Ship Fuel Usage Monitoring System Based on Big Data Technoloy

Yi ran Shi

1

and Liang xiong Dong

1

1

ZheJiang Ocean University, ZhouShan 316022, China

Keywords: Big data; Ship fuel consumption; Self-network.

Abstract: In order to meet the compulsory requirements of IMO on fuel consumption data recorded by ships, the

monitoring parameter set based on ship oil-engine-environment system was analyzed in this paper and a fuel

consumption monitoring system based on big data technology was established. In this paper, the factors

affecting the fuel consumption of marine power plant and navigation environment are discussed, it presents

the monitoring modes of instantaneous fuel consumption, displacement fuel consumption and average fuel

consumption of ships, then uses zigbee technology to build a monitoring network with adaptive function

and designs a method of network formation and transformation and an algorithm of network time

synchronization.

1 INTRODUCTION

The 69th meeting of the IMO Marine and

Environmental Committee (MEPC) raised the

mandatory requirement for ships to record and report

their fuel consumption figures. According to IMO

regulations, the data on fuel consumption collected

by the ship is reported to the flag State at the end of

each calendar year and the flag State then forwards

the data to the IMO Ship Fuel Consumption

Database(IMO Ship Fuel Consumption Database).

The IMO will then conduct data analysis and

provide SEEA with environmental, energy

efficiency and other analytical results. The

mandatory data collection requirements are passed at

the 70th SEA. As a general rule, the mechanism

should be implemented after the amendment enters

into force. The first reporting period should be 2019,

which will have an impact on the fuel consumption

of the ship's management monitoring and improving

energy efficiency measures put forward higher

requirements. Ship management, fuel management is

long-standing problem management staff affected by

the vagaries of the marine environment, the vessel

has a fuel consumption of "uncertainty, difficult to

manage," the phenomenon[1]. Traditional

monitoring of ship fuel consumption only considers

the economy of marine power plant, but due to the

fact that it is affected by the performance and natural

conditions of diesel engine, the factors such as cargo

turnover, transportation cost and emission

performance must be considered. Therefore, a big

data set, the introduction of big data technology in

fuel consumption management is an effective way.

Fuel management of big data technologies include

ship resource acquisition, storage management,

mining analysis, visualization techniques to show, in

view of the self-organizing, fault tolerance and

flexible networking of wireless sensor networks. It

designed ships fuel monitoring system that based on

big data technology to effectively solve the problem

of the applicability of fuel consumption monitoring.

2 BIG DATA SET BASED ON SHIP

OIL-ENGINE-ENVIRONMENT

SYSTEM

Ship fuel consumption management big data set

refers to all the possible data used in decision-

making fuel consumption problem. It is

characterized by a huge amount of data, diverse

sources, diverse types. It is a complicated

comprehensive plan of oil-engine-environment, Ship

fuel consumption is a collection IMO proposed the

use of large data sets and large data support the

consumption decision-making activities[2]. In order

to get under what circumstances the ship is fuel-

efficient, and how to adjust to a fuel-saving state, it

is necessary to conduct investigation, statistics and

analysis on fuel consumption of different areas and

types of ships so as to determine the factors affecting

the fuel consumption of the ship. In order to describe

these factors more clearly, these factors can be

divided into oil-engine-environment system and the

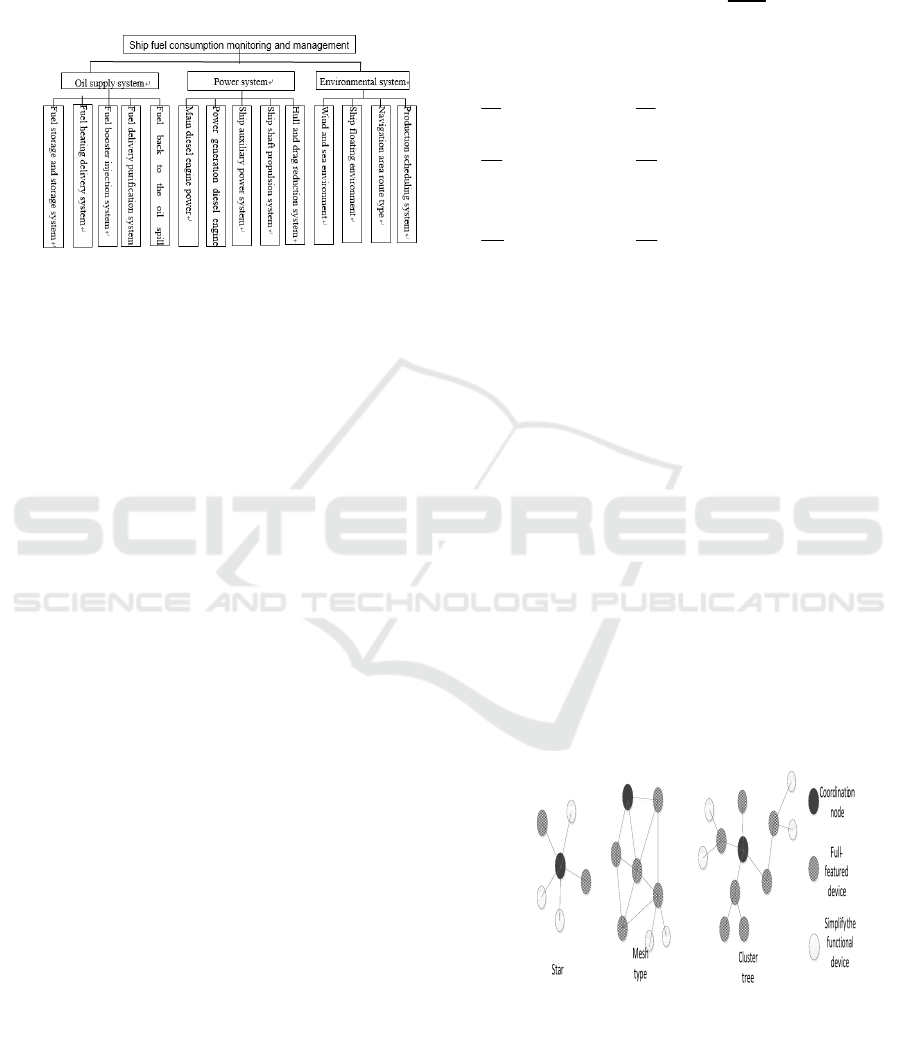

structure shown in Figure 1.

Figure 1 . Ship oil - machine - environment system

diagram.

There is no doubt, if we take a single monitor

fuel flow and calculated manner, the actual situation

is that accurate measurement is difficult to achieve.

Although precise measurement of the actual ship

fuel consumption is difficult, but measurable

parameter is very large, therefore, can be collected

according to the ship and the parameter value related

to fuel consumption, the use of large data processing

technology on the ship fuel consumption value is

determined and data processing, to obtain a more

precise Fuel consumption value.

3.SHIP FUEL CONSUMPTION

MONITORING PARAMETERS

ANALYSIS

In the ship oil - machine - environment system, the

subsystems actually have an impact on fuel

consumption in a coordinated manner. To

accommodate the diversity required data on fuel

consumption, it is necessary to change the sampling

frequency parameters flexible fuel consumption

monitoring mode, the adjustment of the correlation

between the large parameter data, set the number of

system subsystems

m

, use

i

Q

for a parameter in the

system, this subsystem affects the size of the ship's

fuel consumption, due to the system's relevance, any

i

Q

will be affected by

1

Q

to

m

Q

, thus

i

Q

is a

function of all. Also any

i

Q

is affected by all other

i

Q

and systems, this effect can be expressed by

equation (1). According to different fuel

consumption monitoring methods, pick n

subsystems to form equation (2), The steady state of

the system is again characterized by the

disappearance of the variable

i

dQ

dt

, which can be

described by equation (3).

1

1

112

112

112

22

212

212

212

1

n

1212

(, ,... ) (, ,...)

( , ,... ) 0

(, ,...)0

( , ,... )

( , ,... )

(,

( , ,... )(, ,... )

m

n

n

n

m

n

n

m

nnmm

dQ

dQ

fQQ Q fQQ Q

dt

dt

fQQ Q

dQ

dQ

fQQ Q

fQQ Q

fQQ Q

dt

dt

fQQ

dQ

dQ

fQQ QfQQ Q

dt

dt

⎧

⎧

==

⎪⎪

=

⎪⎪

⎪⎪

=

=

=

⎪⎪

⇒⇒

⎨⎨

⎪⎪

⎪⎪

⎪⎪

==

⎪⎪

⎩⎩

M

M

M

(1)(2)

2

,... ) 0

n

Q

⎧

⎪

⎪

⎨

⎪

⎪

=

⎩

(3

)

Among them, equation (3) has many sets of

solutions, which represent the existence of a number

of states of the system, which is the mathematical

model for calculating the fuel consumption of ships.

It can be seen from the above that the interaction

between the parameters collected and monitored by

the fuel consumption monitoring system of the ship

is coupled with each other, and the appropriate

acquisition precision and frequency must be selected

and adjusted in real time according to the correlation

between the parameters. Therefore, this system

selects the acquisition system based on the ZigBee

chip of the internet of things. ZigBee technology is a

short-range wireless communication technology

with uniform technical standards, and can coordinate

and communicate among many tiny sensors. The

technology uses the 2.4-GHz IEEE 802.15.4

standard, it is a standard which is a wireless network

protocol control network designed for the low-rate,

typically has three topologies: Star, Mesh, and

Cluster Tree are shown in Figure 2:

Figure 2.Zigbee network structure.

Star network topology networking technology is

simple, but its communication range is very limited;

Mesh network topology using peer-to-peer peer-to-

peer communications, the router will not only send

beacons on a regular basis, but also can improve

network fault tolerance, However, the problem of

time synchronization and the adaptability of the

network must be solved. Because the cluster tree

network topology facilitates the synchronization by

periodically sending beacons, it can reduce system

power consumption and extend the life of the entire

network. In the marine fuel consumption monitoring

system network structure, due to the great difference

between the acquisition accuracy of various

monitoring parameters and the frequency, in order to

improve the computational efficiency of the

network, so, it is necessary to adopt the

corresponding network structure according to the

fuel consumption calculation demand.

4 BIG DATA BASED FUEL

CONSUMPTION MONITORING

NETWORK DESIGN

3.1 Monitoring Network Formation

Requirements

At present, not only the IMO put forward the fuel

data collection requirements, but also the EU MRV

regulations regulate the annual fuel consumption,

CO2 emission and shipping management of the ship.

China has also formulated the fuel consumption

calculation and evaluation for shipping vessels

National Standard (GB7187.1-2010), which takes

into account factors such as speed of ship,

navigation environment, oil, loading and distance[4].

In order to meet the requirements of these codes, the

system adopts the following data processing modes

of fuel consumption .

1) A power plant operating conditions calculated

instantaneous fuel consumption rate. By means of

the power failure identification instantaneous fuel

consumption of ships, such as oil, or deterioration of

combustion state, the instantaneous consumption

rate of the main propulsion device by monitoring the

main parameters calculated with high accuracy and

the sampling frequency acquisition requirements.

2) Ship fuel consumption value is calculated

from the displacement conditions of ship sailing.

The optimum working point of ship power plant

performance can be calculated by displacement oil

consumption value. The displacement fuel

consumption value is mainly calculated by

monitoring the ship sailing performance parameters,

which has lower acquisition precision and sampling

frequency requirements.

3) Calculate the average ship oil consumption

according to the ship's operation management. Based

on this value, the operation mode and speed of the

ship can be optimized and managed. The average

fuel consumption can be obtained by data fusion

using instantaneous fuel consumption and

displacement fuel consumption.

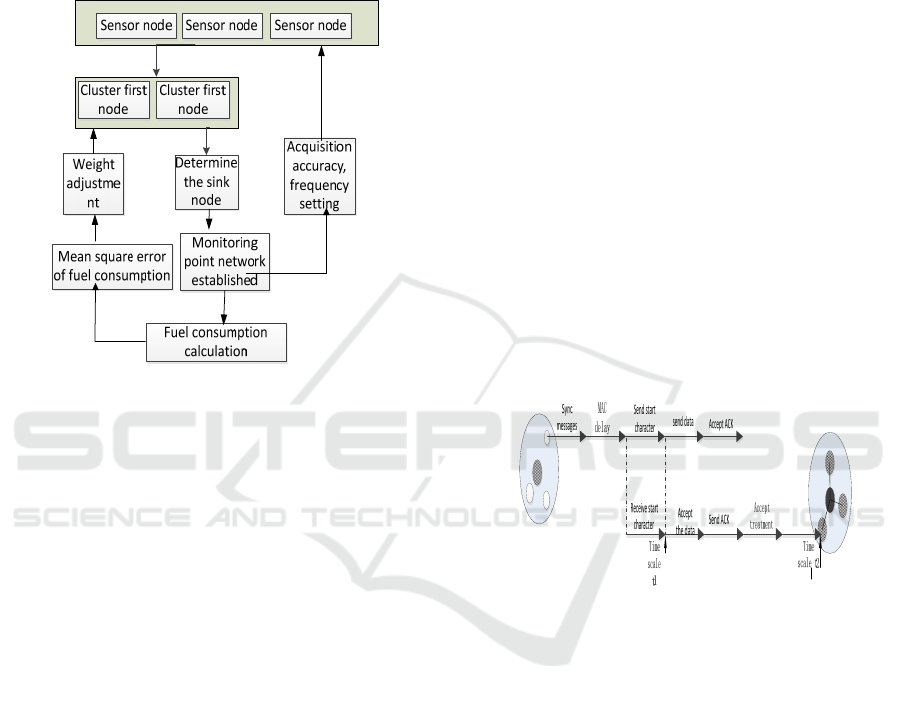

Figure 3 . Ship fuel consumption monitoring system

structure.

In order to adapt to the different fuel

consumption monitoring modes of the above ships,

this system designs a multi-hop self-organizing

monitoring network with adaptive function so that

the network can be transformed in network, tree, star

and other models to meet the needs, as shown in

Figure 3 .

In Figure 3, the system consists of a control

center, a wireless network, a sink node and a cluster

node network. A plurality of sensors in the fuel

consumption parameter of the ship form a cluster,

and each cluster has a cluster head node. The

collected data is transmitted to the cluster head node

first. Then transmitted to the sink node of the

network. The cluster head node represents the

specific fuel consumption value calculated by the

sensor network. The sink node receives the data

transmitted by each cluster and transmits the data to

the control center through the wireless network. The

control center calculates various fuel consumption

values by using various big data fusion algorithms.

3.2 Monitoring Network Formation

Method

In the established sensor network, the data sampling

accuracy and sampling frequency of different cluster

nodes network are different, and the influence

weight of network output value on fuel consumption

value is also not the same. Therefore, according to

the influence weight of network output on fuel

consumption value to select monitoring network.

Considering the many factors that affect the cluster

node weight, including the accuracy, relevance and

sensitivity of the monitoring parameters, it is

difficult to accurately measure the weight of cluster

nodes. Therefore, this paper adopts the weight

adjustment process based on the minimum variance

of fuel consumption, as shown in Figure 4 .

Figure 4 . Sensor network formation process.

1.Each cluster head node based fuel consumption

are measured

12

,,

n

X

XXL

, the corresponding

weights are

12

,,

n

ωω ω

L

, the measurement variance

are

22 2

12 n

σσ σ

L,,

,the weighted fusion algorithm of

nodes in a cluster is used to calculate the fuel

consumption value as

1

ˆ

n

ii

i

x

X

ω

=

=

∑

,network output

value of the mean square error can be expressed as:

2222

1

ˆ

(( ) )

n

ii

i

Ex x

σωσ

=

=−=

∑

(4)

2. In order to minimize the mean square error of

the network output value, we should minimize the

value of

2

σ

when calculating the weight value. The

Lagrangeian adjoint equation can be established by

solving Lagrange's extremum

value:

()

2

1,

11

,1

nn

niii

ii

f

ωωλ ωσλ ω

==

⎛⎞

⋅⋅⋅ = − −

⎜⎟

⎝⎠

∑∑

(5)

The equation can be obtained on the node

optimized weighting coefficients, according to the

weight and thus the formation of sensor nodes in the

network, so that the fuel consumption of the network

output of the right weight accuracy and frequency

match network data collection, monitoring to ensure

the accuracy of fuel consumption.

3.3 Network Time Synchronization

Method

In the ZigBee mesh topology constructed by this

system, because the router does not send beacons

periodically, the unicast beacons are only required

when the equipment in the network requires it.

Although the fault tolerance of the network is

improved, the nodes in the network. It is difficult to

achieve synchronization; on the other hand, due to

the different frequency of data collection in different

cluster networks, to improve the effectiveness of

data fusion of fuel consumption, we must solve the

time synchronization problem of node network.

Currently ZigBee network clock synchronization

algorithm mainly RBS synchronization algorithm,

PSN synchronization algorithm, LTS algorithm, etc.,

the system uses a DMTS algorithm, the algorithm

mechanism shown in Figure 5.

Figure 5 .Time synchronization algorithm

In FIG. 5, when the channel is idle, the sink node

adds the current timestamp 1, the start character and

the preamble to the broadcast data packet, sets the

sent information as 2 bits and sends the required

time for each bit as 3, calculate the start character

and preamble sending time is 4, the receiving node

in the broadcast packet arrival time stamp 5, record

the time at this time 6, then the receiving end of the

receiving processing delay is 7, and then adjust their

own clock is 8 . The receiving node adjusts the clock

from 9 to 10. This clock through the receiving node

to adjust the entire network to achieve the time

synchronization.

5 CONCLUSIONS

In order to meet the requirements of IMO for ships

to collect fuel consumption data, energy efficiency

management of ships is strengthened. In this paper,

aiming at the present situation of fuel consumption

deviation caused by the influence of fuel system,

power plant and navigation environment on ships, a

fuel consumption monitoring and management

system based on big data is designed. Based on the

analysis of oil-engine-environment-based

monitoring model of ship fuel consumption and

corresponding network requirements of nodes, a

multi-hop self-organizing monitoring network with

adaptive function was constructed by using zigbee

technology to ensure fault tolerance and flexibility.

In this paper, a weight-based data fusion method is

used to set up and transform the network. At the

same time, the network time synchronization

algorithm is used to ensure the validity of the data.

This method can be applied to both oil consumption

monitoring under various ship operating conditions.

And it also satisfies the needs of current ship fuel

consumption monitoring and management.

ACKNOWLEDGEMENTS

This research was supported by Zhejiang Province

College students' innovation and entrepreneurship

incubation project

(2018).

REFERENCES

1. Xiong Lin. Design of Ship Fuel Consumption

Management System Based on Compass Satellite

Communication[D]. Xiamen: Jimei University, 2015.

2. http://www.eworldship.com/html/2016/ship inside and

outside 0703/117079.html.

3. Liu Qing, Wu Yanzi. Establishment of the

forewarning management system of highway traffic

safety. Journal of Wuhan University of Technology:

Traffic Science and Engineering Edition, 2003, 27(3).

4. Shi Jingli. Global collection mechanism of ship fuel

consumption debut [J]. China Ship Inspection, 2016,

(6)42-45.

5. GUO Jian - guo, CHEN Liang.Design of Long - range

Monitoring System for Ship Fuel Consumption in

Ninghuan Shipyard[J]. Technology wind, 2013, 13:48-

49.

6. Lin Rongmou. Research on Ship Energy Consumption

Assessment Method and Energy Consumption

Prediction[D]. Xiamen: Jimei University, 2012.

APPENDIX

Shi Yiran (1994-), female, Ocean Data Mining and

Application Lab, Zhejiang Ocean University, No.1,

Haida Nan Road, Lincheng Street, Dinghai District,

Zhoushan City, Zhejiang Province.

mailbox:2579992917qq@.com,