Research on Agile Manufacturing Supply Chain Formation Based on

Improved Ant Colony Algorithm

Yiting Wang

1

, Shaohui Su

2

, Dongyang Zhang

3

, Chang Chen

4

, Lu Lu

5

and Guojin Chen

6

1,2,3,4,5,6

College of mechanical engineering, Hangzhou Dianzi University, No. 2 Street, Hangzhou, China

Keywords: Agile manufacturing, Ant colony algorithm, Genetic algorithm, Supply chain formation.

Abstract: In view of the agile manufacturing supply chain formation strategy and the lack of initial information of

traditional ant colony algorithm, this paper constructs a mathematical model of agile manufacturing supply

chain formation. On the basis of analyzing the characteristics of traditional ant colony algorithm and genetic

algorithm, the traditional ant colony algorithm is improved by introducing the 5 aspects: population

initialization of genetic algorithm, initial value setting of pheromone, path selection strategy, value of ρ, and

cross mutation of genetic algorithm. The improved ant colony algorithm is applied to the solution of agile

manufacturing supply chain for sofa products. After verification, the convergence time and number of

iterations of the algorithm are greatly reduced, and the ability of the algorithm to obtain an optimal solution

at a certain search speed is improved.

1 INTRODUCTION

Agile manufacturing(AM) is the main mode of

production in 21st Century. The degree of AM in a

country directly determines the country's economic

status in the world. The literature points out that AM

is an advanced manufacturing technology with rapid

response, high reliability and high flexibility. Katzy

constructs a conceptual model of AM, and illustrates

the feasibility of the model through an example of an

enterprise. Chen Wen faces the problem of resource

constraints in the selection of AM cooperative

enterprises, and constructs a Bernardo group

decision improvement model to solve the problem of

partner selection under the constraint of resource

constraints.

The core of AM is the establishment of AM

supply chain, which is essentially the optimal

combination of manufacturing enterprises. In

solving the optimal combination problem, ant colony

algorithm(ACA) can make good use of the positive

feedback information of the system and solve the

precision of the results. However, the efficiency of

the algorithm is low because of the lack of the initial

value information and the slow convergence speed

of the traditional ACA. The genetic algorithm has

the characteristics of fast, global search, parallel

search and cross mutation in solving the optimal

combination problem, which can make up for the

defects of the traditional ACA.

On this basis, this paper makes an in-depth study

on the formation of AM supply chain, gives a

graphical representation of the formation of the AM

supply chain, constructs its mathematical model, and

improves the traditional ACA with the genetic

algorithm, making the improved ACA to solve the

problem of the establishment of the supply chain of

AM. It is more efficient and accurate, and the

effectiveness of the algorithm is verified through an

example of AM supply chain in the furniture

industry.

2 MATHEMATICAL MODEL OF

AM SUPPLY CHAIN

ESTABLISHMENT

The AM supply chain can make full use of the

internal and external manufacturing resources of the

customized enterprise, and build dynamic

manufacturing alliance relations among many

enterprises, and make collaborative manufacturing

to meet the customer's personalized needs. The

establishment of AM supply chain is essentially a

partner selection problem. This section illustrates the

cooperative relationship of multiple enterprises in

supply chain by graphical representation of supply

chain. By constructing the mathematical model of

supply chain, it is the objective function chosen by

cooperative enterprises.

2.1 Graphical Representation of the

Supply Chain Establishment

The AM supply chain is carried out around the

manufacturing task. Each module of the

manufacturing task is undertaken by the

manufacturing enterprises in the network, and the

manufacturing enterprises are combined in a certain

order to get the AM supply chain. Each node in the

supply chain represents a manufacturing enterprise,

and the connection order of each node represents the

synergy relationship among enterprises. Therefore, it

is necessary to consider the relevant factors from

many candidate enterprises, select better enterprises,

optimize the allocation of manufacturing chains,

reduce costs and improve efficiency.

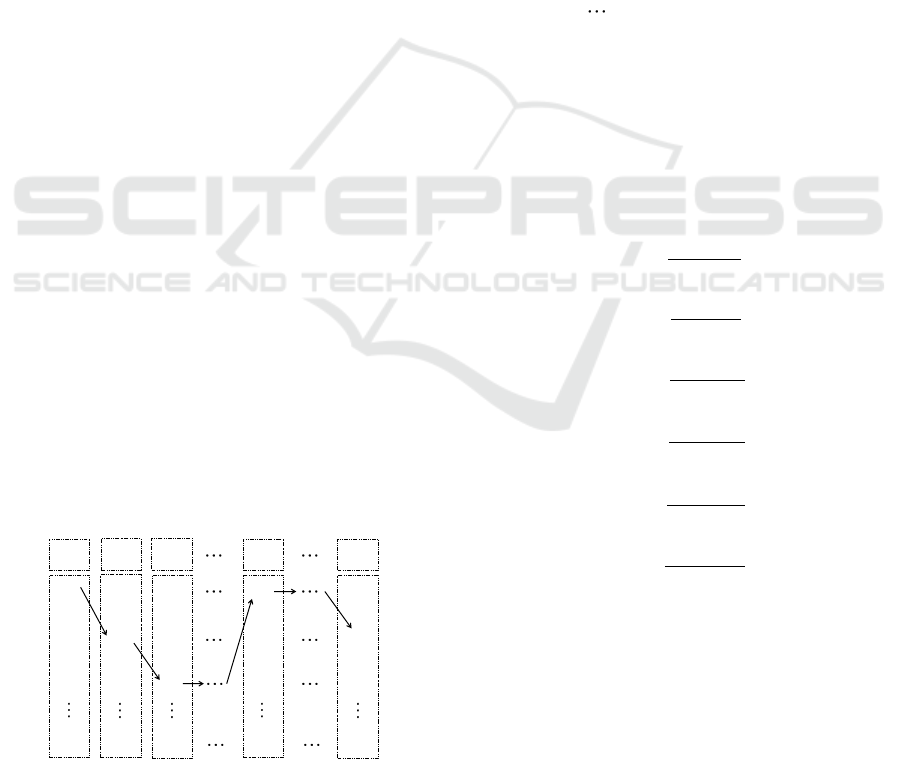

In order to solve the multi-objective optimization

problem, it is assumed that when the supply chain is

set up, the enterprise's target task

M

is divided into

n

branches,

1

i

Mi={ | [ , ] }mn

. Each branch task

i

m

has

i

s

candidates,

1,{ | [ ],

i ij

R i n=r

1[ , ] }

i

j s

represents the collection of candidate

enterprises that can complete the branch task

i

m

.

Each branch task selects a suitable manufacturing

partner

r

ij

from

i

s

enterprises to select

n

manufacturing partners to complete the

manufacturing task. From this, the problem of the

establishment of AM chain can be transformed into

a

n

level decision problem, that is, finding a set of

optimal solutions in the solution space of

1=

n

i

i

m

group. The graphical representation of the supply

chain is shown in figure 1 below.

Figure 1: AM supply chain set up graphical representation.

2.2 Mathematical Model of Supply

Chain Establishment

American scholar Dickson summed up 23 supplier

selection criteria and their ranking and weighting. In

this paper, based on the AM supply chain, the 6

selection criteria of quality Q, delivery time T,

historical performance H, guarantee clause C,

production capacity A and price P are selected as

evaluation parameters to construct a mathematical

model. The objective function of AM supply chain

can be expressed as:

1 2 3 4 5 6

Z w Q + w T + w H + w C + w w=+AP

(1)

1

1

k

k

w

=

=

6

(2)

( 1 2 6 ), , ,

k

wk=

is the corresponding index

weight. This paper uses entropy method to calculate.

Suppose that

1,, , , , , ( [ ],

ij ij ij ij ij ij

r r r r r r

q t h c a p i n

1[ , ] )

i

j s

completes the sub task

i

m

quality,

delivery time, historical performance, warranty

terms, production capacity and price respectively for

enterprise

ij

r

.

11

i

ij

n

max

ij

i= i=

max min

q - q

Qu

q - q

=

s

r

(3)

i

ij

n

min

ij

ij

max min

t - t

Tu

t - t

==

=

11

s

r

(4)

11

i

ij

n

max

ij

i= j=

max min

h - h

H = u

h - h

s

r

(5)

11

i

ij

n

max

ij

i= i=

max min

c - c

Cu

c - c

=

s

r

(6)

i

ij

n

max r

ij

ij

max min

a - a

Au

a - a

==

=

11

s

(7)

i

ij

n

min

ij

ij

max min

p - p

Pu

p - p

==

=

11

s

r

(8)

The constraint conditions are:

11

i

ij

s

n

r ij min

i= j=

q u Q

(9)

11

i

ij

s

n

r ij max

i= j=

t u T

(10)

11

i

ij

s

n

r ij min

i= j=

uA

a

(11)

1

m

2

m

3

m

j

m

n

m

11

r

21

r

31

r

1j

r

1n

r

12

r

22

r

32

r

2j

r

2n

r

13

r

23

r

33

r

3j

r

3n

r

2

2s

r

3

3s

r

i

js

r

n

ns

r

1

1s

r

11

i

ij

s

n

r ij max

i= j=

p u P

(12)

1

1

n

ij

i=

s.t. u =

(13)

Select for agile manufacturing

others

1,

0,

=

ij

ij

r

u

(14)

Among them,

, , , , ,

max max max max max max

q t h c a p

are the

maximum value of the corresponding index when

the candidate enterprise completes the

manufacturing task. The minimum values for the

candidate enterprises to complete the manufacturing

tasks are

, , , , ,

min min min min min min

q t h c a p

.

ij

u

is a

decision variable.

, , ,

min max min max

Q T A P

are the

lowest quality, the longest delivery time, the

minimum production capacity and the highest price

for the whole AM chain, respectively.

Formula (9), (10), (11), (12) respectively indicate

the constraints of quality, delivery time, production

capacity and price. Constraints, as shown in formula

(13) and (14), indicate that each sub task

corresponds to the selection of a manufacturing

enterprise. According to the meaning of each index,

the mathematical expression of the optimal

allocation of AM supply chain makes the objective

function (1) obtain the minimum value.

3 THE IMPROVEMENT OF ACA

Combined with the accuracy of ACA and the

rapidity of genetic algorithm, the ACA is integrated

into the genetic algorithm to improve the ACA. And

the improved ACA is used to solve the minimum

value of the objective function in the supply chain

mathematical model, and then the optimal

combination of the AM supply chain is obtained.

3.1 Traditional ACA

ACA is a bionics algorithm, which simulates the

interaction of pheromones through the pheromone of

the ant colony in nature to find the shortest foraging

path phenomenon, and a simulated evolutionary

algorithm is proposed. The algorithm has the

characteristics of distribution calculation,

information feedback and heuristic search. It is

proposed from the solution of the traveling salesman

problem (TSP) and can be used for the precise

solution of the combinatorial optimization problem.

Taking the TSP problem of

n

cities as an

example, the traditional ACA is described as

follows:

m

is the number of ants in the ant colony,

n

is the number of cities, and

ij

d

is the distance

between city

i

and city

j

.

()

ij

τ t

represents the

pheromone content of

t

on the edge

( , )e i j

.In the

initial time, the pheromone content of each path is

equal, so

(0) ( )=

ij

τ C C is constant

, ant

1 2( ,,kk=

, )m

will choose the path

according to the content of pheromone on each path,

and at the time of

t

, the probability of the ant

k

to

choose the city

j

by the ant of the city

i

is

()

k

ij

pt

:

k

()

allowed

0 others

,

()

,

=

k

α β

ij ij

α β

k

is is

ij

s allowed

τ t η

j

τ η

pt

(15)

Among them,

ij

η

represents the visibility of the

edge

()e i, j

, calculated by the heuristic algorithm

1/=

ij ij

η d

;

0 1 - 1 -{ ,, , }=

kk

allowed m tabu

represents the city set that ant

k

can choose;

k

tabu

represents the city that the ant

k

has passed;

α

represents the relative importance of the trajectory;

β

represents the relative importance of visibility.

When the ant ends a cycle, the pheromone on the

path will be updated according to the number of ants

passing through. The update value will be used as

the basis for the selection probability of the next ant

cycle. The update formula is as follows:

( + 1) (1 ) ( ) Δ ()

ij ij ij

τ t = - ρ τ t+ τ t

(16)

1

Δ () Δ ()

m

k

ij ij

k=

τ t= τ t

(17)

k passes through ( )

Δ ()

others

, ,

0,

k

k

ij

Q / L e i j

τ t=

(18)

Among them,

01( , )ρ

represents pheromone

volatility; while

1 - ρ

represents the pheromone

residual coefficient;

()

ij

τ t

represents the increment

of information on the path

( , )e i j

;

()

k

ij

τ t

represents the amount of information released by ant

k

on the path

( , )e i j

in this cycle;

Q

is a constant,

indicating the amount of information released by

each ant in the cycle;

k

L

represents the path length

of the ant

k

in this cycle. The optimal combination

of parameters

, , , ,QCα β ρ

can be obtained by

experiment.

3.2 The Improvement of ACA

Aiming at the shortcomings of traditional ACA, the

paper improves the ACA as follows:

(1) The population initialization step of the

genetic algorithm is introduced. Genetic algorithm is

used to optimize the initial AM supply chain and

generate the initial pheromone distribution. It avoids

the inefficiency caused by the lack of initial

information in traditional ACA. The X individual

fitness function is set as:

( ) ( )

X

δ X = P Z X

(19)

X 1 Xq 2 Xt 3 4 5 Xa 6 Xp

P = w P + w P + w + w + w P + w P

(20)

11

1 Satisfying formula (

( ) other

)

s

,

,

9

i

ij

s

n

Xq

θ

min r ij

i= j=

P

Q / q u

=

(21)

11

1 Satisfying formula 10)(

others

,

(),

i

ij

s

n

Xt

θ

r ij max

i= j=

P

t u / T

=

(22)

11

1 Satisfying formula (

other

11

s

),

(),

i

ij

s

n

Xa

θ

min r ij

i= j=

P

A / a u

=

(23)

11

1 Satisfying formula 12)(

others

,

(),

i

ij

n

Xp

θ

ij max

i= j=

P

p u / P

=

s

r

(24)

Among them,

X

P

,

Xq

P

,

Xt

P

,

Xa

P

,

Xp

P

are the total

penalty function, the quality penalty function, the

delivery penalty function, the production capacity

penalty function, the price penalty function, and the

θ

as the penalty scale.

(2) The initial value of the pheromone is set. The

maximum and minimum ant system (MMAS) is

used here. In order to make the ant movement global

and avoid the premature convergence of the

algorithm, MMAS sets the minimum value of the

pheromone content on the initial time path, and

limits the value of the pheromone content to

[ , ]

min max

τ τ

. In this paper, the initial value of the

pheromone is set to

S

ij pq

τ

based on the information

quantity and the initial value of the information

generated by the genetic algorithm.

1 2 1 ( , , , , )

S C G

ij pq ij pq ij pq

τ = τ + τ

i p n and i - p

==

(25)

Among them,

C

ij pq

τ

is equivalent to the

min

τ

in

the MMAS algorithm for the given information

constant given by the solution, and

G

ij pq

τ

is the

pheromone content converted from the population

initialization results of the genetic algorithm.

Therefore, the calculation results of the genetic

algorithm are contained in the initial value setting of

the pheromone solved by formula (25), which makes

the ACA have a relatively optimized and complete

initial path and improve the speed of the algorithm.

(3) The introduction of path selection strategy. In

the ACA, the ant's mobile path selection is based on

the pheromone content in the path to calculate the

selection probability. The greater the pheromone

content, the greater the probability of being selected.

This will cause the high local pheromone path to be

chosen by high frequency, thus losing the diversity

of solutions. In order to avoid this problem, this

paper sets a sensory threshold

0

ρ

to the ant. When

the pheromone content of the path is less than

0

ρ

,

the ant ignores the existence of the original

pheromone; when the content of the pheromone is

greater than

0

ρ

, the ant tends to choose the path of

high pheromone content according to the content of

pheromone. That is, the state transition probability

of ant

k

in the inter stage nodes can be expressed

as:

()

()

()

()

others

0

max , (),

, (),

0,

ij ps ij pq

ij pq ij pq

ij pq

ij ps ij pq

ps k ij

α β

r r r ps k ij

α β

r r r r

k

rr

pq k ij 0

α β

r r r r

r J r

τ η r J r r ρ

τ t η

Pt

r J r r ρ

τ t η

=

r

(26)

ij pq

rr

η =

(27)

1 / (

ij ij ij

max min max

1 2 3

max min max min max min

q - q t - t h - h

w + w + w

q - q t - t h - h

r r r

)

ij ij ij

max max r min

4 5 6

max min max min max min

c - c a - a p - p

+w + w + w

c - c a - a p - p

rr

Among them,

(0 1),

0

ρ

;

r

is the random

number in

(0 1),

;

k ij

Jr()

refers to the set of lower

nodes that ants

k

can choose at node

ij

r

. Thus, the

diversity of algorithm solutions is increased, and the

algorithm is avoided to fall into local optimum.

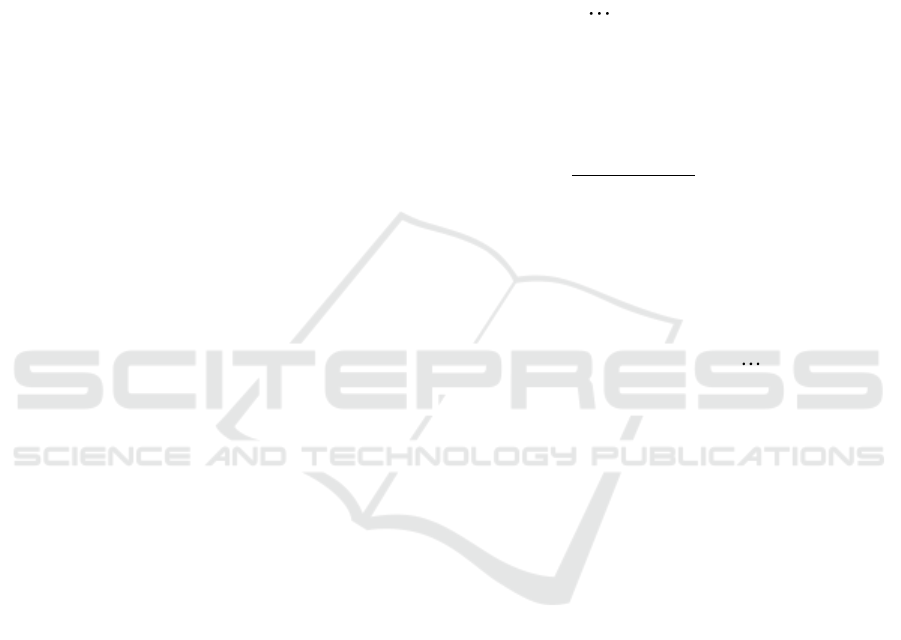

Figure 2: ρ and the optimal path length correspondence.

Figure 3: ρ and the correspondence between the number

of iterations.

(4) The improvement of the value of ρ. In the

ACA, the information is used to imitate human

memory. With the operation of the algorithm, the

volatilization of pheromones weakens the old

information. The value of pheromone volatilization

ρ controls the degree of pheromone content change,

which will directly affect the content of pheromone

and the selection of ants' path, thus affecting the

global searching ability and convergence speed of

the algorithm.

Next, we take the TSP30 problem as the research

object and analyze the influence of ρ on the

performance of the algorithm through computer

simulation experiments. The parameters are set as:

= 16n

,

= 100Q

,

=2α

,

=4β

,

= 100Nc_max

, and stop condition is: the

difference between the two adjacent loops is less

than 0.01. Figures 2 and 3 denote the

correspondence between Nc and the optimal path

length and iteration number, respectively.

The experimental results show that the optimal

path length and the number of cycles have a great

dependence on the value of pheromone volatility in

the case of certain other parameters. On the one

hand, if the ρ value is too large, the algorithm cycle

number is less, the convergence speed will be faster,

but in the initial search, the initial pheromone

content in the initial time path is less, and the initial

pheromone content of the selected path will not be

selected again after the initial pheromone content

volatilization. This will lower the global

performance of the algorithm search, and the

algorithm gets the most. The optimal path length is

only local optimal value, which has randomness and

inaccurate results. On the other hand, if the ρ value

is too small, the change amount of pheromone on the

path after each cycle is small, the algorithm is global

and the result is relatively accurate, but the feedback

effect of the algorithm is not very good, which

makes the cycle times larger and the convergence

speed is slow. In order to solve these problems, this

paper adaptively changes the method of ρ value. Set

the initial time

0.30

mi n

==ρ ρ

; when the cycle is

a certain number, if the optimal value of the

algorithm does not change significantly, then

increase the ρ value, and the value function of ρ is:

0.9 10 + 1

1

+1

others

( () / * ( )) ( ),

()

()

,

min

min

rand RAND_MAX ρ t

ρ t ρ

ρ t

ρ

+

+

=

(28)

Among them,

min

ρ

is the minimum value of

ρ

;

()rand

is a random function. The above method

adaptively changes the

ρ

value in the search

process, which guarantees the global search ability

and the convergence speed of the algorithm.

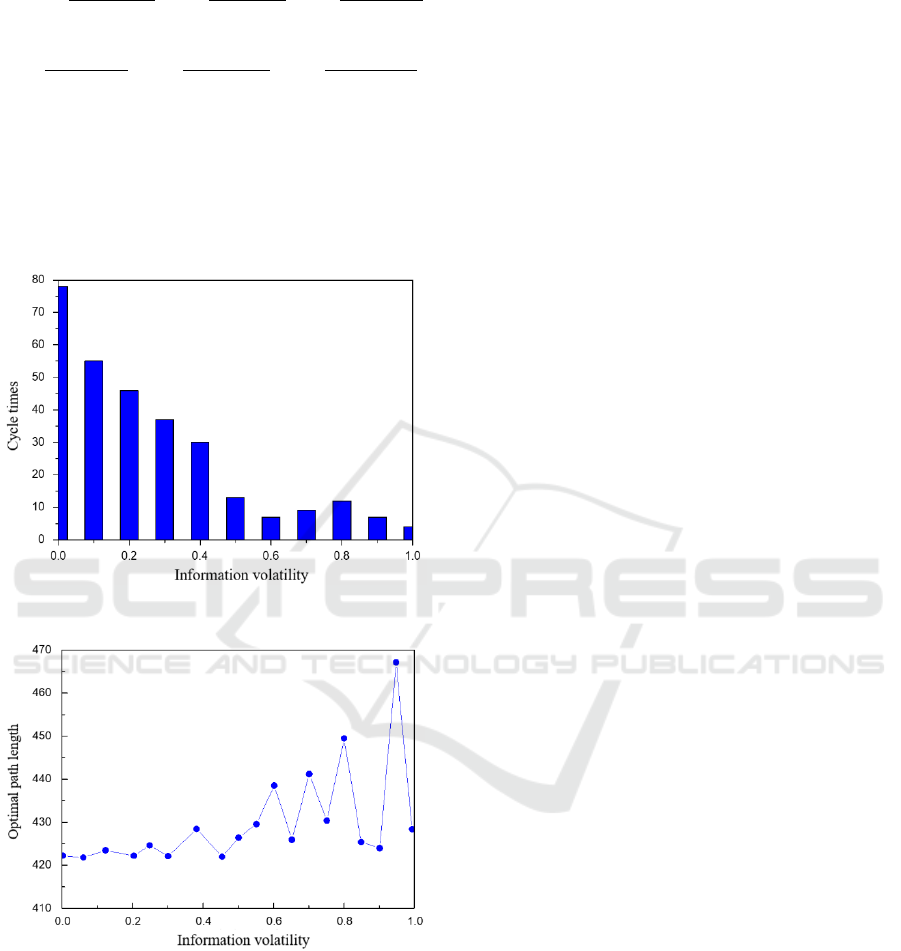

(5) Cross genetic manipulation by introducing

genetic algorithms. In this paper, a new path is

generated by introducing the cross genetic operation

of genetic algorithm to expand the path selection

strategy of ACA and optimize the ACA. When the

ant colony completes one traversal after a crossover

operation, the specific cross process is that two

mating nodes are selected randomly in the two result

parent string, the two parent string is mutated in two

points, then the sequence number of the sub task is

modified, and the cross process schematic diagram

is shown in figure 4 below.

Figure 4: ρ and the optimal path length correspondence.

3.3 The Execution Flow and

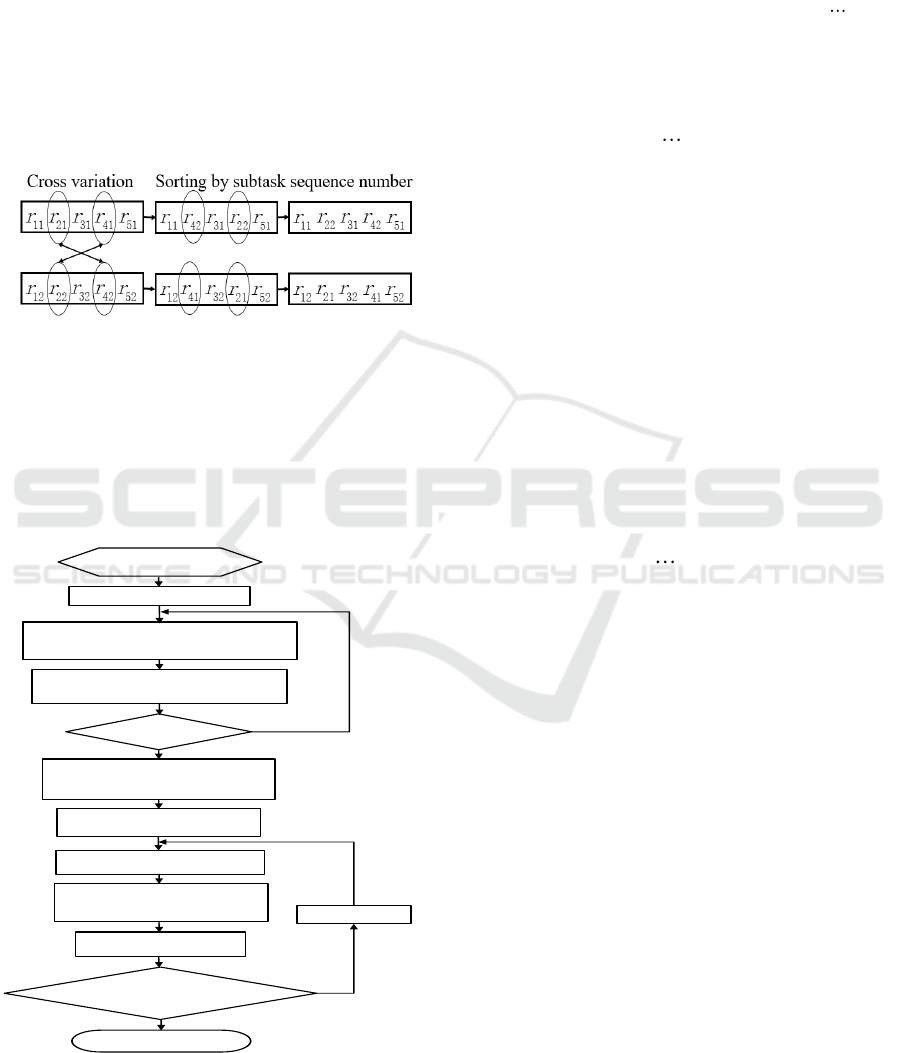

Description of the Improved ACA

The execution process of the improved ACA is

shown in figure 5. The algorithm is described as

follows:

Figure 5: ImprovedACAflow chart.

① Initialize the genetic algorithm. The

probability of setting crossover is

P

, and the

number of genetic iterations is

n

. In the feasible

region of the solution space,

N

individuals satisfying

the constraint conditions are randomly generated to

form the initial population

1 2 {| , ,

l

S X l==

, }N

.

② The formula (20) is used as a penalty function

to deal with constraints.

③ Taking the formula (1) as fitness function, a

certain number of highly adaptive individuals are

screened from

12

, , ,

p

N

X X X

.

④ The genetic cross mutation operation was

performed with the probability of

P

.

⑤ The genetic algorithm terminates the genetic

algorithm after operation, and converts the better

combination solution of the genetic algorithm into

pheromone

G

ij pq

τ

.

⑥ACA is introduced to initialize the parameters

of ACA. The relative importance of the trajectory is

α

, the relative importance of visibility is

β

, the

pheromone volatilization is

ρ

, the ant number is

ant

N

, and the largest ant iteration number is

Cmax

N

.

⑦ The

ant

N

ants are assigned to

1

n

i

i=

s

candidates.

⑧ For

1 2, , ,=

ant

kN

, the probability of

ant node transfer is calculated according to formula

(26), and the supply chain

k

Z

formed by ant

k

is

calculated according to formula (1).

⑨ The content of pheromone was updated

according to formula (25).

⑩ If the algorithm converges or reaches the

maximum number of iterations, the optimal supply

information is output; otherwise, a cross operation is

carried out and the cycle of ACA is continued.

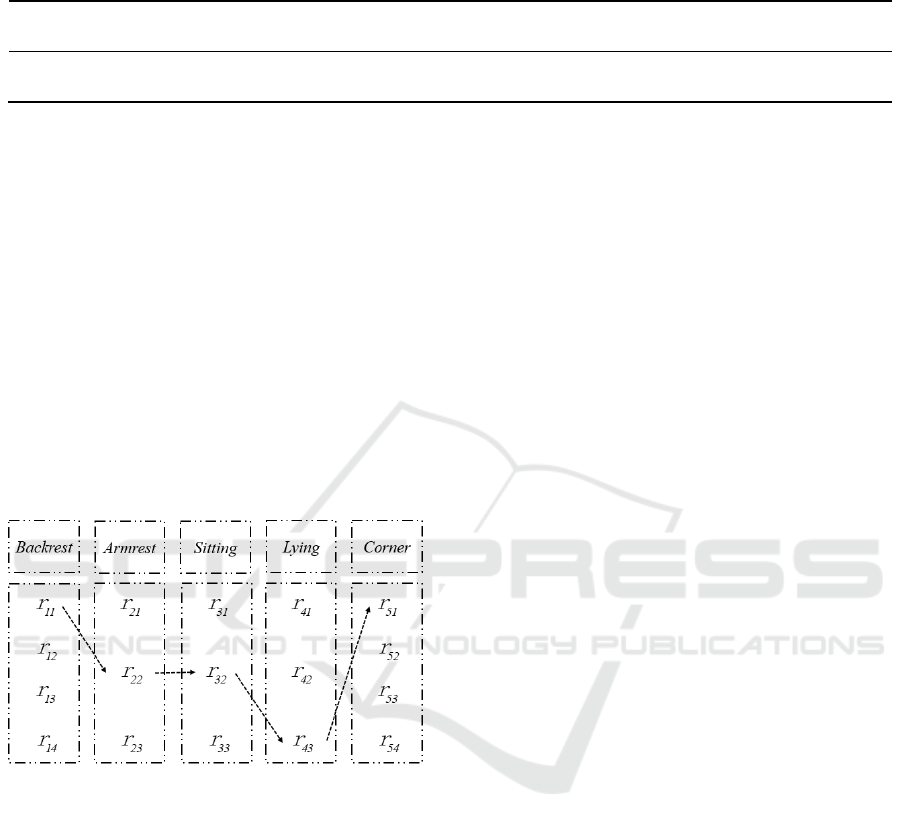

4 SOFA PRODUCT AM SUPPLY

CHAIN FORMATION EXAMPLE

A furniture enterprise needs to set up the AM supply

chain to complete the manufacture of a batch of sofa

products. The manufacturing task is divided into five

modules: backrest, armrest, sitting frame, lying

position and corner. The constraints of the enterprise

on this manufacturing task are: quality constraint

= 0.9

min

Q

; delivery time constraint

= 20

max

T

days;

Initialize the

genetic algorithm.

Generate the initial group.

Select the individual according to the

penalty function and the fitness function.

The operation of genetic cross mutation

is carried out at a certain probability.

Some sets of optimization solutions

are generated and transformed into

initial pheromone distribution.

Evolutionary

algebra?

Y

N

Initialization of the ant colony

algorithm parameters.

The ants are arranged on the

various candidates.

Calculate the node transfer

probability of each ant and move

each ant to the next level node.

Update the pheromone

content of each path.

Converging or reaching

the maximum number

of iterations?

Output optimal solution

Cross operation

Y

N

production capacity constraint

= 0.85

min

A

; price

constraint

= 180 000,

max

P

yuan. After market

research and bidding, the enterprise selected four

backrest module manufacturing enterprises (r

11

, r

12

,

r

13

, r

14

); three armrest module manufacturing

enterprises (r

21

, r

22

, r

23

); three sitting frame module

manufacturing enterprise (r

31

, r

32

, r

33

); three lying

module manufacturing enterprise (r

41

, r

42

, r

43

), four

corner module manufacturing enterprises (r

51

, r

52

, r

53

,

r

54

). The quality, delivery time, historical

performance, warranty terms, production capacity

and price data of each candidate are shown in table

1.

In this paper, the Java language is used to encode

the algorithm. There is no theoretical basis for

setting the parameters in the algorithm. It can only

be determined by experiment. According to the

algorithm several experiments, the parameters are

determined as follows:

= 45;n

= 0.8;p

= 100;N

= 20;

ant

N

= 200;

Cmax

N

= 100;Q

= 0.6;ρ

= 0.4;α

=4;β

= 0.1

0

ρ

. The

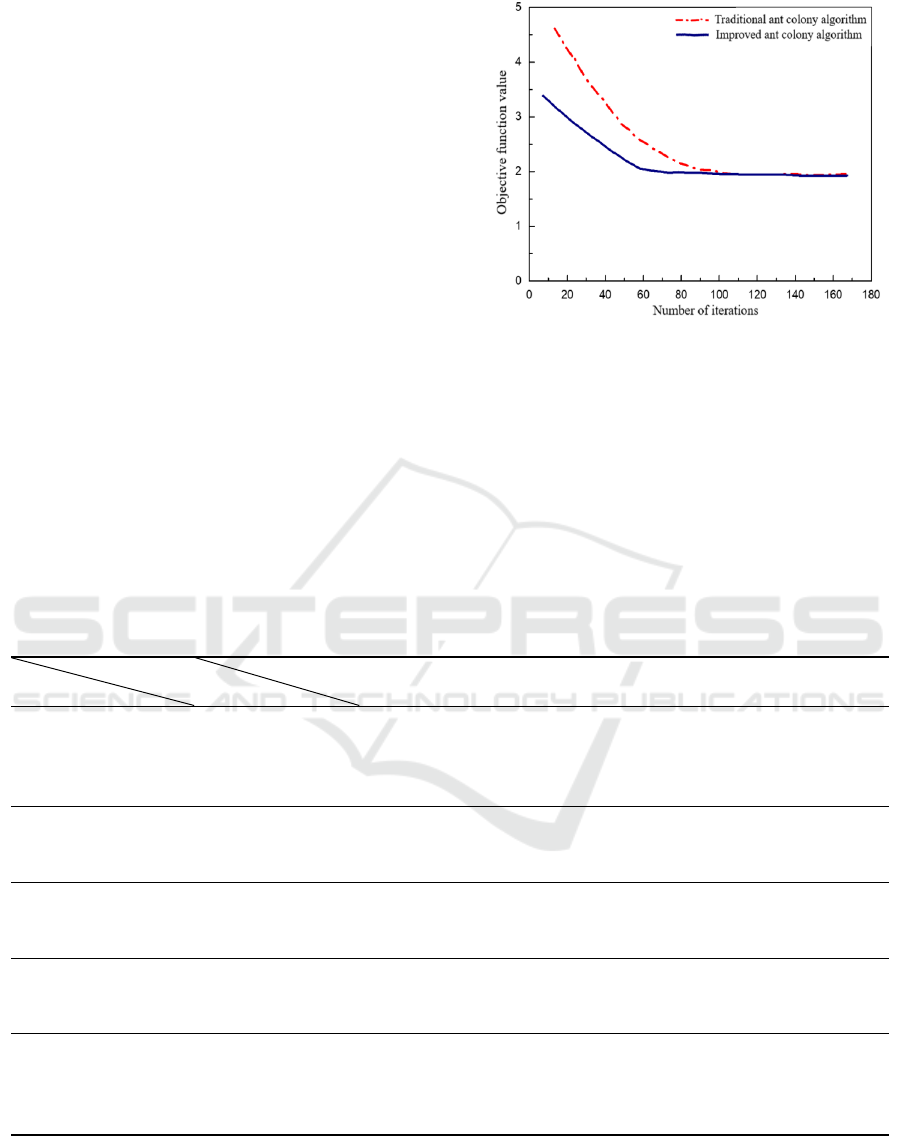

improved ACA is compared with the traditional

ACA, and the convergence relationship between the

number of iterations and the objective function is

obtained, as shown in figure 6.

Figure 6: Contrast improved ACA before and after the

convergence.

For the same parameter setting, the improved

ACA and the traditional ACA run 50 times each.

The average iteration times and the convergence

time of the improved ant colony algorithm, as well

as the final output results are calculated, and the

table 2 is summed up, and the performance of the

improved algorithm is compared.

Table 1: Candidate manufacturing companies’ related data.

ij

r

q

ij

r

t

ij

r

h

ij

r

c

ij

r

a

ij

r

p

Backrest module

r

11

0.96

6.2

0.92

0.95

0.93

4.1

r

12

0.91

5.5

0.86

0.79

0.76

4.9

r

13

0.94

5.9

0.88

0.87

0.84

4.3

r

14

0.89

7.3

0.92

0.89

0.95

4.0

Armrest module

r

21

0.96

5.7

0.83

0.85

0.90

6.1

r

22

0.95

5.3

0.89

0.94

0.88

6.3

r

23

0.94

4.8

0.86

0.89

0.86

6.6

Sitting frame module

r

31

0.94

4.0

0.82

0.87

0.93

6.2

r

32

0.96

3.8

0.92

0.91

0.90

6.9

r

33

0.92

4.2

0.81

0.89

0.86

6.8

Lying module

r

41

0.97

5.8

0.90

0.90

0.90

4.6

r

42

0.88

4.9

0.86

0.81

0.87

4.5

r

43

0.96

5.5

0.95

0.89

0.88

4.3

Corner module

r

51

0.95

5.7

0.93

0.95

0.92

5.0

r

52

0.93

5.1

0.87

0.80

0.87

5.7

r

53

0.96

5.4

0.88

0.73

0.76

5.1

r

54

0.98

7.1

0.81

0.90

0.88

5.7

Table 2: Comparison between improved ACA and traditional ACA.

The results of the simulation analysis and the

experimental summary show that the results of the

improved ACA are all: the optimal solution of the

target function is 1.90, and the combination of the

corresponding AM supply chain is (r

11

, r

22

, r

32

, r

43

,

r

51

), as shown in figure 7. But the improved ACA has

converged at about 60 times and reached the optimal

solution. Compared with the traditional ACA, the

number of iterations and the time of convergence

have been reduced to a great extent, which ensures

the ability of the algorithm to obtain the global

search optimal solution at a certain speed. Therefore,

the improvement of the traditional ACA is an

effective improvement algorithm, which improves

the running speed of the algorithm significantly.

Figure 7: The best combination of candidate

manufacturers.

5 CONCLUSIONS

In this paper, the strategy of improving the ACA in

the AM supply chain is described, and a graphical

representation of the establishment of the AM supply

chain is made and its mathematical model is

constructed. It is pointed out that the essence of AM

supply chain is the optimal combination of

manufacturing enterprises. On the basis of analyzing

the characteristics of the traditional ACA and genetic

algorithm, the traditional ACA is modified from 5

aspects, including the introduction of the population

initialization of the genetic algorithm, the initial

setting of pheromone, the introduction of the path

selection strategy, the value of ρ, and the

introduction of the cross mutation of the genetic

algorithm. The improved ACA and its execution

process are described in detail. By comparing the

traditional ACA with the improved ACA, the

advantages of the improved ACA in solving the

optimization combination problem of the AM supply

chain are verified by the example of the AM supply

chain of sofa products.

ACKNOWLEDGEMENTS

Thank the National Natural Science Foundation of

China (Grant No. 51475129,51675148, 51405117)

for its strong support for this paper.

REFERENCES

1. Jiang Xinsong. 1996, The main mode of enterprise in

twenty-first Century - agile manufacturing enterprise,

Computer integrated manufacturing system,2 (4): 3-8.

2. Katzy, B. R., 1998, Design and implementation of

virtual organizations, Hawaii International Conference

on System Sciences. IEEE Computer Society, 142.

3. Zhang Qiang, Chen Wen, 2004, A method of selecting

partners in dynamic alliance based on fuzzy multi-

attribute group decision making, Fuzzy system and

Mathematics, 18 (S1): 332-336.

4. Dong Jingfeng, Wang Gang and Lu Min, 2007, Multi

supplier selection problem based on improved ant

colony algorithm, Computer integrated manufacturing

system, 13 (8): 1639-1644.

5. Dickson, G. W., 1996, An analysis of vendor selection

systems and decision, Materials Science Forum. 1377-

1382.

6. Weber, C. A., Current J R and Benton W C, 1991,

Vendor selection criteria and methods, European

Journal of Operational Research, 50(1):2-18.

7. Liu Jin, Guo Jinchao, 2018, Supplier selection in

supply chain environment based on entropy method

and TOPSIS method, Business economy research,

(06): 34-36.

8. Reed, M., Yiannakou A. and Evering R., 2014, An ant

colony algorithm for the multi-compartment vehicle

Algorithm

Number of

iterations

Convergence

time (s)

Optimal solution of

objective function

Corresponding optimal

combination

Traditional ACA

105.7

16.4

1.90

r

11,

r

22,

r

32,

r

43,

r

51

Improved ACA

58.5

9.6

1.90

r

11,

r

22,

r

32,

r

43,

r

51

routing problem, Applied Soft Computing, 15(2):169-

176.

9. Ghafurian, S., Javadian N, 2011, An ant colony

algorithm for solving fixed destination multi-depot

multiple traveling salesmen problems, Applied Soft

Computing, 11(1):1256-1262.

10. Lai Xuewei, 2017, Research on TSP problem based on

ant colony algorithm, Journal of Foshan University

(NATURAL SCIENCE EDITION), 35 (3): 72-74.

11. Kang Lanlan, 2008, Hybrid ant colony algorithm

based on genetic algorithm, Jiangxi University of

Science and Technology.