Numerical Simulation of Welding Deformation and Flame

Straightening of Ear Plate Structure

Liping Zhang

1

, Ang Ji

1

, Guo Ma

2

, Changyu Lu

3

and Xiaohong Zhan

4

1

XCMG Research Institute. Ltd, Xu Zhou, China

2

State Key Laboratory of Intelligent Manufacturing of Advanced Construction Machinery, Xu Zhou, China

3

XCMG Environment Technology. Ltd, Xu Zhou, China

4

Nanjing University of Aeronautics and Astronautics, Nan Jing, China

Keywords: Ear plate structure, welding deformation, flame straightening, DOE

Abstract: In this thesis, the simulation model of welding and flame straightening process based on the Thermal

elastic-plastic method is developed by taking the ear plate structure as object of study. The primary and

secondary relations of straightening effect influenced by heating temperature, heating width and heating

time are analyzed through DOE procedure. The results show that: The parameters of flame straightening are

dependent on each other, and the heating width has the greatest influence on deformation straightening;

When the heating temperature is 750℃, the heating time is 20±2 s and the heating width is 30 mm, the

distance between two ear plates is 130.5 mm, which satisfies the design requirement reasonably.

1 INTRODUCTION

Due to the advantages of simple production process,

short manufacturing cycle and high flexibility of

structure design, welding has become found amental

processing method of complex construction.

Nevertheless, welding residual strain resulting from

uneven temperature field should not be ignored on

account of the extremely complex special

characteristics of high temperature, dynamicity and

transience in welding process. Hence deformation

straightening process should be added after welding

procedure so as to avoid structural geometrical

imperfection and instability of product quality

caused by welding deformation[1,2].

As a distortion rectification method used widely

at home and abroad, flame straightening is utilized

to rectify the welding deformation through heating

plate locally based on the thermal expansion theory

of metallic materials using a simple equipment,

which is suitable to the straightening of large

welding products typically. However, the

straightening effect is affected by the operator's

experience including various factors such as heating

temperature, heating time, heating area and heating

position, which increase the uncertainty of the

straightening effect. The process of flame

straightening has been studied in detail by a lot of

researchers[3,4]. Zhang Yujuananalyzed the

microstructure and mechanical properties of S355J2

structure steel after the correction process[5]. Zhu

Zhaohua expounded the factors to be taken into

consideration in flame straightening and welding

deformation[6]. ZengXiaopeng discussed the usage

of inherent strain method in simulation of flame

correction[7]. K B Jayananalyzed the flame

straightening process of Corrosion Resistant

Structural Steel. Based on the experimental results,

the study revealed the consequences of flame

straightening on microstructure and mechanical

properties of the work material influenced by oxy

acetylene pressure, torch nozzle diameter and the

holding time[8]. Zhao Dongsheng proposed a

formula for selection of gas flow based on

‘straightening energy input = welding energy input’,

which was verified reasonable by test results[9].

Juan Blandon compared three different gas heating

methods commonly employed in actual practice and

judged which was more efficient in terms of

correcting welding distortion while reducing energy

and time consumption[10].

In this paper, welding deformation and flame

straightening process of ear plate are simulated in

FE software and DOE method is provided to analyze

the main factor of straightening effect in order to

supply effective guidance to the actual flame

straightening operation of ear plate structure.

2 PHYSICAL MODEL OF EAR

PLATE STRUCTURE

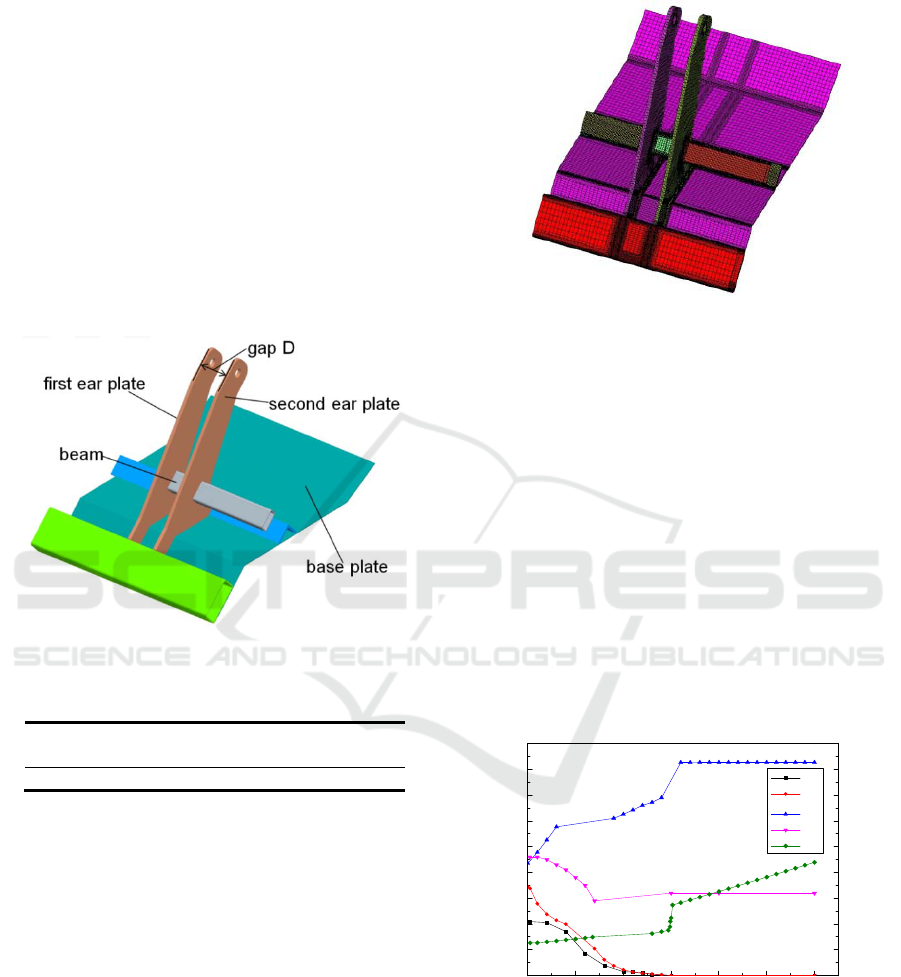

The overall geometrical model of the ear plate

structure is shown in Fig1, including base plate,

beam and two ear plates. The material of plates is

Q345 and the fillet joint is achieved in carbon

dioxide gas shielded welding with the Fronius

TPS5000 welding power. There is no welding

groove on the plate and the surface of specimen

would be cleaned before welding. The welding

process parameters are shown in Tab 1. The gap D

between two ear plates shall not meet the assembly

requirements of 131mm after welding, and the

welding deformation of the first ear plate should be

rectified by means of flame straightening.

Fig1:Geometrical model of ear plate.

Tab1:Welding process parameters.

name I /A U/V ν/(mmꞏs

-1

)

value 260~280 26~28 6

3 WELDING SIMULATION

MODEL OF EAR PLATE

3.1 Generation of Grid Model

The geometrical model of ear plate is partitioned

into solid grid model. The base mental is divided

into 2~3 layers in order to ensure the accuracy of

calculation and the size of grid around weld and

HAZ is set as 2mm so as to improve the calculation

speed, while the size of grid remote from the

welding zone is 6mm. Two element transitions are

adopted in the width direction among the above-

mentioned regions to ensure the accuracy of

calculation and reduce the number of elements. As

shown in Fig2, the element number of ear plate grid

model is 144956.

Fig2: Grid model of ear plate structure.

3.2 Relevant Parameters Setting of

Finite Element Model

Double ellipsoid thermal source is used as the

boundary condition of welding heat source due to

the temperature change of welding process is totally

involved during the welding process. The material of

ear plate grid model is set as Q345 and it is assumed

that the whole model has the same thermal physical

property parameters with the change of temperature.

The base metal and welding wire are set equipped

with isotropic properties: poisson's ratio is 0.33,

mass density is 7870 kg/m3, and the other

parameters such as thermal conductivity, specific

heat, elastic modulus, thermal expansion coefficient

with the temperature change are shown in Fig 3.

0 500 1000 1500 2000 2500 3000

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

αl×10

-5

/(mm/mm/C)

()

λ×10/(N/ s.C )

c×10

8

/(mm

2

/s

2

/K)

R

eL

×10

2

/MPa

E×10

5

/MPa

T/

℃

E

R

eL

c

λ

αl

Fig3: The relationship between heat-force parameters and

temperature of Q345.

3.3 Welding Deformation Analysis of

Ear Plate Structure

The welding deformation of ear plate structure as

shown in Fig 4 is extracted after the calculation is

complet

e

cooled t

o

structur

e

material

’

results

i

zone

w

deforma

t

directio

n

sides w

h

up to -

5

input.T

h

of weldi

n

actual s

i

of ear pl

is show

n

achieve

d

340 MP

a

HAZ is

welding

Fig4:We

l

structure.

na

m

val

u

e

d when the

o

room temp

e

e

deformatio

n

’

s expansion

i

n some plas

w

hich would

t

ion of the

s

n

is only 0.1

m

h

ile the defor

m

5

.5mm as a

h

e gap D is al

n

g deformati

o

i

tuation.The

V

ate structure

a

n

in Fig5, fr

o

d

that the ma

x

a

and the wel

d

much high

e

zone which e

l

ding deform

a

m

e

Oxygen

p

/M

P

u

e 0.

7

ear plate st

r

e

rature.The

m

n

of ear plat

e

during the

tic distortio

n

retain afte

s

econd ear p

l

m

m due to h

e

m

ation of th

e

result of on

tered to 126.

2

o

n, which is c

V

ONMISES

a

fter the com

p

o

m which so

m

x

imum of VO

N

d

ing residual

s

e

r than that

ven close to

z

a

tion nephogr

a

p

ressure

P

a

p

7

r

ucture has

b

m

ain reason fo

r

e

is that the

b

welding pr

o

n

around wel

r welding.

l

ate along t

h

e

at input on

b

e

first ear pla

t

ly one side

2

5mm on acc

onsistent wit

h

stress nepho

g

p

letion of wel

m

e results ca

n

N

MISES stre

s

tress of wel

d

remote from

z

ero.

a

m of ear

Tab 2. Pa

r

acetylene

ressure(low)

/MPa

0.07

b

een

r

the

b

ase

o

cess

ding

The

h

e Y

b

oth

t

e is

heat

ount

h

the

g

ram

ding

n

be

ss is

d

and

the

plate

Fig

5

stru

4

4.

1

Th

e

sa

m

of

p

a

p

si

m

p

ar

a

ma

t

p

ro

si

m

inf

l

an

a

fun

de

fo

the

p

o

s

are

a

he

a

Th

e

r

ameters of fla

m

acety

l

p

ressur

e

/M

P

1.

1

5

:Welding res

i

cture.

FLAME

ANALY

S

STRUC

T

1

Finite

E

Flame

S

Structu

e

physical pr

o

m

e as that of

w

thermal, stru

c

p

er, the metho

m

ulation of fl

a

a

meters of

f

t

erial are set

cess. With

m

ulation as t

h

l

uence of w

a

lyzed during

w

ction would

fo

rmation and

welding

d

s

ition of flam

e

a

above the

b

a

ting method

e

parameters

o

m

e heating.

l

ene

e

(high)

P

a

a

c

1

i

dual stress

n

STRAIG

H

S

IS OF E

A

T

URE

E

lement M

o

S

trai

g

hteni

re

o

cess of fla

m

w

elding, both

c

ture and p

h

d of direct co

u

a

me straighte

n

f

inite eleme

n

in the sam

e

the result

o

h

e initial bo

u

elding on f

l

w

hich the “P

r

be used

t

residual stre

s

d

eformation

e

straighteni

n

b

eam in the

f

adopts the l

i

o

f flame heati

n

c

etylene gasflo

w

/m

3

•h

-1

2.25

n

ephogram of

H

TENIN

G

A

R PLAT

E

o

del Settin

g

n

g

of Ear

P

m

e straighteni

n

including the

h

ase transitio

n

u

pling is utili

z

n

ing, and th

e

n

t such as

m

e

way as th

e

o

f welding

n

u

ndary cond

i

l

ame straigh

t

r

evious Anal

y

t

o read the

s

s results. Ac

c

analysis res

u

n

g is located

a

first ear plat

e

i

near heatin

g

n

g are shown

w

nozzle di

a

/m

m

2.

5

ear plate

G

E

g

of

P

late

n

g is the

coupling

n

. In this

z

ed to the

e

r

elevant

m

esh and

e

welding

n

umerical

i

tion, the

t

ening is

y

sis State”

welding

c

ording to

u

lts, the

a

t the top

e

and the

g

method.

in Tab2.

a

mete

r

m

5

4.2 Design of Simulation Scheme

The effects of heating temperature, heating time and

heating width on the deformation were mainly taken

into consideration during the design of simulation

scheme and the three factors as well as

corresponding three levels are shown in Tab 3. The

experimental design of above-mentioned parameters

is carried out by the Latin hypercube method. As

shown in Tab 4, the experiment scheme is composed

of 10 samples and all of them are distributed evenly

in the sample place.

Tab 3: Distribution of heating factors and levels.

Temperature/℃

Time/s Width/mm

Level1 650

10±2

10

Level2 700

15±2

20

Level3 750

20±2

30

Tab 4:Test scheme and final results.

NO.

Temperature

/℃

Time

/s

Width

/mm

D

/mm

1 650

20±2

10 127.94

2 750

15±2

20 129.17

3 650

10±2

30 129.77

4 750

20±2

20 129.43

5 650

10±2

20 128.55

6 750

10±2

30 130.37

7 700

10±2

10 127.69

8 700

15±2

20 128.89

9 750

15±2

30 130.71

10 750

20±2

30 131.13

4.3 Thermal Deformation Analysis of

Flame Straightening of Ear Plate

Structure

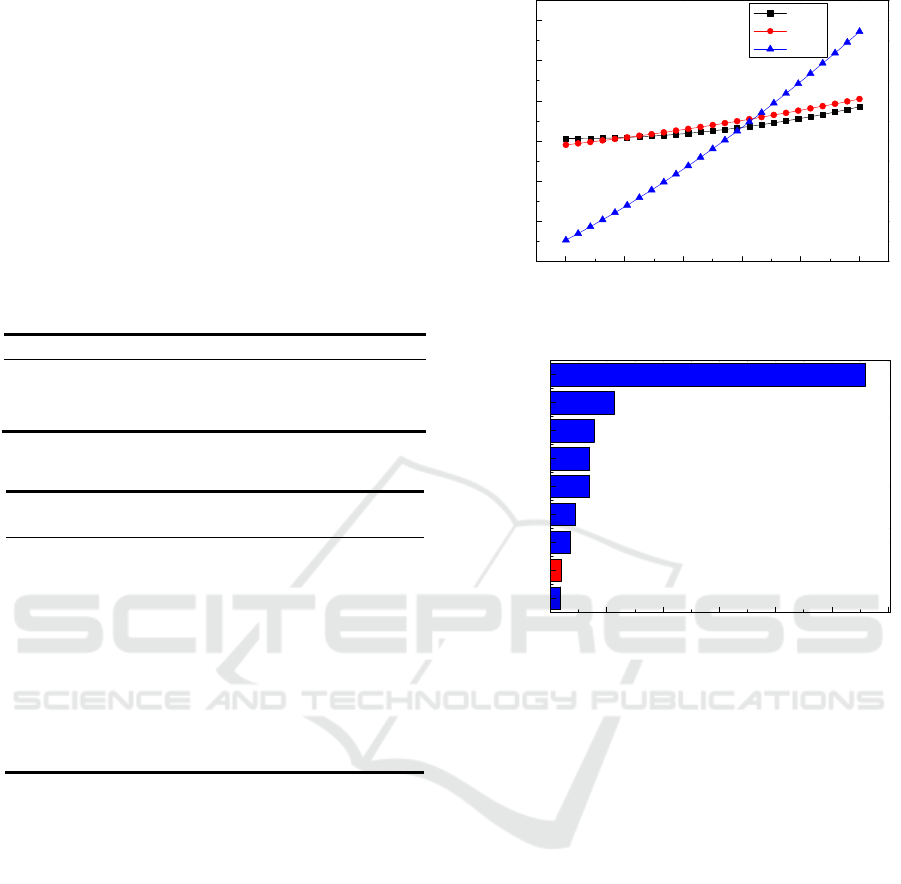

The simulation results of DOE are analyzed by the

main effect diagram and Plato after the calculation

completed so as to determine the effect of

parameters such as heating temperature, heating time

and heating width on the distance between two ear

plates.

1.0 1.2 1.4 1.6 1.8 2.0

127.5

128.0

128.5

129.0

129.5

130.0

130.5

distance /mm

level value

temp

time

width

Fig6:The main effect diagram of straightening parameters.

time^2

temp-time

temp-width

temp^2

time-width

width^2

temp

time

width

0 102030405060

% effect on distance

Fig7:The Plato of straightening parameters.

The main effect diagram of heating temperature,

heating time and heating width is shown in Fig6, as

can be seen from the figure, the heating width has

the largest influence on the gap D and the distance

changes dramatically with the change of heating

width, while the influence of heating temperature

and heating time are more gentle.

Fig7 shows the Plato of heating temperature,

heating time and heating width, and from the graph

it is evident that all of the parameters have a positive

effect on the gap D, among which the heating width

has the most positive effect on ear plate spacing,

followed by heating temperature and heating time.

Besides, the secondary and interaction terms have

less influence on the gap D and the interactivity of

temperature and time is negative for the ear plate

spacing.

The result is shown in Tab 3 that the distance

between two ear plates is 131.13 mm when the

heating temperature is 750 ℃, the heating time is 20

s and the heated width is 30 mm. As shown in Fig 8,

the Y direction deformation cloud diagram of the ear

plate structure under the straightening parameter is

obtaine

d

amount

o

remains

Howeve

r

the def

o

deforma

t

larger d

u

Fig 8: T

h

p

late stru

c

The

structur

e

is show

n

achieve

d

340 MP

straight

e

that of

a

The VO

higher t

h

same a

r

VONMI

d

. It can be

o

f the second

0.1mm

b

ec

a

r

, as far as t

h

o

rmation at

u

t

ion at the to

p

u

e to the flam

e

h

e welding def

o

c

ture.

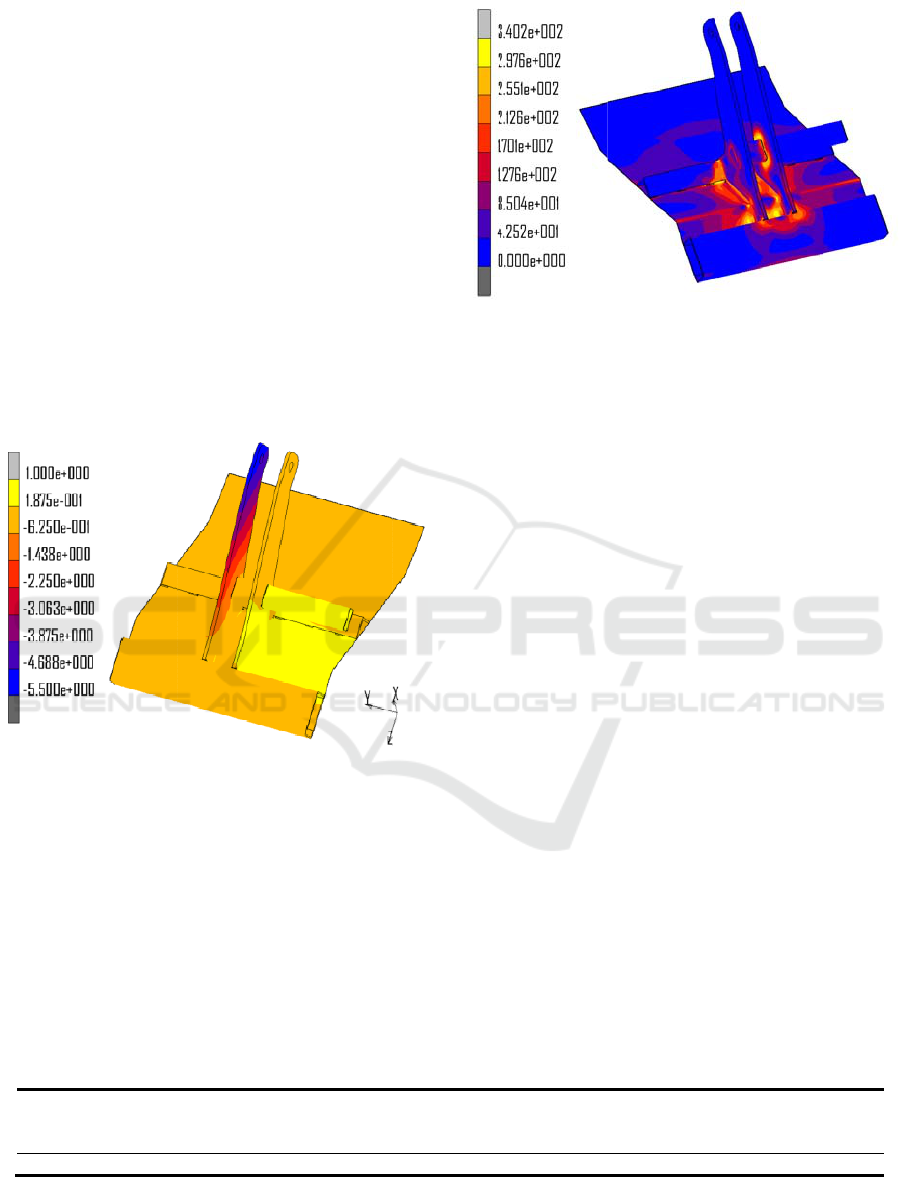

VONMISES

e

after the co

m

n

in Fig9, fr

o

d

that the ma

x

a and the w

e

e

ning area an

d

a

rea remote fr

NMISES str

e

h

an that of

s

r

ea from t

h

SES stress n

e

Req

u

D

131

found that

ear plate alo

n

a

use there i

s

h

e first ear p

l

u

pper part is

p

area above t

h

e

straightenin

g

o

rmation clou

d

stress nepho

g

m

pletion of fl

a

o

m which so

m

x

imum of VO

N

e

lding residu

a

d

HAZ is still

om the abov

e

e

ss in the str

a

s

tructure aft

e

h

e comparis

o

e

phogram.

Tab

5

u

irement

W

e

m

u

±1mm

1

2

the deform

a

n

g the Y dire

c

s

no heat i

n

l

ate is conce

r

small while

h

e beam is a

l

g

.

d

diagram of th

e

g

ram of ear

p

a

me straighte

n

m

e results ca

n

N

MISES stre

a

l stress of

w

much higher

e

-mentioned

z

a

ightening ar

e

e

r welding i

n

o

n between

5

: Different res

u

e

ldingsi

u

lation

We

l

ct

u

2

6.5mm 12

6

a

tion

c

tion

n

put.

r

ned,

the

l

ittle

e

ear

p

late

n

ing

n

be

ss is

w

eld,

than

z

one.

e

a is

n

the

two

Fig

stru

str

a

we

l

he

a

san

sa

m

tw

o

me

a

des

u

lts of gap D b

e

l

dinga

u

ality

flam

s

6

.3mm

1

9:The VON

M

cture.

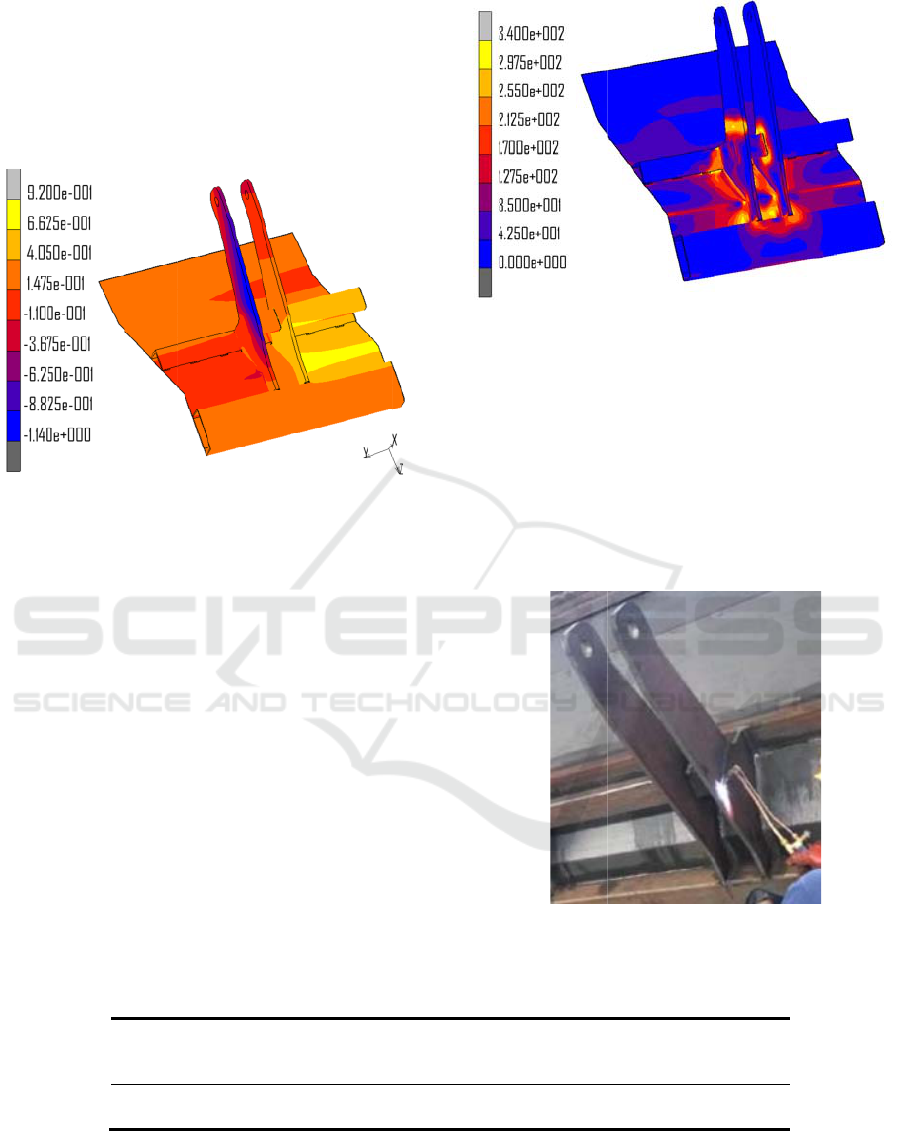

According t

o

a

ightening pr

o

l

ding deform

a

a

ting tempera

t

d the heatin

g

m

ple is shown

o

ear plates is

a

sured gap

D

ign requirem

e

Fig10:T

h

e

tween two ear

e straightening

s

imulation

1

31.13mm

M

ISES stress

n

o

the analysis

o

cessing is

u

a

tion of ear

p

t

ure is 750℃,

g

width is

3

in figure 10

a

measured.

A

D

is 130.5

m

e

nts.

h

e rectified sa

m

plates.

flame strai

g

actua

l

130.5

m

n

ephogram of

of the DOE

u

tilized to r

e

p

late which s

e

the heating t

3

0 mm. The

a

nd the gap

D

A

s shown in

T

m

m, which

m

m

ple of ear plat

e

g

htening

l

ity

m

m

ear plate

results, a

e

ctify the

e

t as: the

ime is 20

rectified

D

between

T

ab 5, the

m

eets the

e

.

5 CONCLUSIONS

(1) The finite element model of the welding

deformation prediction of the ear plate structure is

established based on the thermal elastoplastic finite

element method and the predicted results of welding

deformation are consistent with the measured results.

(2)The flame straightening processing

parameters are analyzed and optimized through

DOE experimental analysis method. Parameters

which have positive effect on deformation

rectification are as follows: heating width, heating

time and heating temperature while their quadratic

terms have little influence on distances between two

ear plates.

(3) According to the analysis of DOE results, the

straightening processing is determined as: the

heating temperature is 750℃, the heating time is 20

±2s and the heating width is 30 mm. The verified

test results show that the gap D meets the design

requirements.

REFERENCES

1. Pinzon, C., Hasewaga, K., &Murakawa, H.

(2016). Artificial Neural Network Application for

Parameter Prediction of Heat Induced

Distortion. Trends in Applied Knowledge-Based

Systems and Data Science. Springer International

Publishing.

2. Pinzon, C., Hasewaga, K., &Murakawa, H.

(2016). Artificial Neural Network Application for

Parameter Prediction of Heat Induced

Distortion. Trends in Applied Knowledge-Based

Systems and Data Science. Springer International

Publishing.

3. Doynov, N., &Michailov, V. G. (2018). Distortion

analysis of heat spot straightening thin-walled welded

structures: part 1: formation of the plastic deformation

zone. International Journal of Advanced

Manufacturing Technology, 94(1-4), 1-10.

4. Lacalle, R., Álvarez, J. A., Ferreño, D., Portilla, J.,

Ruiz, E., & Arroyo, B., et al. (2013). Influence of the

flame straightening process on microstructural,

mechanical and fracture properties of s235 jr, s460 ml

and s690 ql structural steels. Experimental

Mechanics, 53(6), 893-909.

5. Zhang Yujuan (2013). Flame straightening and

analysis of microstructure and mechanical property on

S355J2 structure steel. Chang Chun: Jilin University.

6. Zhu Zhaohua, Huang Juhua, Zhang Tingfang et al.

(2009). Application of flame correction method in

steel structure. Welding Technology,38(5), 63

-

66

.

7. ZengXiaopeng, Xu Ying. (2012).The Numerical

Simulation of Flame Correction to Ship Hull Plate

Based on ABAQUS. Science Technology and

Engineering, 12(35), 9635-9639.

8. Jayan K B, Kumar J P. (2016). Experimental

Investigation on Flame Straightening of Corrosion

Resistant Structural Steel Sheet Used for Rolling

Stock.

9. ZHAO Dongsheng, HUANG Zhenyu, MIAO Tangjun.

(2016). Experimental Parameter Calculation of

Welding Deformation Correction by Flame

Straightening. DEStech Transactions on Materials

Science and Engineering, mmme.

10. Blandon J, Osawa N, Masanori S, et al. (2015).

Numerical Study on Heat Straightening Process for

Welding Distortion of a Stiffened Panel Structure.