Influence of Superabsorbent Polymers on the Mechanical Properties

and Shrinkage of Pavement Concrete

Xiao Qin

1

*, Zhihui Chen

1

, Zhenghua Lyu

1

and Aiqin Shen

1

1

School of Highway, Chang’an University, Middle-section of Nan'er Huan Roat, Xi’an, China

Keywords: Superabsorbent polymer, Internal curing, Mechanical strength, Shrinkage, Mechanisms.

Abstract: This paper examines the effect of superabsorbent polymers (SAPs) with varied particle sizes and contents

on the mechanical strength and shrinkage of cement concretes. SEM measurements were performed to

identify the mechanisms of internal curing. It was shown that the incorporation of SAPs generally increased

the compressive strength and shrinkage resistance capability of specimens, especially the relatively small

particle sizes. A large number of hydration products were generated and grouped around the remained pores

of SAP, which could enhance the hydration degree and improve the compactness of cement concretes, as

well as the performance growth.

1 INTRODUCTION

Nowadays, High-performance concrete (HPC) has

been increasingly promoted for use in road

egngineering because of its potential durability

benefits, which normally has a low water-to-cement

(w/c) ratio of 0.20–0.38 [1]. However, water is

insufficient to promote complete hydration of

cement under compact conditions in concretes with a

w/c ratio below 0.42 [2]. The above problem will

result in an early-age autogenous shrinkage and a

strength difference between interior and surface of

cement concrete, probably reducing the long-term

properties of cement concrete.

Superabsorbent polymers are cross-linked

polymer networks able to swell in solution. These

reservoirs can absorb significant amount of water

either during mixture and release water gradually

during concrete hardening [3]. The released water

contributes in restoring part of the water that has

been lost through autogenous or drying shrinkage,

achieving the curing effect. In addition, water

released from SAPs could also contribute to the

hydration of unhydrated cement particles, thereby

improving the microstructure and, as a result, the

durability of the materials [4].

The effect of SAPs on the shrinkage behavior

and mechanical properties of cement concretes have

been investigated by several researchers [5]. The

results have indicated the effectiveness of SAPs in

reducing the autogenous shrinkage. For the

mechanical properties, some researchers discover

that the strength of cement concretes with SAPs

would be reduced, while the other researchers find it

increased. These phenomena indicate that the

swelling capacity of SAPs has not been accurately

assessed till now, because the swelling capacity is

influenced by several factors, including the SAP

variety, partical size and content, especially the ionic

concentration of different cement grout[6–7].

As a thin plate with large area exposed in the

envirnment, concrete pavements could be more

easily to crack than concrete structures. However,

the applications of SAPs are mainly on structural

concretes, except the pavement concretes. Thus the

influence of SAPs on the mechanical properties of

pavement concrete has not been explored presently .

The goal of this article is to elucidate the effect

of a variation in the particle sizes and content of the

SAPs on the strength and shrinkage resistance

capability of pavement concretes modified with

SAPs. Swelling capacity of SAPs in the cement

grout was meansured by the tea bag method. Cement

concretes with additions of various SAPs were

prepared for testing. Mechanical strength and

shrinkage strain were investigated using flexural

strength test and displacement sensor, respectively.

Ultimately, the mechanisms of internal curing on

pavement concrete were explored using Scanning

Electron Microscope (SEM).

2 EXPERIMENTAL METHODS

2.1 Materials

Ordinary Portland cement (PO. 42.5) was employed

with a Blaine fineness of 365 m

2

/kg and the

following chemical composition in wt.% (SiO

2

:

22.06, Al

2

O

3

: 5.13, Fe

2

O

3

: 5.25, CaO: 64.37, MgO:

1.06, and SO

3

: 2.03). Its physical and mechanical

properties are shown in Table 1. The coarse

aggregate (limestone) was divided into 4.75~9.5 mm

and 9.5~19.00 mm and the mixing ratio was 1:4. The

fine aggregate was river sand with a fineness

modulus of 2.6 and an apparent density of 2.65

g/cm

3

.

Table 1: Physical and mechanical properties of cement.

Blaine

specific

surface

/(m

2

/kg)

Setting time

/min

Compressive

strength

/Mpa

Flexural

Strength

/Mpa

336

Initial

set

Final

set

3d

28d

3d

28d

210

270

27.4

54.8

6.1

8.7

A polycarboxylic acid type high performance

water-reducing admixture with 26% water-reducing

rate was used. Polyacrylicacid-based SAP were used

with a dry particle size of 380-830 μm (SAP 1), 180-

380 μm (SAP 2) and 120-150μm (SAP 3) (Figure 1).

(a) (b)

Figure 1: (a)SEM image of SAPs, (b) SAP after swelling.

2.2 Mixture Proportions

Cement concrete with 0.31 w/c was used in the

study. The contents (the proportion of cement) of

SAP and the extra water absorbed by SAPs could be

determined by its swelling capacity in cement grout

(The measuring procedure is shown in Figure 2) and

the Powers formula (Eq.1), the results are presented

inTable 2. Dry SAP powders were mixed with

cement before the wet-mixing procedure of cement

concrete. And the extra water was added together

with the common water and the water reducer.

Figure 2: The meansuring procedure of swelling capacity

of SAPs by the tea bag method.

The Powers formula is shown in Eq.1:

w/c≤0.36,(w/c)

e

=0.18(w/c)

(1)

Table 2: Compositions of cement concrete.

2.3 Experimental Testing

The flexural strength test was conducted using

concrete beams (100mm×100mm×400mm)

experienced 3 days’ and 7 days’ curing with three-

point loading according to ASTM C78. A material

testing machine was utilized to perform the flexural

strength test and the average results of three

specimens were obtained and reported.

The shrinkage test was performed by a high

precision displacement sensor system at a standard

environment (20±2 °C, 80% RH) continuously from

1 day to 7 day, which is the most crucial period to

the concrete cracking, as shown in Figure 3.

Figure 3: The displacement sensor system.

The microstructure of the concretes cured by

SAPs was measured using the SEM.

3 RESULTS AND DISSCUSSION

3.1 Flexural Strength

The flexural strengths of the control concrete

without SAP and the internal curing concretes with

different paticle sizes and contents of SAP are

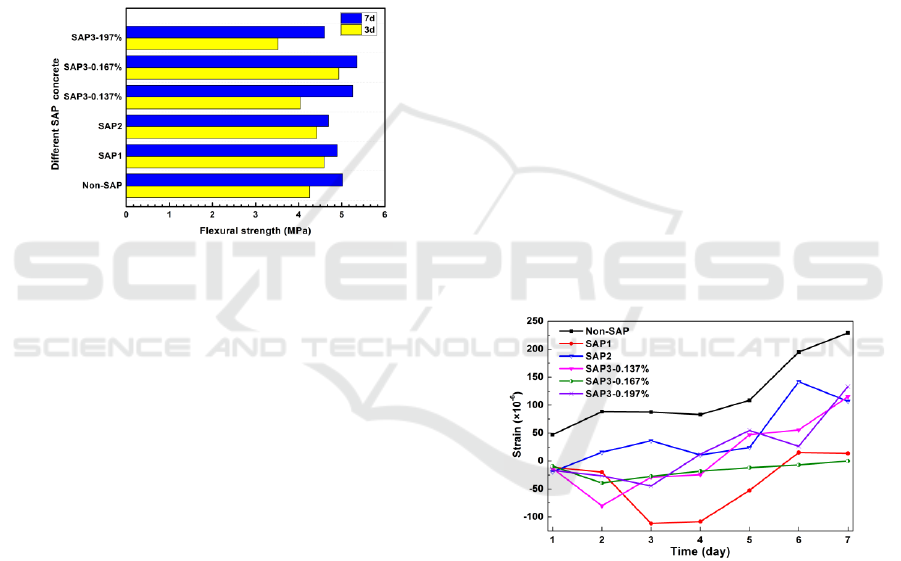

presented in Figure 4. The results correspond to

flexural strengths at 3days and 7 days of curing, .

Figure 4: Flexural strength of different internal curing

concrete.

It can be concluded from Figure 4 that the

addition of SAPs studied here is not always

accompanied with a decrease in the strength of

concretes as the references mentioned before. For 3

days’ concretes, the flexural strength of SAP 1, SAP

2 and SAP 3-0.167% (with the same extra water) are

overall higher than that of the concrete with no SAP.

It means that an appropriate extra water for internal

curing plays a critical role in the mechanical

property of concrete. On the contrary, inadequately

extra water would decrease the curing effect while

excessively extra water may increase the effective

w/c (0.31), reducing the concrete strength, such as

SAP 3-0.137% and SAP 3-0.197%, respectively.

Interestingly, although the flexural strength of

SAP 3-0.137% is 5.09% lower than that of the Non-

SAP on the 3rd day , it surpasses the latter for about

5% in the 7th day. It can be explained by the internal

curing effect played by SAPs during the days from

3-7, meanwhile this effect could promote the

hydration process of the cement, which can also

enhancing the degree of compaction and making up

for shortage of the SAP pore that occured in early

stage.

It is worth noting that the flexural strength of

SAP 1 and SAP 2 is 7.78% and 3.89% higher than

the concrete with no SAP on the third day , however,

they are 2.54% and 6.60% lower than the latter on

the seventh day. Due to the relatively large particle

size and quick water-release speed of SAP 1 (380-

830 μm) and SAP 2 (180-380μm), the internal

curing effect of these two SAP are excellent, which

can restrain the shrinkage cracks that would

probably generated in the first three days, thus the

flexural strength could also be improved during the

same period.

Unfortunately, the water-release speeds of SAP 1

and SAP 2 make them release water prematurely in

the first three days, thus there is no enough time for

SAPs to cure the concrete gradually and adequently.

In addition, the remained pores generated from SAP

could not be filled with hydration products from day

3 to day 7 due to the useless water release of SAPs

in the first three days, which is not good for the pore

structure of concrete. Consequently, the flexural

strength of SAP 1 and SAP 2 are all lower than that

of Non-SAP.

3.2 Shrinkage Strain

Figure 5 exhibits the shrinkage of the concretes with

and without SAPs from the first day to the seventh

day continuously.

Figure 5: Shrinkage strain of different internal curing

concrete.

It is seen that the addition of SAPs can

significantly reduce the shrinkage strain in the early

days, which can minigate the risk of cracking for

concrete. In the first three days and with the same

amount of extra water, SAP 3-0.167% achieves the

best shrinkage property, then the SAP 2, SAP 1. It

can be indicated that the number of particles and

distribution of SAP 3 gel in the concrete is more

uniformly than SAP 2 and SAP 1 (with the same

amount of extra water), thus the range for internal

curing of SAP 3 is wider than the rest, which can

reduce the capillary force of concrete effectively.

Accoring to the datas at the seventh day, it can

be found that SAP 3-0.167% obtains the best

shrinkage property again, immediately followed by

the SAP 1, SAP 2, SAP 3-0.137% and SAP 3-

0.197%. These results can be explained that

inadequately extra water (SAP 3-0.137%) could not

reduce the capillary force and shrinkage strain, and

excessively extra water is unnecessary for the curing

process, which always accompanied with a side

effect.

3.3 Microcosmic Mechanism

SEM measurements were performed to identify the

microcosmic mechanism of the concretes cured by

SAPs. As exhibited in Figure 6, the hydration

products are highly crystalline into the remained

pore of SAP, together with the shrivelled SAP.

Furthermore, the shape of the pore is sphere, which

can also plays a air entraining role and optimizes the

pore strctucture on the cement concrete.

Next, the release of extra water adsord by SAP

can accelerate the hydration process of cement

concrete, enhancing the degree of compactness and

flexural strength.

Figure 6: Microstructure of the concrete cured by SAP.

4 CONCLUSIONS

The mechanical strength and shrinkage strain of

cement concretes with and without SAP were

investigated using flexural strength test and

displacement sensor, respectively. On this basis,

reinforcement mechanisms of SAP were revealed by

using SEM.

Based on the results presented in this paper, the

following concluding remarks can be drawn:

(1) SAP 3 with appropriate amount of extra

water obtained an excellent flexural strength and

shrinkage property in 7 days.

(2) Inadequately extra water would decrease the

curing effect while excessively extra water may

increase the effective w/c, reducing the concrete

strength.

(3) An appropriate water-release speeds of SAP

for at least 7 days was imperative.

(4) A large number of hydration products were

generated and grouped around the remained pores of

SAP, which could enhance the hydration degree and

improve the compactness of cement concretes.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the financial

supports from the Fundamental Research Funds for

Central Universities (No. 310821175014) of

Chang’an University and the Nation Science

Foundation Project (51778061). Special thanks are

expressed to Dr. Xiaolong Sun for his assistance

with the experimental and data analysis works.

REFERENCES

1. Hasholt, M. T., Jensen, O. M., Kovler, K., &

Zhutovsky, S. (2012). Can superabsorent polymers

mitigate autogenous shrinkage of internally cured

concrete without compromising the strength?

Construction & Building Materials, 31(31), 226-230.

2. Zhutovsky, S., Kovler, K., & Bentur, A. (2013). Effect

of hybrid curing on cracking potential of high-

performance concrete. Cement & Concrete Research,

54(54), 36-42.

3. Mignon, A., Snoeck, D., Schaubroeck, D., Luickx, N.,

Dubruel, P., & Vlierberghe, S. V., et al. (2015). Ph-

responsive superabsorbent polymers: a pathway to

self-healing of mortar. Reactive & Functional

Polymers, 93, 68-76.

4. Justs, J., Wyrzykowski, M., Bajare, D., & Lura, P.

(2015). Internal curing by superabsorbent polymers in

ultra-high performance concrete. Cement & Concrete

Research, 76, 82-90.

5. Deng, Z., Cheng, H., Wang, Z., Zhu, G., & Zhong, H.

(2016). Compressive behavior of the cellular concrete

utilizing millimeter-size spherical saturated sap under

high strain-rate loading. Construction & Building

Materials, 119, 96-106.

6. Zhutovsky, S., Kovler, K., & Bentur, A. (2011).

Revisiting the protected paste volume concept for

internal curing of high-strength concretes. Cement &

Concrete Research, 41(9), 981-986.

7. Kang, S. H., Hong, S. G., & Moon, J. (2017).

Absorption kinetics of superabsorbent polymers (sap)

in various cement-based solutions.Cement & Concrete

Research, 97, 73-83.