The Numerical Simulation of Thermal Fatigue Crack Propagation on

Mold Steel

Jiangang Ding

Shanghai Aircraft Manufacturing Co., Ltd, Shanghai, 201324, P.R. China

Keywords: Mold Steel; Thermal Fatigue; Crack Propagation; Numerical Simulation

Abstract: H13 steel suffered periodic heating and cooling when used as die casting mold materials, and this will

leading to emerge thermal fatigue easily. To solve this problem, this paper studied the thermal fatigue

process of die casting mold steel by comparing the results of thermal fatigue test and ANSYS simulation

method, and try to predict the initiation and propagation of thermal fatigue cracks. In this paper, HMTH1

thermal fatigue testing machine was employed to heat and cool the specimen in periodicity, and recorded

the cycle times and crack lengths when thermal fatigue cracks were observed. The ANSYS software was

used to complete finite element simulation of the experiment and obtain the result of temperature fields,

heating stress fields and cycle crack paths of different thermal fatigue cycles. The result indicated that as the

thermal fatigue cycles up to 500 and 1000, the main crack propagated 567.29μm and 225.29μm, and

compared the simulation result under the same conditions to solve the problem of initiation and propagation

of thermal fatigue cracks better.

1 INTRODUCTION

Die casting mold is a kind of hot work mold, which

working environment is very bad. Under the service

conditions of hot and cold shock, it will appear a lot

of micro-cracks on the cavity surface of the mold,

which mostly presenting the form of radially,

parallel, and reticular, and is called the thermal

fatigue crack. Therefore, it is a kind of die failure

forms and its proportion has reached 60%~70%[1,

2]. Die casting mold requires low roughness of the

surface, it can not continue to service after the hot-

cold fatigue cracks have appeared, hence the key

point of the service life of die casting mold is the

time of thermal fatigue cracksappears.Moreover, the

factors that affect the thermal fatigue of the mold

include the cycle of different temperature, thermal

conductivity and the coefficient of thermal

expansion. The methods of thermal fatigue

performance test includes rating crack method

namely Uddeholm method, the plate specimen

method[3], etc, and one of the earliest which is

proposed by COLFIN in 1953.Compared with the

plate specimen method, the cost of Uddeholm

method is lower, resulting in its widely applied.

The Uddeholm is a method of thermal fatigue

test, which heating and cooling the rod specimens

repeatedly in high frequency induction, then

compared with the standard fingerprint to evaluate

the degree of surface cracks[4-5]. The advantages of

this method is considering the local width and the

overall breadth of the crack, andit is visual but with

the drawback that it is difficult to be quantified, and

it needs a lot of experienced engineers to evaluate

the thermal fatigue crack, which was great

influenced by subjective factors. And the test rod

heating in the induction conditions have great

difference with the actual casting conditions.The

current study for the life of die casting mold is

focused on improving the mold thermal fatigue life

from the casting mold design[6-8],mold structure[9-

12], mold material, mold processing, heat treatment

process and die casting process parameters. In the

paper, the HMTH1 thermocouple heating self

constraint thermal fatigue testing machine was

adoptedto conduct the thermal fatigue experiment

and the ANSYS software was used to simulate the

experiment. Finally, By comparing the results of the

experiment and the finite element simulation, to

explore how to improve the thermal fatigue life of

die casting mold[13].

2 THE METHOD OF THERMAL

FATIGUE TEST

In the experiment, the high frequency power was

used to heat and cool the sample for the Uddeholm

method[14], which can initiate thermal fatigue crack

in the surface of the specimen. But it can only obtain

the expansion trend of thermal fatigue crack, and can

not accurately and intuitively observe the dynamic

changes over time of the specimen’s interior

temperature field, thermal stress field. According to

the situation of the numerical simulation of thermal

fatigue crack, currently in the domestic and foreign

research, the majority of the two-dimension plane

model has been used[15, 16], yet the actual extend

of crack, mostly occurs in the 3D model. Based on

this situation, this paper used the ANSYS software

to complete finite element analysis of the H13 die

steel and gain the results of the temperature field and

thermal stress of the three-dimensional crack, and

compared with the result of the experiment to

explore the thermal fatigue crack location, crack

length and crack growth path better.

2.1 The Basic Theory of Thermal

Transmission Ways

2.1.1 Thermal Radiation

This experiment adopts the way of the

electromagnetic induction coil heating, which is a

kind of heating transference of thermal radiation.

The heat radiation refers to objects emit

electromagnetic energy, which can be absorbed and

transferred into the heat by other objects, as a kind

of the heat exchange process. Its transfer mode does

not require any medium, and the net heat radiation

between the two objects can be calculated in the

Stephen Boltzmann equation.

)(q

4

2

4

1121

TTFA −=

εσ

(1)

Where

q

is the rate of heat flow,

ε

is the

radiating rate of actual object and the numerical

value is between 0 to 1, σ is the Stephen Boltzmann

constant, which is about

428-

.m/1067.5 KW×

,

1

A

as the area of the radiating surface 1,

12

F

is the

shape coefficient from the radiation surface 1 to the

radiation surface 2,

1

T

is the absolute temperature of

radiation surface 1,

2

T

is the absolute temperature of

the radiation surface 2.

2.1.2 The Heat Convection

Thermal convection refers to the heat exchange

caused by temperature difference between the solid

surface and the contacting fluid surface. In this

experiment, adopted the way of water cooling is a

kind of transferring way of heat convection. Thermal

convection can be described by Newton cooling

equation.

)(q

"

BS

TTh −=

(2)

Where

h

is the transferring coefficient of

convection,

S

T

is the solid of surface temperature;

B

T

is the temperature of the around fluid .

2.2 The Basic Theory of The Thermal

Fatigue Crack

The fatigue process is generally divided into the

following stages, one is the formation of micro

crack; then is the extension of small crack, next is

the extension of large crack, the last one is the final

failure. The first two stages are called "period of

crack initiation”, the growth of large crack are called

as "period of crack extending". But one point should

be clear, it is almost impossible to accurately

determine the transition point of crack from crack

initiation to crack extending. The total fatigue life N

in the crack initiation period is determined by the

stress cycle numbers N

i

when fatigue crack initiation

and the stress cycle numbers N

P

when crack

propagation.

pi

NNN +=

(1)

One of the most important stage of the fatigue

process is fatigue crack initiation, its form mainly

depends on the material’s geometric structure, the

micro structure of the material and the type of

applied stress. In the analysis, it is customary to

assume that cracks usually occur at the maximum

point of the material, and the fatigue crack initiation

life in low cycle as follows.

6.0

6.0

12.0

mb

-1

1

ln

-

5.3

−−

⎥

⎦

⎤

⎢

⎣

⎡

+=Δ NN

E

φ

σσ

ε

(2)

Where

ε

Δ

is the total cyclic strain amplitude, N

is the number of load cycles,

ψ

is shrinkage rate of

the materials section,

m

R

is average stress, when in

the analysis of fatigue crack propagation, it’s usually

assuming that the fatigue crack propagation rate

a

d

/

N

d

is function of the range of stress intensity factor

KΔ

,then determining the relationship between the

crack growth rate and the propagation life as

follows:

2mm

1a

add )(

σ

Δ= C

N

(3)

the integrals:

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

⋅

Δ

⎟

⎠

⎞

⎜

⎝

⎛

−

==

∫

2

m

-1

th

2

m

-1

c

m

1

0

a-a

)(

2

m

1

1

d

σ

C

N

P

N

NP

(4)

m

1

a

⎥

⎦

⎤

⎢

⎣

⎡

Δ

Δ

=

σ

K

CC

(5)

Where a is the crack length,

c

a

is the critical

length of crack extension,

p

N

is the number of load

cycles, C, m are parameters related to the materials,

KΔ

is the range of stress intensity factor ,a

th

is the

critical length of the crack initiation.

2.3 The Sample

H13 is most commonly used in die-casting mold,

its composition is shown in Table 1, and the size of

specimen is 32mm × 18mm × 3.5mm, as shown in

Fig.1, in the middle of each sample processes a V

notch by the way of line cutting, in order to the

concentration of the thermal stress, and shorten the

time of experiment. In the bottom of the groove,

presets a width of about 1mmasthe crack source of

the experiment. Before the experiment, polishing the

surface of the specimen with sandpaper, then the

specimen is tied up with copper wire to the test

bench of thermal fatigue testing machine, set up the

experimental parameters, and conducts the thermal

fatigue test. Finally, the propagation mode of crack

is observed and the experiment record is done.

Fig.1 H13 steel sample.

Tab.1 Chemical compositions of H13 steel.

2.4 Thermal Fatigue Testing

Thermal fatigue test can be completed on the

HMTH1thermal fatigue test machine as shown in

Fig.2, which can automatically control the heating

temperature, cooling time and record the numbers of

cycle. The high-frequency coil heating method is

used in the experiment, and the heating time is 3

seconds and the heating temperature is 680 ℃.Then

adopt the cooling way of spray water and the cooling

time is 6 seconds, the temperature is 95 ℃ after

cooling. The first experiment was conducted with

500 cycles of thermal fatigue, and then took out of

the specimen from the machine and removed the

surface oxide of the specimen with dilute

hydrochloric acid, then polished the surface and

analyzed the total length of crack expansion and the

path of crack propagation with Nikon

MA100inverted microscope and UPO image

software. After that, every 500 times is a hot and

coldcycle, and record the length of the fatigue crack

and direction of crack propagation after each cycle,

until the end of 10000 cycles.

Fig.2 Thermal fatigue testing machine.

3 ANALYSIS AND

OBSERVATION OF THERMAL

FATIGUE CRACK

3.1 The Analysis of Surface Crack of

the Die Mold

Thermal fatigue crack is one of the main failure

forms of hot work die/mold, which is commonly

known as thermal cracks. It is caused by the thermal

stress of the material. Under the function of the

thermal stress[14], due to the repeated and systolic

strain, making the materials produce a continuous,

local and permanent organizational changes. And the

heat cracks usually occur in the surface of mold

cavity, leading to the changes of the stress

distribution state, and when the thermal crack grows

to a certain length,as the plastic strain, resulting in

the stress relaxation and the crack stop expanding.

But along with the gradual increase of the

alternating hot and cold cycles, some small holes

appear around the tip of the crack and gradually

developing into micro cracks, and then will merge

with the cracks at the beginning of the formation

continue to expand. Eventually, those cracks

connected with each other to form a kind of serious

network cracks, leading to failure and seriously

affecting the surface quality of products as shown in

Fig.3.

Fig.3 Thermal fatigue crack of the hot work mold surface.

3.2 The Observation of Thermal

Fatigue Cracks

In this paper, due to the limited experimental

conditions and the practical application condition for

H13 die casting mold, and the crack initiation length

of thermal fatigue is defined as 0.3 mm, and only

take the first 3000 cycles to be accurately analyzed

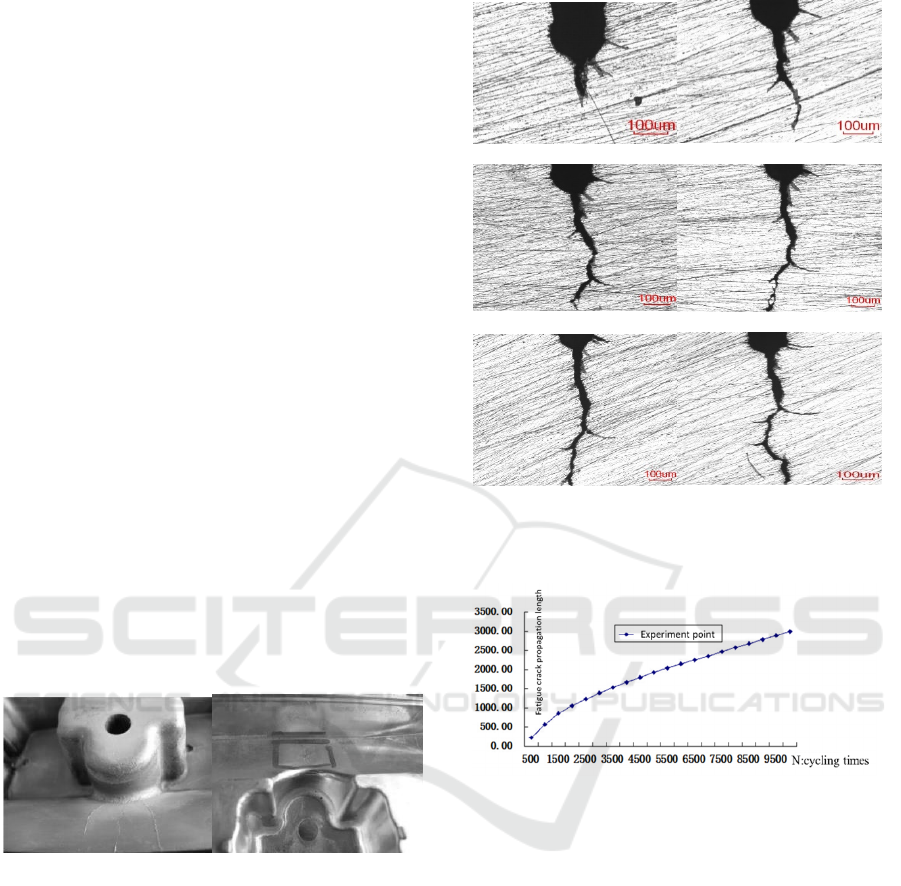

as shown in Fig.4 and Fig.5.

(a)500 cycles (b)1000 cycles

(c)1500 cycles (d)2000 cycles

(e)2500 cycles (f)3000 cycles

Fig.4 Crack growth after different cycles of thermal

fatigue test.

Fig. 7 A diagram on the connection between N

cycling

times and crack propagation length.

The crack initiated at the local of the V type

notch, as the hot and cold alternating thermal stress

in the material. When the thermal fatigue cycles are

500 times, three cracks occurred at the gap, and the

main crack at the notch has expanded 225.29 μmas

shown in Fig.4(a).When the thermal fatigue cycles

are 1000 times, as shown in Fig.4(b), a crack in the

notch continues to expand, which has extended to

567.29 μ m, but the other two cracks don’t continue

to expand clearly. As the concentrate stress in the V

type notch, it’s easier to produce cracks, and a

second crack occurs based on the main crack; when

the thermal fatigue cycles up to 1500 times, as

shown in Fig.4(c)the thermal fatiguecrack has

reached to 860.82 μm, and a second thermal fatigue

crack has appeared again. As can be seen in

Fig.4(d), when the cycles are 2000 times, the length

of the crack up to 1057.54 μm. Finally, when the

thermal fatigue cycles reach to 2500 times and 3000

times, the thermal fatigue cracks have extended to

1229.06 μm and 1391.86 μm, and appears two

second cracks as shown in Fig.4(e) and

Fig.4(f).Combined with Fig.4 and Fig.5, it can be

concluded that with the increase of the thermal

fatigue cycles, after the thermal fatigue crack has

initiated, the rate of the primitively crack

propagation is very high, and then the speed

decreases gradually and tends to be stable at last.

4 THE NUMERICAL

SIMULATION OF THERMAL

FATIGUE

4.1 Numerical Simulation of Thermal

Stress

The parameters of H13 such as the coefficient of

linear expansion, the coefficient of thermal

conductivity, elastic modulus, ultimate strength, and

yield stress are shown in Tab.2

Table 2 The physical parameters of the H13.

CT

0

)( KW ⋅m

λ

10

)(

−

C

α

MpaE

)(Mpa

b

σ

)(Mpa

s

σ

20 25.0

6

100.10

−

×

227000 1790 1100

100 25.9

6

109.10

−

×

221000 1748 900

200 27.6

6

104.11

−

×

216000 1710 810

300 28.4

6

102.12

−

×

208000 1650 708

400 28.0

6

108.12

−

×

200000 1580 600

500 27.6

6

103.13

−

×

192000 1400 398

600 26.7

6

106.13

−

×

190000 1100 208

The temperature of the simulated sample will

change in the process of heating and cooling, and the

parameters of simulation are set to heat 3 seconds at

the temperature of 680 ℃, and cold 6 seconds at the

temperature of 95 ℃.

The analysis of thermal stress, actually that is the

coupling analysis between two physical fields of the

thermal and stress, and due to the change of load

temperature over time, it belongs to the transient

thermal analysis. ANSYS provides two analysis

methods of thermal stress, the direct method and the

indirect method [16].The direct method adopts the

coupling unit with temperature and displacement

degrees of freedom, then gets the results of the

analysis of thermal stress and structure-stress at the

same time; while the indirect method is carrying on

the thermal analysis at the first, and then obtaining

the node temperature, which is applied to the

analysis of structure stress as body load.

In this paper, using the direct method for the

thermal stress analysis, in the pretreatment, the unit

of Coupled Field, Scalar Tet 98 was used to define

the material parameters of H13 steel as shown in

Table 2. Then the three dimensional model is built

and meshed, adopting the way of free type mesh,

and refine the meshing of the V notch part of the

specimen as shown in the Fig.6,and then applying

cyclic load of the thermal fatigue. At last, obtaining

the temperature fields and the mises equivalent

stress fields respectively, as shown in Fig.7 and

Fig.8.

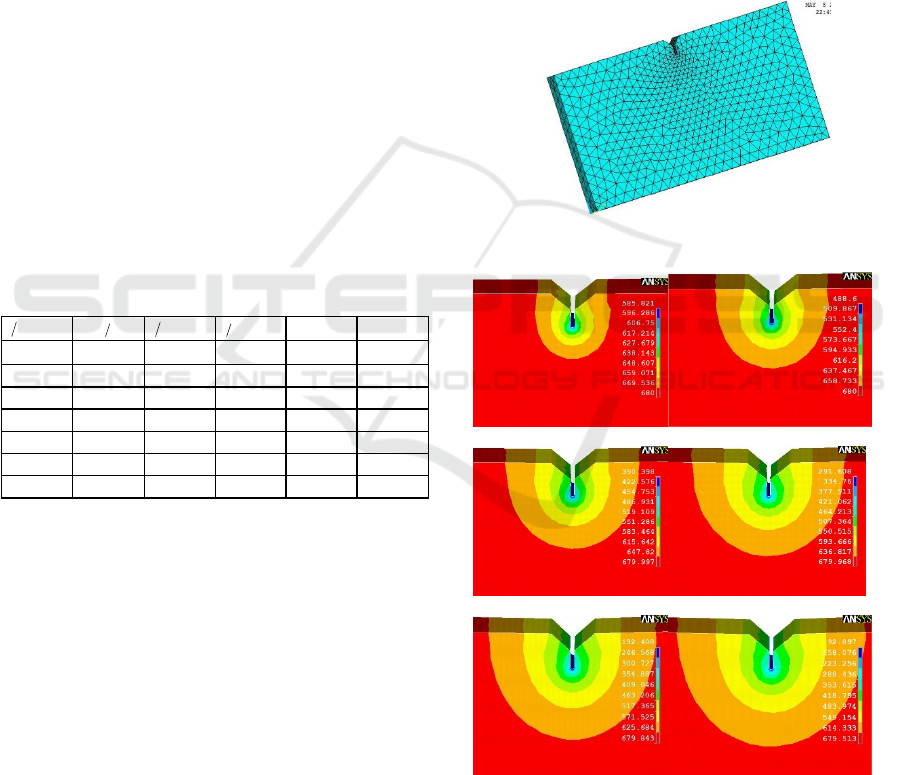

Fig.6 The meshed model.

(a) (b)

(c) (d)

(e) (f)

Fig.7 The different cooling time of the temperature fields:

(a) 0.1s, (b) 0.2s, (c) 0.3s, (d) 0.4s, (e) 0.5s, (f) 0.6s.

(a) (b)

(c) (d)

(e) (f)

Fig.8 The different cooling time of the mises equivalent

stress fields: (a) 0.1s, (b) 0.2s, (c) 0.3s, (d) 0.4s, (e) 0.5s,

(f) 0.6s.

As given inFig.7 and Fig.8, in each process of

the heat cycle, getting the temperature field and

stress field changing with time. It can be seen in the

process of cooling with water, the temperature in V

groove of the specimen reduces by the time changes

gradually. At the cooling time of 6 seconds, the

temperature in the position of crack tip reaches a

minimum value at 92.897 ℃,and the distribution of

temperature field basically makes the crack tip as the

center of a circle, presenting as a semicircle shape.

The more closer to the center position, the more

lower the temperature is, as the center of a circle

cooling in water, and it transfers heat in the way of

heat convection, leading to the lower temperature.

As presents in Fig.8, the maximum equivalent

stress is in the red region, and it is the position to be

easiest occurred crack initiation and propagation at

the different points of the time. But the maximum

equivalent stress of the v groove position (the red

zone) does not change with the time, and through the

verification of the experiment, which is basic

consistent with the position of the crack initiation,

therefore the position of thermal fatigue crack can be

predicted by the simulation effectively.

4.2 Numerical Simulation of Thermal

Fatigue Crack Propagation Path

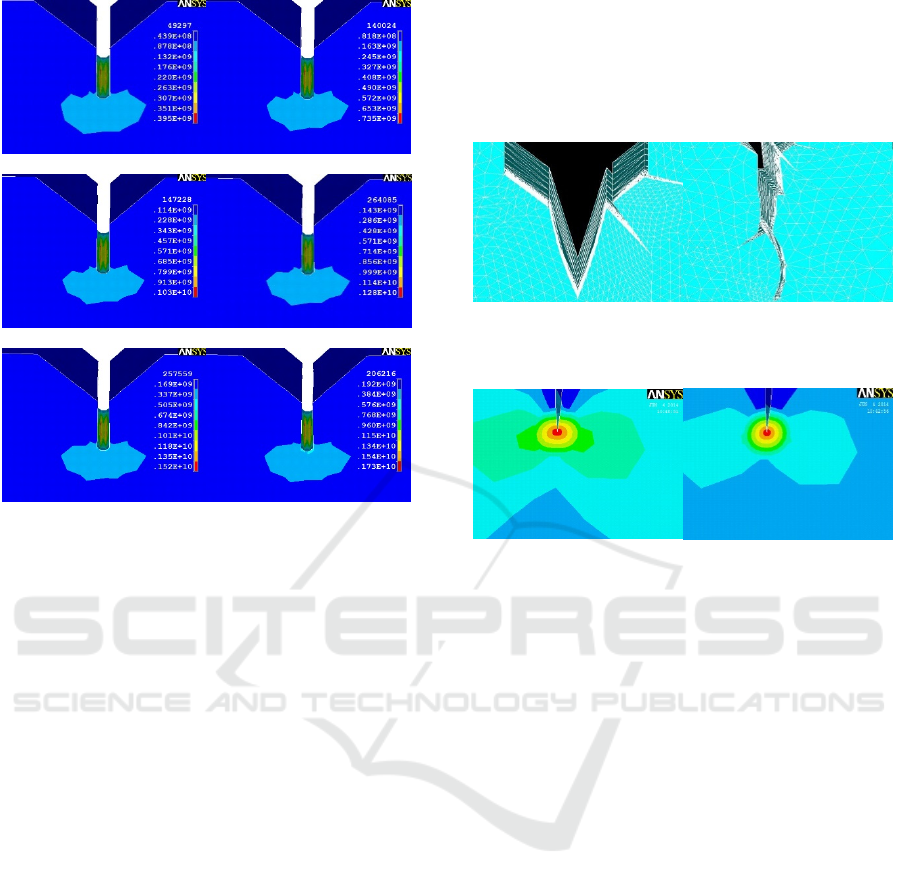

The finite element simulation results of the thermal

fatigue crack propagation path and the Von mises

stress and strain are shown in Fig.9 and Fig.10.

(a)500 times (b)1000 times

Fig.9 Crack growth paths after different cycles of thermal

fatigue test. a 500 cycles. b 1000 cycles

(a)500 times(b)1000 times

Fig.10 The Von mises stress and strain in 500 cycles. a

The Von mises stress. b The Von mises strain.

Fig.9(a) shows the thermal fatigue propagation

path of the specimen under cycles of 500 times, and

the main crack has extended to 231.58 μm. During

the cycle of heating, the thermal strain produced due

to the heat expansion of the specimen, and the two

sides of specimen are bonded by copper wire,

causing the compressive stress. When the stress

exceeds the yield limit of the material, the

compressive plastic deformation will be induced.

While in the process of cooling, the specimen will

appear shrink deformation, but due to the

unrecoverable plastic deformation, resulting in the

tension stress, which is perpendicular to the crack

surface, causing the open of the crack. It can be seen

in Fig.10(a) and Fig.10(b),the Mises equivalent

stress and strain in the position of crack tip is the

largest, and it’s also the most easily extensible place

for cracks. With the thermal cycle times increased

gradually, the opening displacement of the crack

will increase gradually. The length of the main crack

increased to 580.62 μm, when the thermal fatigue

cycles up to 1000 times. Compared the Fig.10(a)

with Fig.4(a), and Fig.10(b) with Fig.4(b)

respectively, it can be found that the results of the

experiment is in accord with the ones of numerical

simulation analysis in the path of thermal fatigue

crack propagation and the position of crack

occurring. It indicated that the fatigue cracks can be

more accurately predicted in the path of thermal

fatigue crack propagation and the position of crack

occurring.Therefore, it will provide guidance for the

prevention of die casting mold’s failure in the actual

production.

5 CONCLUSION

The thermal fatigue experiment indicated that with

the increase of the thermal fatigue cycles, after the

thermal fatigue crack has initiated, the rate of the

primitively crack propagation is very high, and then

the speed decreases gradually and tends to be stable

at last.

The finite element simulation results indicated

that the thermal fatigue crack easily appears at the

area of maximum concentration of thermal stress

and also easily to be produced at the position with

larger difference of temperature. Besides, at the tip

of the thermal fatigue crack, it is easier to expand at

the position of the largest mises equivalent stress

and strain.

Compared with the results of the experiment and

the simulation, it can be found that the results of the

experiment is in accord with the ones of numerical

simulation analysis in the path of thermal fatigue

crack propagation and the position of crack

occurring. Therefore, it will provide guidance for the

prevention of die casting mold’s failure in the actual

production.

REFERENCES

1. Wang RB. Research on failure analysis and selection

andstrengthen treatment of die-casting die of the

aluminum alloy [J]. Die Mold Manufacturing, 2008.

2. Leo B. Prediction of life to thermal fatigue crack

initiation of die casting dies[J].International

Conference on Tooling, 1999, 5:225-234.

3. Chemvavsk A. Method of analysis of development of

a network of thermal cracks[J]. Strength of Materials,

1990, 22:404-412.

4. Zhu RC, Li YD, Wang CY, et al Thermal fatigue

analysis of aluminum alloy die casting mold[J].

Special Casting Nonferrous Alloys, 2010, 30:224-226.

5. Fu MW, Lu J,Chan WL. Die fatigue life improve-ment

through the rational design of metal-forming

system.Journal of Materials Processing Technology,

2009, 209:1074-1084.

6. Tian GH. Analysis of the factors affecting thedie-

casting die life[J]. Die Mould Industry, 2005, 1:54-

58.

7. Fu M W, Yong M S, Muramatsu T. Die fatigue

lifedesign and assessment via CAE simulation[J].

International Journal of Advanced Manufacturing

Technology, 2008, 35(9-10):843-851.

8. Zhang H, Lu Z. Thermal deformation of die casting

die and its counter-measures[J]. Special Casting &

Nonferrous Alloys, 2006, 26:229-230.

9. Srivastava A, Joshi V, Shivpuri R. Computer

modeling and prediction of thermal fatigue cracking in

die-casting tooling[J]. Wear, 2004, 256(1):38-43.

10. Damjan Klobčar, Janez Tušek. Thermal stresses in

aluminium alloy die casting dies[J]. Computational

Materials Science, 2008, 43(4):1147-1154.

11. Long A, Thornhill D, Armstrong C, et al. Predicting

die life from die temperature for high pressure dies

casting aluminium alloy[J]. Applied Thermal

Engineering, 2012, 44(2):100-107.

12. Ming Y, Sun Z L, Qiang Y, et al. FEM Simulation of

Initial Cracking Process Due to Thermal Fatigue[J].

Journal of Northeastern University, 2007,

28(12):1741-1744..

13. Paffumi E, Nilsson K F, Taylor N G. Simulation of

thermal fatigue damage in a 316L model pipe

component[J]. International Journal of Pressure

Vessels & Piping, 2008, 85(11):798-813.

14. Fajdiga G, Sraml M. Fatigue crack initiation and

propagation under cyclic contact loading[J].

Engineering Fracture Mechanics, 2009, 76(9):1320-

1335.

15. Remes H, Varsta P, Romanoff J. Continuum approach

to fatigue crack initiation and propagation in welded

steel joints[J]. International Journal of Fatigue, 2012,

40(40):16-26.

16.

Shang D G, Yao W X, Wang D J. A new approach to

the determination of fatigue crack initiation size[J].

International Journal of Fatigue, 1998, 20(9):683-687.