Experimental Study on Electrochemical Machining of Conical Micro-

Holes

Weimin Gan

1

, Ye Zhu

1,2

, Bo Xu

1

, Yang Chen

1

and Xiangzhi Wang

1

1

Jiangsu Key Laboratory of Non-Traditional Machining

,

Changzhou Institute of Technology, Changzhou 213002,CHN

2

School of Mechanical Engineering, Changzhou University, Changzhou 213164

Keywords: Tube electrode; simulation analysis; conical hole; ECM.

Abstract: Micro holes with internal features are widely used as nozzle of engine nowadays, which are usually required

to be with high aspect ratio and shape accuracy, as well as good surface quality. In order to solve the

machining problem of the engine nozzle, a small taper hole was studied by electrochemical machining

which has online machining tube cathode .By processing machining model and doing simulation of flow

field and electric field, analyze the influencing factors in the experiment. Finally, the law of the feed speed,

the voltage and electrolyte concentration and taper of hole are studied. A good conical micro-hole was

worked out and taper error is 0.46 °.

1 INTRODUCTION

Mechanical components tend to be miniaturized and

refined, and are widely used in engines, micro-

electromechanical systems, precision instruments

and other fields. Among them, the structure of the

conical hole is complex and difficult to process. The

conventional machining technology cannot achieve

the general adoption of special processing

technology. For example, the micro-tapered cavity is

machined by electric spark or laser [1], and then the

surface quality of the side wall is improved by

abrasive flow polishing. However, in the EDM

process of micro holes, the electrode loss is serious,

the machining accuracy is difficult to ensure, and

there are defects such as surface microcracks in laser

processing [2]. The surface processed by the

abrasive flow is improved compared with laser

processing, but the residual stress is difficult to

eliminate [3].Electrochemical machining has the

advantages of no loss of cathode, good surface

quality, and no residual stress. Prof. Li Yong of

Tsinghua University processed micro-holes with

smaller taper in the ECM test by changing the

voltage between the electrodes, the duty ratio, and

the feed rate, and achieved better results. Good

effect, import deviation is 3μm and cone angle error

<0.1° [4]. XuShiyu of Xi'an University of

Technology successfully processed tapered holes by

formulating a layered electrolytic milling process

[5]. Nanjing University of Aeronautics and

Astronautics adopts a compound feed electrolytic

machining process to machine large taper holes with

clear contours and stable machining [6].

The electrochemical product of micro-conical

hole is difficult to discharge in the electrochemical

machining. In order to eliminate manufacturing and

secondary assembly errors, set up a micro-hole

processing device, on-line machining conical tube

electrodes. With the use of electrolyte injection

technology and rotation of cathode, through the

experimental study the influence of factors such as

cathode feed rate, processing voltage and electrolyte

concentration on the processing results.

2.INFLUENCE OF

ELECTROLYTIC PROCESSING

PRECISION OF TAPER HOLES

From the basic laws of electrolytic machining,

namely Faraday's law and Ohm's law, it can be

deduced that the dissolution rate of the anode during

electrochemical processing in formula (1).

v

a

=ηωi=

(1)

In the equation (1) where v

a

is the anode phase

dissolution rate; η is the electrolyte current

efficiency; i is the current density; ∆b is the end

clearance; ω is the volume electrochemical

equivalent; к is the electrolyte conductivity; U

R

is

the ohmic pressure drop between poles . This

formula reflects the parameters of the

electrochemical machining and is the theoretical

basis for analyzing the forming law of

electrochemical machining.

In electrochemical machining, the size of the

machining gap and its variation are the main sources

of error in machining. The machining gap is affected

by many factors such as electric field, flow field,

temperature and electrochemical characteristics [7].

According to electrolytic processing end surface

equilibrium gap formula(2).

b= (2)

Fully differentiate it to get the gap d∆b:

= [ (3)

Formula (3) shows that the use of small gaps can

reduce the amount of change in the gap, thereby

increasing the gap of electrochemical machining.

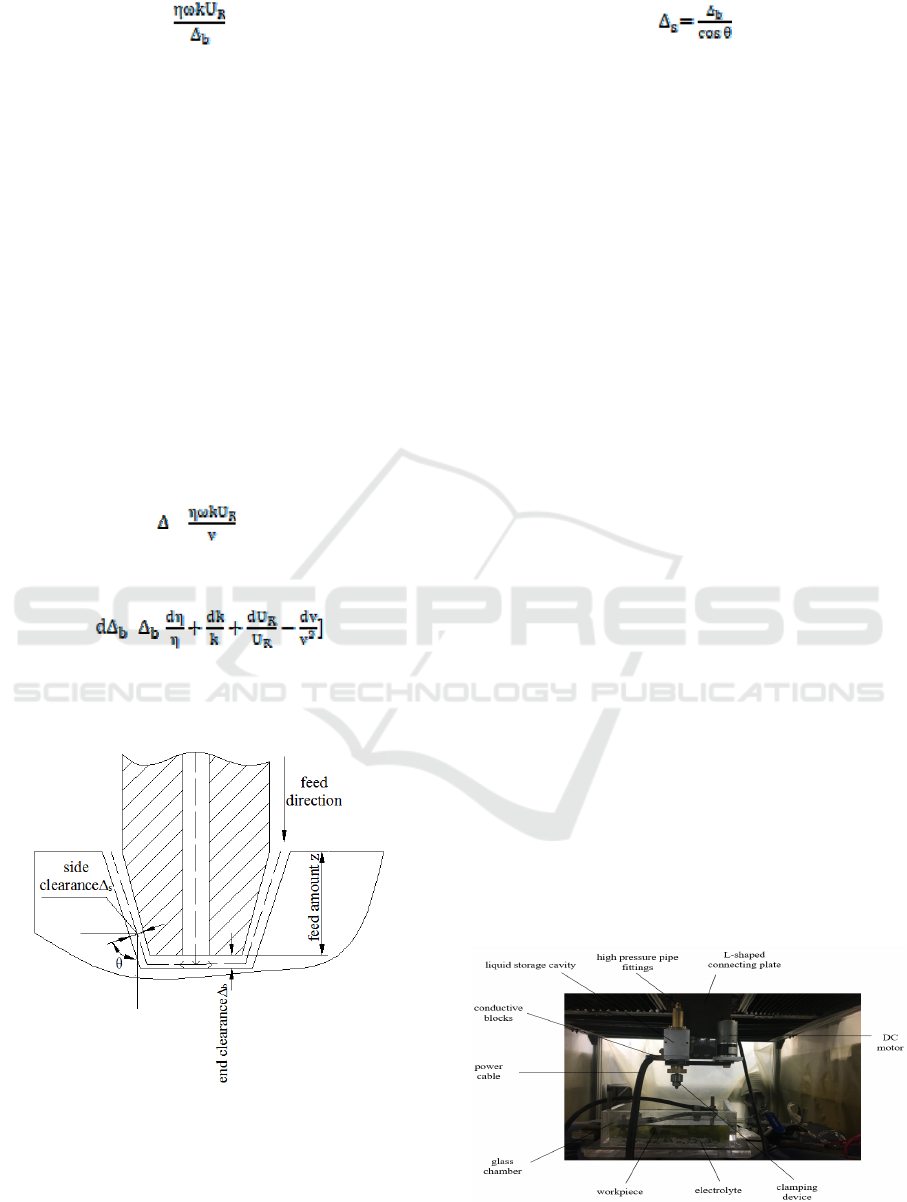

Figure 1 Schematic diagram of electrochemical machining

of tapered tube electrode.

As shown in Figure 1, at any one of the cathode

feeds z, it is again available:

(4)

Formula (4) shows that when the conical cathode

continuously feed, end clearance ∆b affect the

important factors of the precision of the tapered hole

processing. From formula (3) ,the processing

voltage, feed rate and electrolyte concentration

affect the end of the tapered hole Gap, thus affecting

the processing stability and machining accuracy of

the tapered hole.

3.PREPARATION OF

EXPERIMENT

3.1 Device of Experiment and Online

Machining of Cathode

This experiment was based on a CNC engraving and

milling machine. An L-shaped stainless steel plate

was placed on the lower end of the spindle, and the

processing device was connected to feed the taper

hole up and down. As shown in Fig. 2, the high-

pressure pipe joint leads to the electrolyte and flows

from the liquid storage cavity into the cathode of the

tapered pipe to form a liquid. As the diameter of the

conical pipe is small, a 0.8 mm seal ring is inserted

into the liquid storage cavity to avoid high pressure.

The electrolyte overflows to ensure that the

electrolyte flow is normal during processing. The

drill chuck can hold 0.15mm-3mm diameter and it is

not easily deformed. A carbon brush is placed in the

conductive block, and the cathode and the power

line are connected to form a path. The DC motor

drives the cathode through the belt to rotate during

processing and the spindle feed speed of CNC

machine tool can reach 1μm/s, which can meet the

requirements of the micro-hole machining.

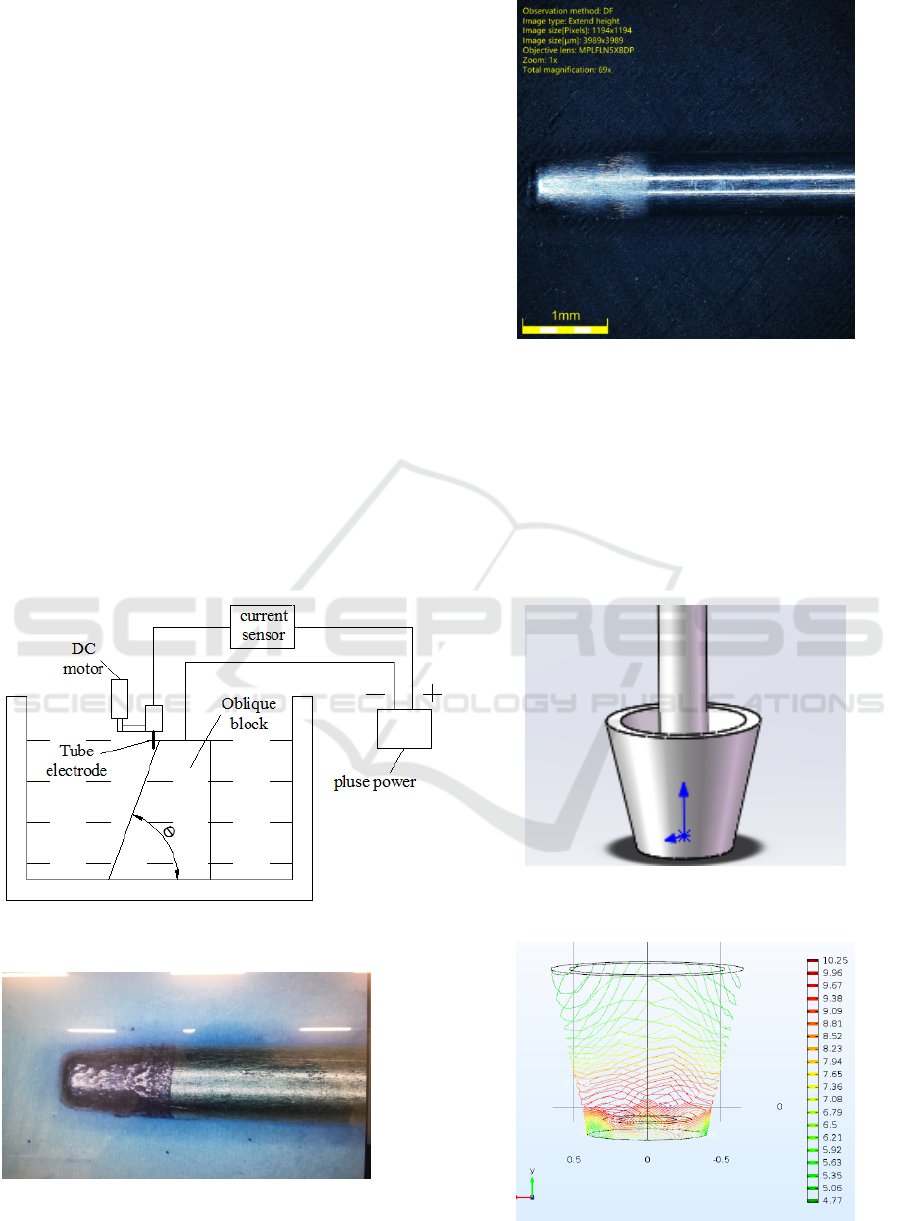

Figure 2 Device of ECM.

The manufacture of tool electrodes in the electro-

processing of cone-shaped holes is very important.

Turning and grinding of the tube electrodes can

easily lead to bending of the front section of the

cathode and leave marks on the surface, failing to

meet the test requirements. The cone electrode can

be obtained by electrochemical processing with a

conical block. The processing device is as shown in

FIG. 3. At this time, the tool electrode is connected

to the anode of the power supply, the cone

correction block is connected to cathode, and the

motor drives the cathode to rotate at a relatively high

speed. The current sensor is used to observe the

processing current, and control the removal amount

by changing the processing voltage and processing

time. In the experiment, two types of materials that

copper and stainless steel were used to make the

cathode of the tapered tube. The surface of the

resulting copper electrode was seriously pitted due

to the use of nitric acid. Sodium electrolyte is not

suitable for this type of material. Since the stainless

steel is resistant to electrolyte corrosion and the

hardness of the material is high, the stainless steel

electrode obtained in FIG. 5 has a uniform taper and

a good surface quality, and can be used as a forming

cathode for the electrolysis of a tapered hole.

Figure 3 Device diagram for on-line cathode fabrication.

Figure 4 Copper conical tube electrode.

Figure 5 Stainless steel tapered tube electrode.

3.2. Analysis of Flow Field Simulation of

Conical Tube Electrode

Assuming that the fluid is constant, incompressible,

ideal, the loss of energy due to electrolyte

temperature changes and temperature differences

during processing is negligible, and the flow follows

mass and momentum conservation equations.

Figure 6 Three-dimensional model diagram of electrolyte

flow channel.

Figure 7 Velocity distribution of conical surface.

In electrochemical machining, in order to satisfy

the assumption of a steady distribution of the flow

field, and to better remove the electrochemical

products at the surfaces of cathode and anode to

reduce the concentration polarization near the

electrodes and to make the liquid flow uniform, the

processing gap should be turbid. Flow state

electrolyte, electrolyte flow rate v0 should meet [5].

(5)

In the formula (5),v is the viscosity coefficient of

water, which is used here as an alternative to the

viscosity coefficient of the electrolyte. The

electrolyte temperature is 25°C in the experiment,

and the viscosity coefficient is 0.89 10^(-6)

m2/s[5];Dh is the hydraulic diameter, that is, the

hollow diameter of the tube electrode, which is

substituted into the formula.

5.1m/s (6)

From the formula (6), the stability of the

electrochemical processing can be guaranteed only

when the flow rate of the electrolyte in the

processing gap is at least 5.1 m/s. From the taper

tube electrode processing gap flow velocity

distribution chart, when the inlet pressure is 0.5Mpa,

the flow velocity in the processing gap is greater

than 5.1m/s, and the velocity distribution is uniform

stable. A very small number of processing areas

outside the emergence of low flow rates, so need to

choose import pressure parameters over 0.8Mpa.

3.3. Electric Field Characteristics of

Cone Tube

Assuming that the electrolyte is isotropic, according

to the electric field theory, it can be seen that the

potential distribution conforms to the Laplace

equation and its equation is

(7)

Boundary conditions of anode surface

is

: (8)

The boundary condition of cathode surface is:

(9)

In the formula,φ is the potential of each point

in the electric field, generally φ = φ (x, y, z); U is the

surface potential of the anode; n is the normal

coordinates of the anode surface everywhere; θ is the

angle between cathode feed rate and the normal

direction of anode; is the current efficiency; η

0

is

the current efficiency at θ=0; i0 is the current density

in the normal direction of the anode surface at θ=0; к

is the electrolyte conductivity.

Because (10) (11)

The boundary between the processed material

and the electrolyte is

(12) (13)

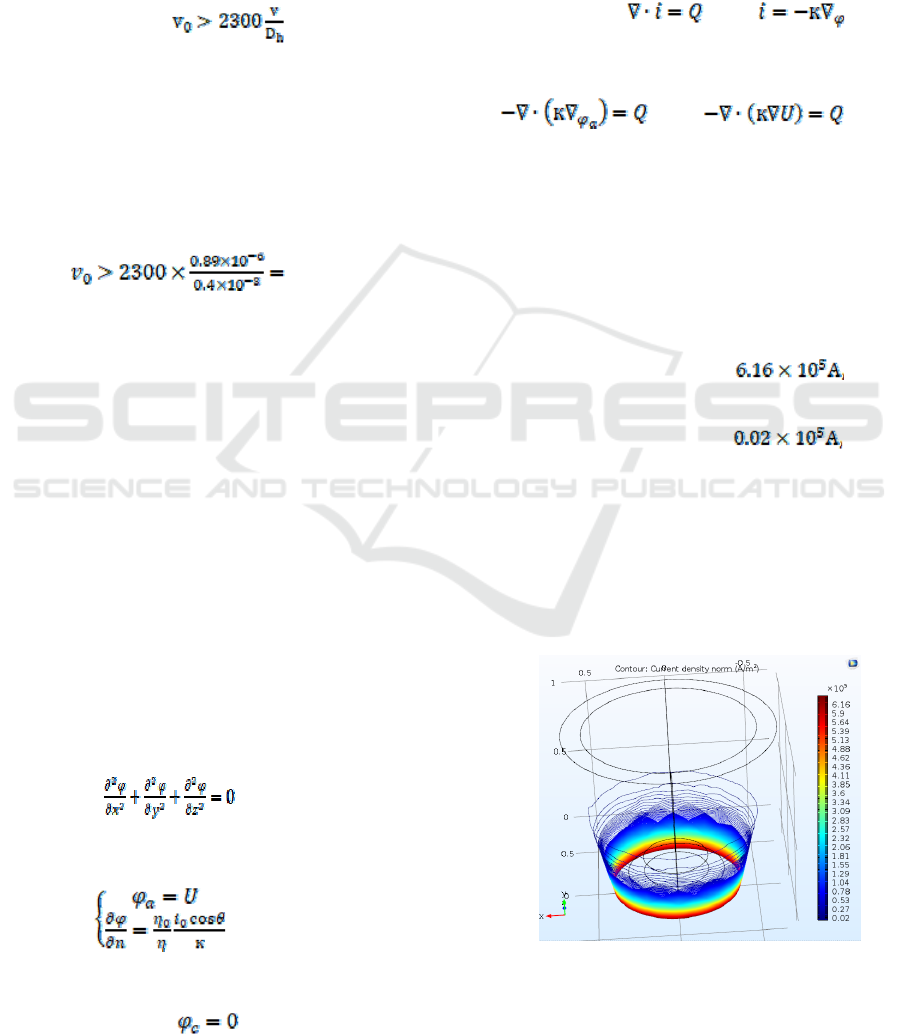

Electric field simulation uses 14% sodium nitrate

solution whose conductivity is 8.7 (S/m) and the

anode material is 0Cr18Ni91 (304 Stainless steel),

where the processing voltage 4v. From the figure 8,

the current density is gradually weakened along the

material to the micro-electrode direction, and the

maximum value appears on the interface between

the processed material and the electrolyte, and is

unevenly distributed along the boundary surface.

The maximum value is

, the

minimum value appears on the contact surface

between the conical tube electrode and the

electrolyte. The value is

. The

current density is an important parameter for

electrochemical machining. Generally, with the

voltage increasing, the current density increases, and

the bottom surface processing effect is better. [6]

However, the side current density is too large, the

material removal amount increases, and the taper

increases. The faster the machining speed, the less

stray corrosion on the side, the smaller the taper, the

closer to the taper of the forming cathode.

Figure 8 Distribution of electric field density.

4. EXPERIMENT OF PROCESS

PARAMETERS

In order to study the influence of process parameters

on the precision of the electro-processing of conical

holes, a single-factor comparison test was conducted

on the feed rate, processing voltage, and electrolyte

concentration, keeping the other processing

parameters unchanged. And taper effect of the law.

The unilateral lateral clearance ∆s and both sides of

the taper were used as evaluation indexes. In the test,

the taper hole was measured with an ultra-depth

digital microscope and the hole diameter and hole

taper were measured. Since the gap between the top

and bottom side of the taper hole was not uniform,

the three-point calculations were taken at the inlet

end, the middle end, and the bottom end. Unilateral

side of the average side of the gap ∆ s, the formula is

below.

(14)

In the formula (14), D is the diameter of the

upper surface of the conical hole obtained by

electrochemical machining, whose unit is μm and d

is the diameter of the tube electrode. The main

parameters are shown in Table 1.

Table 1 Selected main parameter tables.

Category Main parameters

Electrolyte

composition

NaNO

3

Electrolyte

temperature (°C)

25

Electrolyte pressure

(MPa)

0.8

Cathode taper (°) 20

Cathode speed

(r/min)

200

Power type Pulse power

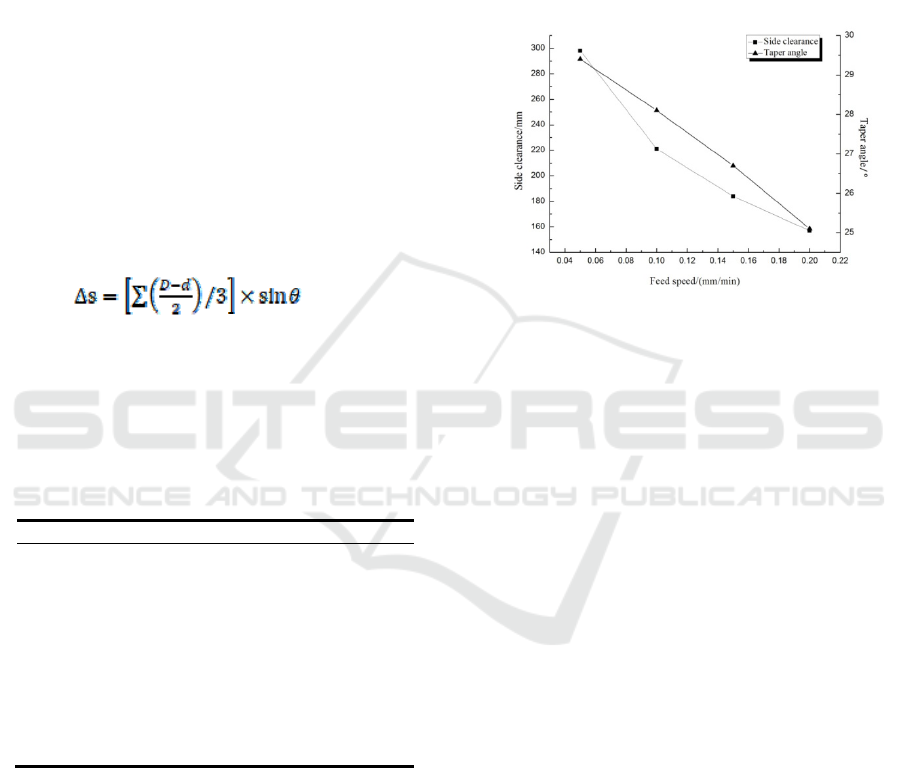

4.1 The Influence of Feed Rate on Taper

of Taper Hole

Select the sodium nitrate electrolyte mass fraction of

14%, the processing voltage which is 4v, change the

processing speed to obtain the test data, and get the

effect of the feed speed on the unilateral gap and

taper. The processing quality is the basis of the

electrochemical machining of the tapered hole.

Appropriately increasing the feed rate helps to

increase the processing efficiency and is essential for

improving the productivity of electrolytic

processing. As shown in the figure 9, as the feed rate

increases, the side gap gradually decreases, the

secondary corrosion time on the side becomes

shorter, and the inlet diameter becomes smaller.

However, when electrolysis is performed at a

relatively fast feed rate, a short-circuit phenomenon

is likely to occur, and the taper on the side surface is

not uniform.

Fig. 9 Influence of feed speed on side clearance and taper.

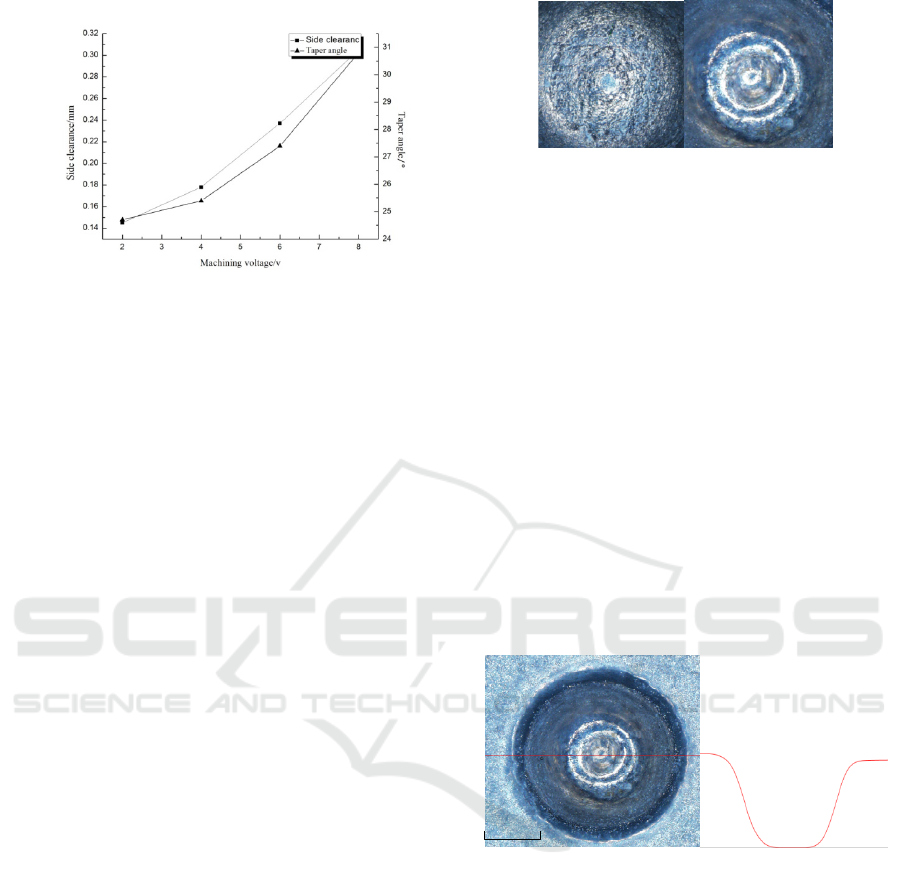

4.2 Effect of Processing Voltage on Taper

Cone Drilling

From the analysis of the electric field characteristics,

it can be seen that the higher the voltage, the higher

the current density at the end face and the side, and

the more serious the diffusion of the tapered hole,

resulting in a larger taper, an increase in the taper

error with the cathode, and a lower processing

accuracy.

For machining smaller conical holes, choose

lower tool cathode feed rate, preferentially

0.1mm/min, 14% sodium nitrate solution for testing.

As can be seen from figure 10, as the processing

voltage is increased, the unilateral gap on the side

becomes larger, the larger the hole diameter, the

more severe the corresponding stray corrosion, and

the greater the taper of the workpiece. Therefore, in

the electrolysis process, the choice of processing

voltage is extremely important. However, as the

processing voltage decreases, the material removal

rate and the machining efficiency are lower, and the

radial clearance increases. Therefore, a reasonable

processing voltage must be used.

Fig. 10 Influence of processing voltage on side clearance

and taper.

4.3 Influence of Electrolyte

Concentration on Taper

Select 10%, 14% and 18% sodium nitrate electrolyte

as a comparative test, and found that 10% sodium

nitrate solution in electrochemical processing, the

number of short circuit more, and the surface shown

in Figure 10, select 18% sodium nitrate solution

processing When the processing speed is adjustable

to 0.3mm/min, the machining efficiency is better,

but the taper is larger and the machining accuracy is

not high. With proper increase of the electrolyte

concentration, ion concentration become higher and

effect of ions in the processing area become

stronger. Because the localized effect of the

electrochemical material removal reaction get

smaller, the stray current increases removing of

material. Therefore, in order to improve the

processing accuracy, it is necessary to reasonably

limit the electrolyte concentration. Experiments have

shown that by choosing a smaller electrolyte

concentration and processing voltage, the lateral

clearance can be reduced. The processing gap

decreases as the electrolyte concentration decreases.

Therefore, the selection of a low concentration of

electrolyte is advantageous for forming a small

processing gap. The excessive reduction of the

concentration of sodium nitrate solution leads to a

decrease in the electrical conductivity and hence to a

decrease in the current density. This results in a

rapid decrease in the removal rate of the workpiece

and a short-circuiting and burning of the workpiece.

A B

Fig. 11 Bottom map of mass fraction 10% A and 14% B

sodium nitrate solution.

5. OPTIMIZATION OF TEST

RESULTS

Based on the above experimental research and

analysis, the optimization parameters were selected

for electrolytic processing of conical tube electrodes.

The NaNO

3

solution with a mass fraction of 14%

was selected for the test, the processing voltage was

4V, and the feed rate was 0.1mm/min. Taper

difference between the two sides of 0.46 ° taper, to

meet the processing needs. The error in the

machining results shown in Fig. 8 is small, and it

can be seen from the partial enlargement that the

accuracy of the shape is high, and both sides show

good localization and processing capability.

500

μm

Figure 12 Conical hole profile view.

6. CONCLUSIONS

(1) An experimental study on the production of two

different materials of the tube electrode by on-line

electrolytic machining has been carried out, and it

has been found that the stainless steel conical tube

electrode can be used as a cathode for processing a

tapered hole.

(2) By establishing the mathematical model and

processing model of the electrolysis machining of

the tapered tube electrode, the influence factors and

electric field characteristics of the processing

precision of the tapered tube electrode are analyzed,

and the parameter test is verified in the ECM

experiment.

(3) Set up a conical tube electrode tester to

analyze the effects of processing voltage, feed rate,

and electrolyte concentration on the unilateral gap

and taper. Select NaNO

3

solution with a mass

fraction of 14%, the processing voltage which is 4V,

and the feed rate which is 0.1mm/min and process a

better tapered hole whose taper error is smaller,

import roundness is better and cone burns is less.

ACKNOWLEDGEMENTS

The research of this subject has been funded by the

Jiangsu University Natural Science Research Project

(No. 15KJA460002),Jiangsu Postgraduate Practice

Innovation Plan (No. SJCX17_0732), National

Natural Science Foundation of China(Grant No.

51705040) and Natural Science Foundation of

Jiangsu Province, China (Grant No. BK20150255).

We also extend our sincere thanks to all who

contributed in the preparation of these instructions.

Thank you very much!

REFERENCES

1. L Yong ,HRuiqin. Micro Electrochemical Machining

for Tapered Holes of Fuel Jet Nozzles[J] ProcediaCirp

, 2013 , 6 :395-400.

2. Kraus Martin, Collmer Stephan, Sommer Steffen,

DausingerFriendrich. Micro drilling in steel with

frequency-doubled ultrashort pulsed laser radiation[J].

Journal of Laser Micro,2008 , 3 (3) :129-134 .

3. Huang Ying, Zhang Xiangjun, Li Yong. Extrude

honing abrasive slurry and its honing experiments for

fuel jet nozzle[J]. China SurfaceEngineering,2011,24

(5) :68-72.

4. G Liu , Y Li , Q Kong , H Tong. Research on

ECM process of micro holes with internal

features.Precision Engineering , 2017 , 47 :508-515.

5. QiLu. Fundamental Research on compoundFeeding

Precision ECM of Nozzle Taper Hole

[D].NanjingUniversity of Aeronautics and

Astronautics, 2016.

6. XuShiyu. Microelectrochemical processing of a

certain engine nozzle spin chamber [D].Xi'an

University of Technology, 2013.

7. DU Pan, ZHAO Jianshe, YU He etc. Effect

ofCompound Feed on Electrolytic Processing of

Conical

Holes[J].ElectromachiningandMolding,2017(02):23-

27.

8. He Yafeng, Lu Wenzhuang, GanWeimin et al.

Numerical study of micro-pit electrolytic machining

based on the coupling of electric field and flow

field[J]. ChinaMechanical

Engineering,2016,27(10):1365-1370.