Effect of Heat Treatment on Mechanical Properties and

Microstructure of L80-13Cr Martensitic Stainless Steel

Yilong Zhang

1

, Wei Wu

1

, Bingbing Li

1

, Dezhi Yuan

2

, Kejian Li

1,3

,Kessam Shin

1,4

and Pengjun

Cao

1

1School of Metallurgy and Materials Engineering, Chongqing University of Science and Technology, Chongqing, China

;

2Steel Tube Co., Ltd., Chongqing Iron & Steel Group, Chongqing, China;

3The center of Material Analysis and Testing, Chongqing University of Science and Technology, Chongqing, China;

4School of Nano & Advanced Materials Engineering, Changwon National University, Changwon, Korea)

Keywords: Heat treatment, Martensitic stainless steel, Microstructure, Precipitation.

Abstract: L80-13Cr martensitic stainless steel (MSS) is a kind of oil casing steel. It has good resistance to carbon

dioxide corrosion and seawater corrosion, which makes it common oil casing steel in marine oil and gas

exploration. The effect of heat treatment on mechanical properties and microstructure of L80-13Cr MSS has

been studied. The specimens were analyzed using the micro-hardness test, optical microscope (OM),

scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The hardness test

showed that the steel was secondarily hardened when tempering at 300 ~ 500°C. But continuous softening

occurred when the temperature was above 500°C. The martensite was recovered at temperatures around 300

~ 500°C, and higher temperature tempering (600°C) caused grain growth and even recrystallization. It has

been found that the precipitates in the steels that were tempered at 300°C, 500°C and 700°C, were need-like

Fe

3

C carbides, coarsed needle-like Fe

3

C carbides and rod-like or sphere-like Cr

23

C

6

carbides. Especially

when tempered at 700°C, the Cr

23

C

6

carbidesprecipitation along the marten site lath was rod-like and

precipitation along grain boundaries was sphere-like. Secondary hardening between 300 ~ 500°C tempering

of 13Cr is attributed to the precipitation of needle-like Fe

3

C. The recovery and recrystallization of the

matrix and the coarsening of carbides resulted in the continuous softening of 13Cr MSS during tempering.

1 INTRODUCTION

Oil casing in the process of oil extraction is often

directly affected by corrosion, with the depth of the

formation of oil mining depth, oil casing to

withstand the temperature and pressure is getting

higher and higher, more and more harsh

environmental environment (Feng Z et al.2016).

Ordinary carbon or low alloy steel cannotsatisfy the

corrosion resistance requirements, so more and more

oil and gas fields began to use the L80-13Cr

MSS(Jianqiang Y et al.2015). 13Cr MSS has high

thermal strength, oxidation resistance, good impact

resistance (Cabello G et al.2013) In the weak

corrosive medium has good corrosion resistance,

fresh water, sea water, steam, air also has enough

corrosion resistance(Sidorin D et al.200).Because of

low carbon content in 13Cr MSS, it usually needs to

be appropriate heat treatment, in order to obtain a

stable small uniform organization (Larsen Jet

al.2015). The heat treatment for 13Cr MSS is

quenching at a high temperature and followed with

tempering. After high temperature quenching, the

microstructure of MSS is martensitic with high

hardness and low toughness. After tempering,the

hardness of the MSS will reduce and the toughness

will rise (Isfahany A N et al.2011).However, during

tempering, the formation and transformation of

second phases may harden the MSS, causing the

dramatic reduction of toughness (Chakraborty Get

al.2015). At the same time, the complex carbide

reactions that occur during tempering may directly

determine the corrosion resistance (Pfennig A et

al.2013).Therefore, it is necessary to study the

impact of tempering temperature on the 13Cr MSS.

The present work is designed to acquire an

understanding of the relationship between the

microstructure and the mechanical behavior of 13Cr

MSS after quenching and tempering. The

microstructure and precipitate are characterized

using OM, SEM, TEM analysis.

2 MATERIALS AND

EXPERIMENTAL

2.1 Material and Heat Treatment

The steel used in this work is the 13Cr martensitic

stainless steel, which hasthe chemical composition

(in weight percent) of 0.18C, 0.23Si, 0.47Mn,

12.66Cr, 0.15Ni, 0.7Cu and balance Fe. The heat

treatment used the SRJX-4-13 chamber electric

furnace. Solution treatment was performed at

1050°C for 1 h to allow the complete dissolution of

all carbides. After solution treatment, the specimens

were water cooled and then tempered at 300°C,

400°C, 500°C, 600°C, 700°C for 2 hrs.

2.2 Microstructure Observation and

Precipitation Characterization

The samples were cut by wire cutting machine. All

the specimens were ground and mechanically

polished, then were etched by a particular etchant

comprising 25 ml HNO3, 25 ml HCl, and 50 ml

distilled water. The sample prepared for hardness

measurements were ground through abrasive papers

in turn of 400-, 800-, 1200-, 1500-, 2000-grit.The

micro-hardness test was performed with a load of

200 kgf and loading time of 10 s on HVS-1000 type

micro-sclerometer. Seven points were tested, take

average of five points except the highest and lowest.

The microstructure of each specimen was

characterized by OLYMPUS GX71 inverted

metallurgic microscope and JSM-6510 SEM. TEM

thin foil specimens were prepared by using a Struers

TenuPol-5 double-jet electrolytic polisher with a

solution of 120 ml HClO4 and 1080 ml CH3COOH.

Carbon extraction replication method was used to

monitor the precipitation in the heat treated

specimens using JEM-2100F TEM.

3 RESULTS AND DISCUSSIONS

3.1 Effect of Heat Treatment on the

Hardness of 13Cr MSS Steel

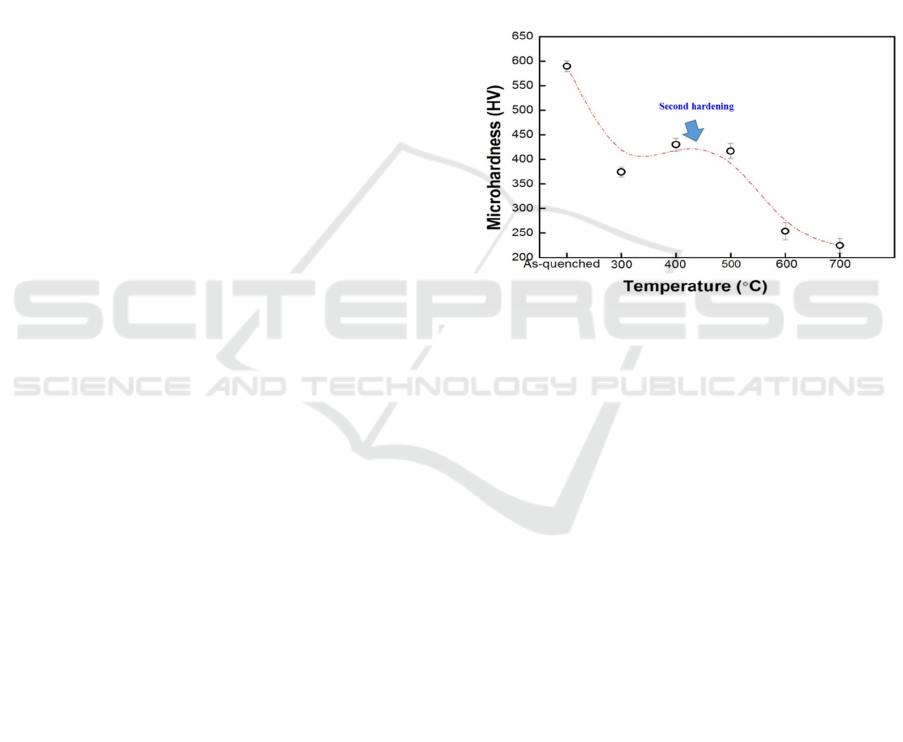

The hardness of the quenched and tempered

specimens is shown in Fig. 1. After quenching, the

specimen was hardened (~590 HV) by martensitic

transformation.The hardness decreased even

tempering at a low temperature (<300°C). But

whenthe tempering temperaturerose to 300°C (~375

HV), the hardness abruptlybecame harder. It showed

the steel was secondarily hardenedafter tempering at

300 ~ 500°C that the hardness abruptly increased.

When the steel was tempering ata higher

temperature like 600 ~ 700°C, the hardness of steel

decreased (~254 HV) at 600°C, and continuous

decreased (~225 HV) at 700°C.

Figure 1:Hardness test results of 13Cr MSS quenched and

tempering.

3.2 Effect of Heat Treatment on the

Microstructure of 13Cr MSS Steel

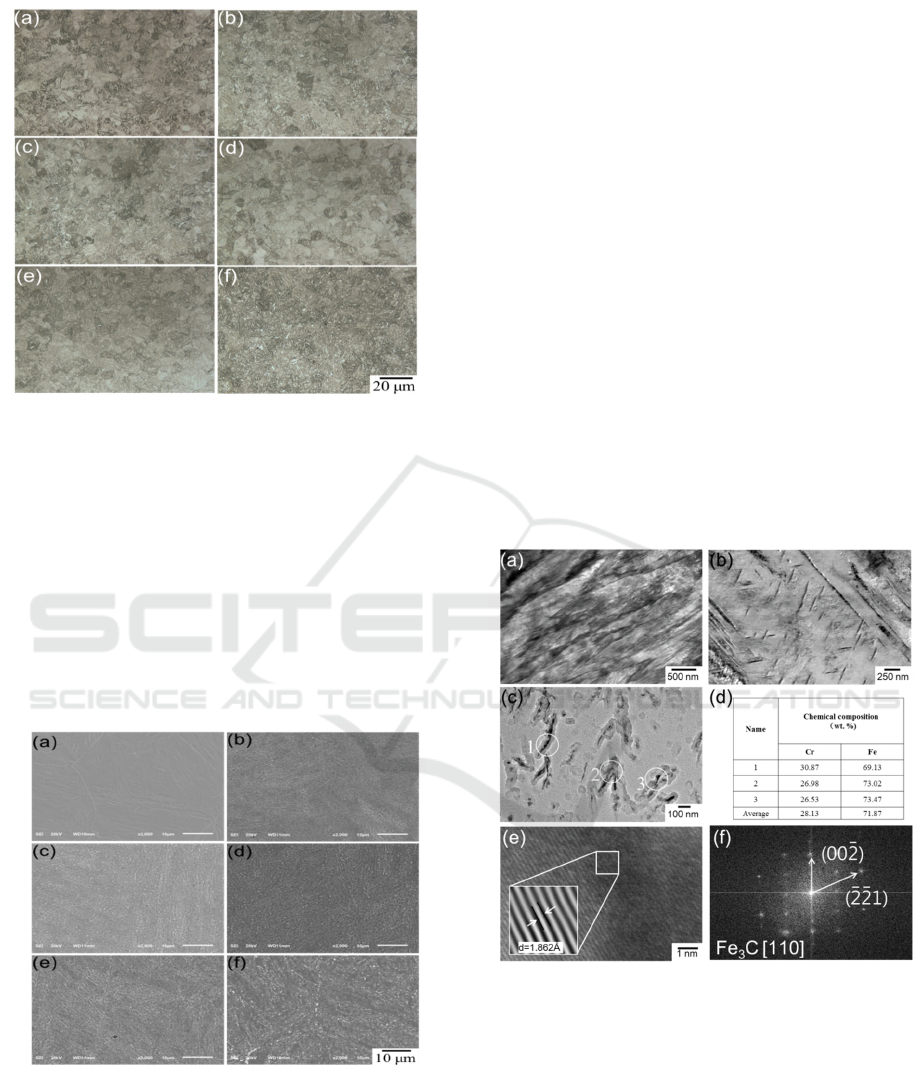

The OM microstructure of 13Cr MSS is shown in

Fig. 2.The martensitic of 13Cr MSS changes with

the tempering temperature rise. In the Martensitic

stainless steel after quenching and tempering, the

martensite decomposition, through the diffusion of

elements, grain boundary migration, the occurrence

of organizational changes (Caron R Net al.1972).

When the tempering temperature under 600°C, the

characteristics of martensite slabs are still evident in

Fig.2(a, b, c, d). As the temperature rise to 700°C,

the microstructure changes as fine ferrite with

carbides in Fig. 2(e).

Figure 2:OM microstructures of 13Cr steel (a) quenched

at 1050°C tempered at (b) 300°C, (c) 400°C, (d) 500°C,

(e) 600°C, (f) 700°C for 2 hrs.

The SEM microstructure of 13Cr MSS is shown

in Fig. 3. Carbides are precipitated from the matrix.

With the increase of tempering temperature, the

matrix, the morphology and distribution of carbides

have changed. At a low tempering temperature, the

matrix of martensite coarsed in Fig.3(b, c), and at a

higher tempering temperature, the martensite matrix

began to disappear in Fig.3(d). As shown in

Fig.3(e,f),the martensite lath already disappeared,

and carbides have gathered to grow into sphere-like .

Figure 3 : SEM microstructures of 13Cr steel (a)

quenched at tempered at 1050°C tempered at (b) 300°C,

(c) 400°C, (d) 500°C, (e) 600°C, (f) 700°C for 2 hrs.

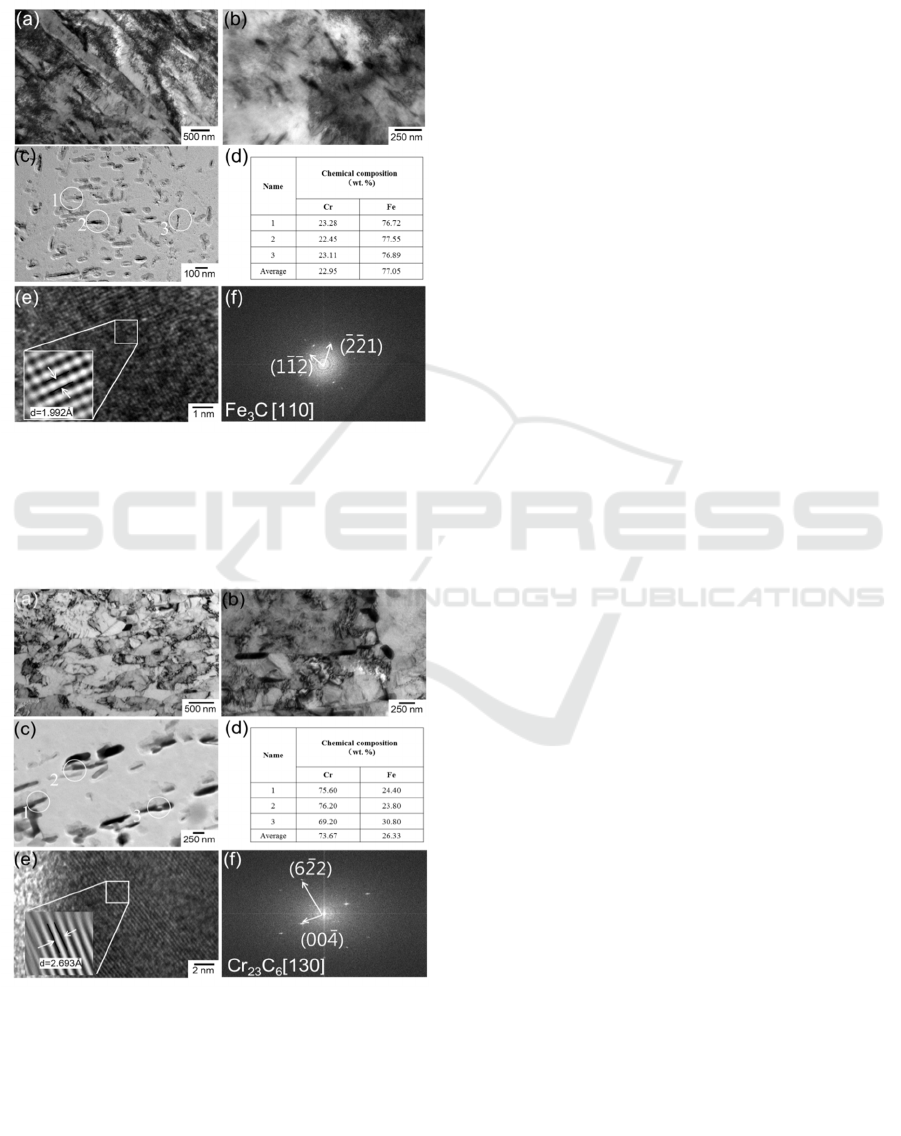

In order to judge the different carbides in 13Cr

MSS with tempering temperature rising. The TEM

samples were prepared with the 300°C, 500°C,

700°C tempering temperature. The TEM analysis

indicates that two processes can occur during

tempering: recovery and recrystallization of the

matrix and the precipitation of various carbides. The

TEM micrographs of 13Cr MSS tempered at 300°C

is shown in Fig. 4.

As shown in Fig. 4(a), the figure shows a

martensite lath area, composed of multiple slabs

single crystal, roughly parallel, the slab width,

length and length, the thickness of about tens of

nanometers to hundreds of nanometers, the existence

of slats dislocation substructures. The needle-like

carbides is shown in Fig. 4(b). To specifically

examine the formation of precipitates, a carbon

extraction replica was utilized to precisely identify

the carbides formed by tempering in Fig. 4(c).The

EDS, high-resolution TEM (HRTEM), fast Fourier

transformation (FFT) and the corresponding inverse

fast Fourier transformation (IFFT) has been

employed to identify the detailed information of

these carbides in Fig. 4(d, e, f).The orthorhombic

type Fe

3

C carbide was found in the specimen

tempered at 300°C.

Figure 4:TEM images of 13Cr steel tempered at 300°C

for 2 hrs: (a) matrix, (b) carbides in matrix, (c)carbides

analysis by carbon extraction replica technology, (d) EDS

results from (c) carbides, (e) HR-TEM images of carbides,

(f)The FFT pattern from (e), and inset of (e) shows the

IFFT image.

The TEM micrographs of 13Cr MSS tempered at

500°C is shown in Fig. 5. The martensite lath

coarsed in Fig. 5(a). The needle-like carbides

coarsed in Fig. 5(b,c). The EDS results show the

Fe3C carbides increase with the tempering

temperature in Fig. 4(d) and Fig. 5(d). The HRTEM,

the FFT pattern and the inverse FFT pattern shows

that it is also Fe3C carbide when tempering at 500°C

in Fig. 5(e, f).

Figure 5: TEM images of 13Cr steel tempered at 500°C

for 2 hrs: (a) matrix, (b) carbides in matrix, (c)carbides

analysis by carbon extraction replica technology, (d) EDS

results from (c) carbides, (e) HR-TEM images of carbides,

(f)The FFT pattern from (e), and inset of (e) shows the

IFFT image.

Fig. 6. TEM images of 13Cr steel tempered at 700°C for 2

hrs: (a) matrix, (b) carbides in matrix, (c)carbides analysis

by carbon extraction replica technology, (d) EDS results

from (c) carbides, (e) HR-TEM images of carbides, (f)The

FFT pattern from (e), and inset of (e) shows the IFFT

image.

The TEM micrographs of 13Cr MSS tempered at

700°C is shown in Fig. 6. After tempering at 700°C,

recovery and recrystallization of the matrix is shown

in Fig.6(a). The rod-like Cr-rich carbides was found

in original martensite lath and sphere-like Cr-rich

carbides was found in original austenite grain

boundary in Fig. 6(b, c). The EDS results, HRTEM

image analysis, fast Fourier transformation (FFT)

and the corresponding inverse fast Fourier

transformation (IFFT) indicates that these carbides is

Cr

23

C

6

carbide in 13Cr MSS when tempering at

700°C in Fig. 6(d, e, f).

4 CONCLUSIONS

During tempering, the matrix recovery by the

migration of lath boundaries and annihilation of

dislocations to slightly coarsen the lath and decrease

the dislocation density at temperatures lower than

500°C, and the formation of fine ferrite grains and

subsequent grain growth during tempering at

temperatures at 700°C to replace the original lath

structure.

Two types of Fe

3

C and Cr

23

C

6

carbides

precipitation are suggested. The needle-like

precipitation of Fe

3

C in lath martensite occurs at 300

~ 500°C. As the tempering temperature increased

(700°C), the phase transformation of Fe

3

C carbides

to Cr23C6 carbides occurred. The Cr

23

C

6

carbides

precipitation along the martensite lath is rod-like and

precipitation along grain boundaries is sphere-like.

Precipitation of Fe3C carbides at low

temperature enhances the hardness of the steel upon

precipitation hardening. As the tempering

temperature increased, the steels were dramatically

softened by grain growth and recrystallization.

REFERENCES

1. Feng Z. et al.2016.Analysis of Pitting Corrosion on

N80 3Cr Anti-corrosion Casing. Steel Pipe. 45(5),

p.60-63.

2. Jianqiang Y. et al. 2015. Selection and evaluation

methods of casing and tubing materials for sour

environments. Chemical engineering of oil & gas.

44(3). p.70-73.

3. CabelloG.et al. 2013.CO and trans-cinnamaldehyde as

corrosion inhibitors of I825, L80-13Cr and N80 alloys

in concentrated HCl solutions at high pressure and

temperature. ElectrochemicalActa. 97(5). p.1-9.

4. Sidorin D. et al. 2005. The electrochemistry of 13%

chromium stainless steel in oilfield brines.

ElectrochemicalActa. 50(20). p.4109-4116.

5. Larsen J. et al. 2015. Effect of Intervention History on

Corrosion State of Production Tubulars. Heat

Treatment of Metals. 34(1). p.75-77.

6. IsfahanyA N. et al. 2015.The effect of heat treatment

on mechanical properties and corrosion behavior of

AISI420 martensitic stainless steel. Journal of Alloys

& Compounds. 509(9). p.3931-3936.

7. Chakraborty G. et al. 2015. Study on tempering

behaviour of AISI 410 stainless steel. Materials

Characterization. 100. p.81-87.

8. Pfennig A. et al. 2013. Corrosion and corrosion fatigue

of AISI 420C (X46Cr13) at 60 °C in CO 2 -saturated

artificial geothermal brine. Corrosion Science. 68.

p.134-143.

9. Caron R N. &Krauss G. 1972. The tempering of Fe-C

lath martensite. Metallurgical and Materials

Transactions B. 3(9). p.2381-23