The Research Status and Analysis of Melt Spinning Pac

k

Fengdong Pi

1

,Mingyuan Du

1

,He Liao

1

, Jinhong Li

1

and Xuehui Gan*

1

1 Textile Equipment Engineering Research Center of the Ministry of Education, Donghua University, No. 2999 North

Renmin Road, Shanghai, China

Keywords: Melt spinning pack, processing level, structural optimization, development direction.

Abstract: The article briefly describes the importance of the spinning pack that is the core component of the melt

spinning equipment. The current processing technology of the spinning pack is described in detail. Based on

the structural optimization design of the spinning pack, a sorting study was performed. Finally, the

development direction of the spinning pack is pointed out in the light of the production demand in recent

years.

1 INTRODUCTION

According to the statistics, the output of chemical

fiber in China has been ranked first in the world

since 1998. In 2015, the output of chemical fiber in

China was 48.43 million tons with year-on-year

growth of 12 percent which accounting for 73% of

the world's total chemical fiber production. The

output of polyester filaments was 36.81 million tons,

an increase of 9% year-on-year, which is still the

main driving force for the growth of the fiber

market. In 2016, China’s chemical fiber production

reached 49.44 million tons, accounting for 70% of

the global total. The "13th Five-Year Development

Plan for Chemical Fibre Industry" formulated by the

China Chemical Fibre Industry Association pointed

out that it is expected that by the end of the

"Thirteenth Five-Year Plan", China's chemical fiber

production will reach 55 million tons per year1.

The core process of chemical fiber production is

spinning. The commonly used spinning methods are

classified into two types: melt spinning and solution

spinning. As the world’s public awareness of

environmental protection has increased, international

regulations on solvent-polluting environments for

chemical production have become more stringent,

and solution spinning will face severe environmental

challenges. Melt spinning is more adaptable to the

requirements of the new situation. The technology

uses no solvents, waste water, and simple

equipment, saves investment, and has the lowest

production cost. It is the most economical and most

competitive technology. Therefore, many of the

original manufacturers that used solution spinning

have adopted the melting method recently, and the

melt spinning technology has also achieved rapid

development2.

In the melt spinning process, the spinning pack,

also known as the spinning nozzle, is referred to as

the heart of the melt spinning process. It finely

filters out mechanical impurity and gel particles

doped inside the melt, and evenly and thoroughly

mixes the melt. Under a certain pressure of the

assembly, the fibers are stably and uniformly spun

out from the microcellular of the spinneret.

Therefore, spinning pack has a direct impact on the

spinnability and performance of the fiber. More and

more attention has been paid to the research on the

processing quality and structural design optimization

of spinning pack.

2 RESEARCH STATUS OF

SPINNING PACK PROCESSING

TECHNOLOGY

The spinneret is the core of the spinning pack whose

function is to accurately spray the spinning solution

through microcellular in the spinneret to spray out

the fiber bundle with a certain thickness and fine

texture3. As the parent of new synthetic fibers, its

quality is an important condition for ensuring the

quality of finished fibers and good spinning

process4. Therefore, the processing technology level

of the spinning pack is reflected in the processing

quality of the spinneret.

In the spinneret processing, foreign advanced

production technology and management technology

are still ahead of domestic companies, but domestic

companies are also catching up.

Kasen Corporation is well-known in the world

for the design and manufacture of spinnerets,

especially for the development of differentiated

fibers such as profiled and bi-component

composites, which has a very high market share. The

company's newly introduced spinneret controls the

holes’ precision to within 1μm, making it possible to

produce round holes or profiled holes with diameters

from 0.01mm to 0.1mm.

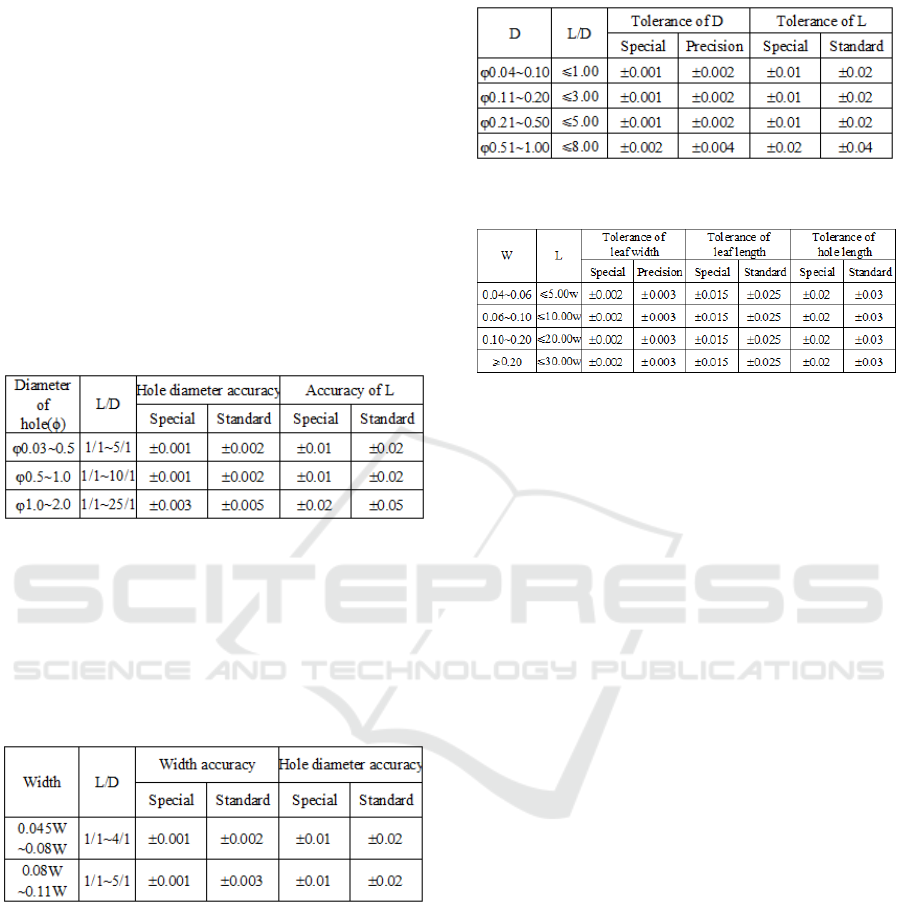

Table 1: The accuracy of round hole.

Since 1930, Nippon Nozzle has succeeded in

realizing the localization of man-made chemical

fiber in Japan, Nippon Nozzle is a leading

manufacturer of spinnerets for chemical fiber

manufacturing. The processing precision of

spinnerets for melt spinning pack is shown in Table

1 and Table 2.

Table 2: The accuracy of profiled hole.

Enka Technica is the world's leading

manufacturer of spinneret manufacturing, offering a

full range of spinnerets and spinning pack for the

melt spinning process. The average value of the

spinning holes tolerance of the product is less than

0.001mm, and the minimum diameter of the

spinning hole is less than 0.05mm.

Table 3: The accuracy of ordinaryspinneret.

Table 4: The accuracy of profiledspinneret.

Changzhou Spinning Precision Machinery Co.,

Ltd. is a state-controlled, Sino-Hong Kong joint

venture high-tech enterprise engaged in the

professional production of spinnerets, and has made

achievements in the development of varieties and

improvement of production capacity. Polyester

spinneret design and manufacturing technology is at

the leading position in the country. The precision of

spinneret of its melt spinning pack is shown in Table

3 and Table 4.

Beijing Chonglee Machine Spinning Plate Co.,

Ltd. is one of the earliest manufacturers to develop

and produce spinnerets in China, and is also one of

the manufacturers participating in the formulation of

spinneret standards. The spinnerets used in various

melt spinning, compound spinning, melt-blown

spinning and other equipment produced by the

company are spread all over the country and

exported to Russia, Iran, India and other countries.

The company now has an annual processing capacity

of 3.5~500 million holes.

After decades of hard development, we can see

from the above table that the gap between the

accuracy of domestic spinnerets and foreign

production is gradually narrowing. At present,

Changzhou Spinning Precision Machinery Co., Ltd.

and Beijing Chonglee Spinning Machine Co., Ltd.

have become the main force in the production of

spinning components in China.

3 RESEARCHSTATUS OF

STRUCTURAL DESIGN OF

SPINNING PACK

The structure and dimensions of the spinning pack

are determined by the spinning process route, the

size of the supporting winder, the size of the

spinneret, the fastening method, the feeding method,

and the installation method. There are two ways to

fasten the bolts: the bolts are screw tightening and

the bolts are self-bring fastened. There are two types

of feeding methods: upper loading and side feeding.

There are two installation methods: top loading and

bottom loading.

As the core component of spinning equipment,

many innovative designs or improvements of

spinning pack are based on certain practical

applications of production. These innovative work

have further improved the quality and yield of spun

fiber. The following three directions will be

introduced in detail.

3.1 Research on Optimization Design

of Component Filtering Structure

The filter part is an important part of the spinning

pack. The role is to remove the mechanical

impurities of the polymer melt and form a certain

melt pressure, so that the melt is evenly mixed to

form a good melt stream. When the filtering effect

of the component is not good, the melt is likely to

form a plugging hole at the spinneret and cannot be

normally spun. Generally, the filter media of the

component is mostly composed of different

proportions of metal sand or coarse-grained sea sand

and metal filter meshes, and there are also

combinations of several metal meshes with different

mesh numbers.

When metal sand or sea sand is used as a

filtering material, in addition to collecting impurities

in the melt, their sharp parts can divide the gelled

part of the polymer melt and reduce the melt

viscosity. However, the local porosity between sand

grains is also changing under the pressure of the

components. When the voidage increases, the

filtration performance decreases, and when the

voidage decreases, the pressure of the assembly

increases, shortening the life cycle of the assembly.

At the same time, varying porosity leads to uneven

polymer melt flow and inconsistent filament number

so that the quality of fiber will be affected. The

Chinese patent has adopted different number of

annular filter columns for the melt filtration between

the spinneret plate and the cover plate, which

overcomes the influence of the voidage change of

the sand filter, shortens the residence time of the

polyester melt in the module, and prolongs the time.

The service life of the spinning assembly

increases the quality and spinnability of the tow and

reduces production costs.

In view of the drawbacks of the single sand, the

Chinese patent overcomes the defects by layering

the filter sand. The filtering part is optimized to be a

coarse filter sand layer on the upper layer and a fine

filter sand layer on the lower layer. The spinning

melt is filtered through two layers of filter sand. The

u level accuracy melt is obtained, thereby extending

the service life of the spinning assembly and

ensuring the quality of each monofilament.

In recent years, there have been more and more

studies on alternative sands. Japan TMT’s patents

use a polygonal section metal short fiber filter as

part of the filter section. The filter also has the

function of refining the gel-like portion of the

molten polymer as the granular filter material. The

advantage is that the volume of the spinning pack

can be reduced several times, and the internal

structure of the module is more compact. However,

attention should be paid to the fact that the position

of the spinning pack and the position of the blower

cooling device must be adjusted after the filter

section becomes smaller. However, the filling space

for this type of assembly is relatively large and the

retention time becomes longer. In addition,

deterioration caused by heat aging is liable to occur,

which is a main cause of yarn breakage and uneven

yarn quality.

3.2 Research on Assembly Structure

Design of Spinning Pack

The traditional spinning pack is the assembly of

spinnerets and other components into the interior of

the assembly cavity, and then bolted and connected

to ensure the overall tightness of the spinning

assembly. The spinning assembly is then placed in a

spinning box with heating and heat retention effect

for spinning process. However, this assembly

method is time-consuming and labour some. At the

same time, in order to ensure good sealing of the

spinning pack, the spinning pack must be

disassembled and cleaned frequently, which is

inconvenient. Therefore, many new ideas emerged

gradually in the assembly effect.

Zhiqiang Xuan5studied the spinning pack's use

and operating conditions and designed a crimp

spinning assembly. The spinning pack has good

overall rigidity, high precision, stable performance

and reasonable pressure design within the spinning

pack. The design completely eliminates the problem

of slurry leakage from spinning pack, and is

particularly suitable for the production of large short

fibers. It solves the problems of current thread

components that are vulnerable to threading and

inconvenient to operate, and reduces manufacturing

and use costs.

Chinese Patent discards traditional spinning

assembly type that put the spinneret, distribution

plate, filter sand cup into the spinning pack housing

in sequence. Instead, the above components are

designed into three major parts. In the premise of

guaranteeing that the feed port and the distribution

plate are not disassembled, the spinneret can be

replaced quickly and conveniently, facilitating the

replacement of spinning species and the spinning

test. The design of the structure is simple and the

working efficiency is high with less heat loss.

When the melt is directly spinning, the number

of spinning stations is usually more and the spinning

box has a certain size so that it is inconvenient to

switch between spinning types. Chinese patent

provides a spinning pack which sheathed the outside

of the spin pack body for melt spinning of fine

denier filaments. The overall size of this spinning

pack coincides with the outer diameter of the coarse

denier spinning pack, so that the original coarse

denier production line can be easily converted into a

fine denier production line. Then it avoided various

problems such as unstable production and poor

physical properties due to the large gap between the

fine denier filament spinning pack and the coarse

denier filament spinning pack cavity.

Chinese patent provides a new spinning pack

without housing, locking ring, and gasket. All the

contained parts are locked together by bolts to

complete the assembly and fixation of the entire

spinning pack. The assembly eliminates the need to

fix the built-in parts such as the housing, which

saves materials, reduces processing costs, facilitates

assembly, and lowers maintenance costs. In addition,

leakage can be found in time to avoid the occurrence

of bad products.

3.3 Research on Spinneret Special

Treatment

Spinneret is the core of spinning pack. The melt is

finally extruded through a spinneret to form primary

fibers, which are then solidified by cooling to form a

filament. The effect of spinneret on the fiber forming

process is extremely important. Therefore, the

special treatment of the spinneret can directly

increase the surface quality of the inner hole of the

spinning pack and improve the quality of the spun

fiber.

Abrasive Flow Machining6 referred to as AMF.

This is a new process technology for surface

polishing and deburring workpieces with fluid

viscoelastic materials. Hongfei Zhu7used abrasive

flow machining technology to perform micro-hole

grinding on spinnerets with large long diameters.

The processing error of the shape of the bell mouth

did not occur at the orifice of the micro-hole,

indicating that the processing effect was better and

the surface quality of the micro-hole was improved.

However, He did not investigate the influence of

spinnerets on the spinning before and after

processing while he focused on the process of

processing the micro-holes in the spinneret for

abrasive flow machining.

Chinese patent covered a nano or sub-nanometer

oxide film with a thickness of 0.8 to 28 nm on the

surface or inner surface of a spinneret or embedded a

0.1 to 0.25mm thin layer of metal in the spinneret

orifice. It not only avoided the degradation of the

polymer melt, but also avoided the corrosive

substances and impurities of the melt from damaging

the inner surface of the spinning hole. And it

increased the service life of the spinneret and

reduced the scrap rate of the fiber.

4 DEVELOPMENT OF MELT

SPINNING PACK

When the melt spinning pack meets the production

demands of polyester, polyamide, and

polypropylene, with the application of

industrialization and experimentation, spinning pack

is becoming more diversified in terms of production

adaptability and the functions are also more

extensive. Based on the current research status, the

development of melt spinning pack will have the

following characteristics:

4.1 Diversification

During the spinning experiment phase, spinning

pack evolved from ordinary component to bi-

component and tri-component, while conventional

spinning pack evolved to composite, profiled, and

composite profiled spinning pack. In industrial

production, large-capacity spinning pack are more

advantageous, and the large-size spinning packs are

also more plentiful in size and type, such as twin

spinning pack and multiple spin packs in one

spinning station. As a result, spinning packs will

become more diverse as production requirements

increase.

4.2 Adaptation

The polymer melt enters the air blowing device after

being extruded by the spinning pack. The

conventional air blowing device is divided into a

side air blowing device and a ring air blowing

device, but the air blowing device can automatically

adjust the air blowing area or design as the

requirement for cooling effect is improved. In the

form of an inner ring blow, this allows the spinning

pack to be adapted to it, and the spinning pack

develops in the direction of adaptation.

4.3 Flexibility

With the continuous improvement of production

demand, such as the conversion between coarse

denier filament and fine denier filament in melt

direct spinning, to enlarge the spinning varieties and

specifications produced on the same production line,

the spinning pack are required to meet larger

production requirements with smaller changes. This

makes the components of the internal parts towards

the direction of modularity and interchange ability,

For example, rapid replace the spinneret to switch

spinning varieties, the entire spinning pack are

increasingly flexible.

5 CONCLUSIONS

After many years of development, the spinning pack

for melt spinning has been relatively mature in terms

of design calculation and processing. However, as

the production demand increases, spinning

components will be further refined in more detail.

This article only deals with component processing

technology and structure. The optimization design

made some summary descriptions, pointed out the

future direction of spinning components. It is hoped

that this will give some reference to the optimization

of spinning pack design and textile industry.

ACKNOWLEDGEMENT

Thanks very much for the support of the national

key research and development program

(2016YFB0302700) and the key research and

development project of Jiangsu Province (10317480)

during the project.

REFERENCES

1. Lin, B., Zhao, H. 2015. Energy efficiency and

conservation in china's chemical fiber industry.

Journal of Cleaner Production, 103, 345-352.

2. Wang, HP. 2001. Study on Fiber Formation

Mechanism in Melt-spinning Process and

Development of HMLS Polyester Fibers. Donghua

University.

3. Chao, Y. 2006. Numerical Analysis of Flowing for

High Polymer in Spinning Pack and Optimization the

Structural of it.Donghua University.

4. Gao, B. 2013.Research on Spinningfor Bottom Hole

Automatic Processing.Donghua University.

5. Xuan, ZQ. 2010. The Development of a New Type

Screw Conjugate Spinpack. Synthetic Fiber in

China,39(04), 23-26

6. Wu, LS., Li, YZ. 2005. Process of Abrasive Flow

Machining. Diamond& Abrasive Engineering, (01),

69-74.

7. Zhu, HF., Yang, CC. 2009. Application of Abrasive

Flow Technology in Microporous Processing of

Spinneret. Textile Accessories, 36(01), 27-29.