Study on Frictional Properties of Micro-texture Obtained by

Ultrasonic Elliptical Vibration Cutting

Guowen Peng

1

,Dong Lu

1,2*

, Mingming Yang

3

and Jiang Zeng

1

1

College of Aeronautical Manufacturing Engineering,Nanchang Hangkong University, Nanchang, 330063, JIangxi, China;

2

Department of Mechanical and Energy Engineering, Southern University of Science and Technology, Shenzhen, 518055,

Guangzhou, China

3

COMAC Shanghai Aircraft Design and Research Institute, Shanghai, China

Keywords: Micro-texture; Ultrasonic vibration;Friction; Feed rate; Cutting speed; Spindle speed;

Abstract: Because the influence of cutting parameters on the performance of ultrasonic micro texture of radial sliding

bearing hydrodynamic lubrication is significant, this paper is concerned with the study of elliptic ultrasonic

vibration cutting on

mm30φ

AL6061 bar by single factor experiment. The cutting speed, feed rate, and

ultrasonic vibration direction are all taken into account, and co rotating friction wear experimental device is

employed to measure the hydrodynamic lubrication friction test at different spindle speeds. The results show

that the friction coefficient of the texture surface decreases significantly compared with the non textured

surface, and the maximum value decreases by 34.4%. Moreover, it turns out that the increase of feed rate

leads to the decrease of the friction coefficient. The final observation is that the friction coefficient will also

decrease with the increase of spindle speed.

1 INTRODUCTION

Due to the advantages of aluminum alloy, such as

easy processing, small density, high strength and

excellent conductivity, it can be found that this metal

has been widely used in many industrial fields,

including Life, Military, Capital Construction,

Aeronautics and Astronautics, Ship Engineering ,etc.

And how to improve its service life has become a

hot research topic in recent years. According to the

study, it is found that the surface texture is effective

in reducing friction and damage[1].

Because of the friction and wear characteristics

of micro texture, micro weaving has been regarded

asa current hot research direction. In the traditional

tribology theory, the friction coefficient is closely

correlated with the surface roughness, that is, the

friction between the smooth surface and the concave

convex surface will be smaller, so it will be more

wearable. However, in recent years, a large number

of research results showed that the formation of a

micro-morphology on the surface could improve the

wear resistance[2].Li Weiguang and others

implemented a micro-textured hard alloy to conduct

bi-rubbing tests on birch. Experiments have shown

that the micro-textured hard alloy has a smaller

friction coefficient, which is more than 50% smaller

than that without micro-texture[3] . Hua Xijun et al.

carried out a greasing and filling lubrication

experiment on the GCr15 sample. The results

showed that under dry friction, the friction

coefficient of the textured surface decreases by

47.6% over the untextured surface, decreases by

4.8% under oil lubrication, and decreases by 17.7%

under the lubrication of the filler [4].

Ultrasonic Elliptical Vibration assisted

Machining (abbreviated as UEVM) can also change

the distribution and size of pits by changing the

amount of cutting tool eaten, feed rate, cutting

speed, and ultrasonic amplitude. Therefore, different

surface textures can be processed[5].

2 EXPERIMENTAL

EQUIPMENT AND TEST

PROCEDURES

2.1 Experimental Equipment

The experimental material used was a

35

φ

*40mm

AL6061. The selection of experimental equipment is

shown in Fig. 1, in which the ultrasonic vibration

device is selected from the Japanese Yuejiang

company UL40-Al, which consists of an ultrasonic

generator, a transducer, and a horn. a carbide insert

can be mounted on the horn, which is produced from

Japan Mitsubishi. Rakeangle is 0°, Clearance angle

is 11°, Corner radius is 0.4mm.And Kistler three-

way dynamic dynamometer and Type5070 charge

amplifier and Type5697 data collector. The choice

of machine tool is CKA6150.

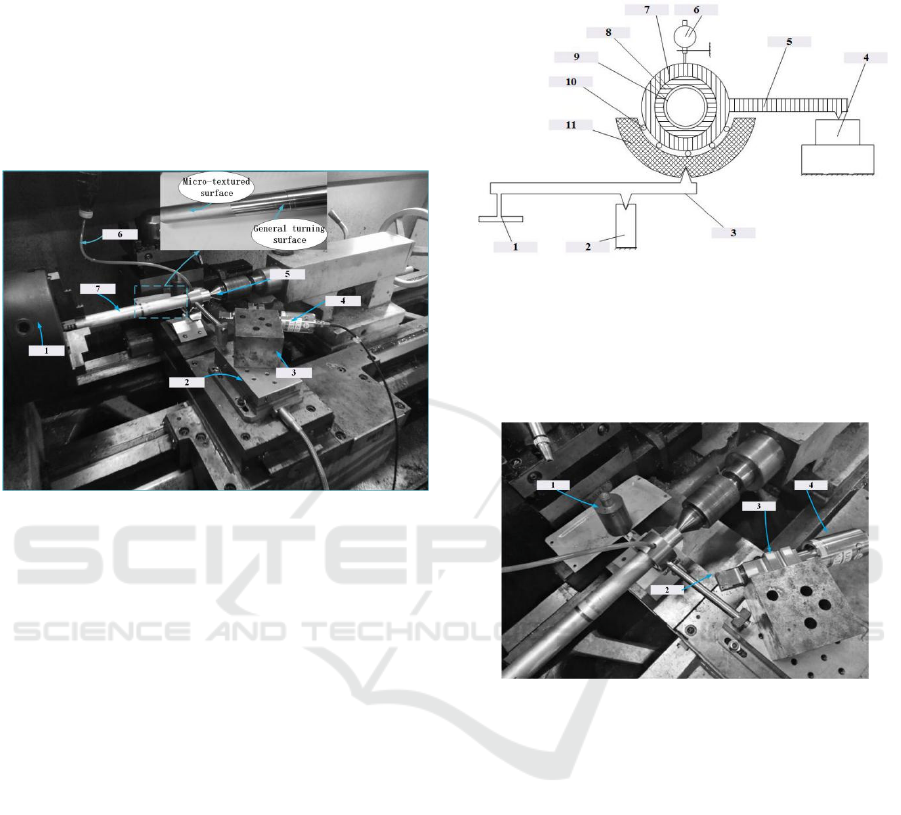

1-Chuck2-Dynamometer3-Tool holder4-Transducer5-

Core clamper6-Tubing7-Sample

Fig.1:Experimental installation diagram.

2.2 Surface Micro-texture Prepared by

UEVM

First, we drill the center hole at both ends of the

AL6061 bar of

35

φ

*40mm, then use the claw of the

three jaw chuck to fix the end. The other end of the

tail seat top is tightly attached to the AL6061 bar, so

that when the hand claw the claw, the top will run

smoothly. Then the 2mm is cutting depthof trial

cutting, the purpose of it is to reduce the impact on

the experimental results because of the difference of

the original surface finish. Then the carbide blade is

fixed on the horn, which is shown in Figure 3 after

the installation is accomplished. Next, the ultrasonic

device is connected and the ultrasonic is also

connected. It is appropriate to put the tweezers on

the blade slightly with a clamped sound, and then

turn off the ultrasonic. The ultrasonic switch is

opened again, and the cycle starts. Experimental

parameters are shown in Table 1.

2.3 Friction and Wear Experiment

A self-made friction and wear device was used to

study the friction force in the oil rich condition at

different spindle speeds. The friction and wear

device is made up of a shaft, an axle bush and a

lengthening rod. As shown in Fig. 2 and Fig. 3.

1-Dial gauge2-Leverage pivot3-lever4-Dynamometer5-

Measuring rod6-Dial gauge7-Bearing sleeve8-Bush9-

Sample10-Roller11-Support base

Fig.2:Structural analysis diagram.

1-Weight2-Carbide blade(TPGX080204)3-Horn4-

Ultrasound generator

Fig. 3:Physical map.

The installation steps of the friction and wear

device are described as follows:

1). Put the axle bush in the axle bush fixed

sleeve, fasten with the tightening screw, and connect

the force rod with the axle bush at the same time.

2). After the rear seat moves, the axle bush and

the bearing bush is placed on the surface of the

micro texture, and the tail seat is moved forward to

the fixed specimen.

3). The loading device is placed, and the

modulation load is perpendicular to the positive

center of the sample.

4). The roller with the support is installed in the

support seat, and then the whole is placed under the

axle bush fixed sleeve to connect with the load.

5). Put the weight of the weight, access the

lubricating oil pipe, start the test.

During the test, the sample is clamped on the

machine to limit the freedom of space movement

and follow the rotation of the spindle of the machine

tool. A friction pair is formed between the sample

and the inner surface of the bearing shell. After the

sample rotates, it drives the lubricating oil into the

friction pair to generate a fluid dynamic pressure oil

film. The oil film shear friction force is transmitted

to the dynamometer through the bearing sleeve-

measuring rod. According to the magnitude of the

force, the friction force of the oil film formed

between the sample and the inner surface of the

bearing bush under a certain spindle speed and load

can be calculated and passed through the μ = F/P

calculates the friction coefficient μ value. Due to the

formation of dynamic pressure oil film, the bearing

bush is offset downwards relative to the fixed

specimen. The dial gauge contacted with the bushing

fixing sleeve shows the offset value of the bearing

bush. The offset is proportional to the thickness of

the oil film.

2.4 Experimental Processing

Parameters

In this paper, the single factor experimental analysis

of AL6061 is performed using UEVM. The AL6061

bar material with a diameter of 30 mm was selected

as the experimental sample. The effect of feed rate

and cutting speed on the micro-texture surface

prepared by UEVM was analyzed. The

hydrodynamic lubrication friction under the self-

made co-rotating friction and wear device was

analyzed.

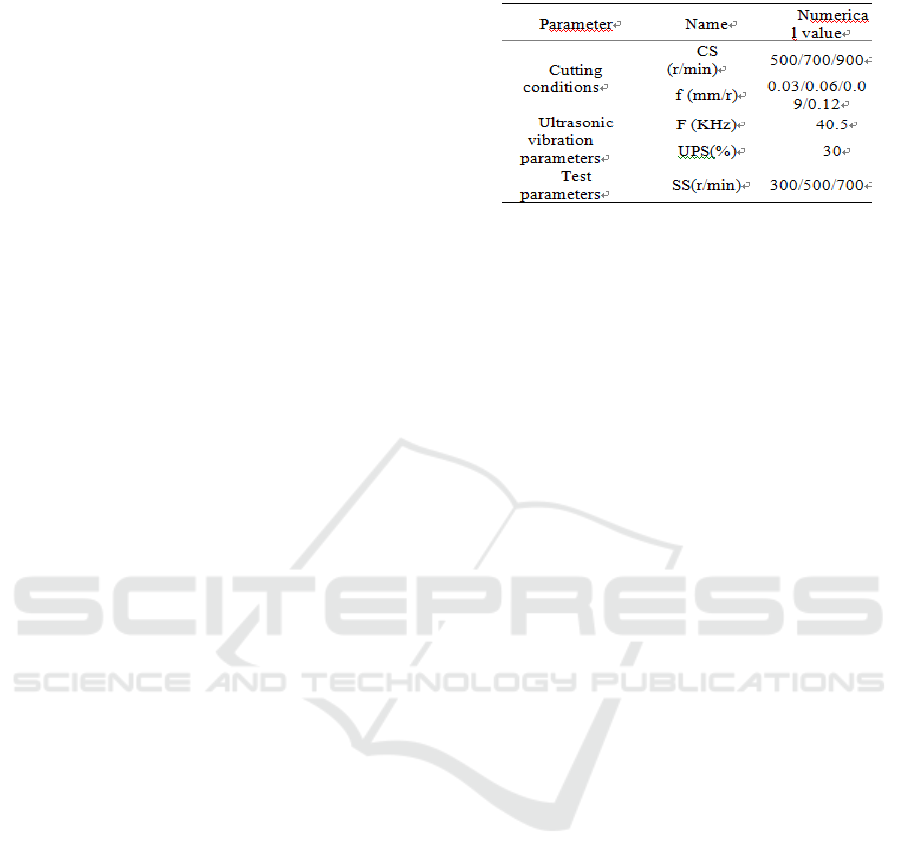

Set the cutting speed to CS and the spindle speed

to SS. the feed rate to f, the frequency to F, and the

ultrasonic voltage power supply to the UPS.

In order to study the variation of the friction of

the UEVM micromachined AL6061 under different

cutting speeds and feed rates, the machining

parameters shown in Table 1 were developed.

Table 1 Experimental processing parameters.

2.5 Purpose

The purpose of this experiment is to investigate how

micro-textures reduce friction and wear when the

workpiece is running, thereby increasing the life of

the workpiece. Ultrasonic parameters and cutting

parameters were used to form different micro-

textures on the surface of the AL6061 rod material.

The frictional performance of the hydrodynamic

lubrication of radial plain bearings was measured at

different spindle speeds using a self-made friction

and wear device. That is, the influence of ultrasonic

parameters and cutting parameters on the

hydrodynamic lubrication friction of the workpiece

when the workpiece is actually loaded is

investigated.

3 .EXPERIMENTAL RESULTS

AND ANALYSIS

3.1 The Effect of Micro-texture on The

Surface of UEVM on The Friction

Coefficient of AL6061

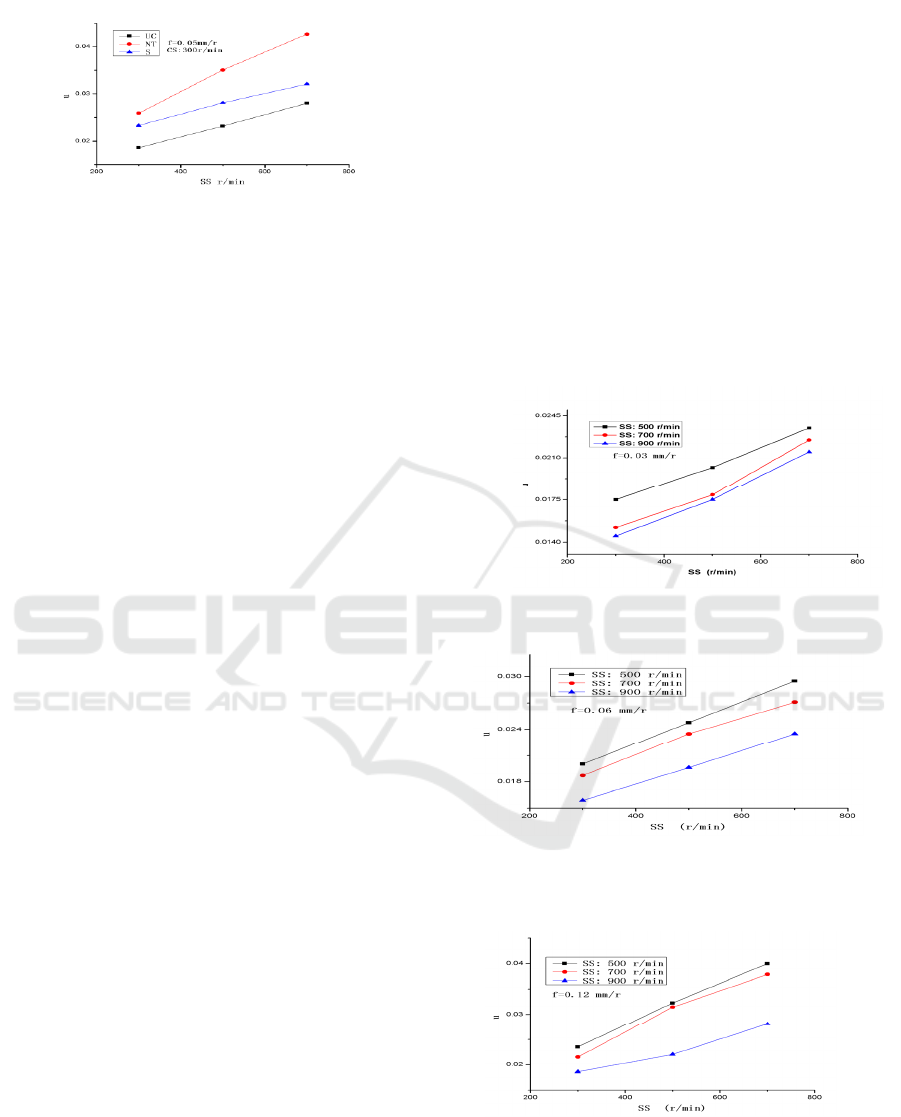

In order to explore the effect of UEVM on the

surface micro-texture of AL6061, the AL6061

experimental specimens were each subjected to

UEVM cutting and general turning with a feed rate

of f=0.05 mm/r and a cutting speed of 300 r/min.

The smooth surface of the length. Therefore, there

are 3 experimental patterns with a length of 50 mm.

And the use of self-made rotating friction wear test

equipment to measure its hydrodynamic friction

lubrication friction.The obtained experimental data

can be processed Fig.4 can be obtained. Suppose

normal turning is NT, ultrasonic cutting is UC, and

smooth (not cutting) is S.The friction coefficient is u.

Fig.4: Comparison of the friction coefficient between

ultrasonically processed micro-texture, ordinary turning

and smooth.

It can be seen from Fig. 4 that the friction

coefficient of ordinary turning compared to smooth

surface has increased, because the surface of

ordinary turning is constantly in contact with the

workpiece, which leads to cutting heat and large and

continuous Factors such as swarf that affect its

surface roughness have a large influence, so the

coefficient of friction will increase.

In Fig. 4, it can be seen that the micro-textured

surface of the UEVM surface has a lower coefficient

of friction than the smooth surface. According to the

understanding of the conventional friction force, the

smoother the surface, the smaller the friction force

should be, but the experimental phenomenon is not

the case. This may be due to micro-texture, under

the lubrication of the oil, the pit surface may form a

small dynamic pressure lubrication effect, while the

role of oil storage and minor impurities, greatly

avoiding the workpiece and The direct contact of the

components reduces the effect of the furrows[6].

With the gradual increase of the spindle speed,

the change of the friction coefficient after

microtexture on the surface of the UEVM is more

gentle, which shows that the surface microtexture

has a better friction reduction effect than the

untextured surface at high speed! And up to a drop

of 34.4%.

3.2 The Influence of The Change of

CuttingSpeed on The Surface

Friction Force

In order to study the influence ofcuttingspeed on the

surface friction coefficient of UEVM

microfabricated AL6061 micro-fabric, we used them

at the feed rate of 0.03mm/r, 0.06mm/r, 0.09mm/r,

and 0.12mm/r. When 500r/min, 700r/min, and

900r/min cutting speeds are used to machine 3

segments with a length of 50mm, a 12-segment

cutting experiment pattern can be obtained. And the

use of self-made rotating friction wear test

equipment to measure its hydrodynamic friction

lubrication friction. After data processing, the

friction coefficient changes of different cutting

speeds of Fig.5.1. Fig 5.2. Fig.5.3 and Fig.5.4 are

obtained.

It can be seen from Figure 5.1 that the friction

coefficient increases with the increase of the spindle

speed, and the rate of change of the friction

coefficient under differentcutting speed cutting

conditions is very small. This may be due to the fact

that the micro-differential micro-texture has little

effect on the liquid flow rate, and the rate of change

will be basically the same. With the increase of the

cutting speed, the friction coefficient decreases

significantly, that is, high-speed cutting helps to

improve the friction coefficient of the workpiece

surface.

Fig.5.1: Effectof CS on Micro-texture Friction Coefficient

at feed rate 0.03mm/r.

Fig.5.2:Effect of CS on Micro-texture Friction Coefficient

at feed rate 0.06mm/r.

Fig.5.3:Effect of CS on Micro-texture Friction Coefficient

at feed rate 0.09mm/r.

Fig. 5.4:Effect of CS on Micro-texture Friction

Coefficient at feed rate 0.12mm/r.

3.3 Effect of Feed Rate on The Friction

Coefficient of Micro-texture on

UEVM Surface

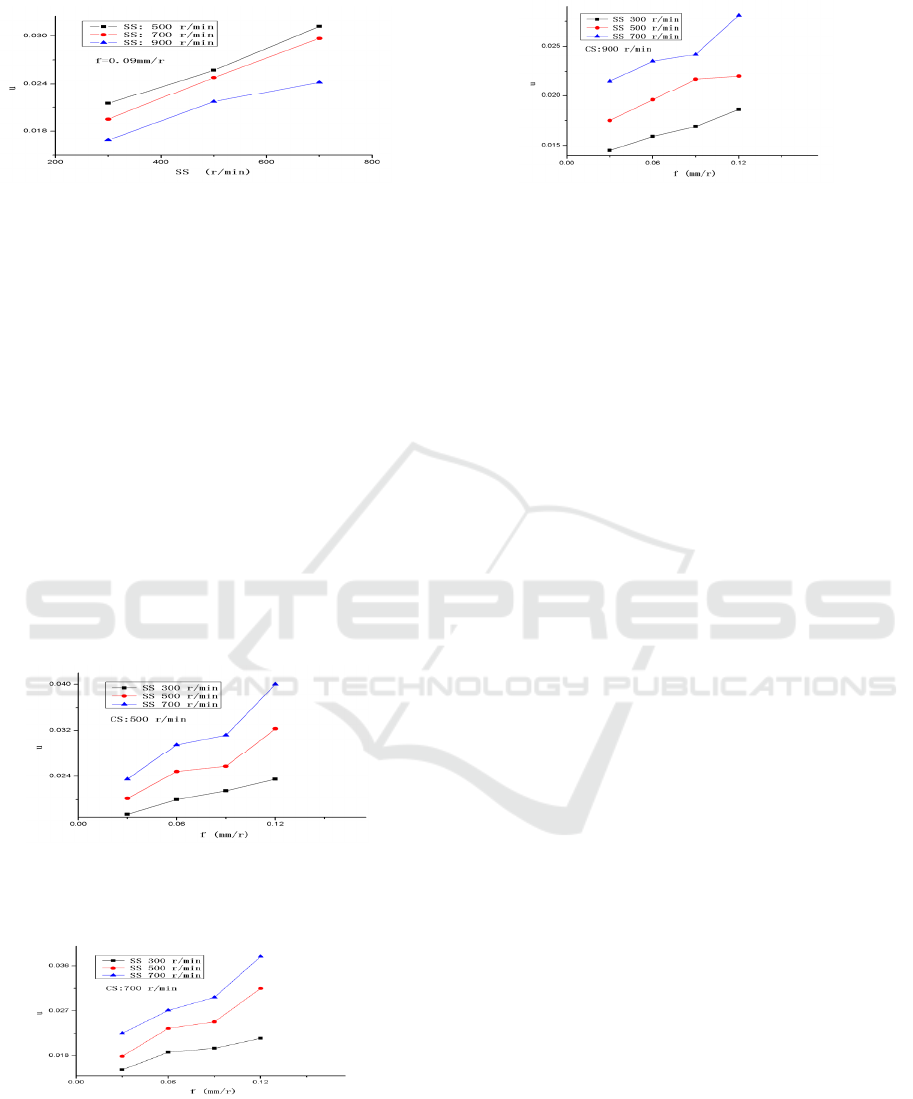

In order to study the influence of the feed rate on the

friction coefficient of the surface micro-texture, the

cutting speed was 500 r/min at feed rates of 0.03

mm/r, 0.06 mm/r, 0.09 mm/r, and 0.12 mm/r,

respectively, 700r/min, 900r/min and other

conditions using UEVM to process three different

cutting speeds and cutting length of 50mm, you can

obtain a 12-segment cutting experiment. And use the

self-made friction and wear test device to measure

its hydrodynamic lubrication friction. After

processing the data, figures 6.1, 6.2, and 6.3 are

available.

Fig.6.1:Effect of feed rate on the friction coefficient of

micro-weave at CS of 500r/min.

Fig.6.2:Effect of feed rate on the friction coefficient of

micro-weave at CS of 700r/min.

Fig.6.3:Effect of feed rate on the frictioncoefficient of

micro-weave at CS of 900r/min.

From Fig.6.1,it turns out that as the feed rate

increases, the friction coefficient on the surface of

the AL6061 increases. And at different

spindlespeeds, the friction coefficient also showed

an upward trend, because with the increase offeed

rate, under the action of UEVM, its effective cutting

part decreased significantly, that is, the surface

friction coefficient increased.

It can be seen in the comparison of Figures 6.2

and 6.3 that the friction coefficient increases with

the increase of the feed rate under different cutting

speed cutting action, and the friction coefficient also

increases gradually during the increase of the spindle

speed.

4 CONCLUSIONS

In this paper, the experimental study of AL6061

Normal Turning (NT), Ultrasonic Vibration Assisted

Turning (UVAT), feed rate, and cutting speed on the

surface micro-texture friction coefficient was carried

out. After summarizing and analyzing, we obtained:

1. Under the precondition of cutting speed of

300r/min and feed rate of 0.05mm/s, the surface

friction coefficient of AL6061 micro-textured on the

surface of UEVM is greatly reduced and can be

reduced by up to 34.4%.

2. The surface friction coefficient of AL6061

micro-textured by UEVM increases with the feed

rate.

3. The surface friction coefficient of AL6061

micro-textured by UEVM shows a decreasing trend

with the increase of cutting speed.

4. When the coefficient of friction is measured

under oil-rich lubrication, the friction coefficient

increases as the spindle feed increases.

5. Under high-speed lubrication, the surface

friction coefficient of AL6061 microtextured on the

surface of UEVM is better than that of the

untextured surface.

REFERENCES

1. Sung I H, Lee H S, Kim D E. Effect of surface

topography on the frictional behavior at the micro /

nano - scale [J]. Wear, 2003, 254: 1 019 - 1 031.

2. Long Shishan. Experimental study on dry-cutting

aluminum alloy with micro-textured carbide tool [D].

Xiangtan University, 2014

3. Li Weiguang, Zhang Zhankuan. Effect of Surface

Micro-textured Cemented Carbide on the Tribological

Characteristics of Birch[J]. Journal of Forestry

Engineers, 2018, 3(01):103-108.

4. Hua Xijun, Xie Xuan, Zhang Peixi, Sun Jianguo,

Wang Hao, Fu Yonghong. Tribological properties of

micro-textured self-lubricating surfaces in oil

media[J]. China Surface Engineering, 2017,

30(02):35- 40.

5. Dornfeld D, Min S, Takeuchi Y. Recent advances in

mechanical micromachining[J]. CIRP Annals-

Manufacturing Technology, 2006, 55(2): 745-768.

6. Wang X L, Kato K, Adachi K, et al. Loads carrying

capacitymap for the surface texture design of Si C

thrust bearing sliding inwater [J]. Tribology

International, 2003, 36: 189 - 197.