The Mises Stress in the Contact Region of Materials with Soft

and Hard Phases in Frictional Process

M Wang

1,2

, S C Yang

1, *

and G L Lu

2

1

Engineering College, Changchun Normal University, Changchun 130032, China

2

Key Laboratory for Bionic Engineering (Ministry of Education), Jilin University,

Changchun 130022, China

Corresponding author and e-mail: S C Yang, ysc2017@mail.cncnc.edu.cn

Abstract. Composite polymers are a class of materials that have demonstrated superior

performance in various applications and thus been widely used in many industries. By

mimicking the soft and hard structure in natural materials, a kind of materials with soft and

hard phases based on flexible rubber /high rigidity ABS has been designed. In this paper, the

numerical simulation of frictional process of materials with soft and hard phases was

performed to analyse the Mises stress state in

the contact region. The results show that hard

phase support more load than soft phase, thus influence the frictional property of materials

with soft and hard phases.

1. Introduction

Natural materials such as nacre, bone or dentin, are biological composites in which soft and hard

element arranged in series, and provide a range of interesting properties, such as prevention of crack

propagation, flexibility and protection for biological armors, and even strain enhancement and signal

filtering for mechanosensing. Brick and mortar structure has been proposed[1] in 2000 to describe

materials such as nacre or the mineralized collagen fibril.[2] Such soft and hard structures exist at all

scales in natural materials,[3] can afford a mechanical performance better than each of soft or hard

element, and have huge potential capacity to enhance the mechanical performance of conventional

pure or simple materials.[4] Since the 1980s, Ren et al. [5, 6] has been dedicating to the study of the

cuticle morphologies and principles of soil animals such as dung beetles, black ants, and pangolins

and found that there were generally five kinds of simple structures on the cuticles, including convex,

concave, stria, bristle and squama. They are called non-smooth construction units, which have been

found to provide excellent anti-wear properties against soil. In this paper, the frictional process of the

materials with soft and hard phases was studied with a finite element analysis tool, and the Mises

stress state in the contact region was studied to analyze the frictional property of materials with soft

and hard phases.

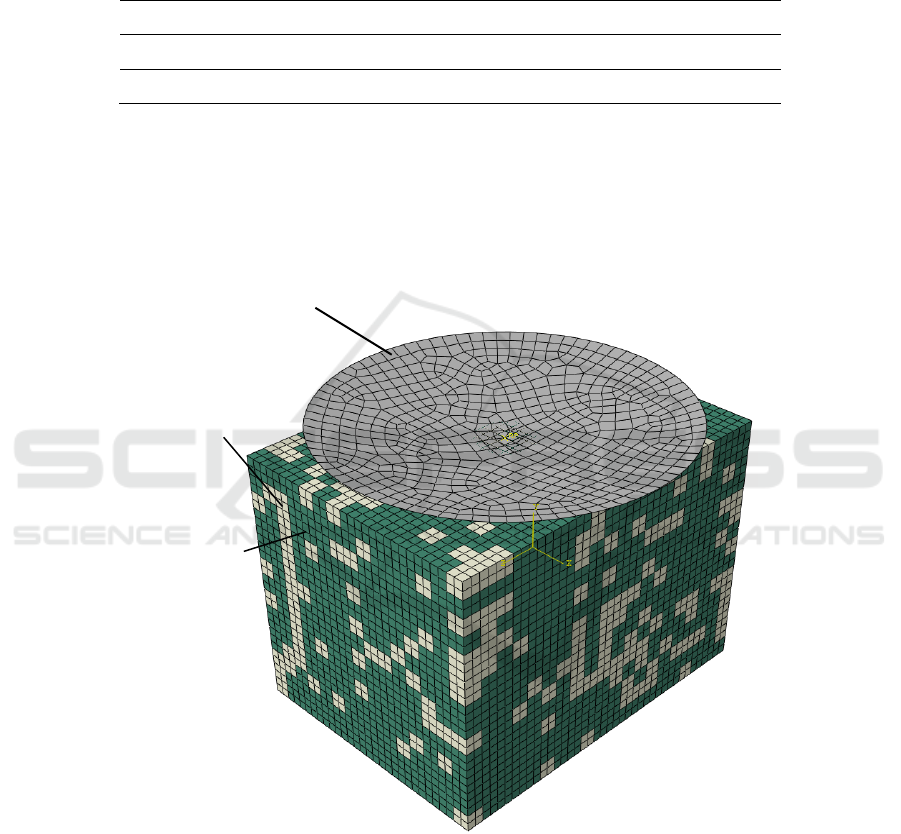

2. Finite element model

To understand the frictional process of materials with soft and hard phases deeply, numerical

simulation of frictional process of materials with soft and hard phases was performed under

ABAQUS/Explicit environment. The finite element model of frictional process is shown in Figure 1.

Wang, M., Yang, S. and Lu, G.

The Mises Stress in the Contact Region of Materials with Soft and Hard Phases in Frictional Process.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 681-684

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

681

The dimension of the material is 6 mm × 5 mm with the thickness 5 mm, and the material was

meshed by C3D8R element which is designed for large strains and deformations. The size of the

element is 0.01 mm × 0.01 mm × 0.01 mm, and a total of 152001 elements were used to model the

material.

Table 1. Material properties of soft phase and hard phase.

E (MPa)

μ

f

Soft material 270 0.4 0.1

Hard material 700 0.4 0.2

To simulate the friction boundary conditions between the material and the rubbing, surface-to-

surface contact mode was used, the friction coefficients (f) were 0.1 for soft phase and 0.2 for hard

phase, the Young’s model (E) is 270 MPa and 700 MPa for soft phase and hard phase respectively,

and the Poisson ratio for both soft and hard phases are 0.4. The material properties of the soft phase

and hard phase are listed in Table 1.

Figure 1. Numerical simulation of frictional process.

3. Results

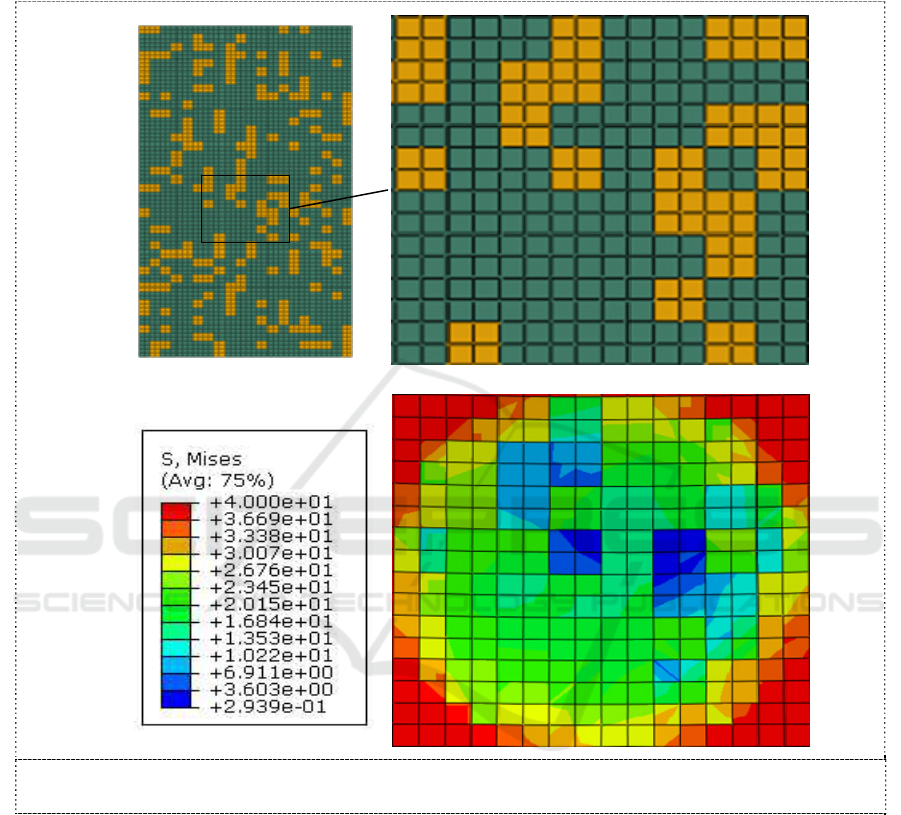

The frictional process for materials with soft and hard phases is more complicated than the material

with only hard or soft material. The materials with integrated hard and soft phases will lead to the

redistribution of the loads, and change the frictional property of the material. Figure 2a shows the

contact region of materials with soft and hard phases in frictional process, in which blue is for hard

region and yellow for soft region. It can be found in figure 2b that the Mises stress in the contact

region is larger than the other region, and the Mises stress is large in the region with hard phase (blue

Soft phase

Hard phase

Rubbing

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

682

region) and small in the region with soft phase (yellow region). This phenomenon shows the

redistribution of load, the hard phase support more load than soft phase, thus influence the frictional

property of the material with soft and hard phases.

Figure 2. Contact region of materials with soft and hard phases in frictional process.

4. Conclusions

Soft and hard structure which contains polymers with hardness differential can afford a mechanical

performance better than each of the composing polymers. The contact region of materials with soft

and hard phases in frictional process was present in this paper. It is obvious that the more load is

applied in the hard phase than the soft phase, and the redistribution of the load will influence the

contact state of two contact surface, thus change the frictional property of the materials with soft and

hard phases.

Acknowledgement

The authors would like to acknowledge the financial support provided by the National

Natural Science Foundation of China (Grant No. 51605187,Grant No.51605188),

Department of Education of Jilin Province (Grant No. JJKH20181163KJ, Grant No.

Contact region

h

1

h

2

h

3

h

4

s

1

s

2

s

3

s

4

h

1

s

1

h

2

s

2

s

3

s

4

h

3

h

4

(a)

(b)

The Mises Stress in the Contact Region of Materials with Soft and Hard Phases in Frictional Process

683

JJKH20180093KJ), Jilin Provincial Science & Technology Department (Grant No.

20180201004GX), China Post Doctoral Science Foundation (Grant No. 2016M601382).

References

[1] Jäger I and Fratzl P 2000 Mineralized collagen fibrils: a mechanical model with a staggered

arrangement of mineral particles Biophysical Journal 79 1737-46

[2] Gao H, Ji B, Jager IL, Arzt E and Fratzl P 2003 Materials become insensitive to flaws at

nanoscale: lessons from nature Proceedings of the National Academy of Sciences of the

United States of America 100 5597-600

[3] Browning A, Ortiz C and Boyce M C 2013 Mechanics of composite elasmoid fish scale

assemblies and their bioinspired analogues Journal of the Mechanical Behavior of

Biomedical Materials 19 75-86

[4] Fratzl P, Kolednik O, Fischer F D and Dean M N 2015 The mechanics of tessellations -

bioinspired strategies for fracture resistance Chemical Society Reviews

[5] Ren L, Deng S, Wang J and Han Z 2004 Design Principles of the Non-smooth Surface of

Bionic Plow Moldboard Journal of Bionic Engineering 1 9-19

[6] Zhang Z H, Zhou H, Ren L Q and Tong X 2007 Tensile property of H13 die steel with convex-

shaped biomimetic surface Applied Surface Science 253 8939-44

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

684