Application of Integrated Device for Produced Liquid Preliminary

Separation and Desanding in Oil Field Production

Junpeng Zhou

1

,Xiaoxi Chang

1

and Xindi Zhou

2

1

Daqing Oilfield Engineering Construction Co., Ltd. ,Kunlun Street 75,Ranghulu Daqing,Heilongjiang,China P.R.

2

School of Electrical and Electronic Engineering ,Harbin University of Science And Technology,Xuefulu Road 52,Nangang

Harbin,Heilongjiang,China P.R.

Keywords: Integrated device , Skid-mounted , Design applications

Abstract: At home and abroad ,there is a large number of theoretical and experimental research on hydro-cyclone

separation equipment, of which the research on the multiphase hydrocyclone desanding device already has

certain theoretical basis. In Daqing oilfield, desanding technology and equipment was adopted in the

produced fluid gathering and transferring process . This paper mainly introduces the application of sand

removal equipment in the oil field research.

1 INTRODUCTION

After the development and production of Daqing Oil

Field entered the stage of high water cut period,the

produced fluid composition changed a lot and the

composition became more complex. To improve oil

recovery, many key technologies, like chemical

flooding, are applied and thus lead to the obvious

sand content in the produced fluid. Long-term oil

field production practice showed that sand

deposition appears in the three-phase separator in the

process of the oil and gas gathering and

transportation and influences the oil-water

separation. This will cause severe scaling in the

heating furnace and finally lead to burning failure of

the equipment at an early stage.To solve the above

problem, preliminary separation and desanding

technology was applied in Daqing oil field produced

fluid gathering and transportation process and

special integrated equipment was designed. This

paper mainly introduces the application of integrated

device in oil field production.

2 TECHNOLOGICAL PROCESS

2.1. The Application of the Existing Sand

Removal Device

Sand Removal Device ( SRD) was specially

designed in Daqing Oil Field in the previous

produced fluid gathering and transportation process

and this causes mud existence in the whole process

and thus lead to a series of problems. To place the

preliminary separation and desanding device in the

upstream part of the gathering and transportation

process , that is , before the three-phase separator, is

expected to minimize the negative impact of mud

sediment on the gathering and transferring process.

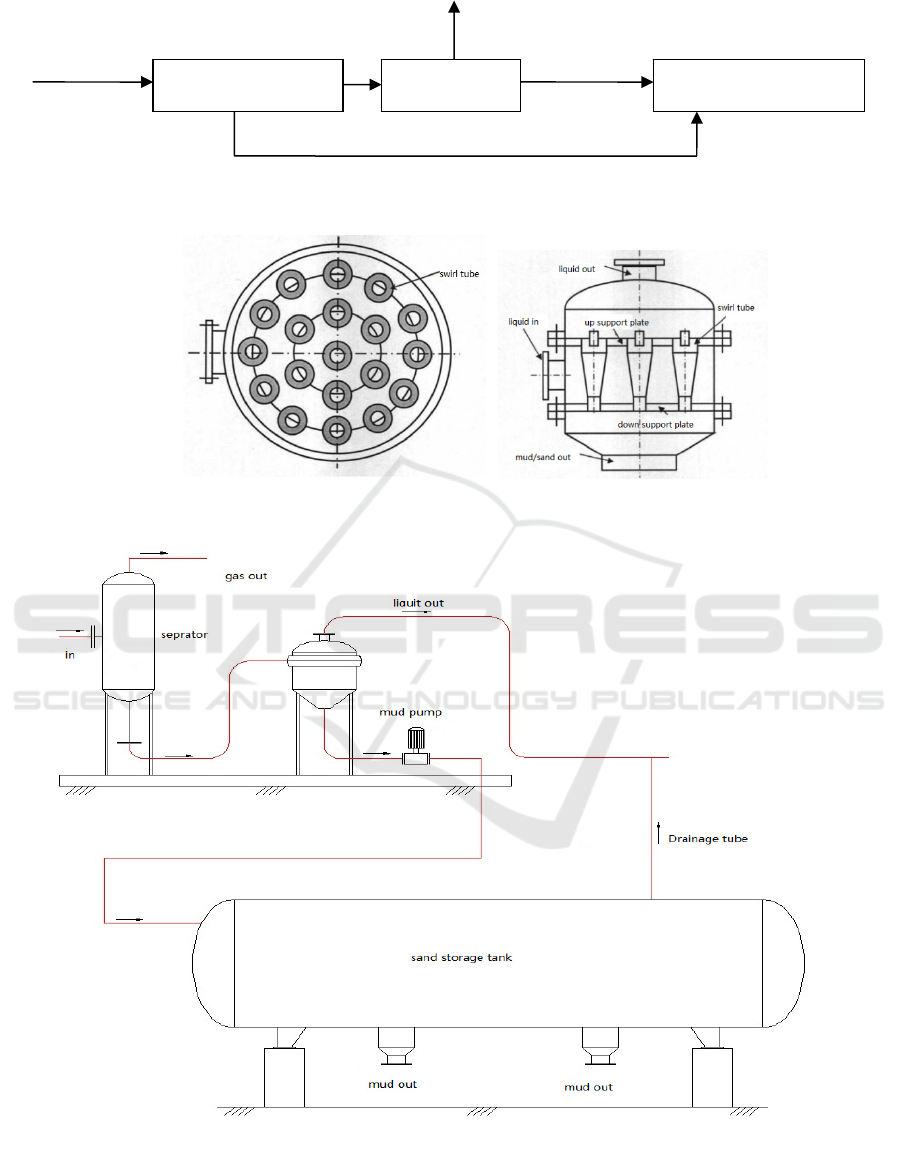

Structure principle and process flow of the

existing design prototype are shown in Figure 4.

Sediment by cyclone desander after separation from

the bottom, to facilitate the separation of sediment

accumulation, clearance and observation,

sedimentation tank in the swirl portion of the bottom

sediment design, part of the settlement tank in the

upper left part of the cyclone underflow and

sediment, sedimentation tanks.

Figure 1 process schematic diagram.

Figure 2 overlook structure . Figure 3 front section view.

Figure 5 device layout.

Oil 、 gas 、

wate

r

Gas-liquid

se

p

arator

Sand removal

device

Three phase

se

p

arator

Oil 、 gas 、

wate

r

Gas

(p

art

)

s

and

Oil, a small amount of gas, water

2.2. Improvement of Integrated Sand

Removal Device(ISRD)

Although the original prototype is convenient for the

separation of sediment after separation, it also brings

many unfavorable problems to the operation of the

equipment. Because the SRD is arranged on the

upper part of the sediment settling tank, the total

height of the sediment settling tank is about 4~5

meters, which will cause the pressure drop of the

system to increase by 0.04 to 0.05MPa. The normal

production of the oil station basic working pressure

0.35~0.4 MPa, increasing desanding integrated

device equals the pressure drop increased by 10% to

12.5%, due to the pressure drop device compared

with the general assembly have an impact on the oil

field ground process system, the most direct is the

super pressure safety valve, therefore need to be

solved to increase integration device system after

increasing the pressure drop problem.

Because the cyclone SRD needs to consume a

certain amount of energy to obtain the swirling flow

power, under the current conditions, the system

pressure drop caused by the best efficiency of the

integrated device is inevitable. Therefore, the system

pressure drop of the whole integrated device is

reduced by reducing the static pressure of liquid

column in the main stream.

The optimized layout of the ISRD is shown in

Figure 5. The sand is arranged in the division level

or above, through the mud pump after the separation

of sand and sediment discharge to the settling tank

lifting. Without affecting the normal process, the

pressure drop of 0.04 ~ 0.05MPa due to the height

difference is reduced. At the same time, by adding

the sludge pump to compensate the pressure drop of

the system, although the investment has increased, it

ensures the feasibility and stability of the operation

of the whole device.

3. ISRD UNIT PRYING AND

MOUNTING

With the continuous improvement of the

construction technology of the oilfield ground

construction, the integrated integrated device is also

used in Daqing oilfield to be used in the existing

process. This set of SRD has skid mounted design,

which integrates mechanical technology, electrician

technology, automatic control technology and

information technology. It has the advantages of

saving investment, saving land, convenient

transportation and installation, high reuse rate and

shortening construction period.

3.1 Skid Design

The dynamic equipment, the static equipment, the

process pipeline, the valve instrument and the

electrical control are put on the joint sled seat to

form an integrated integrated device. Consider the

following main design factors: one is the application

of advanced design method, optimization of

combined skid in space, so space utilization

efficiency, operation and maintenance of reasonable

space; two is the selection of small and efficient

equipment, coordination and optimization of

equipment and piping of the opening, the application

of multi way valve piping installation structure is

simplified; the three is for the convenience of

transportation, reasonably determine the skid the

size of a single skid base length should not be more

than 15 meters wide, not more than 2.8 meters, a

large device can adopt multiple skid joint

assembling form; four is to consider the overall

layout of the device more stable to prevent the lifting

process and overthrow.

3.2 Design Example

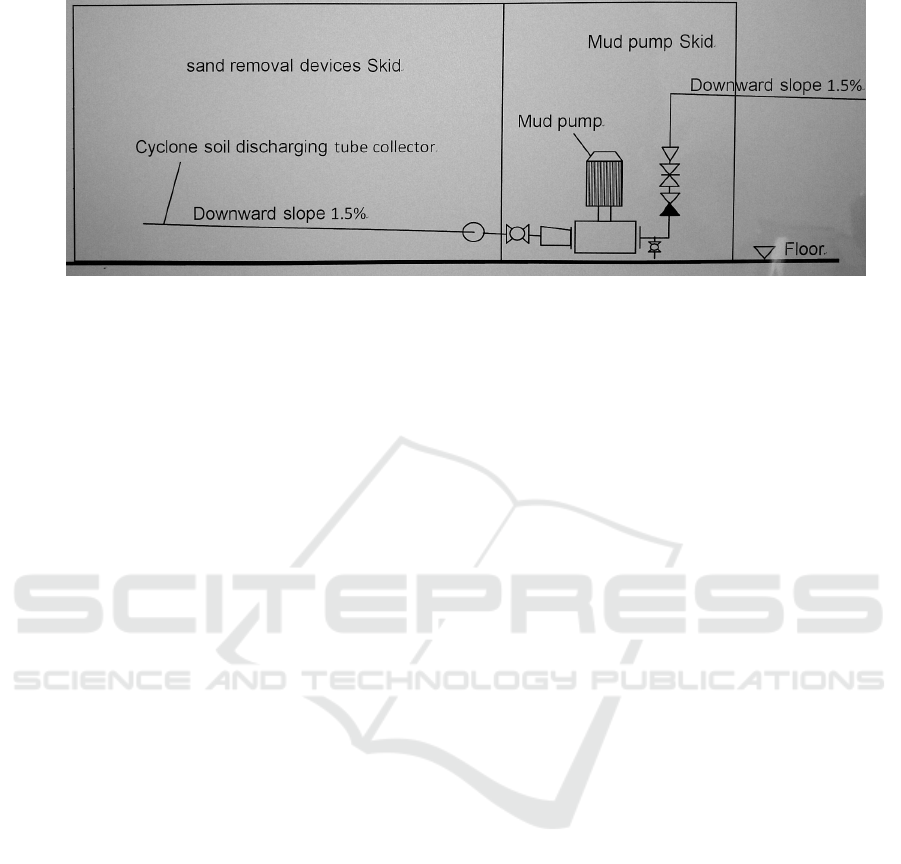

As shown in the Figure 6, the oil and gas separation

and SRDs are used as a sled unit, and the sludge

pump itself becomes a sled unit. The construction

period can be shortened greatly, and more than 80%

of the field work can be reduced. In the actual

application process, sometimes it is necessary to

place the mud pump skid outside. Considering the

environmental requirements of winter operation in

Daqing area, we will upgrade the pump to a

pumping room with features of skid mounted (its

design meets the specific requirements of fire

protection and explosion-proof regulation).

At the same time, the whole device sets the heat

tracing system, the heat source adopts the heating

furnace inside the station, the device and the outside

of the pipeline use the insulation material for heat

preservation treatment. In the process of practical

application, the device is part of the process system,

and the medium of the device is in the state of

operation, which can meet the demand of winter

operation. Considering the device some exposed

instrumentation components affected by low

temperature, there will be a bad situation with heat,

pressure transmission device failure, affecting the

normal operation of the device, so it is necessary to

take measures to increase the electrical heating of

key components, in order to avoid the disadvantages of low temperature operation.

Figure 6 design example.

4. CONCLUSIONS

The integrated device for separating and removing

sand from the produced liquid has the characteristics

of integration and automation. It can realize

standardized design, modular precast and automatic

control, and is suitable for the production of similar

produced liquid in Daqing oilfield and other cold

regions. Through field tests, the data show that the

application of the pre-distributary sand removal

process and the installation of special integrated

equipment can effectively reduce the sediment

content of the produced liquid and greatly improve

the treatment effect of the subsequent three-phase

separator.

With oil production to the standardized, modular,

intelligent direction, such as the pre diversion sand

special integrated device developed into crude oil

desanding proprietary technology products,

effectively saving investment, saving land,

transportation and convenient installation, high

recycling rate, shorten the construction period and

other advantages, will have broad application

prospects.

REFERENCES

1. Li Fulin, Wu Jiming, Ho Limin. Simulation screening

of multi division sand separator structure. Oil and gas

field surface engineering, 2004; Vo1.23 (6): 12 ~ P11

2. Zhang Haiyan, Li Ming, Tian Ying men. Original sand

removal technology, oil and gas field ground

engineering, 2008; 27 (11): P76

3. Da Yu, Wanyan Cao, Multi phase swirl removing sand

in Daqing oilfield application D. China University of

Petroleum, 2018.