Effects of Minor Zirconium on Microstructure and Mechanical

Properties of Al-Mg-Mn-Sc Alloys

Xianming Chen

1

, Yingying Fan

1

and Qinglin Pan

2

1

School of Electronic and Electrical Engineering, Zhaoqing University, Zhaoqing, 526061, China

;

2

School of Materials Science and Engineering, Central South University, Changsha, 410083, China

Keywords: Al-Mg-Mn-Sc alloys; Al3Sc;Al3(Sc,Zr);microstructure and mechanical properties; Al-Mg-Mn-Sc-Zr

alloys

Abstract: Al-5.8Mg-0.4Mn-0.25Sc and Al−5.8Mg−0.4Mn−0.25Sc−0.1Zr (mass fraction, %) alloys were prepared by

water chilling copper mould ingot metallurgy processing which was protected by active flux. The effects of

Zr on microstructure and mechanical properties were studied by means of observations of optical

microscopy and transmission electron microscopy. The results show that after adding Zr into Al-5.8Mg-

0.4Mn-0.25Sc alloy the grains are obviously refined. Tensile properties increase significantly; under the

condition that ductility(δ) is similar, tensile strength(σb) increases by nearly 20%, and the yield

strength(σ0.2) increases by more than 30%. Zirconium in the alloy leads to the formation of more

heterogeneous nucleation core during casting process, and more primary Al3(Sc,Zr) particles precipitate,

thus refining the grain. In the same time the supersaturated solid solubility in the alloy can be improved.

After stabilizing annealing, there is a higher degree of dispersion, and smaller and more secondary

Al3(Sc,Zr) particles come to distribute in the matrix, improving the comprehensive mechanical properties of

alloy with functions of strong pinning dislocations and sub-grain boundaries, and stabilizing sub-structures.

1 INTRODUCTION

Al-Mg-Mn belongs to the moderately strong,

corrosion-resistant, weldable aluminum alloy.

Because of their excellent comprehensive

performance, they have been widely used in

aerospace, transportation, electronic appliances,

instruments and meters, armed ships, etc[1]. With

the development of technology and increasingly

diverse application requirements, higher

requirements on the performance of these alloys

have put forward. This kind of alloy cannot be

strengthened by heat treatment. One way to increase

the properties is by improving the deformation

process; the other way is through micro alloying.

The studies show that in improving Al-Mg-Mn alloy

performance effect is prominent[2-4]. In all of the

adding elements, the most significant element is Sc.

Therefore in Russia a series of scandium aluminum

alloy have been researched and developed depend on

Sc, such as 01570 and 01571 alloys. Adding Sc into

Al-Mg-Mn alloy, the primary Al

3

Sc phase will

precipitate during casting process, dendritic structure

will be removed; and the grain size will be refined.

And in the process of cold and hot deformation and

stabilizing treatment, secondary Al

3

Sc particles will

precipitate, improving the performance of the alloy

greatly with pinning dislocation, sub-grain boundary,

and stable sub-structure.

In order to excavate the potential of Sc as much

as possible, and to improve the performance of alloy

more significantly, the research is focused on the

composite micro alloying in recent, such as Sc and

Zr[5-6], Sc and Ti

[

7-8], Sc and Er[9-10], Sc, Zr and

Ti

[11]

. The study finds out that the effect of adding

Sc and Zr together into Al-Mg-Mn alloy is better

than that of adding single Sc. meanwhile, the

strength properties and the recrystallization

temperature are higher[1]. But the research of

composite micro alloying about Sc and Zr is more

focused on the role of the Sc, and the work about Zr

may not be enough. In this work, both Al-5.8Mg-

0.4Mn-0.25Sc and Al-5.8Mg-0.4Mn-0.25Sc-0.1Zr

alloys are used as the research objects. The aim of

this work is to investigate the role and the effecting

rule of Zr to Al-Mg-Mn-Sc alloy.

2 EXPERIMENTAL

Two alloys for the study (marked A, B) are prepared

by ingot metallurgy, using as the starting materials

pure Al, pure Mg and Al-2.23%Sc, Al-4.48%Zr, Al-

8.5%Mn master alloys. Their nominal compositions

are listed in Table 1. After homogenization at 460°C

for 24h, the ingots are cut head and milled surface to

25mm thickness. Then a hot-rolling process is

applied to 6mm after heat preservation for 3h at

470 °C, which is followed by intermediate annealing

at 400 °C for 2h. Subsequently, the hot-rolled sheets

are cold-rolled to a thickness of 2.0 mm. The total

deformation rate is up to 92%. The cold-rolled

sheets are annealed at 340 °C or 150°C for 1h.

Homogenization; intermediate annealing and

stabilizing annealing processing are made in SPC

box-type resistance furnace, and the error is ±2 ℃.

The microstructures of the alloys are examined

using a POLYVER-Met optical microscope, with the

specimens first mechanical polished, then electro-

polished, followed by anodizing in a water solution

of HF and H

3

BO

3

(30mlHF+11gH

3

BO

3

+970mlH

2

O).

Electrolytic polishing voltage is 20~28V, about 1~3

min, and anodizing voltage is 15~25, about 1~2min.

TEM thin foils are prepared by twin-jet polishing

with an electrolyte solution composed of 30%HNO

3

and 70%CH

3

OH(volume fraction) at the temperature

below -25°C. The foils are examined using

HITACHI-800 and TECNAI G220 transmission

electron microscope at an accelerating voltage of

200kV. Tensile specimens are cut along the rolling

direction of the plates and tested on a MTS-858

tensile testing machine according to GB/T 228-2002

standard.

Table 1: Chemical composition of the studied alloys.

Specimen

No.

Chemical composition

(mass fraction, %)

Al Mg Mn Sc Zr

A Bal. 5.8 0.4 0.25

B Bal. 5.8 0.4 0.25 0.1

3 RESULTS

3.1 Effect of Minor Zr on the Tensile

Properties of Al-Mg-Mn-Sc Alloys

Table 2: Tensile properties of two studied alloys

Heat treatments

σb , MPa

A B

130℃/1h 396 472

340℃/1h 336 395

Heat treatments

σ0.2 , MPa

A B

130℃/1h 304 406

340℃/1h 191 268

Heat treatments

δ,%

A B

130℃/1h 11.4 9.7

340℃/1h 15.5 16.5

Table2 lists tensile properties of the 2 alloys

annealed at 130 °C or 340°C for 1h. It is clear that

co-addition of small amounts of Sc and Zr can have

higher tensile strength(σ

b

) and higher yield

strength(σ

0.2

) than that of adding single Sc. Under

the condition that ductility(δ) is similar, tensile

strength increases by nearly 20%, and the yield

strength increases by more than 30%. It can also be

seen in the table 2 that two kinds of alloy

mechanical properties and annealing system have

close relations. In order to maintain higher ductility,

340℃/1h annealing system is a better choice. The

experimental results show that Zr plays a great role

in improving the mechanical properties of Al-Mg-

Mn-Sc alloy.

3.2 Effects of Trace Zr on the Optical

Microstructure

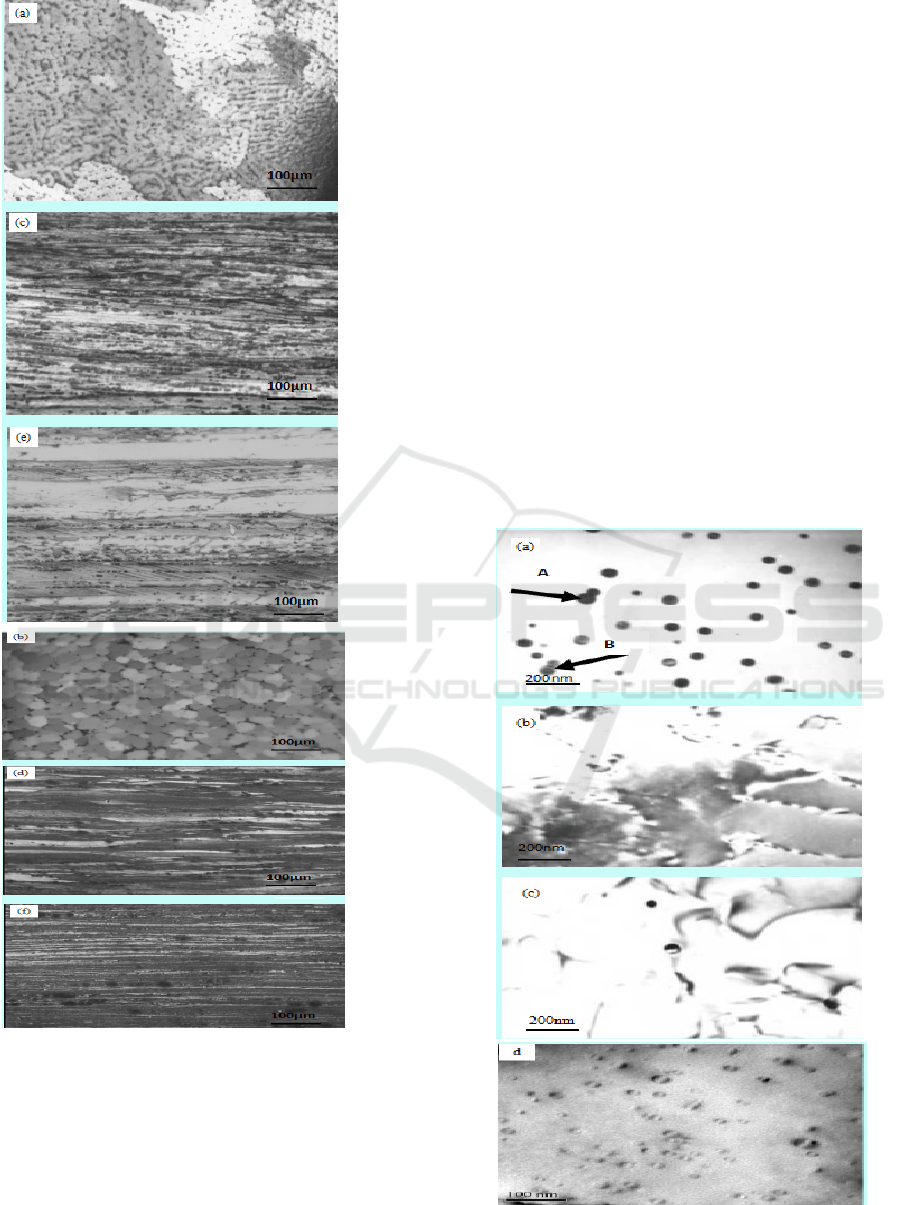

Figure1 illustrates the optical microstructures of the

2 alloys in different states. It is shown that in 2

alloys dendritic structures haven’t been

found(Figure.1a, b). These observations indicate that

addition of 0.2%Sc alone, or co-addition of 0.25%Sc

and 0.1%Zr into the Al-Mg-Mn alloys could bring

about an inoculation effect of the cast

Figure 1: Optical microstructures of the two studied

alloys(a)as-cast organization of alloy A; (b) as-cast

organization of alloy B; (C) hot-rolled organization of

alloy A; (d) hot-rolled organization of alloy B; (e)

annealing organization of alloy A at 340℃/1h; (f)

annealing organization of alloy B at 340℃/1h.

Alloys, thus eliminating the dendritic structure in

them, whereas the grain size in alloy A is above

100μm, in alloy B only 20μm about. So the grain

refinement effect of 0.25%Sc is not obvious, but

trace Zr in Al-Mg-Mn-Sc alloy grain refinement has

a huge role.

Microstructures of the hot rolled alloys are

shown in Figure.1c-d, and Figure.1e-f is that of the

stabilizing annealing processing alloy at 340℃ for

1h. Under these state the 2 alloys possess a fibrous

structure along the rolling direction, never respond

in recrystallization phenomenon. Due to the grain

size in as-cast alloy B is much smaller than that in

alloy A. Therefore, the fibrous structure in alloy B is

much more delicate than that in alloy A. Dense

fibrous structure tensile strength and yield strength

will be higher, which is consistent with the above

the tensile properties. So trace Zr can improve the

organization form of alloy.

3.3 TEM Observation of the Two Studied

Alloys

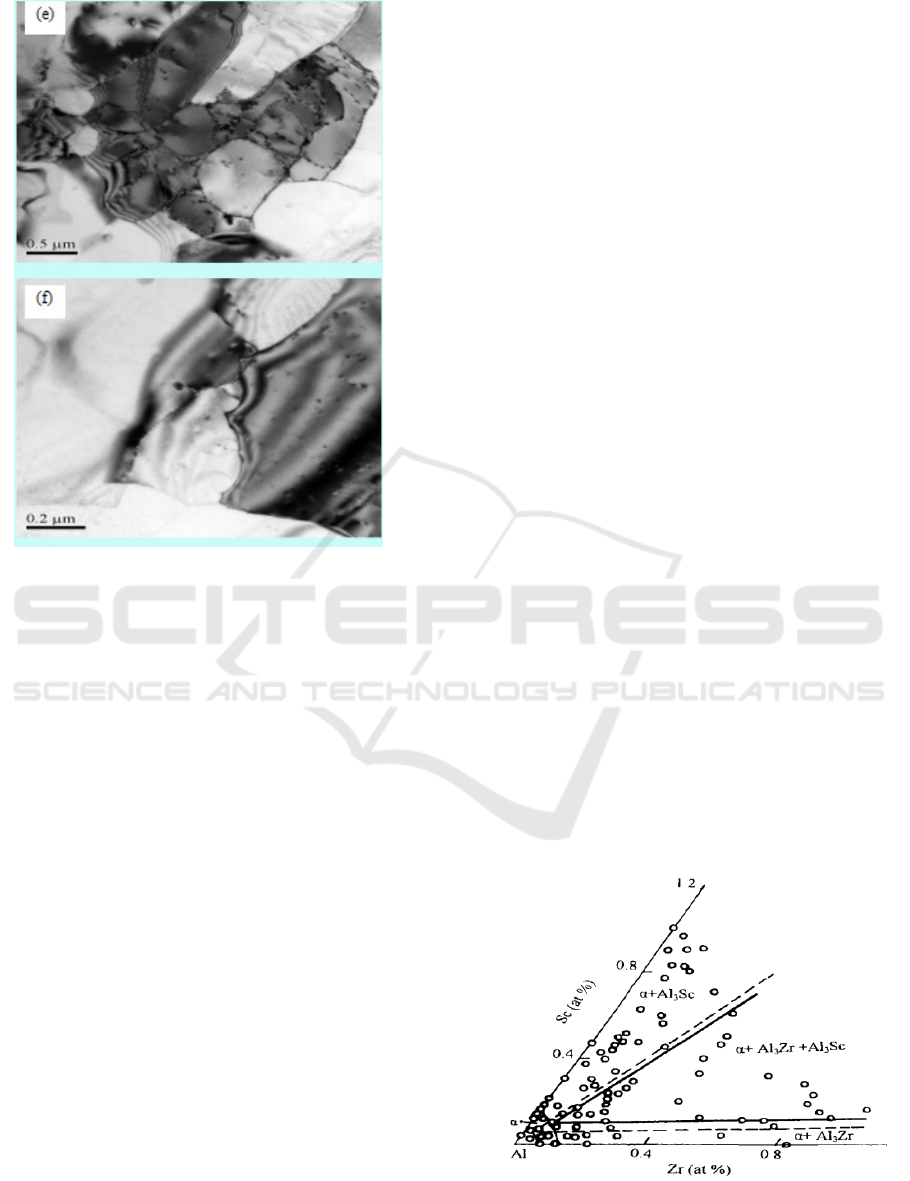

Figure 2: TEM micrographs of 340℃/1h annealed

alloys(a)The fine, spherical and dispersive secondary

Al

3

Sc particles in alloy A; (b-c) The secondary Al

3

Sc

particles pinning up dislocations and subgrain boundaries

in alloy A; (d) The fine, spherical and dispersive

secondary Al

3

(Sc,Zr) particles in alloy B; (e-f) The

secondary Al

3

(Sc,Zr) particles pinning up dislocations and

subgrain boundaries in alloy A.

Figure 2 shows the TEM microstructures of two

alloys, A and B, both annealed at 340°C for 1h. It is

seen that a large fraction of fine and dispersive

particles have precipitated within grains in these

alloy. These particles are Al3Sc(Fig2.a) in Al-Mg-

Mn-Sc alloy, and Al3(Sc,Zr)(Fig2.d)in Al-Mg-Mn-

Sc-Zr alloy, and they tightly pin up the dislocations

and subgrain boundaries(Figure2.b,c,e,f), and

stabilize the substructure in deformation process.

The gathering and coarsening phenomenon of Al3Sc

particles is observed in fig2.a; as indicated by the

arrows A and B, some particles have intersected and

integrated. Based on the comparison of secondary

phase particles in two kinds of alloys, it could be

found that after adding Zr, the particle size of

Al

3

(Sc,Zr) is smaller than Al

3

Sc, Al

3

(Sc,Zr) particles

are more of dispersion and uniform, and the number

was larger. Thus the role of pinning dislocation and

stabilizing substructure is more intense. In alloy B

the intersected and integrated phenomenon of

Al

3

(Sc,Zr) particles cannot’ be found, and the

substructure also haven’t grown up with smaller size

and a larger number of them. Therefore, Zr in Al-

Mg-Mn-Sc alloy can enhance the effect of

precipitation of second phase particles, retarding the

growth and merging of the secondary particle and

substructure more strongly.

4 DISCUSSION

4.1 Role of Zr in Refining the Grain

Structure of As-cast Alloy

Aluminum alloy as-cast grain size is determined by

the nature of the material itself, the cooling rate and

undercooling degree in the process of solidification,

heterogeneous nucleation core, and so on. Under the

same circumstance, the melt provides more

heterogeneous nucleation core with the grain of

smaller size. According to above experimental

results, compared with Al-5.8Mg-0.4Mn alloy[7],

the as-cast microstructure can’t reach the refinement

effect significantly after adding 0.25%Sc, and the

grain size is above 100μm. This illustrates that the

number of heterogeneous nucleation core in the

process of solidification doesn't get substantial

improvement. Analyzing the phase diagram of Al-

Sc[12] alloy can know that the equilibrium solubility

of Sc is 0.32%. When Sc content is less than 0.25%,

the primary Al

3

Sc particles formed in the

solidification process is not too much, so the

refinement effect to grain is not significant. And

most of Sc in the alloy is more inclined to form a

non-equilibrium supersaturated solid solution which

is unstable and is easy to precipitate in later

processing.

Figure 3: the phase diagram of Al-Sc-Zr at 600℃ and

550℃.

Figure 3[13] is Al-Sc-Zr isothermal phase

diagram of rich aluminum angle at 600℃(solid line)

and 550℃(dotted line). At 600℃ the solubility of Sc

and Zr are 0.09% and 0.06% respectively; at 550℃

are 0.06% and 0.03% respectively. Therefore, Zr on

the one hand, greatly reduces the Sc equilibrium

solubility in Al; on the other hand, it also as a

replacement atom replaces the positions of Sc atom

in Al3Sc. This makes Al

3

Sc particles change into

Al

3

(Sc,Zr) particles, and let Sc atoms have more

chance to form more secondary particle, which gives

the melt to provides a much larger number of

heterogeneous nucleation core, thus refining grain

size significantly. Dependent on the experimental

result, by adding 0.1%Zr in Al-5.8Mg-0.4Mn-

0.25Sc alloy, the grain size reduces from 100μm to

20μm, and the effect is very good.

4.2 Role of Zr to Improve the Mechanical

Properties

From the above analysis, Zr can reduce the

equilibrium solubility of Sc in Al, and can also

improve the degree of supersaturation of the original

solid solution. The increase in degree of

supersaturation makes more and more diffuse

secondary phase Al

3

(Sc,Zr) particles precipitate in

the process of deformation processing and heat

treatment, making pin dislocation, boundary and

sub-structure more intense, so that the strength of the

alloy and recrystallization temperature have greatly

improved.

Zr will also reduce the coarsening rate of

secondary Al

3

(Sc,Zr) particles. Al

3

Sc particles under

the action of heat have tended to gather, grow up and

dissolve back in matrix. Once the Al3Sc particles

grow up, they will lose the coherence with Al matrix,

and also let the distance between the particles

increase, thus losing the role to pin dislocation and

sub-structure, which reduces the mechanical

properties of these alloys. Ye Yicong[14] had

studied the precipitation and coarsening of

secondary Al

3

Sc phase in Al-0.4Sc alloy and found

when aging temperature was greater than 400℃

Al

3

Sc particles grew up quickly, and at 500℃ aging

four hours, these particles had lost coherent

relationship(If particle radius is larger than 20nm, it

will lose coherent relationship). Christian B.

Fuller[15] did the creep experiment at 300℃ for

above one week, and found the Al

3

(Sc,Zr) particles

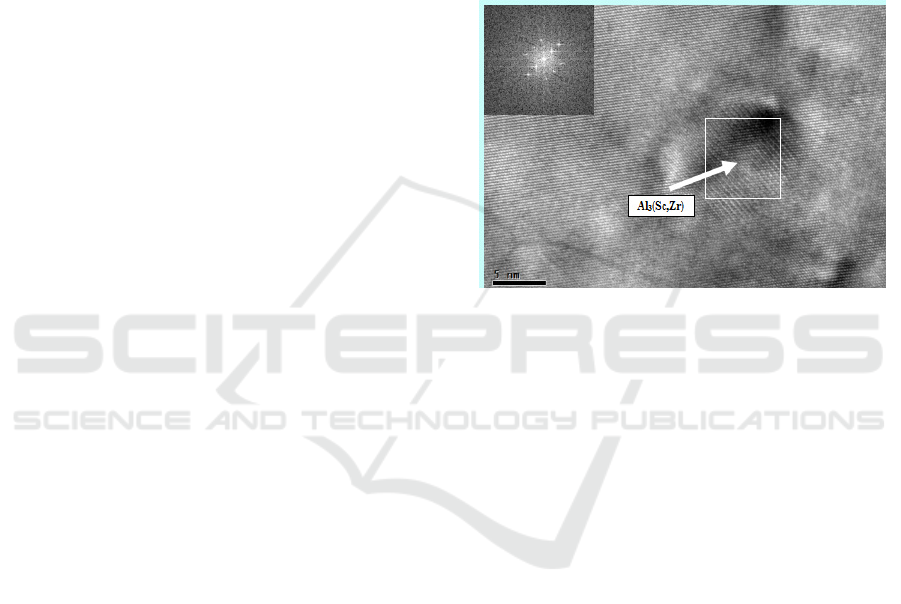

without apparent coarsening. Figure 4 was

HRTEM(high-resolution electron microscopies)

image of Al

3

(Sc,Zr) precipitates. The preparation of

TEM sample was to use cold-rolled sheet of Al-

5.8Mg-0.4Mn-0.25Sc-0.1Zr alloy to anneal at 550

C for 40h. In the left top corner it was FFT

transformation of white box field in the image. It

illustrates that Al

3

(Sc,Zr) particles haven’t grown up

and are still less than 10 nm in good coherent

relationship with matrix. When 50%Sc atoms in

Al

3

Sc is replaced by Zr atoms, Al

3

Sc phase changes

into Al

3

(Sc

0.5

Zr

0.5

) phase which has the smallest

aggregation bias[11]. The secondary Al

3

(Sc,Zr)

particles have good thermal stability and always

maintain good coherent relationship with matrix, so

strengthening effect is significant.

Fig.4 HRTEM image of Al3(Sc,Zr) precipitates.

5 CONCLUSIONS

(1) Adding 0.1%Zr in Al-5.8Mg-0.4Mn-0.25Sc

alloy can refine the as-cast microstructure

significantly, and the grain size reduces from 100μm

to about 20μm. This is mainly due to the reason that

after adding Zr it can precipitate more primary

Al

3

(Sc,Zr) particles in the casting process, and can

provide more heterogeneous core so as to form more

grains.

(2) The comprehensive mechanical properties

can be improved when 0.1%Zr is added into Al-

5.8Mg-0.4Mn-0.25Sc alloy. Tensile strength(σ

b

) can

be improved by about 20%; the yield strength(σ

0.2

)

can be increased by 30%, and maintain good

elongation. The reasons are that in stabilizing

annealing process more diffuse secondary Al

3

(Sc,Zr)

particles precipitate and the quantity is larger, and

that their thermal stability is better than Al

3

Sc

particles. So the role to pin the dislocation and sub-

structure is more intense, and strengthening effect is

better.

ACKNOWLEDEMENTS

This project was supported by the post doctoral

foundation of Central South University(126226),

the national key basic research development

plan(2012CB619503),the Guangdong Province

Science and technology (2012B011000038) and

the Zhaoqing city science and technology

plan(2013C011).

REFERENCES

1. YIN Zhi-min, ZHU Da- peng , JIANG Feng.

Recrystallization of Al-Mg-Mn and Al-Mg-Mn-Sc-Zr

Alloys[J]. Journal of Materials Engineering,

2004,(6):3-6.

2. WANG Xudong, LIN Shuangping, YANG Junjun,etal.

Microstructure and mechanical properties of Al-Mg-

Mn alloy with erbium[J]. RARE METALS, 2012,

31(3):237-243.

3. Bi-Yu Tang, Dong-Lin Li, Ping Chen, etal. The

thermal properties of Al–Mg–TM (TM¼Sc, Zr):Ab

initiostudy[J]. Solid State Sciences, 2010, (10):845-

850.

4. G.R. Argade, N. Kumar, R.S. Mishra. Stress corrosion

cracking susceptibility of ultrafine grained Al–Mg–Sc

alloy[J]. Materials Science & Engineering A,

2013,565:80-89.

5. HE Zhen-bo, PENG Yong-yi, YIN Zhi-min, etal.

Comparison of FSW and TIG welded joints in Al-Mg-

Mn-Sc-Zr alloy plates[J]. Transactions of Nonferrous

Metals Society of China,. 2011, (21): 1685-1691.

6. Ying WANG, Qing-lin PAN, Yan-fang SONG, etal.

Recrystallization of Al-5.8Mg-Mn-Sc-Zr alloy[J].

Transactions of Nonferrous Metals Society of China,,

2013, 23(11):3235-3241.

7. CHEN Xianming, PAN Qinglin, LUO Chengping, etal.

Effects of micro-alloying with Sc and Ti on the

microstructure and mechanical property of Al-Mg

based alloys[J]. Chinese Journal of Materials Research,

2005, 19(4):419-425.

8. YANG Fubao, LIU Enke, XU Jun, etal. Effects of Er

on the microstructure and mechanical properties of as-

cast Al-Mg-Mn-Zn-Sc-Zr(Ti) filler metals[J]. Acta

Metallurgica Sinica, 2008, 44(8):911-916.

9. Yang Dongxia, Li X Y, He D Y, etal. Microstructure

and Microhardness of Laser Beam Welded Al-Mg-

Mn-Zr-Er Joint[J]. Rare Metal Materials and

Engineering, 2011,40(4):111-114.

10. LIN Shuang-ping,NIE Zuo-ren,HUANG Hui,etal.

Thermodynamic calculation of Er-X and Al-Er-X

compounds existing in Al-Mg-Mn-Zr-Er alloy[J].

Trans. Nonferrous Met. Soc., 2010, (4):682-687.

11. Y. Harada, D.C. Dunand. Thermal expansion of Al3Sc

and Al3(Sc0.75X0.25)[J]. Scripta Materialia,

2003,48:219-222.

12. K. A. Gschneidner Jr., F. W. Calderwood. The Al-

Sc(Aluminum-Scandium) system[J].

Bulletin of Alloy Phase Diagrams, 1989, 10(1):34-36.

13. ZENG Fan hao,XIA Changqing, GU Yi. An

assessment of Al-Mg-Sc-Zr system in aluminum-rich

region[J]. Materials Review, 2002, 16(6):16-19.

14. Ye Yicong, Li Peijie, He Liangju, etal. Precipitation

and coarsening behavior of secondary Al3Sc phase in

Al-Sc binary alloy[J]. Special Casting & Nonferrous

Alloys, 2012,32(3):197-202.

15. Christian B. Fuller, David N. Seidman, David C.

Dunand.Mechanical properties of Al(Sc,Zr) alloys at

ambient and elevated temperatures[J],Acta

Materialia,2003,51:4803-4814.