Study of Low Temperature Performance of Different Asphalt Types

in Qinghai-Tibet Region

Xueyan Zhou

1a

, Xiao qing Wang

1b

and Yue Xiao

1c

1 Chang’an University, Xi’an , Shannxi, China

Keywords: Road engineering, low temperature bending strength, low temperature bending strain

Abstract: The climate conditions in Tibet are special, and the performance requirement of asphalt pavement is

different from that of general area. The study of asphalt pavement in this area is aimed at the secondary

roads. There is no experience for high grade asphalt pavement design .Based on the study of asphalt binder

and mixing materials in high altitude area,used low-temperature bend test, analysis the influence of

asphalt type on the low temperature performance of asphalt mixture. The results show that low temperature

anti-cracking performance of SBS/SBR composite modified asphalt mixture is optimal. It is suggested to

choose composite modified asphalt with high grade.

1 INTRODUCTION

The low temperature cracking of asphalt pavement is

a worldwide problem that has long been concerned

at home and abroad (Ma, 2011). Previous research

has shown that there are many factors influencing

low temperature cracking of asphalt pavement. It

mainly includes the properties of asphalt and asphalt

mixture, the properties of basic materials, climatic

conditions, traffic loads, design factors and

construction factors (Underwood, 2013).According

to the mechanism or main inducement of pavement

cracking, the crack in asphalt pavement is generally

divided into load crack and non-load crack. For

semi-rigid base asphalt pavement cracking and low

temperature cracking of asphalt pavement, non-load

crack is the main form (Sha, 2012).Non-load is

commonly transverse cracks, mainly is the low

temperature, cooling and temperature cycle

repeatedly on the asphalt pavement temperature

shrinkage crack and shrinkage cracking semi-rigid

base and the reflective crack (Li, 2008).

The Tibetan has high altitude, low annual

average temperature, big temperature difference,

frequent freeze-thaw cycle, strong solar radiation

and a variety of adverse conditions, which affects

the mechanical properties and durability of the

asphalt mixture significantly (Ma, 2015). Low

temperature crack seriously affects the service life of

road. However, in the Qinghai-Tibet plateau, the low

temperature crack has a more significant impact on

road life and pavement performance. The low

temperature performance evaluation index of asphalt

mixture is studied systematically by domestic and

foreign researchers. The American highway strategic

research program (SHRP) has proposed a

temperature stress test and J - integral test as the

main method to evaluate the low temperature

cracking of asphalt pavement (Iliuta, 2004).China

"five-year" project with 0 °C bending creep test of

asphalt mixture creep rate as the evaluation index of

asphalt mixture low temperature crack resistance

(Zhao, 2011). In the past, many researchers have

used low temperature bending strength or low

temperature bending strain as the evaluation index in

the study of low temperature crack resistance of

asphalt mixture (Wang, 2016).For the evaluation

method proposed by China "five-year" project,

because its experimental temperature is far from the

actual temperature in the Qinghai-Tibet plateau, it

should not be used to evaluate the low temperature

performance of asphalt mixture in this area.

However, the low temperature bending strength or

low temperature bending strain used by most

researchers can only reflect the characteristics of

asphalt mixture at low temperature, and cannot

comprehensively reflect its low temperature

performance (Chazono, 1989; Ho, 2002).Therefore,

there are many evaluation indexes for the low

temperature crack resistance of asphalt mixture, and

there is no uniform standard at home and abroad.

In this paper, according to the low temperature

bending test results of asphalt mixture in Qinghai-

Tibet alpine region, the effect of asphalt variety on

the crack resistance of asphalt materials was

analysed.

2 TEST MATERIALS

2.1 Materials

The asphalt used in this study was SBS90#modified

asphalt, SBS/SBR90#co-modified asphalt,SBR90#

modified asphalt, SBS110# modified asphalt,

SBS/SBR110# co-modified asphalt and SBR110#

modified asphalt, the corresponding serial number is

1#~6#. The specific technical indicators and test

results are shown in Table1.

Table1: Technical indicators of modified asphalt

Technical index

Experimental value

1# 2# 3# 4# 5# 6#

Penetration

(0.1mm)

96 96 93 107 102 109

Ductility (cm) 56 84 148 62 120 150

Softening point

(

℃

)

61.5 62.3 60.2 59.7 59.5 57.9

Kinematic

viscosity

(135

℃

)

1.49 2.73 2.94 1.23 2.53 2.87

Penetration index 3.04 4.29 3.46 2.25 3.33 2.77

Flash point (

℃

)

247 231 243 243 234 246

Solubility (%) 99.7 99.6 99.6 99.5 99.6 99. 6

RT

FO

T

Quality change

(%)

0.34 0.34 0.27 0.5 0.45 0.48

Residual

penetration

(%)

74.9 74.9 71.6 74.6 87.8 77.6

Residual

ductility

(cm)

65 65 98 48 88 113

The coarse aggregate was granite, fine aggregate

was artifical sand, mineral powder was limestone

mineral powder.

2.2 Test Methods

The bending test (T 0715-2011) of 《Standard Test

Methods of Bitumen and Bituminous Mixtures for

Highway Engineering》(JTG E20-2011) was used

to test the low-temperature performance of asphalt

mixture.

3 RESULTS AND DISCUSSIONS

3.1 Analysis of the Low Temperature

Bending Strength

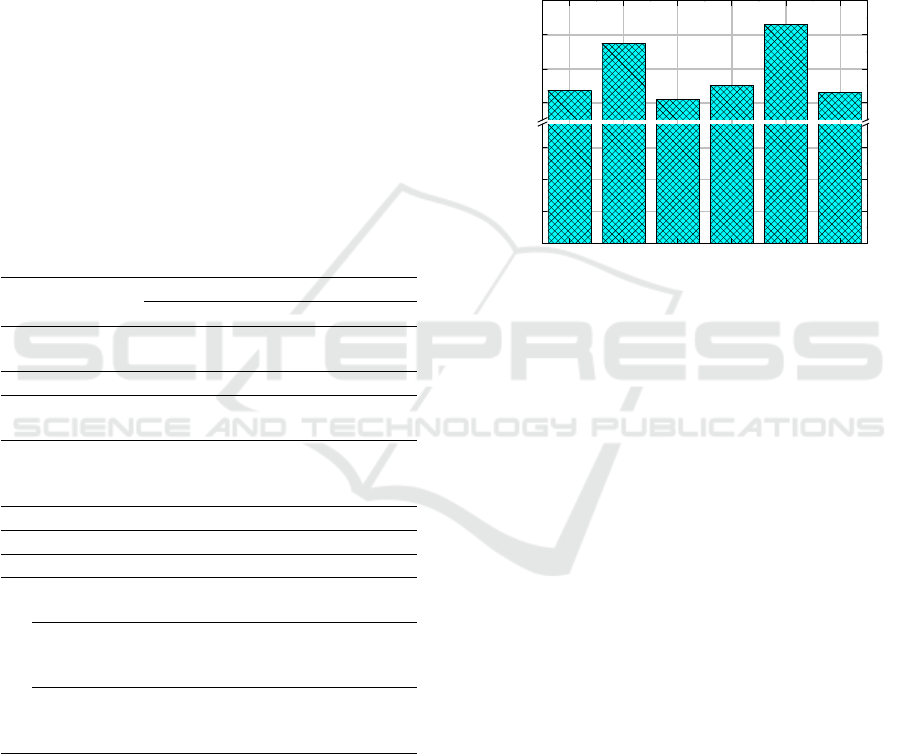

The low temperature bending strengths of different

asphalt are shown in Figure 1.

1# 2# 3# 4# 5# 6#

0

1

2

3

12

13

14

15

Low temperature bending strength (MPa)

Aaphalt mixture

Figure 1Low temperature bending strength of asphalt

mixture .

As can be seen in Figure 1, all kinds of asphalt

mixture low temperature bending strength are high,

and the low temperature bending strength of

different asphalt types differs slightly. More

specifically, the low temperature bending strength of

SBS/SBR110# co-modified asphalt mixture is the

maximum, the corresponding value is 14.3 MPa, and

that of SBR90# modified asphalt mixture is the

minimum, the corresponding value is 12.1 MPa.

As for the asphalt mixture with the same

aggregate gradation and penetration grade, the low

temperature bending strength of composite modified

asphalt mixture is higher than that of the two other

asphaltmixtures, the low temperature bending

strength of SBS modified asphalt mixture and SBR

modified asphalt mixture are almost the same, and

the low temperature bending strength of SBR

modified asphalt mixture is a little bigger thanthat of

SBS modified asphalt mixture.

As for the same modified asphalt, with the

increasing of the penetration degree, the low

temperature bending strength of asphalt mixture

decreased.

From the low temperature bending strength index

of asphalt mixture, the composite modified asphalt

has the advantages of SBS modified asphalt and

SBR modified asphalt, and the low temperature

resistance of composite modified asphalt mixture is

the best.

3.2 Analysis of the Low Temperature

Bending Strain

The low temperature bending strains of different

asphalt are shown in Figure 2.

1# 2# 3# 4# 5# 6#

0

2500

3000

3500

4000

4500

Low temperature bending strain(10

-6

)

Asphalt mixture

Figure 2Low temperature bending strain of asphalt

mixture

In Figure 2, the low temperature bending strain

of all asphalt mixtures is greater than 3000, which

meet the specifications. It is different from low

temperature bending strength, there is a significant

difference between different asphalt mixture the low

temperature bending strain. Specifically speaking,

the low temperature bending strain of SBS/SBR110#

co-modified asphalt mixture is the maximum, the

corresponding value is 4017, and that of SBR90#

modified asphalt mixture is the minimum, the

corresponding value is 2751.

As for the asphalt mixture with the same

aggregate gradation and penetration grade, the low

temperature bending strain of SBR modified asphalt

mixture is the minimum, the low temperature

bending strain of SBS/SBR co-composited modified

asphalt mixture is the maximum, and the low

temperature bending strain of SBS modified asphalt

mixture is middle. The difference between low

temperature bending strain of SBS/SBR co-

composited modified asphalt mixture and SBR

modified asphalt mixture is significant, while the

difference between SBS/SBR co-composited

modified asphalt mixture and SBS modified asphalt

mixture is small.

As for the same modified asphalt, with the

increasing of the penetration degree, the low

temperature bending strength of asphalt mixture

increased, and the influence of penetration degree on

the low temperature bending strain of asphalt

mixture is significant.

From the low temperature bending strain index

of asphalt mixture, the low temperature resistance to

deformation of SBS/SBR co-composited modified

asphalt mixture is the best, the SBS modified asphalt

mixture is the second, and the SBR modified asphalt

mixture is the worst. Combined low temperature

bending tensile strength and bending strain of

asphalt mixture, the low temperature performance of

SBS/SBR co-composited modified asphalt mixture

is the optimum.

3.3 Analysis of the Low Temperature

Stiffness Modulus

1# 2# 3# 4# 5# 6#

0

3500

4000

4500

Low temperature stiffness modulus(MPa)

Asphalt mixture

Figure 3Low temperature stiffness modulus of asphalt

mixture

As can be seen from Figure 3, the low temperature

bending stiffness modulus of different asphalt

mixture is small. The low temperature bending

stiffness modulus of SBR90# is the maximum, the

corresponding value is 4398MPa, and that of the

SBS/SBR110# is the minimum, the corresponding

value is 3560MPa.

As for the asphalt mixture with the same

aggregate gradation and penetration grade, the low

temperature bending stiffness modulus of SBR

modified asphalt mixture is the maximum; the low

temperature bending stiffness modulus of SBS/SBR

co-composited modified asphalt mixture is the

minimum, and the low temperature bending stiffness

modulus of SBS modified asphalt mixture is middle.

As for the same modified asphalt, with the

increasing of the penetration degree, the low

temperature bending stiffness modulus of asphalt

mixture decreased.

The low temperature bending stiffness modulus

is a comprehensive performance of low temperature

strength and deformation resistance of asphalt

mixture, which reflect the flexibility of asphalt

mixture to some extent. Generally speaking, the

smaller the bending stiffness, flexible of asphalt

mixture under cold condition, the better.

In conclusion, the low temperature bending

strength and bending strain of SBS/SBR co-

composited modified asphalt mixture are both larger,

the low temperature stiffness modulus of SBS/SBR

co-composited modified asphalt mixture is smaller.

4 CONCLUSIONS

As for the low temperature bending strength of

asphalt mixture, the composite modified asphalt has

the advantages of SBS modified asphalt and SBR

modified asphalt, and the low temperature resistance

of composite modified asphalt mixture is the best;As

for the low temperature bending strain index of

asphalt mixture, the low temperature resistance to

deformation of SBS/SBR co-composited modified

asphalt mixture is the best, the SBS modified asphalt

mixture is the second, and the SBR modified asphalt

mixture is the worst; As for the low temperature

bending stiffness modulus of asphalt mixture, SBR

modified asphalt mixture is the worst; the low

temperature bending stiffness modulus of SBS/SBR

co-composited modified asphalt mixture is the

best.In a word, the low temperature performance of

SBS/SBR co-composited modified asphalt mixture

is optimum. In addition, high grade asphalt is

selected to improve the low temperature

performance of asphalt mixture.

ACKNOWLEDGEMENTS

This research was financially supported by the

Excellent Doctoral Dissertation Project of Chang’an

University (No. 310821175012).

REFERENCES

1. Ma, B., Li, J. and Liu, R.W. et al., 2011. Study on

Road Performance of Phase-Change Temperature-

Adjusting Asphalt Mixture. Advanced Materials

Research, 287-290:978-981.

2. Underwood, B. S. and Kim, Y. R., 2013. Effect of

volumetric factors on the mechanical behavior of

asphalt fine aggregate matrix and the relationship to

asphalt mixture properties.Construction & Building

Materials, 49(6):672-681.

3. Sha, A.M. and Tu, S., 2012. Cracks Characteristics

and Damage Mechanism of Asphalt Pavement with

Semi-rigid Base. 7th RILEM International Conference

on Cracking in Pavements.Springer Netherlands,

2012:985-995.

4. Li, Z.L., Gong, N.F. and Luan, X. B, 2008.

Development Mechanism Analysis of Temperature

Shrinkage Type Reflective Crack in Asphalt Pavement

on Semi-rigid Base. Journal of Highway &

Transportation Research & Development,1,25(142).

5. Ma, B., Zhou, X. and Si, W., et al., 2015. Study of the

water stability and high temperature performance of

asphalt mixtures in Qinghai-Tibet cold regions.

Journal of Glaciology & Geocryology, 37(1):175-182.

6. Iliuta, S., Hesp, S. and Marasteanu, M. et al., 2004,

Field Validation Study of Low-Temperature

Performance Grading Tests for Asphalt

Binders.Transportation Research Record Journal of

the Transportation Research Board,1875(1):14-21.

7. Zhao L. H., Xu, G. and Zhao, J., 2011. Research of the

Low Temperature Crack Resistance for the Mineral

Fiber Rein-Forced Asphalt Mixture. Applied

Mechanics & Materials, 97-98(11):172-175.

8. Wang, H., Zhang, C. and Li, L., et al., 2016.

Characterization of Low Temperature Crack

Resistance of Crumb Rubber Modified Asphalt

Mixtures Using Semi-Circular Bending Tests. Journal

of Testing & Evaluation,44(2):20150145.

9. Chazono, H., Oshio, M. and Murai, S., et al., 1989.

Low temperature sintered ceramic capacitor having a

high resistivity and bending strength, and method of

manufacture: US, US4809131.

10. Ho, S.M.S., Zanzotto, L. and Macleod, D., 2002.

Impact of Different Types of Modification on Low-

Temperature Tensile Strength and T critical of Asphalt

Binders. Transportation Research Record Journal of

the Transportation Research Board, 1810(1):1-8.