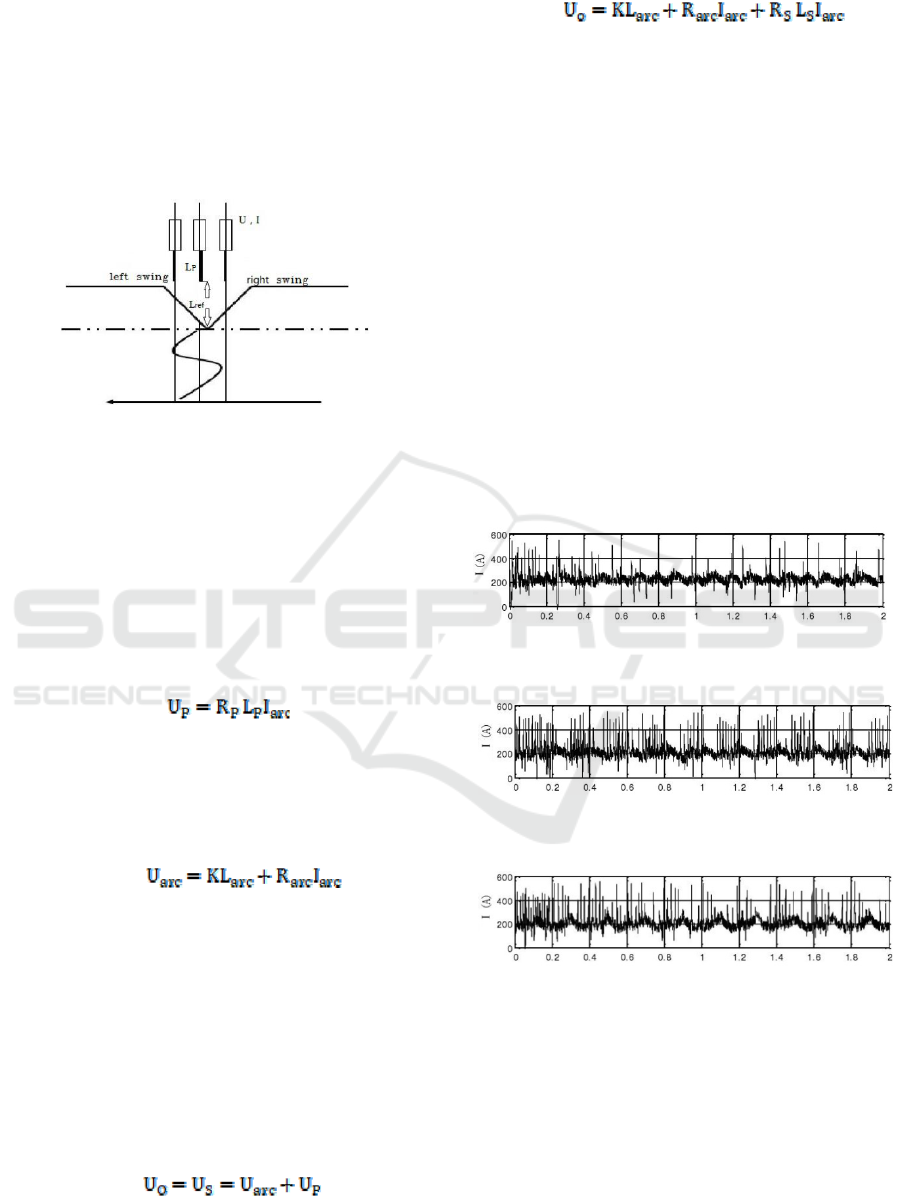

principle is shown in Figure 7).

Figure 7.Working principle of arc sensor.

By establishing a simplified numerical model

between the output voltage Uo and the arc length

Larc and the corresponding current Iarc, and

compare the current Iarc at different distances with

the reference current Iref of the system, thus

realizing the position tracking of the welding seam

in the periodic swing welding process.

Among them, the voltage drop of electrode

extension is:

(1)

In the formula, RP is resistance per unit electrode

extension. Lp for electrode extension.

The relation between the voltage Uarc and the

current Iarc and the arc length Larc is:

(2)

In the formula, K is a unit of arc long voltage

drop, L

arc

is arc length, and R

arc

is arc equivalent

resistance.

In the process of welding, the supplyenergy

between welding power and welding arc should be

balanced[9]. That is to say, the output voltage of the

welder U

O

is equal to the arc load voltage U

S

, while

the arc load voltage U

S

includes the arc voltage U

arc

and the voltage drop of electrode extension U

P

as

follows:

(3)

Comprehensive formula (1), (2), (3) available

(4)

In the welding process, the distance from the

welding wire to the bottom of the V type weld is set

to the reference distance L

ref.

According to the

formula (4), we can see the value of the

corresponding current at this time, and set it as the

reference current I

ref

in the system. In welding

process, the distance of the wire from the bottom of

v-shaped weld will change in real time by setting the

welding torch to swing welding. At this point, the

currentvalue of the arc sensor is I

arc

as shown in

Figure 8-10.Comparing with the reference current

I

ref

, when the welding trajectory is located in the

center of the weld as shown in Figure 8, I

arc

=I

ref

, the

current waveform is symmetrical, and the torch is

advancing along the current weld trajectory; When

the welding seam trajectory deviate left or right of

the weld seam as shown Figure 9 and 10, I

arc

≠I

ref

.At

this time, the position of welding gun is modified

continuously during the welding process, to searched

the position of I

arc

= I

ref,

which can achieve the

purpose of real-time weld tracking.

Figure 8.Current waveform diagram when the welding

trajectory is located in the center of the weld

[10].

Figure 9.Current waveform diagram when the welding

trajectory deviate left of the weld seam [10].

Figure 10.Current waveform diagram when the welding

trajectory deviate right of the weld seam [10].

5 FLEXIBLE FIXTURE DESIGN

At present, most hydraulic stations are designed and

manufactured in non-standard format, which results

in various types and sizes of the fuel tanks.

Furthermore, the plates have a certain size error in

cutting and bending process. Therefore, it is

necessary to have some flexibility for the

corresponding fixture clamping device, which can be

compatible with different types of fuel tank for

quick loading and positioning. Aiming at the above

problems, this paper designs a flexible fuel tank

fixture based on pneumatic four-jaw as shown in

figure 11 and 12.

Figure 11.3D design of fuel tank fixture (1).

Figure 12.3D design of fuel tank fixture (2).

6 CONCLUSION AND PROSPECT

(1) Using robot to weld fuel tanks at the production

site, the speed can be as high as 245mm/s. With

special fixture, it can realize batch welding, high

welding efficiency and good welding quality. The

workload of a robot is equivalent to 3 to 4 ordinary

welders. Besides, in the case of reasonable welding

process, the welding qualification rate is high, the

rework quantity is small, the labor cost is greatly

saved, and the economic benefit is significant.

(2) In the aspect of study on seam tracking

technique,the research of this paper only based on

arc sensing at the present stage. Tracking stability

and compatibility is relatively poor and we are going

to conduct the study of weld tracking technology

based on machine vision.

(3) At the present stage, this paper just studied

welding process and fixture design of fuel tank.The

follow-up will be carried out through the test of

welding quality research, such as ultrasonic testing,

tensile and bending, metallographic experiment,

focusing on analysis of welding seam inside the

porosity, crack defects, and then optimize the

welding process.

ACKNOWLEDGEMENTS

This paper was financially supported by the 2015

Guangdong Science and Technology Project

(No.2015B010918002), 2016 Guangzhou Science

and Technology Project (No.201604016115) and

2017 Sinomach Intelligence Technology Co., Ltd

Fund Project (No.62300002).

REFERENCES

1. Wang Lifeng,Liu Fengde,Liu Weina. Study on

control method of porosity in laser-arc hybrid

welding for high nitrogen steel[J]. Journal of

Mechanical Engineering , 2016,52(20):51-59.

2. Lin Rui.Causes and control measures of welding

porosity in long distance pipeline[J]. Petro-Chemical

Equipment, 2016,19(5):75-77.

3. Chen Wuzhu, Quality control of laser welding and

cutting[M] ,China machine Press, 2010.

4. Huang Jiaqing, Improvement of welding process for

hollow shaft robot[J]. Welding Technology,

2016:601-605.

5. Sun Wei. Study on the seam tracking control system

based on CCD visual sensor[D].Shanghai Jiao Tong

University,2008.

6. Gao Xiangdong,Ding Dukun,Zhao Chuanmin,et

al..Seam tracking technology based on machine

vision[J]. China welding, 2006 (2):19-23.

7. ZhangWenzheng,Chenqiang,Dudong,Sunzhenguo,et

al.. 3-D vision-based trajectory tracking of welding

robots[J]. Journal of Tsinghua University (Science

and Technology),2007, 47 (8):1270-1273.

8. [8]Sun Mei.Research on seam recognition and

tracking technology of mobile welding robot based

on stereo vision[D]. Nantong University, 2013.

9. Liuyue,Liunian, et al.. Research on seam tracking

system of arc welding robot based on sine pendulum

welding. Machinery & Electronics, 2016,34(10): 76-

80.

10. Liunian, et al.. Research and implementation of

seam tracking system for arc welding robot[D].

Harbin Institute of Technology, 2015.