Thermal Optimization Design of PBGA Package Based on

Finite Element Analysis

Hui Yang

1

,Jihui Wu

1

and Yang Zhang

1

1

College of Mechanical and Control Engineering

,

Guilin University of Technology,Yanshan District,Guilin,China

Keywords: Tlectronic packaging, heat dissipation structure, inite element, optimization design.

Abstract: In order to solve the problem of chip heat dissipation in PBGA package, this paper takes PBGA as the

research Object to study the reliability of electronic packaging. Since the BGA package form is the main

packaging technology at present, the problem of thermal failure has been particularly prominent in BGA,

which also became the hot issues^([1]). Now a method is proposed to establish a finite element

approximation model of the package structure, perform thermal stress analysis, and reconstruct the original

optimization problem. Identify the influencing factors of thermal failure, and based on these problems,

through the establishment of mathematical model analysis, optimize the structure. And for problems that

can not be fully solved by the stablilization, the key points of future research directions are proposed and the

next step of research work is guided.

1 INTRODUCTION

At present, one of the most important failure forms

of electronic devices is thermal failure. According to

relevant statistics, due to the high temperature, the

proportion of electronic equipment failures is as high

as 55%, and from a quantitative point of view, with

increasing temperature, the failure rate will show

exponential growth, for most electronic devices,

Even lowering the temperature to a very small value

will greatly reduce the chance of its equipment

failure. It can be seen that how important the thermal

design of electronic equipment is, and that it will

receive more and more attention[2].Therefore, using

a reasonable thermal design to improve heat

dissipation is one of the key technologies to ensure

the overall reliability of electronic products.

2. TWO-DIMENSIONAL MODEL

ANALYSIS

The most common BGA package type PBGA, as

shown in Figure 2.1. The PGBA carrier or interposer

is a common printed board substrate. The chip is

connected to the upper surface of the carrier by wire

bonding, then injection moding is performed using a

plastic model, and an array of solder balls containing

the alloy components is connected to the lower

surface of the carrier[3].The array of solder balls can

appear completely or partially distributed on the

bottom surface of the device. Generally, The

diameter of the solder ball is in the range of

0.75mm-0.89mm, and the center distance of the

solder ball is 0.8mm, 1.0mm, 1.27mm, 1.5mm, etc.

The minimum is 0.5mm.

Fig.2.1 PBGA structural model diagram.

In the model, the plastic package, the chip, the

adhesive, the substrate, the board, the copper traces,

and the solder joints under the substrate constitute a

seven-layer structure that does not consider the

influence of other fine structures such as bond

wires[4-6].The purpose is to avoid the analysis.

Handle complex structures. In addition to the solder

joints, the six-layer material in the model structure is

considered to be an isotropic and evenly distributed

material. The characteristic parameters of the

material use the characteristic parameters of the

main material of each layer, as shown in Table 2.1.

Tab.2.1 Material characteristics table.

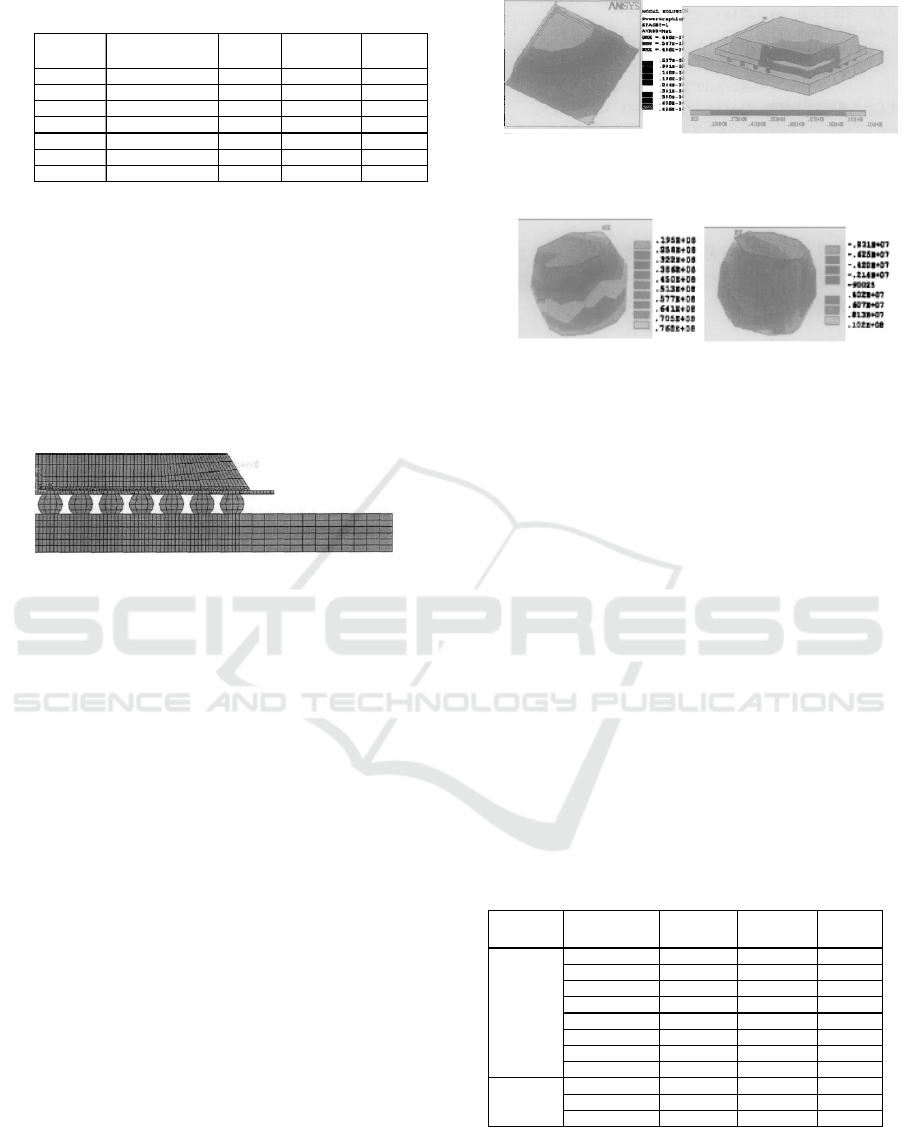

3. FINITE ELEMENT MODEL

Based on the two-dimensional model, the PBGA

three-dimensional model was established on

ANSYS. Because the package is a symmetrical

structure, a quarter structure is used here for

analysis. Using three-dimensional 10-node

tetrahedral elements for meshing, there are 30485

finite elements, there are 56432 nodes.

Fig.3.1 Meshing

Thermal cycling and heat generation analysis

considering the actual working conditions of the

package.

In the actual operation of PBGA, there will be a

stable energy applied to the chip layer. We assume

that the value is 2W. After applying energy under

normal operating conditions, a temperature

distribution will be generated in the package and it

will be a heating. The process of warming up. Now

suppose that the temperature gradient still remains in

the ambient temperature change, that is, the thermal

cycle, so the temperature distribution has an initial

temperature distribution and the resulting initial

stress before the temperature distribution increases

from room temperature 20°C to 105°C to 125°C[7-

8]Then in this way, the value of each parameter

obtained by numerical simulation will change in the

subsequent thermal cycle. Also from the thermal

deformation of the PBGA package, the equivalent

stress at the chip, and the thermal fatigue life of the

solder joint, as shown in Figure 3.2, 3.3,3.4.

Fig.3.2 Deformation Fig.3.3 von Mises Stress distribution.

Picture of PBGA Package.

Fig.3.4 Stress distribution map of key solder joints.

4.OPTIMUM DESIGN OF PBGA

PACKAGE

The optimal design of the package is to optimize the

thickness and material of each device under the

constraints of its stiffness, strength and thermal

deformation to reduce the maximum stress of the

package and enhance its reliability. However,

considering the numerical simulation analysis of the

thermal-structure of the packaged integrated circuit

chip package and the practical application of the

optimized design body, the structural self-weight

must be appropriately limited to ensure the actual

weight. Therefore, in this paper, two optimization

schemes are adopted for this situation: one is to

minimize the weight of the structure as the objective

function; the other is to minimize the maximum

stress as the objective function.

Tab.4.1 The parameters of model components material.

Mode l parts Mate rial ingredient

Elastic

Modulus

Poisson's ratio

Co e fficie nt

of expans ion

Solde r ball

63Sn37Pb 14.7 0.3 2.10E-05

PCB board

FR -4 22 0.28 1.80E-05

Subs trate

P olyimide 22 0. 28 1. 80E-05

Printed line

coppe

r

120.658 0.345 1.70E-04

Binder

Epoxy resi

n

5.2 0.3 40.0E -6

Chip

silicon 131 0.3 2.80E-06

Plas tic s e al

Resi

n

26 0.3 7.00E-06

Mate rial name Mate rial coding

El a s t i c

Modu lu s(G pa)

Coefficient of

the rmal

expansion

Poisson

rati o

A 12.4 11.6 0.3

B 12.3 12 0.3

C 11.3 12.2 0.3

D 11.8 14.2 0.3

E 12.5 12.7 0.3

F 13.8 13.2 0.3

G 14.2 13.8 0.3

H 14.7 14.5 0.3

a 0.893 55 0.35

b 1.405 45 0.21

c 2 40 0.3

Binder

Packaging

materials

5. OPTIMIZATION

The objective function is to minimize the maximum

stress on the package. Optimizing the design

variables is the choice of the thickness of each

device and the material[9.]The state variables are

considered as follows: 1.The maximum temperature

of the package after heat generation to ensure that

the initial temperature and initial stress distribution

are not large before the thermal cycle; 2. The

deformation of the package to meet the structural

rigidity requirements. 3 The weight of the entire

package to ensure that the weight of the structure

changes within a certain range, with good

application. Writing a mathematical model is as

follows: Design variable:

T

,

,

,

⋯,

t refers to the thickness of

each device

The objective function:

min

max(T)

(T) (k1,2,⋯,

)

Restrictions:

1,2,⋯

σ,w denotes stress and deformation; j,k denotes

the number of stress and deformation variables.

Tab.4.3 he result with Chip Thiekness

From the data in Table 3.2, it can be seen that,

except for the data of the temperature gradient

column, the other data is almost the same as the

trend of the data in the scenario 1. Only the effect of

stress and heat distortion is slightly different. The

greater the thickness of the chip, the smaller the

temperature gradient generated by the heat

dissipation power

. This is due to the increase

in the thickness of the chip, the volume of which

also increases, and the heat generation per unit

volume is inversely proportional to the volume, that

is, the larger the volume, The smaller the heat

generation, the lower the resulting temperature. The

reduction of the chip thickness is beneficial to

reduce the thermal stress, and the initial temperature

gradient produced by the smaller thickness chip is

also smaller, and the effect of the two causes the

thermal stress value to be greatly reduced. Analysis

from thermal deformation is more complicated. If

the heat generation of the chip is not taken into

account, the thermal deformation will become

smaller and smaller as the thickness increases; the

greater the thickness, the lower the temperature

value resulting from heat generation, and the

Structural analysis will have a reduced effect on

thermal deformation, but this part of the impact

factor is small, and the thermal deformation between

the two is still smaller with increasing thickness.

Although the greater the thickness of the chip, the

smaller the stress and deformation can be but the

weight will increase. Therefore, many aspects of the

impact of the design calculations should be

considered.

6 CONCLUSIONS AND OUTLOOK

In this paper, two-dimensional and three-

dimensional finite element models are established

for BPGA package, and the PBGA package is

analyzed due to the factors such as alternating

temperature load, heat dissipation power and forced

heat dissipation, and the thermal performance

parameters of each device are mainly thermal

conductivity and thermal expansion coefficient.

Internal thermal stress, thermal deformation and

mechanical strength issues. Based on the numerical

simulation analysis, the material and geometric

dimensions of the package are optimized and

calculated. The package model materials and

dimensions for different design requirements are

given.

Based on the numerical simulation analysis, the

entire package body was comprehensively

optimized, and the optimization design was

performed with the objective of minimizing the

Chip

thickness

/mm

0.3191 0.3309 0.3471 0.3515

Maximum

temperature/

℃

63.39 63.315 63.228 63.209

Maximum

thermal

stress/

Mpa

92 90.03 88.3 87.8

Solder joint

stress/

Mpa

62.5 62.3 62.3 62.3

Solder joint

strain

0.008478 0.008498 0.008519 0.008508

Hot

de formation

of solder

joints /

μm

48 47.6 45.9 44.4

weight and thermal stress. Among them, the analysis

of materials and geometric dimensions is mainly to

obtain a smaller elastic modulus and thermal

expansion rate can effectively reduce the thermal

stress, the thickness of the substrate and the chip is

the main factor affecting the package thermal

deformation and solder joint reliability.From the

model presented in this paper and the results

obtained, further work can be done:

a. For eutectic solder viscoplastic analysis;

b. Consider the optimization of height, width and

material of eutectic solder balls;

c. For small-size models internal structure

refinement issues.

In addition, the sequential condensation method

is used in the analysis of the heat-structure, and the

direct coupling method can also be used to perform

thermal analysis and optimization design of the

package. Due to the high practicality of this topic,

the academic fields of encapsulation include

electricity, mechanics, thermals, and materials

engineering. It is possible to consider the

combination of heat, electricity and structure to

analyze and optimize the package.

REFERENCES

1. R.Darveaux,K,Baneerji, A.Mawer,and G.Dody

Realiability of plastic ball grid array assembly in Ball

Grid Array Technology 1995,pp.379-442

2. A,Mawer,R,Darveraux,and A.M.Petrucci,Caleulation

of thermal cycling andapplication fatigue life of the

plastic ball grid array(BGA) package in Proc.1993

Int.Eleetron.Paekage.Conf.SePt.12-15,1993,pp.718-

730

3. Mustain.H.A.,Yasir,A.Q,Hassan,A.Y. and

Seetharamu,K.N. Thermo-mechanical stress Ansysis

of PBGA 1998 IEEE/CPMT Electronic Pachaging

Conference pp183-187

4. Terry Dishongh,Cemal Basaran,Alexander

N,Cartwring et al Impact of Temperature Cycle Profile

on Fatigue Life of Solder Joints IEEE Transactions on

advanced Packaging,Vol.25,No.3,August 2002,433-

438

5. Jamil A.Wakil,Paul S.Ho.Simu1ating paekage

behavior under power dissipation using uniform

thermal loading.IEEE Transaetions on advanced

Paekaging, 2001, 24, 60-65

6. Jamil Wakil,Paul S,Ho.Nonunifom temperature and

strain fields in a powered package.IEEE Transaetion

on components and Packaging

technologies,2000,23,521-527

7. [Pao Y H,Goviza R,Badgler S,Jih E.An Experimental

and Finite Element Study of Thermal Fatigue Fraeture

of PbSn Solder Joints ASME Journal of Electronic

Packaging,1993,115:34-48

8. Bryan Rodgers,Jeff Puneh,John Jarvis Finite element

modeling of a BGA package subjected to power

cyeling 2002 Inter Society Conference on Thermal

Phenomena PP.993-996

9. Integrated Circuit Packages Sony semiconductor IC

Packages Guide(1-14)

10. D.J.Xie,Z.P.Wang Process capability study and themal

fatigue life prediction of BGA solder joints Finite

Elements in Analysis and Design 30(1998)31-45

11. Kuo-Ming Chen,Kuo-Hsiung Horng,Kuo-Ning Chiang

Coplanarity analysis and validation of PBGA and

BGA packages Finite Elements in Analysis and Design

38(2002) 1165-2275