Research on the NC Maching ToolpathTtrategy of Complex Curve

Surface

Zhu ming Cao

1

, Lu Lu

1

,Kun Qiu

1

,Dongying Zhang

1

and Jiatian Guo

2

1.

School of Mechanical Engineering,Beijing Polytechnic,Beijing 100176

,

China

;

2

.Department of Automotive Engineering

,

Shandong Vocational College of science and technology,Shandong Weifang

261053

,

China

Keywords: Complex curve surface; NC machining; Tool path; Cutter axis vector; optimize.

Abstract: With the progress of science and technology and the personalized needs of users, complex curve surface has

been widely used in aerospace, ship, vehicle, molds, medical devices and other industries. Efficient and

precise manufacturing of complex curve surfaces is an important research direction of the advanced

manufacturing technology. This paper research the NC machining tool path for a complex curve surface,

and for the feature of the surface to choose the variable contour milling strategy. Optimization of the cutter

axis vector, achieve the projection from cutting point of the cutter to the cutter axis is the largest when

cutting the surface. So as to achieve the maximum cutting speed and improve the surface quality. This paper

constructs the change model of the cutter axis vector of the cutting process, and the optimization of the

rotation angle of the cutter axis vector is completed. The design and precision requirements, high surface

quality and precision can be obtained by using this strategy and model.

1 INTRODUCTION

With the progress of the personalized needs of

users, complex curve surface has been widely

used in aerospace, ship, vehicle, molds, medical

devices and other industries. Common products

include impeller blades for aero engines,

propellers in ships, turbines for vehicle engines,

etc. The machining of these surfaces requires a

complex cutting motion between the cutter and

the workpiece on the multi-axis NC machine tool.

The NC machining technology determines the

machining accuracy and the machining efficiency

of these complex curve surface parts, thus

affecting their performance. The key and

difficulty of complex curve surface machining is

the process of computer aided manufacturing.

Professional, efficient, safe and intelligent CAM

software must be used. And the processing

technology, precision and efficiency can be

embodied in the tool path through computer

assistance. Therefore, the research on the

machining technology of complex curve surface is

focus on the research of the path of the machining

tool, and the tool path planning has a direct

impact on the machining efficiency and precision

of the parts.

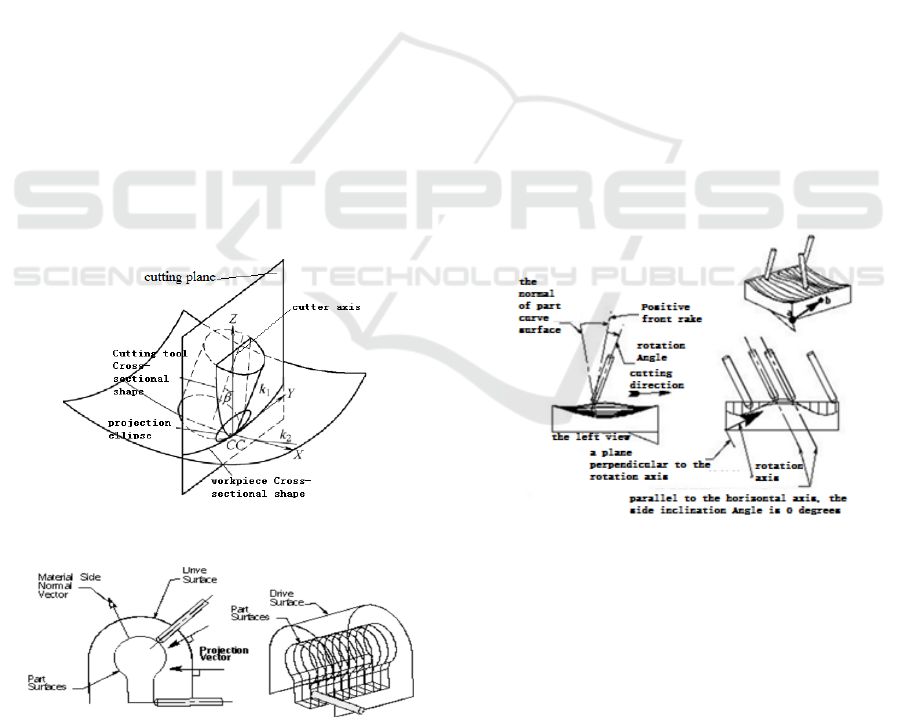

As shown in Fig 1-a,the mainly work of the

tool path planning of the complex curve surface is

determination of the completion of the cutter site

and the cutter axis vector. Cutting position is

selected by a driver, and based on the determined

projection vector, the cutter location point is

created by making the driving point generated on

the drive to project onto the component geometry

by the specified projection vector. As shown in

Fig 1-b.The tool axis vector setting refers to the

tool axis pointing in the machining process to

move according to certain strategies. Commonly

used strategies of the knife shaft include away

from point, orient to point, away from straight line,

orient the straight line, perpendicular to the driver,

relative to the driver, interpolation vectors, four

axis perpendicular to the driver and four axis

relatives to the driver body, etc. When machining

complex curve surfaces, it is usually necessary to

have multiple cutting tools to complete. In theory,

only pass the three steps of cutting point

positioning, cutting tool path planning and

collision inspection, then be sure non-interference

tool path, it can be done. The main process of tool

path generation is: ① determine the tool

positioning strategy, realized the maximization of

machining line width without over-cutting; ②

determine the method to generate the knife path,

calculate row spacing, walking distance, cutting

depth and other parameters, to minimize the total

length of tool path in the premise of ensuring the

continuity and smoothness of the knife road; ③

avoid the interference of tools with workpieces

and fixtures with workbenches. These three

aspects are mutually complementary and closely

related. In the actual processing, we should

consider the tool positioning, the axial vector light,

the shape of the knife, the length of the tool, the

machining parameters, the interference and the

characteristics of the machine movement, etc. It is

the difficulty of complex curve surface machining.

Therefore, most research on tool path planning is

limited in several aspects. In this paper, we

research the cutter axis strategy of "four-axis

relative to drive". This strategy is used to

construct the change model of the cutter axis,

optimize the relevant parameters, and complete

the efficient and precise manufacturing of a

complex curve surface.

(a)The principle of cutter location algorithm

(b)cutter location point generation principle

Fig1 generating tool path of the complex curve surface.

2 RESEARCH ON THE STRATEGY

OF "4-AXIS RELATIVE TO THE

DRIVER"

The "4-axis relative to the driver" is a commonly

used tool path strategy in the four-axis CNC

machining process, and it is widely used in the

manufacture of mould, blade and aviation parts.

This cutter axis strategy adds a "front rake Angle"

and an "side inclination Angle" based on the "4-

axis perpendicular to the component" tool axis

strategy to make the cutter shaft more flexible and

reliable, as shown in Fig2.The cutter axis strategy

requires the cutter axis to be perpendicular to the

driver or machining surface, and the plane

projection which is perpendicular to the axis

rotation Angle X. Then it can set the front rake

Angle, side inclination Angle and rotation Angle

to adjust the direction of the axis vector to meet

the processing demand of various curved surfaces.

The operation mode of the 4-axis relative to the

driver is: Select 4- axis relative to the driver as the

cutter axis strategy; then define the connection of

two points as the axis of rotation; at last input the

desired 4 axis rotation Angle, front rake Angle and

side inclination Angle.

Fig2 the strategy of "4-axis relative to the driver".

As shown in Fig2,the main parameters of the

strategy of 4-axis relative to the driver include

rotation axis vector, front rake Angle, side

inclination Angle and rotation Angle. The rotation

axis vector refers to the vector direction of the

rotation axis in the parts during the four-axis

machining process; The front rake refers to the

cutter axis tilted toward the direction of the cutter,

it is affected by the direction of the tool

movement. The forward refers to the slope along

the direction of the tool path-Pull the walk, the

reverse refers to the reverse direction of the tool

path- push the walk, it is based on the vertical face

of the walking knife. The rotary surface of the

cutter is perpendicular to the direction of the

cutter when the cutter side inclination. Looking

back the first cutter feed direction, counter

clockwise is positive, clockwise is negative, it is

based on the direction of the walking cutter to

calculate the Angle. The rotation Angle makes all

the axes revolve around the defined rotation axis,

at the same time, keep the tool perpendicular to

the rotation axis. Looking from the direction of

the positive side of the rotation axis to the

negative, counter clockwise is positive, clockwise

is negative. Unlike the "front rake Angle", the

four-axis rotation Angle is always tilted to the

same side of the normal axis, which has nothing

to do with the direction of the cutter movement.

As shown in Fig3-b,When the direction of the

cutter is perpendicular to the rotation axis X, the

cutter axis can only be set forward and rotated,

and the setting side inclination is invalid. In order

to avoid the swing of the cutter axis too often, the

"one-way" strategy is set in the drive. As shown in

Fig3-c,When the direction of the cutter is parallel

to the axis of rotation, the axis of the cutter can

only set the side inclination Angle and rotation

Angle, and the front inclination is invalid, and the

effect of setting the side inclination Angle and

rotation Angle is the same, and the lateral

inclination cannot be greater than 90, otherwise

the cutter path is invalid. From the positive side of

the rotation Angle vector looks forward to

negative direction, counter clock wise is positive,

clockwise is negative. The rotation Angle vector

is calculated by the angular reference based on the

rotation vector.

(a) front rake and (b) perpendicular to the

side inclination rotationaxis

(c)parallel to the (d) rotationaxis

side inclinationrotationaxis rotationaxis

Fig3 cutter axis vector parameters.

3 APPLICATION RESEARCH ON 4-

AXIS RELATIVE TO THE

DRIVER

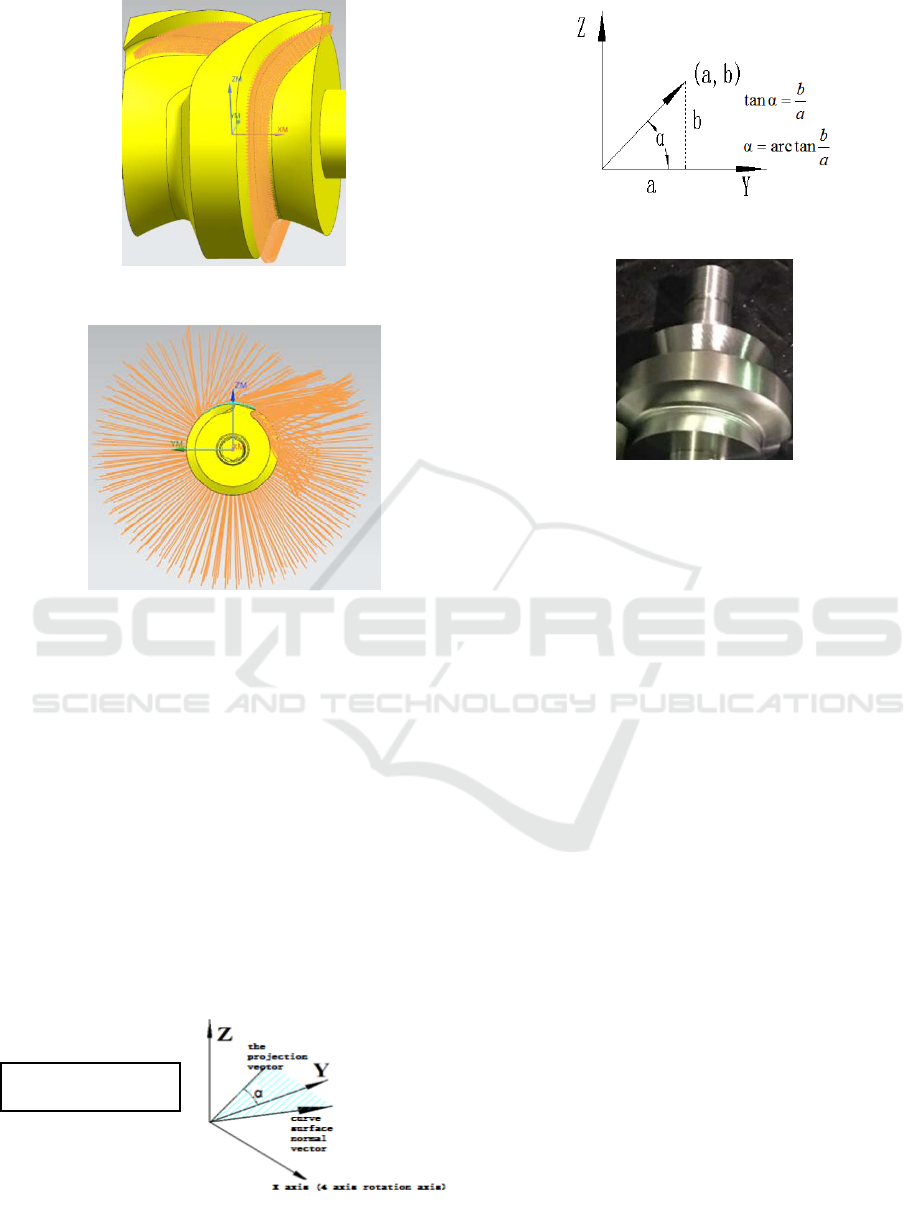

As shown in Fig4-a, the specimen in this paper is

a curved camshaft. The side curve surface of the

part and the hub need to use the four-axis NC

machining. The planning of tool path is required

before processing, including the setting of cutter

site and cutter axis vector. The tool path of the

lateral surface adopts the variable contour milling

strategy of UG10.0, machined surface selects the

processed surface; the projection vector is

perpendicular to the driver, the cutting mode is

reciprocating, the tolerance is set to 0.01,the cutter

point will be generated in the normal direction of

each point of the surface, as shown in Fig4-b;the

cutter axis is selected on the 4 axis relative to the

driver, when all the parameters are set to

0,generated the cutter axis as shown in Fig4-c,it

can be found that the cutter axis interferes with

the hub of the camshaft, therefore, the tool path

should be optimized.

(a)the surface of the driver

(b)the cutter point cloud

(c)cutter axis vector

Fig4 design the tool path for the curve surface of cam.

Because the rotation axis A of the component

is rotated around the X-axis, the cutter axis can

only rotate around the X-axis, so the rotation

Angle α of the cutter axis is the Angle that is

perpendicular to the driver at the cutter point, and

projection on the YZ plane, the Angle formed

with the Y-axis, as shown in Fig5-a.The cutter

axis can be interfered when the cutter axis

parameter is not set. Therefore, it is necessary to

optimize the cutter axis vector. This paper

research the tool path of the side curve surface of

the part, and design the maximum cutting speed to

be achieved without interference.

(a)cutter axis vector

(b)test pieces

Fig5 4 axes relative to the driver.

4 AXIS VECTOR OPTIMIZATIONS

To ensure the smoothness of the curved surface,

according to the cutting speed V=ωR1(R1 is the

vertical distance from the spher mill cutting point

to the cutter shaft),it should be ensured that R1

is the largest during processing, this will achieve

maximum cutting speed. Suppose the space plane

is a X+bY+cZ+D=0, the normal vector is(A,B,C),

so the space line can be represented as two planes

simultaneous. The result of the simultaneous

expression can be expressed θas the determinant,

as shown in formula 1;according to the spatial

linear two points, as shown in formula 2;the

normal vector of each point after cutting

is

f

a

=(

fff

zyx ,,

),The tool vertical it; the

normal vector for each point before cutting is

0

a

=(

000

,, zyx

); therefore, the change of the

normal vector per cutting

is(

000

,, zyx

)......(

nnn

zyx ,,

); if once reciprocate

can complete processing, then the Angle formula

cuttr poin

t

of

f

a

=(

fff

zyx ,,

) and

0

a

=(

000

,, zyx

) is as

shown in formula 3, the fastest cutting speed V

can be calculated by formula 4, 5 and 6.

According to the algorithm, use the software

verify that the θ value can be 63.476 ° --

78.889°.In this case, the rotation Angle θ is

selected as 70°, the higher surface quality can be

obtained through trial production, as shown in

Fig5-3

c

zz

b

yy

a

xx

000

( a 、 b 、 c is the

direction of the vector)①

2

1

2

1

2

1

zz

zz

yy

yy

xx

xx

(a、b、c is the

direction of the vector) ②

0

0

.

.

θcos

aa

aa

f

f

(

f

a

0

a

is unit vector)③

0000000

),,).(,,(.θcos zzyyxxzyxzyxaa

fffffff

④

)arccos(θ

000

zzyyxx

fff

(R is radius of spher mill for machining)⑤

2

000

2

1

)(-1R.θcos-1R.θsin.R zzyyxxR

fff

⑥

5 CONCLUSIONS

This paper research the cutter axis vector in the

machining process of camshaft side wall curve

surface. The tool path strategy of the curved

surface adopts the variable contour milling of

UG12.0;to maximize processing speed, the

direction of cutter axis vector is optimized, and

ensure that the cutting tool's cutting position is as

large as the vertical distance from the cutter shaft.

In this paper, the change process model of the

cutter axis vector of the cutting process is

constructed, and the optimization of the rotation

Angle of the cutter axis vector is completed. It can

obtain high surface quality and precision by using

this strategy and model, and achieve the design

and precision requirements. At the same time, we

should pay attention to not selecting geometry in

the setting process of the tool path for sidewall

curve surface, otherwise, we cannot generate the

tool path that revolves around the X-axis. In the

process of actual processing, it is necessary to

adjust the position reference alignment for the

work blank to ensure the unification of the design

standard and the clamping standard.

REFERENCES

1. Chen Guang-ming.The principle and method study of

technological design based on NC

machining[J].Manufacturing

Automation2005,27(9):54-59,72.

2. Gui Qun-fei.CAD/CAM technique of ship model

numerical control machining based on UG[D].Wuhan:

Huazhong University of Science & Technology,2005.

3. Zhao Yan-hua,LI Wei-long,Dong Xiao,etc.Application

of variable axis curved contour milling in special thin

wall part machining[J].Aeronautical Manufacturing

Technology,2008(16):87-90.

4. Wang Xian-kui. Modern manufacturing technology

and its development trend [J]. Modern manufacturing

engineering, 2008, (1): 1-8.

5. LI Chao. The Research of Five-axis Numerical

Controll Machining Programming[J].Machinery

Design & Manufacture, 2009(01):60-62.

6. CHENG Wei,ZHANG Yue-ming,BU Fang-hua.Study

on the CNC processing of globoidal

cam[J].MACHINERY DESIGN &

MANUFACTURE,2011(03):171-173.

7. CAO Ju-lu,ZHANG Shu-sheng, SHI Yun-fei,FAN

Hai-tao , YANG Yan.A process route simulation

method of parts cutting[J].Machinery Design &

Manufacture,2011(03):171-173.

8. Hu Zi-hua,Zhang Ping,Qi Rui.A Study on Multi - axis

NC Machining Processes for Continuous Indexing

Globoidal Cams[J].China Mechanical

Engineering,2005(24):2184-2187.

9. (FAN Wengang YE Peiqing.Research Progress in

Tool Path Planning for Five-axis End Milling

Machining of Sculptured Surfaces[J].Journal of

Mechanical Engineering,2015(08):168--182.

10. YANG Yong-sheng,Wang Min.An Algorithm for

Interference_Free Tool Path Generation in NC

Machining[J].Aeronautical Manufacturing

Technology,1998(12):9-11.