The Design of the Electronic Control System of Self-cleaning Pulsed

Electrooxidation Sewage Treatment Based on Photovoltaic System

Jie Shen

1

and Haichen Yu

2

1

Iinstitute of Photovoltaic applying ,Tianjin light industrial vocational technical College, No. 1 Ya Guan Road,Tianjin

,China

2

Institute of Sewage treatment solution, Tianjin Academy of Environmental Sciences, No. 17 FuKang Road, Tianjin ,China)

Keywords: PV electrochemical, catalytic oxidation, PLC, Storage control, Impulse voltage.

Abstract: In order to improve the efficiency of chemical wastewater treatment as well as the security and reliability of

systems operation, PLC light tracking technology is applied to the photovoltaic device in the system.

According to the requirements of electro-catalytic oxidation process, design the energy storage and impulse

voltage generating control system using SCM technology,to realize the sewage treatment by catalytic

oxidation of pulsed power.

1 INTRODUCTION

Solar energy is an efficient, clean and never-fail

renewable energy source. In recent years, solar

power has been widely used in various industries.

Combined with the catalytic oxidation of sewage

treatment process, solar energy can provide the

power source for electrolyzing wastewater, which

can transform and upgrade the traditional process.

In order to remove the refractory substances in

the wastewater, it is necessary to electrolyze the

wastewater with impulse voltage in the water

treatment industry. In fact, this is applying periodic

voltage to the wastewater intermittently according to

the law of time. The width and frequency of the

periodic voltage can be adjusted according to the

pollution condition of treating water and the

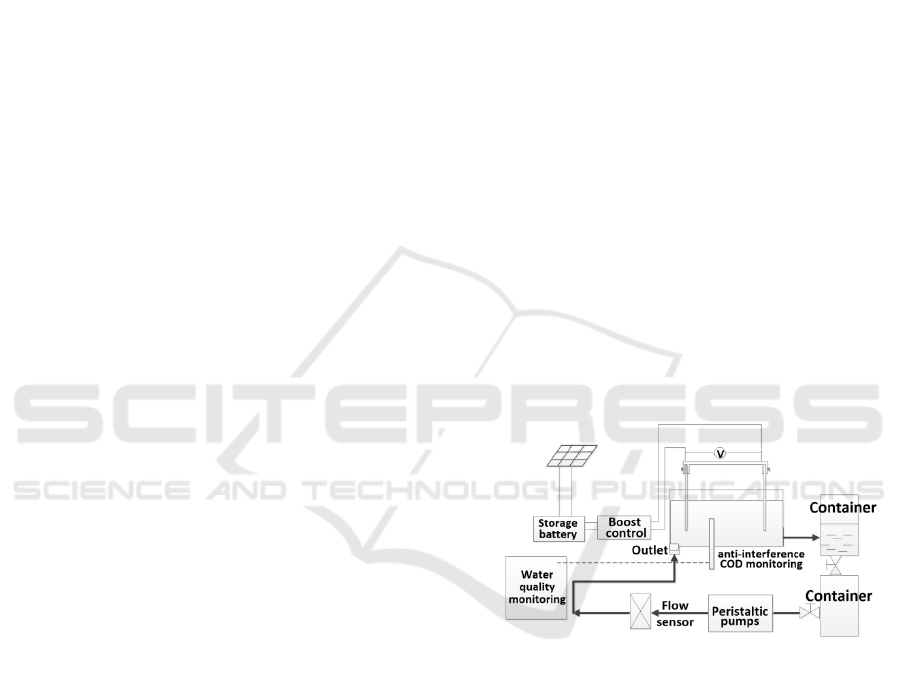

corrosion resistance of the electrode. The structure

of the sewage treatment control system based on PV

electrochemical catalytic oxidation is shown in

Figure 1.

2. SYSTEM DESIGN

This design uses PLC technology to realize the fully

automatic three dimensional rotation of photovoltaic

panels tracking the sun and it also uses SCM

technology to control the energy storage of

photovoltaic panels and the automatic adjustment of

high voltage pulse, which breaks through the

technology bottleneck that the electrode is easily

vulcanized and the service life is shortened during

the use of the electric storage appliance.

Figure 1: The structure of the sewage treatment control

system based on PV electrochemical catalytic oxidation.

2.1 Light Tracking System

Using IC200UDR040-CC as a system controller,

this system can process the incident angle of the

solar light collected by the light tracking device to

control the DC motor and adjust the angle of solar

energy plate. Realizing the function of solar energy

plate tracking solar light automatically can make the

solar energy plate face to the sun automatically,

which can improve the efficiency of photovoltaic

conversion in photovoltaic system.

There are two modes in this control system:

testing and running. In the running mode, the light

signal is converted to the electrical signal through

the photosensitive sensor, and PLC control system

receives the electrical signal and then it controls the

motor rotation. The photosensitive resistance is used

as the photoelectric sensor and the circuit is

controlled by the characteristic of the photosensitive

resistance when it meets light that makes the

resistance smaller and current conduct. Four groups

of photodiodes detect four directions respectively

through special devices, so that the system can

determine the direction of the sun by judging

whether any of the four groups of photodiodes is

illuminated. Combined with a mechanical device, it

can track sunlight. PLC determines the current state

by the instruction of the test / run button. In the

testing mode, we can control the lighting of the three

analog light sources by manual buttons to determine

whether the operation of the program and the

hardware device is normal and to test the stability of

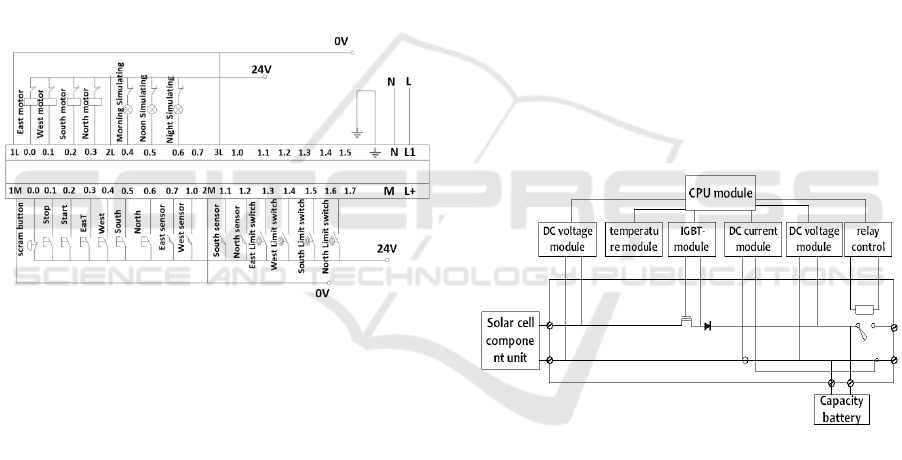

light tracking. The PLC wiring diagram of the solar

light tracking system is shown in Figure 2.

Figure 2:The PLC wiring diagram of the solar light

tracking system.

The control system determines the stopping

position automatically according to the wind speed.

When there is no wind, it does real-time tracking in

the daytime and stays at 15 degrees in the elevation

at night to ensure that the condensate can flow

down. When there is a wind, it returns to the initial

horizontal position to reduce wind resistance. The

control system switches between the day and night

modes automatically according to the time. When

the system time is in the night time, the solar light

tracking motor is in a stop working state. When the

system time is in the daytime, the motor is in a

working state.

2.2 Energy Storage Control System

This system is mainly used to detect the output

voltage and current parameters of photovoltaic cells

and control over charging, balanced charging and

float charging to the battery through the DSP.

Meanwhile, it supplies power to the DC load by

judging the over discharging protection, over current

protection, under voltage protection and other

situations in the discharging technology of storage

battery.

The system analyses and processes the collected

data of the system clock, the working state of the

electric storage appliance and so on. When there is

continuous rainy weather and the electric storage

appliance lacks power and it is unable to obtain solar

energy, the controller quickly cuts off the

discharging circuit of the electric storage appliance

and switches on the high voltage input side of the

stand-by power to provide energy for the electrolysis

system. The input side and the high voltage power of

the standby power are always in a state of circuit

breakage, so that there is no energy consumption of

the standby power. The system is consist of solar

cell component unit, DC voltage acquisition module,

temperature acquisition module, IGBT-driving

module, DC current acquisition module, relay

control module, battery pack, DC load,

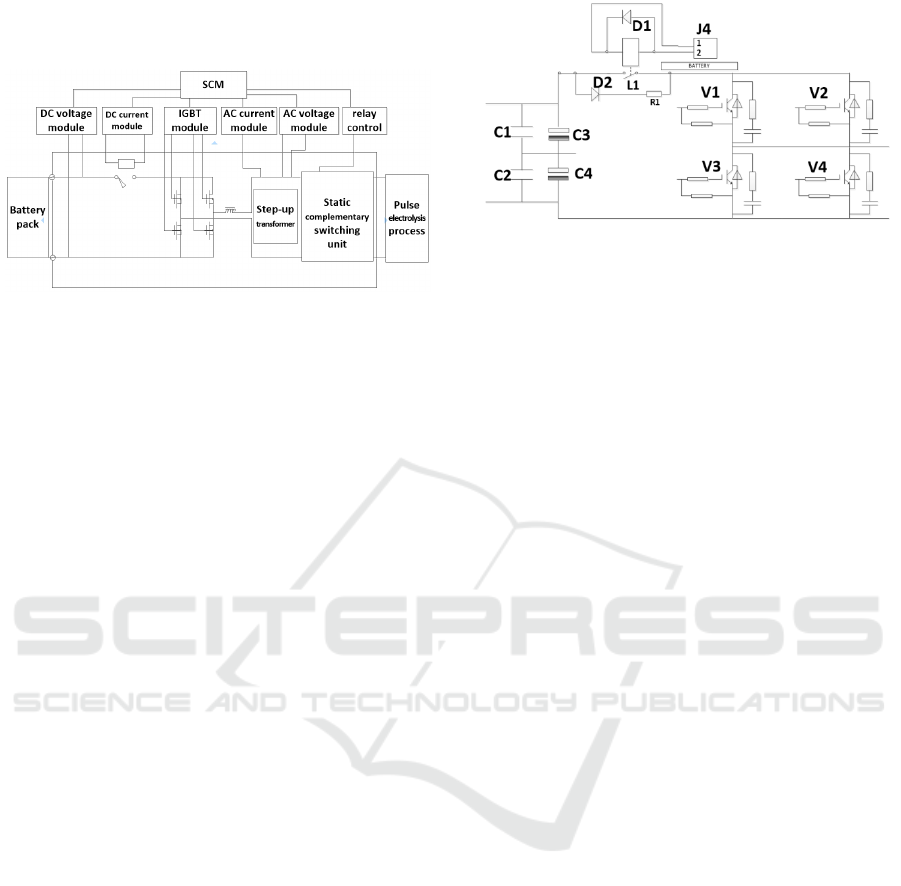

communication module and so on. Figure 3 is the

schematic diagram of the electric energy conversion

system.

Figure 3:The schematic diagram of the electric energy

conversion system.

2.3 Pulse Control System

The main power supply methods of electro-catalytic

oxidation wastewater include DC power supply and

pulse power supply. The effect of sewage treatment

by pulse electrolysis can be maintained, whose

energy consumption is lower than DC electrolysis.

In addition, impulse action can reduce sediment on

the surface of the plate and maintain high current

efficiency. According to the technical requirements

of the catalytic oxidation of sewage treatment

process and the design index of the impulse power

supply, a pulse bias power supply with a frequency

range of 10-40 kHz and a rated power of 1kW is

developed. The duty ratio is continuously adjustable

in the range of 10%-60%. The schematic diagram of

the control unit is shown in Figure 4.

Figure 4: The schematic diagram of the control unit.

Based on the control technology of SCM, IGBT

with high frequency high pressure resistance and

PWM, using high frequency transformer, this system

proposes a new system structure suitable for high

power pulse power supply. This design is made up

of voltage regulation circuit, full bridge inverter

circuit, high voltage rectifier and filter circuit, pulse

voltage output circuit and protection and control

circuit. Full bridge inverter circuit is the core part.

The single-phase full bridge inverter circuit of

Figure 5 is the inverter circuit. The V1 - V4 in the

diagram are the main inverter switch tubes. This

circuit uses voltage source type inverter—VSTI. The

DC side is the voltage source. There is a smooth

capacitor with a rectifier and filter circuit in front of

the reverse bridge, which can make the DC circuit

appear low resistance and make the DC side voltage

stable and smooth without voltage fluctuation

basically. This can provide a smooth DC current for

the full bridge inverter circuit. The DC conversion

circuit also determines and switches inverter input

current through the controller, according to the state

of the battery. And meanwhile, it can test whether

the input current meets the conversion condition

through a Hall current sensor to ensure the stability

of the output pulse signal. In this design, there is a

resistance between the grid and the emitter of the

IGBT, which is made close to the emitter,

restraining the overvoltage between the collector and

emitter. In the end, the high frequency transformer is

used to make the output voltage variable in a certain

range. And the frequency can be adjusted by the

SCM in order to meet the requirements of different

wastewater treatment.

Figure 5: Single-phase full bridge inverter circuit.

3. CLOSING REMARKS

A control system for sewage treatment based on

solar electro catalytic oxidation method is talked in

this paper, which can track the sun by the fully

automatic three dimensional rotation of solar panels

and increase the utilization of solar energy. The

design of battery charging control mode and the

automatic adjustment and control of electrolysis

pulse voltage of wastewater can reduce energy

consumption and prevent electrode corrosion

effectively.

New energy photovoltaic technology is in the

early stage and electrolysis wastewater with pulse

method is an important tendency in waste water

treatment. With the continuous development of the

use of equipment and the improvement of the

stability and reliability of pulse power supply, this

system will play a positive role in water treatment.

ACKNOWLEDGEMENTS

Fund projects: Scientific research project of Tianjin

Jinnan Science and Technology Commission 《

Design of self purification system for underground

water storage system in sponge city with green

energy》(20180120)

REFERENCES

1. ShenJie.(2011)The design of solar tracking system

based on PLC[J]. Industrial control computer,

2011( 11) :36-38.

2. Haiping Luo; HuiLi; Yaobin Lu; Guangli Liu; Renduo

Zhang.(2017) Treatment of reverse osmosis

concentrate using microbial electrolysis desalination

and chemical production cell[J].2017(4): 52-

9.

3. Zhi-junHu;You-mingLi.(2011)A Combined

Electrocoagulation electrooxidation Treatment on

CTMP Wastewater [ J ].Advanced Materials

Research 233-235.1: 619-22.

4. WangDong, xieChenxin. (2017)Research on the

treatment of domestic sewage by maritime mobile

facilities [ J ].Industrial Water Treatment

Vol.37No.12017(1).

5. Fan Chunyan.(2011)Design of high frequency and

high voltage pulse power supply controller for crude

oil dehydration [ J ]. Automation in

petrochemical industry,2011( 2) :48-50.

6. Zhou,Jing ; HeWei.(2011) Intelligent charging

controller of battery-buffered stand-alone photovoltaic

system[J].Electric Power Automation Equipment,

2011(11) : 13-17.

7. Kotha, Venkateshwarlu .Maximum power point

tracking with fuzzy logic approach for grid

connected photovoltaic system [ J ] .

International Conference on Industrial and

Information Systems, 2010 (5) : 586-589.

APPENDIX

A brief introduction to the author: Shen Jie(1981-),

female, was born in Hefei, Anhui. She is an

associate professor with a master’s degree in control

engineering. She is the director of the new energy

development center and is engaged in research on

photovoltaic system control and energy saving

engineering.

Tel:13920165996; E-mail:sj_tina@126.com