Research on Ultrasonic Vibration

R

olling of Aluminum Alloy

Xiangfu Zhong

1

, Dong Lu

1,2*

, Mingming Yang

3

and Jiang Zeng

1

1

. College of Aeronautical Manufacturing Engineering, Nanchang Hangkong University, Nanchang, 330063, Jiangxi,

China;

2.

Department of Mechanical and Energy Engineering, Southern University of Science and Technology, Shenzhen, 518055,

Guangzhou, China

3.

COMAC Shanghai Aircraft Design and Research Institute, Shanghai, China

Keywords: Aluminum alloy; Ultrasonic vibration rolling; Surface roughness; Surface microhardness

Abstract: Ultrasonic vibration rolling is the process of collision, extrusion and friction between the rolling head and

the workpiece surface, which causes the plastic deformation and plastic flow of the workpiece surface

material, which makes the convex peak of the material surface be filled with flattened valleys. Therefore,

the surface quality of the workpiece can be improved by a new processing method that is relatively

conventional. In order to study the effects of different cutting methods on the surface quality and surface

microhardness of aluminum alloys, ultrasonic vibration assisted rolling aluminum alloy technology was

introduced in this paper, and three groups of control experiments were designed, namely: aluminum alloy

ordinary cutting experiments, aluminum alloys ordinary rolling test and aluminum alloy ultrasonic vibration

assisted rolling test. The influence of cutting three factors on the surface roughness Ra and surface

microhardness of aluminum alloy was studied. The experimental results show that the surface quality and

surface microhardness of ordinary rolled aluminum alloy are better than that of ordinary cutting. Ultrasonic

vibration assisted rolling significantly improves the surface quality and microhardness of aluminum alloy

compared with ordinary cutting. Three cutting factors affecting the surface roughness of ultrasonic vibration

assisted rolling Aluminium alloys. Importance: The amount of cutting depth is greater than the cutting

speed, which is greater than the feed rate; the effect of three cutting factors on the microhardness of the

aluminum alloy surface. The amount of cutting depth greater than the feed speed is greater than the cutting

speed.

1 INTRODUCTION

Today, the national defense, aeronautics, and

astronautics industries have developed rapidly, and

the materials that have been applied to military

defense and aerospace have also been further

developed. A large number of conventional

materials such as aluminum alloys are gradually

being replaced by aerospace materials (such as

titanium alloys) and new composite materials with

superior overall performance. However, aluminum

alloys are the most widely used type of nonferrous

metal structural materials in the industry, and it is

still necessary to further study them, especially the

processing properties of aluminum alloys. As

customers place higher demands on the quality of

parts and components, the quality control of

aluminum alloy products becomes very important.

Rolling is a surface hardening process. After

rolling, the physical state of the workpiece changes,

but the chemical composition of the surface material

does not change. Rolling processing took place

decades ago. In 1929, Germany had already had the

idea of rolling processing[1]. Since then, U.S.

researchers have applied roll-rolling ingenuity to the

manufacture of railways. The exploration of this

technology is in the wake of the Soviet Union

following the Americans. Roller strengthening

technology is also used in railways[2]. Until the

1950s, China invented the screw rolling technology,

so that rolling technology has been widely explored

in China[3]. Due to the wide application prospect of

rolling technology, a large amount of manpower and

material resources have been invested, making the

rolling hardening technology develop rapidly. In the

rolling process research, foreign researcher Ryhzov.

E. V. found through experiments that the surface

roughness of steel workpieces can be reduced from

Rz3.2-6.4pm to RzO.4-0.2pm through the vibration

rolling process. Roughness is hardly affected by

wear scars[3]. Former Soviet Union Markovikov and

India's Pande et al. first introduced ultrasonic

vibration assisted processing technology into surface

hardening techniques such as surface rolling [4]. The

University of Nottingham, UK, performed ultrasonic

cold deep-rolling on TC4 titanium alloy workpieces.

The results showed that the surface roughness was

greatly reduced, the surface hardness increased by

25.8%, and the surface formed a residual

compressive stress of 800-1200 MPa[5]. Nowadays,

traditional rolling processing technology cannot

fully meet the development of today's science and

technology, and it needs to be combined with other

processing technologies on this basis. In recent

years, ultrasonic rolling technology has been widely

used in aerospace and other fields.

Ultrasound-assisted rolling has the following

advantages over traditional rolling processing:

(1) Little friction and little elastic pressure;

(2) The surface finish will be better if the

conditions of accuracy can be;

(3) The surface hardness is greatly increased,

thereby improving the surface wear resistance;

(4) Corrosion resistance and fatigue strength are

improved;

(5) The ultrasonic-assisted rolling trajectory is

easy to control, so that it can reduce the vibration

during processing.

In order to study how to reduce the surface

roughness value and improve the surface quality in

the process of aluminum alloy machining, the

ordinary cutting experiment, the ordinary rolling

experiment and the ultrasonic vibration assisted

rolling experiment were designed respectively, and

the excellence of the three processing methods was

compared. The effect of three factors of cutting on

the surface quality and surface microhardness of

aluminum alloy during the process of ultrasonic

vibration assisted rolling aluminum alloy bar

material was studied.

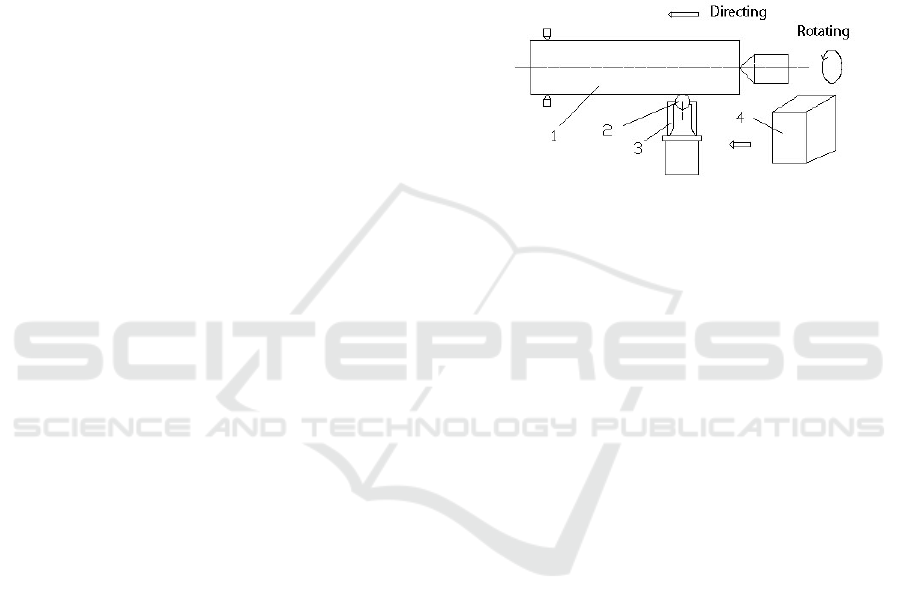

2 ULTRASONIC VIBRATION

ROLLING PRINCIPLE

Ultrasonic vibration rolling processing device

(1) Ultrasonic generator: It converts industrial

alternating current into ultrasonic frequency voltage

signal [6].

(2) Transducer: Converts high-frequency voltage

signals into high-frequency mechanical vibrations.

(3) Rolling heads: cylindrical rollers and

spherical balls are used.

(4) Horn: Amplify the amplitude of the

transducer. Classification: Ladder, Cone,

Cylindrical, Index, and Catenary.

Working principle: The ultrasonic generator

outputs ultrasonic frequency energy, the transducer

converts the ultrasonic frequency electric energy

into high-frequency mechanical vibration, and the

horn enlarges and transmits the amplitude to the

rolling head, so that the parts are subjected to

ultrasonic rolling processing.

1- Aluminium alloy bar stock 2- Rolling head 3- Horn 4-

Ultrasonic generator.

Fig. 1 Ultrasonic Vibration Rolling Device.

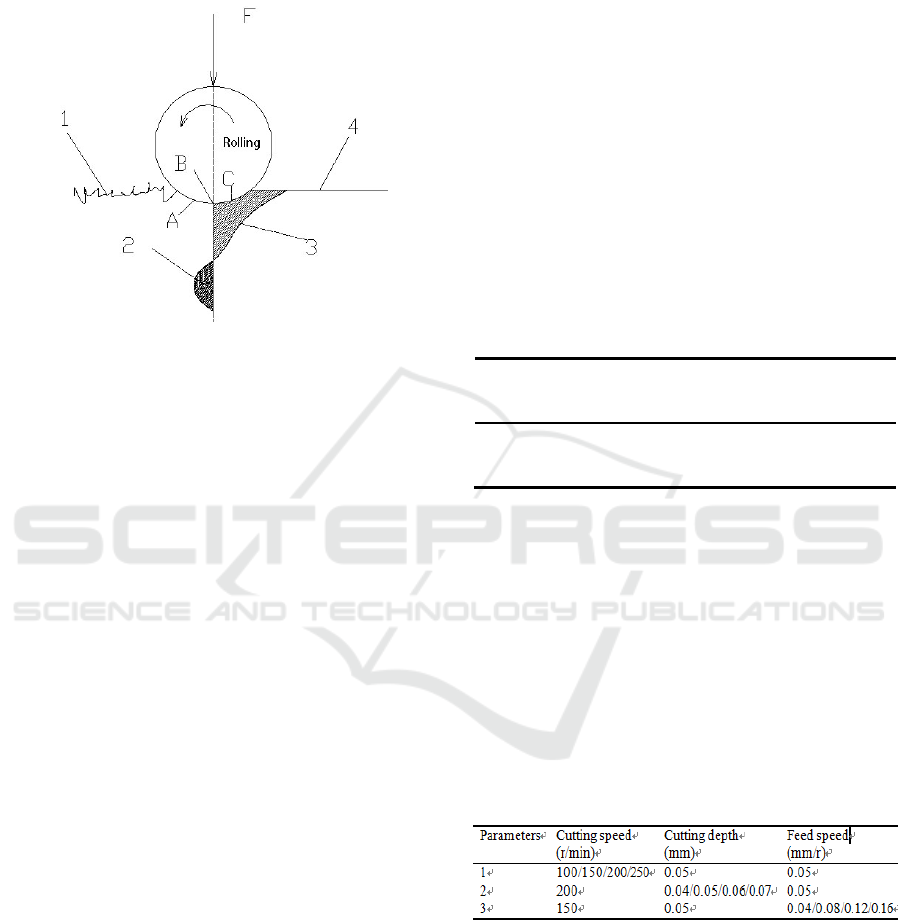

In many materials, most of the surfaces that have

been processed are uneven, and there are many

irregular peaks and troughs of different heights and

widths. The essence of rolling is to use a rolling tool

made of hard material of a certain shape, and then

apply a certain pressure on the surface to be

machined (ultrasonic rolling is provided by the

transducer to provide high-frequency mechanical

vibration), and then it is driven by the machine tool

freely rolling, changing the material distribution of

the workpiece surface, as shown in Fig.2, in the

grinding zone A area, the roller and the cutting

surface contact and gradually compacted, in the

plastic deformation zone B area, the pressure is

greater than the yield point of the material, local

plastic deformation, after the maximum load under

the roller, elastic recovery in the smooth area of the

C area, the roller and the surface slowly separated.

Rolling machining is such an action that is carried

out repeatedly and the workpiece surface is

processed into a smooth surface. The distribution of

the stress tensor causes the bottom of the trough to

rise, the crest of the unevenness to fall, the crests

and troughs to be ironed and filled, and the surface

tends to be smooth. Analysis of notch impact test

results shows that the rolling allowance increases

gradually and the toughness increases, and it

gradually decreases after reaching the maximum

value. This is the most important feature of

ultrasonic rolling process, through the toughness of

the area, eliminating the roughness of the surface

[7].

1 - Surface to be rolled 2 - Residual tensile stress 3 -

Residual compressive stress 4 - Rolled surface.

Fig.2 Rolling principle.

3 EXPERIMENTAL SETUP AND

METHODS

(1) Experimental equipment

One CKA6150 lathe, one W1974 signal

generator and one HSA4052 power amplifier,

ultrasonic vibratory rolling vibrator (lateral

amplitude: 2.1um; longitudinal amplitude: 11um),

rolling tool heads, fixtures, etc.

(2) Measuring equipment

MarM300C Surface Roughness Tester,

DureScan50 Vickers Microhardness Tester

(3) Workpieces

Specifications are Φ30×200mm# 6063 aluminum

alloy rods.

(4) Pre-cutting experiment

Tool: Mitsubishi Carbide Insert (Model

TPGX080204)

Select a set of machine cutting parameters (

cutting speed : 150r/min, cutting depth: 0.05mm,

feed speed: 0.04mm/r)to pre-process the aluminum

alloy bar, and measure the surface roughness and

surface micro-hardness several times to average. The

pre-roughness Ra is 1.173 and the micro-hardness

Hv is 68.9.

3.1 Comparative Experiment

This In order to study the effects of different

processing methods on the surface quality and

surface microhardness of aluminum alloys, three

groups of control experiments were designed:

aluminum alloy ordinary cutting experiments,

aluminum alloy ordinary rolling experiments and

ultrasonic vibration assisted rolling aluminum alloys

experiment. In order to save materials, the aluminum

alloy bar processed in the experiment was subjected

to a section test, that is, multiple groups (4 groups)

of tests were performed on the same bar, and the

length of each section was 30 mm. When measuring

surface roughness and surface microhardness, three

sets of data need to be measured and averaged, i.e.,

one set of data is measured every 120°.

Table 1: Difference test methods on aluminum alloys.

Parameters Cutting

speed

(r/min)

Cutting

depth

(mm)

Feed speed

(mm/r)

1

2

3

150

0.05

0.04/0.08/0.12/0.16

In the table1:

1- Ordinary cutting experiment

2- Ordinary rolling test

3- Ultrasonic Vibration Aided Rolling Test.

3.2 Single Factor Experiment

Effect of cutting speed/cutting depth/feed speed on

surface roughness Ra and surface microhardness of

aluminum alloy with Ultrasonic Vibration Aided

Rolling.

Table 2: Ultrasonic Vibration Aided Rolling Test.

4 EXPERIMENTAL RESULTS

AND ANALYSI

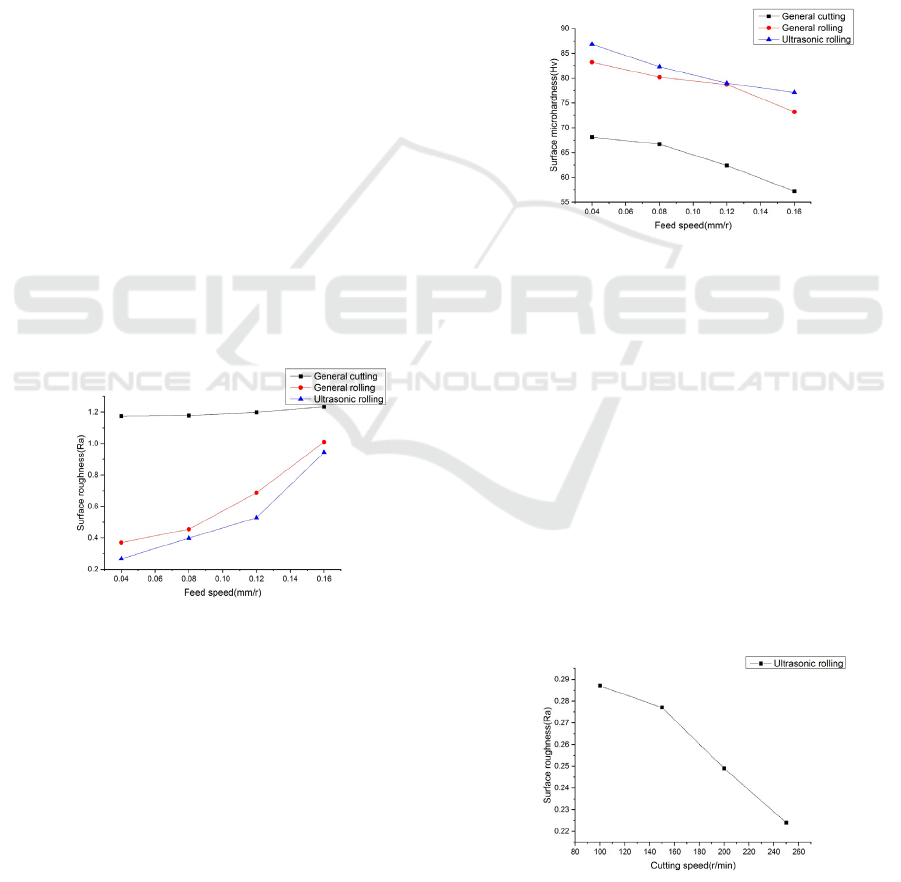

In order to compare the superiority of different

cutting methods, the surface roughness Ra and

surface microhardness measured for three different

processing methods are shown in Table 1-2. As can

be seen from Fig.3, as the feed rate increases, the

surface roughness Ra of the aluminum alloy

gradually increases under the three different

processing methods, and the surface quality

deteriorates. As the feed rate increases, the surface

roughness Ra of the ordinary rolling test (general

rolling) and the ultrasonic vibration assisted rolling

test (ultrasonic rolling) has a significant increase

compared to the ordinary cutting (general cutting).

Therefore, it can be seen that The rolling method is

not suitable for improving the surface quality of

aluminum alloys at large feed rates. Comparing the

three curves in Fig.3, the surface quality of ordinary

rolling aluminum alloy is better than that of ordinary

cutting. Ultrasonic vibration-assisted rolling greatly

improves the surface quality of aluminum alloy at a

lower feed rate than 0.04mm/r. When the aluminum

alloy surface roughness Ra value decreased by about

77.277%, at a larger feed rate of 0.16mm/r still

reduced by 23.439%, and after ordinary rolling, the

surface roughness of aluminum alloy Ra value is

low, that is, the surface Under the condition of better

quality, ultrasonic vibration assisted rolling still

further reduces the surface roughness Ra of

aluminum alloy and improves the surface quality of

aluminum alloy. When the feed rate is 0.04mm/r, the

surface roughness Ra of aluminum alloy decreases

by about 28.032. %, at the feed rate of 0.16mm/r still

reduced 6.553%, which reflects the superiority of

using ultrasonic vibration rolling aluminum alloy.

Fig. 3 Effect of feed rate on surface roughness Ra under

different processing methods.

As shown in Fig.4, as the feed rate increases, the

surface microhardness of the aluminum alloy

gradually decreases with three different processing

methods, and the fatigue resistance of the aluminum

alloy surface deteriorates. Comparing the three

curves in Fig.4, the microhardness value of the

ordinary rolling aluminum alloy surface is small, the

surface microhardness value of the ultrasonic

vibration assisted rolling and ordinary rolling is

much higher than that of the ordinary cutting, so the

ultrasonic vibration assists the rolling and Compared

with ordinary cutting, ordinary rolling greatly

improves the microhardness value of the aluminum

alloy surface. After rolling, the fatigue strength of

the aluminum alloy surface is greatly enhanced.

Under different feed speeds, the micro-hardness of

ultrasonic assisted rolling aluminum alloy surface is

increased by about 27.831% than that of ordinary

cutting. The average microhardness of aluminum

alloy surface is about 23.939% higher than that of

ordinary cutting, and the ultrasonic vibration is

assisted. Rolling aluminum alloy surface

microhardness value increased by about 3.139%

compared to ordinary rolling.

Fig. 4 Effect of feed rate on surface microhardness under

different processing methods.

Under the single factor experiment method, the

influence of ultrasonic vibration assisted rolling on

the surface quality and surface microhardness of

aluminum alloy under different cutting parameters

was studied. As shown in Fig. 5, the surface

roughness Ra value of aluminum alloy at the cutting

speed less than 260r/min. As the cutting speed

increases, the surface quality improves. The high

cutting speed makes the contact time of the rolling

head ball with the aluminum surface of the same

place in the unit time become shorter, the scratch

marks change from the line to the point, and the

rolling is more even and stable, thereby reducing the

surface roughness Ra value.

Fig. 5 Effect of cutting speed on surface roughness Ra of

aluminum alloy assisted rolling with ultrasonic vibration.

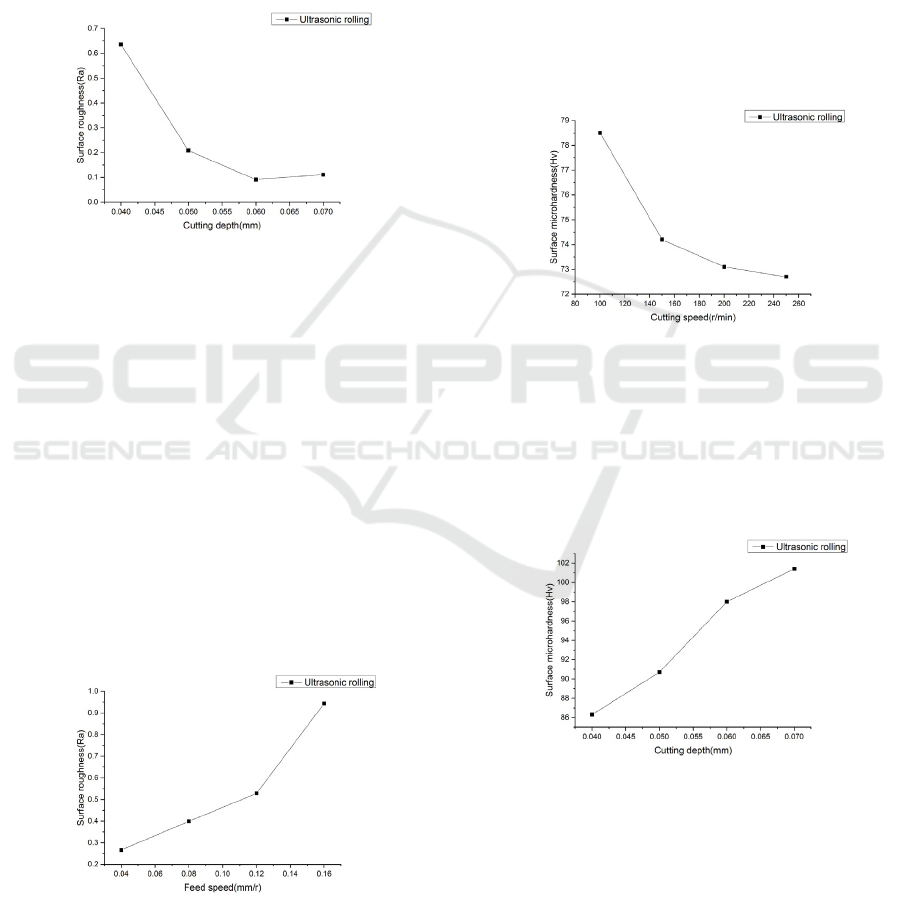

It can be seen from Fig. 6 that when the back

knife amount is less than 0.06 mm, the surface

roughness Ra of the aluminum alloy decreases with

the increase of the back knife amount, and the

surface quality is improved. If you continue to

increase the amount of back-side knives, the surface

roughness Ra of aluminum alloys gradually

increases. Therefore, to improve the surface quality

of aluminum alloys, it is necessary to select an

appropriate backing blade.

Fig.6 Effect of the back knife on the surface roughness Ra

of ultrasonic vibration assisted rolling aluminum alloy.

As shown in Fig.7, when the feed speed is less

than 0.12mm/r, the Ra value of the surface

roughness of the aluminum alloy gradually increases

as the feed speed increases, and the surface quality

deteriorates. When the feed rate is greater than

0.12mm/r, the surface roughness Ra of the

aluminum alloy increases sharply. Therefore, to

improve the surface quality of the aluminum alloy, it

is necessary to reduce the feed rate. However, in

order to obtain better processing efficiency, Ra may

be increased appropriately. Feed rate, but due to the

feed rate on the surface roughness Ra value of

aluminum alloy is not stable, so in the ultrasonic

vibration rolling aluminum alloy should be careful to

choose the appropriate feed rate.

Fig.7 Effect of feed rate on surface roughness Ra of

ultrasonic vibration assisted rolling aluminum alloy.

Under the single factor experiment method, the

effect of ultrasonic vibration assisted rolling under

different cutting parameters on the surface

microhardness of the aluminum alloy was studied.

As shown in Fig. 8, the microhardness value of the

aluminum alloy surface with cutting speed was less

than 260r/min. Increasing and decreasing, the

surface fatigue strength becomes worse. When the

cutting speed is less than 150r/min, the

microhardness value of aluminum alloy surface is

very high. When the cutting speed is greater than

150r/min, the microhardness value of aluminum

alloy surface drops rapidly, and it can be seen that it

can obtain better at low cutting speed. Aluminum

alloy surface microhardness.

Fig. 8 Effect of cutting speed on microhardness of

ultrasonically assisted aluminum alloy rolling.

As can be seen from Fig.9 when the back knife

amount is less than 0.07 mm, the microhardness

value of the aluminum alloy surface increases with

the increase of the back knife amount, and the

surface anti-fatigue strength is improved.

Fig.9 Effect of the back knife on the microhardness of the

surface of aluminum alloy assisted by ultrasonic vibration.

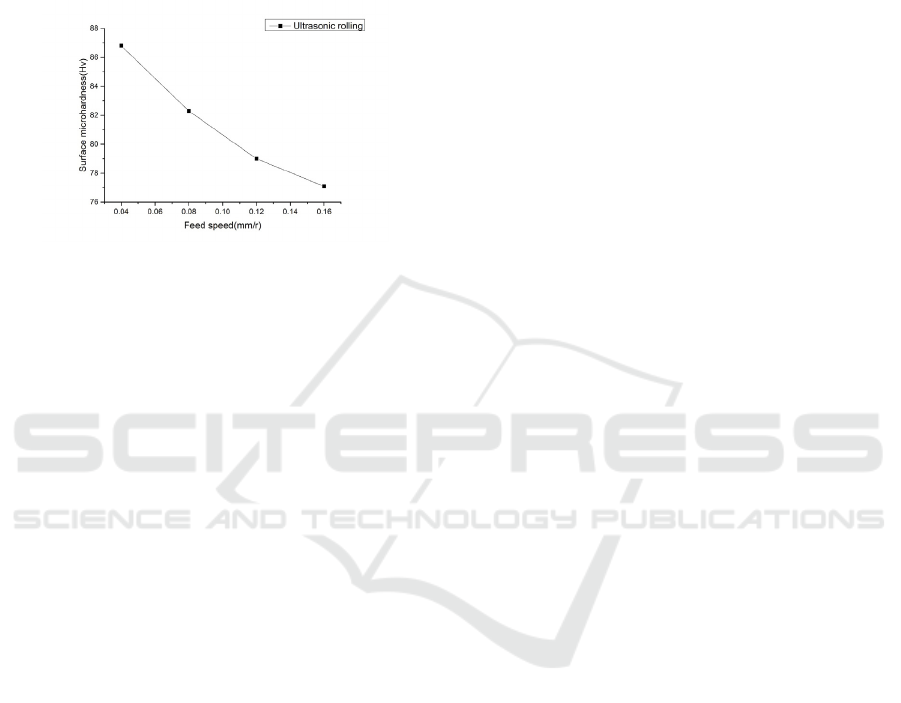

As shown in Fig.10, when the feed speed is less

than 0.16mm/r, the microhardness value of the

aluminum alloy surface gradually decreases as the

feed rate increases, and the surface fatigue strength

deteriorates. Therefore, to improve the surface

quality of aluminum alloys and improve the fatigue

strength of the aluminum alloy surface, ultrasonic

rolling is required at a small feed rate. However, in

order to obtain better processing efficiency, the feed

rate can be appropriately increased, but due to the

The speed is inversely proportional to the

microhardness value of the aluminum alloy surface,

so it is necessary to carefully select the appropriate

feed rate when ultrasonic vibration is used to roll the

aluminum alloy.

Fig.10 Effect of feed rate on microhardness of

ultrasonically assisted rolling aluminum alloy surface.

5 CONCLUSIONS

Using three different processing methods to study

the surface roughness and surface microhardness of

aluminum alloys, the following conclusions were

obtained:

(1) The surface quality and surface

microhardness of ordinary rolled aluminum alloys

are better than those of ordinary cutting. Ultrasonic

vibration assisted rolling significantly improves the

surface quality and microhardness of aluminum

alloys compared to ordinary cutting.

(2) Rolling aluminum alloys is not suitable for

improving the surface quality of aluminum alloys at

higher feed rates.

(3) Ultrasonic vibration-assisted rolling improves

the surface quality and surface microhardness of the

aluminum alloy further than ordinary rolling.

(4) Three cutting factors affecting the surface

roughness of ultrasonic vibration assisted rolling

Aluminium alloys. Importance: The amount of

cutting depth is greater than the cutting speed, which

is greater than the feed rate; the effect of three

cutting factors on the microhardness of the

aluminum alloy surface. The amount of cutting

depth greater than the feed speed is greater than the

cutting speed.

REFERENCES

1. Wang Baoyun, Li Zhengxian, Ma Dongkang.

Titanium and titanium alloy surface strengthening

technology [J]. Rare Metals Express, 2005, (07):6-10.

2. BOZDANA A T, GINDY N Z. Deep cold rolling with

ultrasonic vibrations-a new mechanical surface

enhancement technique [J]. Int. J. Machine Tools &

Manufacture, 2005, 45: 713-718.

3. Liu Yu, Wang Lijun, Wang Dongpo, et al. Nano-

mechanical properties of ultrasonic surface rolling

plus 40Cr surface[J].Journal of Tianjin

University,2012,45(7):656-660.

4. Zhu Youli, Wang Yanli, Bian Feilong, Hou Shuai, Xie

Junfeng. Research progress and application of

ultrasonic surface strengthening technology for

metallic materials [J]. Journal of Mechanical

Engineering, 2014, (20):35-45.

5. ZHU Y L,WANG K,LI Li,et al. Evaluation of an

ultrasound-aided deep rolling Process for anti-fatigue

applications[J].Journal of Materials Engineering and

Performance,2009,18(8):1036-1040.

6. Wang Yi, Bao Shaoxuan, Liu Guobi. Research on

Ultrasonic Vibration Extrusion Process (V) [J].

Electromachining, 1996(2):27-29.

7. Zhou Hang, Zhou Xudong, Zhou Wan. Current status

and prospects of rolling reinforcement technology for

metal parts [J]. Tool Technology, 2009, (12): 18-22.