Study on the Damping Mechanism of Chlorinated Butyl

Rubber/C5 Petroleum Resin Composites by Experimental

and Molecular Dynamics Simulation

C Yin, J Zhu, L Lu, M F Wang, Q Zhang and S Z Wu

*

College of Materials Science and Engineering, Beijing University of Chemical

Technology, Beijing 100029, P. R. China

Corresponding author and e-mail: S Z Wu, wusz@mail.buct.edu.cn

Abstrac t. In this work, the damping mechanis m of C5 petroleum resin/chlorinated butyl

rubber (CIIR) composites were studied by combin ing experimental and mo lecular dynamics

(MD) simu lation. From a macro perspective, the damping parameters (glass transition

temperature T

g

and effective da mp ing temperature region ΔT) and the activation energy (E

a

)

were obtained by dynamic mechanical thermal analysis. In the micro level, four

intermolecular interaction parameters (binding energy E

binding

, fractional free volume, mean

square radius of gyration and mean square displacement) were calculated by molecular

dynamics simulations. These studies are expected to provide the useful information in

understanding the damping mechanism and to offer the theoretical guidance for optimizing

the damping properties of polymer composites.

1. Introduction

In the past decades, how to effectively reduce the noise pollution or mechanical vibration has become

a hot topic[1]. Viscoelastic polymer used as damping materials have attracted a considerable

attention for converting vibration or noise energy to heat energy. As we know, the excellent damping

materials should have suitable glass transition temperature which is better close to application

condition and also should be with the wide effective damping temperature region.

Comparing with other polymer matrices, the chlorinated butyl rubber (CIIR) has preferable

damping properties due to its dense side methyl groups, lower molecular mobility and higher energy

loss. According to reports in the literature[2], CIIR shows a unique relaxation behavior which are the

asymmetrical double-peak structure with a maximum on the high temperature side and the additional

shoulder on the low temperature side. Plazek [3]

and Huang[4, 5] examined that different modes of

CIIR molecular motion contribute to the transition region from local segmental motion, sub-Rouse

mode, and Rouse mode. However, the loss peaks of the above three modes of CIIR molecular motion

are located at lower temperature region rather than room temperature. Therefore, in order to broad

the effect damping temperature region of CIIR composites, many ways have been attempted such as

blend modification, copolymerization,

gradient polymers,

interpenetration network (IPN) polymers

etc[6].

644

Yin, C., Zhu, J., Lu, L., Wang, M., Zhang, Q. and Wu, S.

Study on the Damping Mechanism of Chlorinated Butyl Rubber/C5 Petroleum Resin Composites by Experimental and Molecular Dynamics Simulation.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 644-650

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Hindered phenols or hindered amines [6]

often be used to improve the damping properties of

composites. For example, Yang [7] investigated that hindered phenol AO-80 effectively improved

the damping performance of hindered phenol/polyacrylate hybrids. However, the method of

modifying with small polar molecules also has many shortcomings, such as the easy migration of

small molecule [8],

which makes the loss factor tan δ decrease, and consequently the damping

properties of composites fall off. Meanwhile hindered phenols are also relatively expensive. Such as

the price of C5 petroleum resin (Puyang Ruisen Petroleum Resin Factory (China)), which can also

effectively improve the damping properties, is just 3.9 dollar per kilogram in 2017 for reducing the

costs drastically. The C5 petroleum resin is a kinds of amorphous polymers with low molecular

weight (from 300 to 3000) and the glass transition temperature region is located near the room

temperature which shows the capacity to improve the damping performance of rubber composites in

practical application. Wu and co-workers investigated the CIIR/C5 petroleum resin composites with

different contents, the glass transition temperature increased and the effective damping temperature

range was successfully broadened[9,10]. However, the mechanisms for improving the damping

performance is not very clear, some microscopic parameters (such as the interactions and mobility of

the molecular chains) cannot be obtained. With the development of computational technology, the

molecular simulation has provided an effective tool to figure out the microstructural and the

properties of materials at a molecular level. Therefore, in this work the molecular dynamics

simulation is introduced to study the damping mechanism of C5 petroleum resin/CIIR composites.

2. Simulation results and analysis

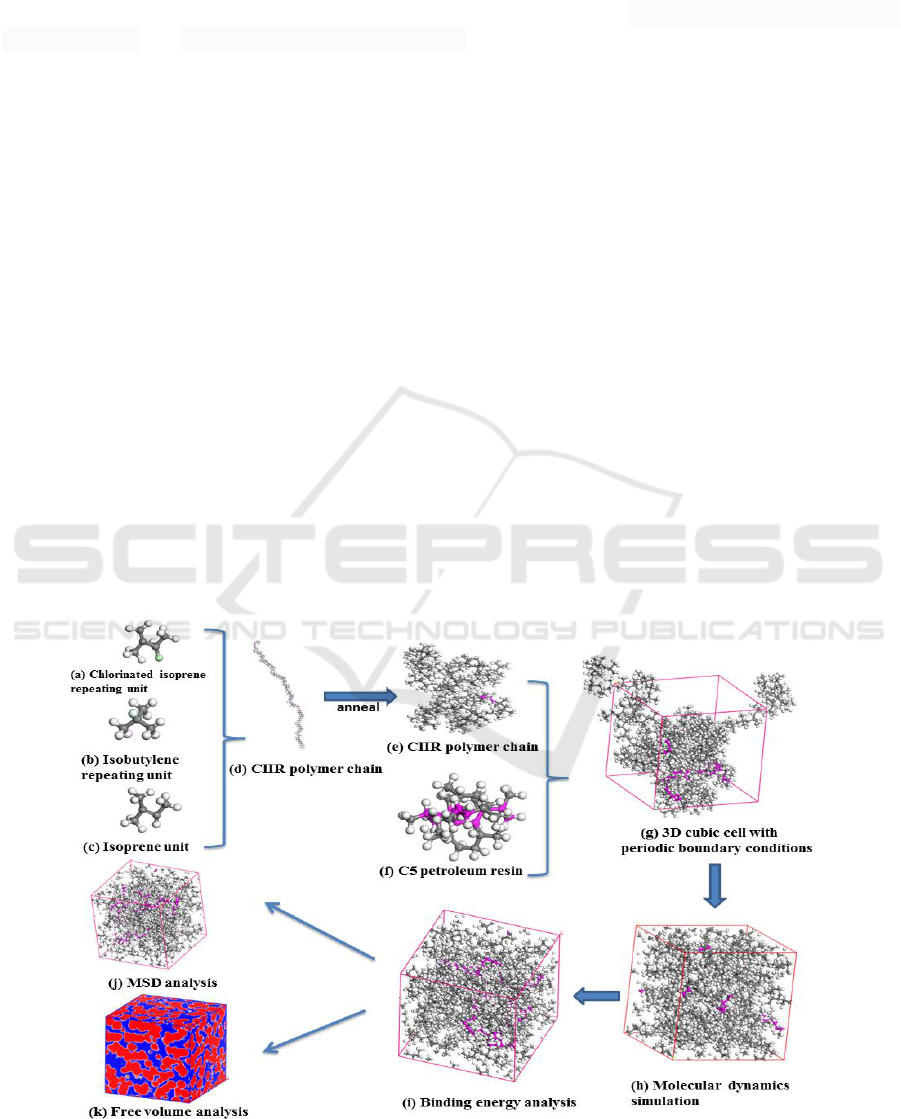

The construction procedure of the C5 petroleum resin/CIIR composites cells is shown in Figure 1.

The chlorinated isoprene repeat unit, isobutylene repeat unit and isoprene repeat unit were first

randomly copolymerized as a CIIR polymer chain. Subsequently, 500 ps of NVT simulation was

performed at 298 K and 1000 ps of NPT simulation is performed at 0.1MPa pressure to further relax

the polymer chain structure.

Figure 1. Construction procedures of C5 petroleum resin/CIIR systems for MD simulation.

Study on the Damping Mechanism of Chlorinated Butyl Rubber/C5 Petroleum Resin Composites by Experimental and Molecular Dynamics

Simulation

645

The binding energy (E

binding

) is introduced to investigate the influence of intermolecular

interaction on damping properties. Table 1 shows that with increasing content of C5 petroleum resin,

E

binding

increases gradually, which indicates that the intermolecular interactions between CIIR and C5

petroleum resin are constantly increased. Meanwhile, the binding energy is always kept the positive

value which indicates good compatibility in the C5 petroleum resin/CIIR system [11].

Table 1. Binding energy with different C5 petroleum resin contents.

Mass ratio of

C5 petroleum resin/CIIR

E

total

(kcal mol

-1

)

E

C5 petroleum resin

(kcal mol

-1

)

E

CIIR

(kcal mol

-1

)

E

binding

(kcal mol

-1

)

0/100

443.010

0

443.010

0

10/100

-702.808

52.718

-616.450

139.116

20/100

-1290.370

61.386

-1147.060

204.696

30/100

-766.773

90.170

-576.742

280.160

40/100

-1285.420

136.328

-1052.340

369.408

50/100

-1345.920

137.939

-1042.420

441.438

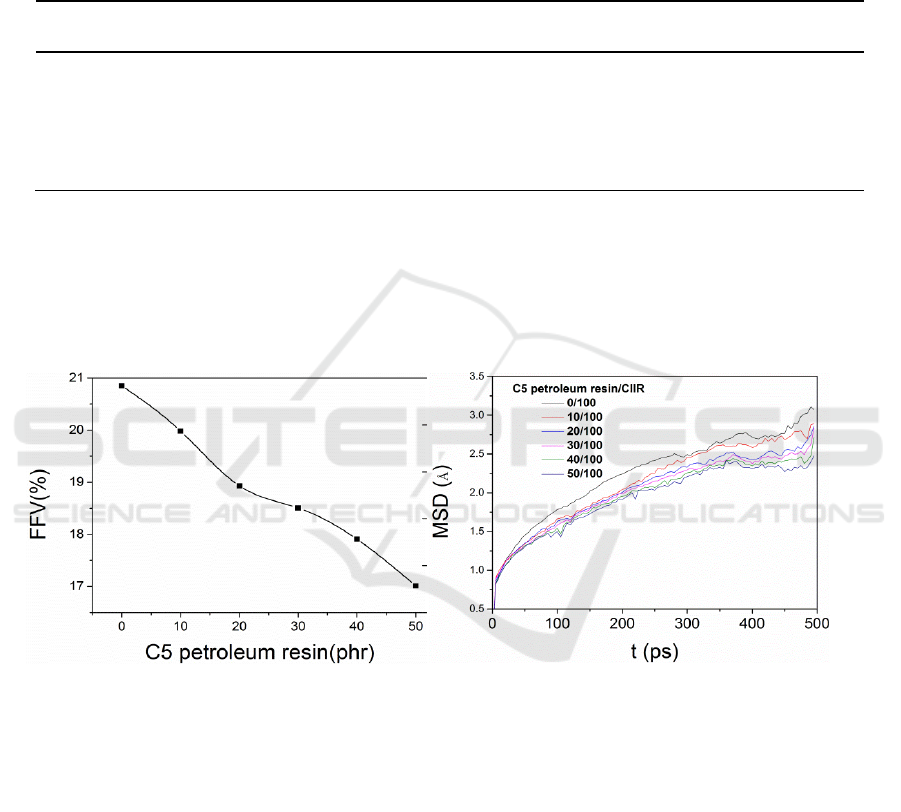

The fractional free volume (FFV) [11] may be used to reflect the efficiency of chain packing in

C5 petroleum resin/CIIR systems which the results are shown in Figure 2. With increasing content of

C5 petroleum resin, the FFV decreases since the stronger intermolecular interaction causes close

packing of molecular chains, shortens the interspace and increases the friction between the molecular

chains, which is resulted the enhanced damping performance.

The mean square displacement (MSD) may be used to describe the activities of the molecular

chain[12]. Figure 3 was the simulation result of MSD. With the increase of C5 petroleum resin

content, the MSD of CIIR chains gradually decreases, which means the movement of CIIR chains

becomes more difficult, and the glass transition temperature (T

g

) of C5 petroleum resin/CIIR systems

should move towards high temperature direction.

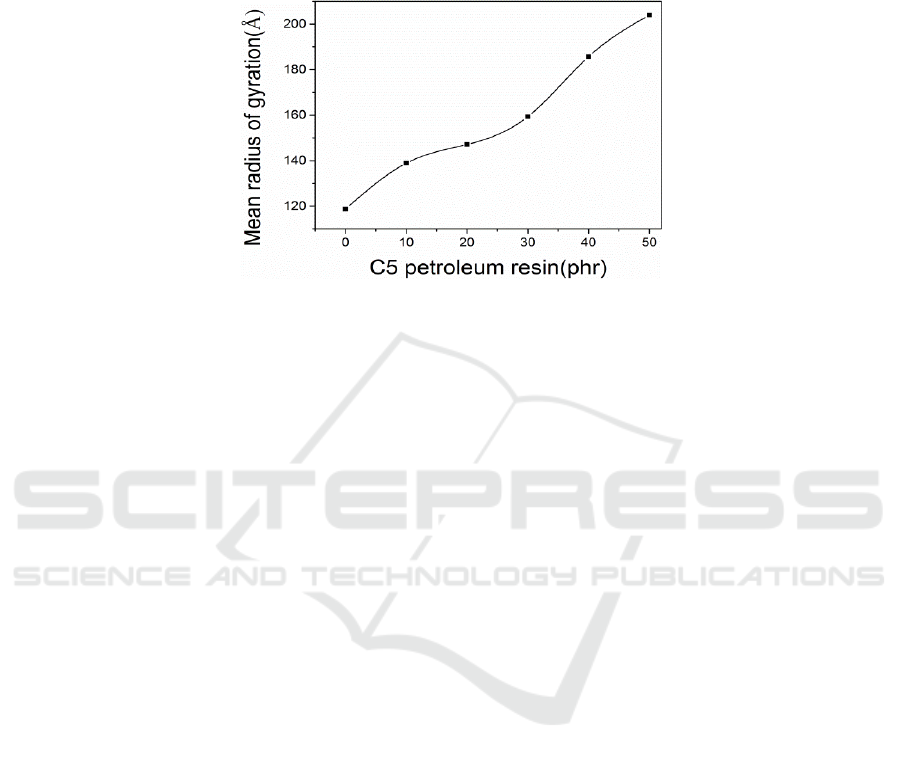

The radius of gyration is a parameter commonly used to describe the size of a random polymer

chain. The polymer chain is more flexible with smaller R

g

[13]. Figure 4 shows that the mean square

radius of gyration of CIIR chains with different C5 petroleum resin content. It was noted that as the

content of C5 petroleum resin increases, the mean square radius of gyration of CIIR chains gradually

enhances. This is because with the increase of C5 petroleum resin content, the intermolecular

Figure 2.The fractional free volume

(FFV) of C5 petroleum resin/CIIR

composites with different C5

petroleum resin content.

Figure 3.

The mean square displacement

(MSD) of CIIR chains with different C5

petroleum resin content.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

646

interaction between C5 petroleum resin and CIIR gradually increases and there are good

compatibility between these two, which the CIIR chains becomes more stretched resulting in

increasing values of the mean square rotation of CIIR chains and the activity of the CIIR chains falls

off. This result is consistent with the previous MSD effects.

Figure 4.The mean square radius of gyration of CIIR chains with different C5 petroleum resin

content.

3. 3. Experiments and results

3.1.1. Materials and sample preparation. The chlorinated butyl rubber (CIIR, product code: 1066)

with a chlorination concentration of 1.2% is purchased from Japan Synthetic Rubber Co. (Japan).

The C5 petroleum resin is from Puyang Ruisen Petroleum Resin Factory (China). The composites

were prepared according to the following procedures: (1) the CIIR matrix was first plasticized on a

Φ152.4 mm two-roll mill at room temperature for 4 min. Then the C5 petroleum resin was added to

CIIR with mass ratio of 0/100, 10/100, 20/100, 30/100, 40/100, 50/100 respectively, which is as same

as the mass ratio to build the amorphous cell in MD simulations. (2) the blends were mixed on a two-

roll mill at room temperature for 5min with compounding and crosslinking additives (including 5.0

phr of zinc oxide, 1.0 phr of stearic acid, 1.5 phr of tetramethylthiuram disulfidee, 3 phr of 2,2'-

dibenzothiazoledisulfde and 2.0 phr of sulfur). (3) the composites were hot-pressed and vulcanized at

160 °C under the pressure of 15 MPa and then make the samples cool down to room temperature.

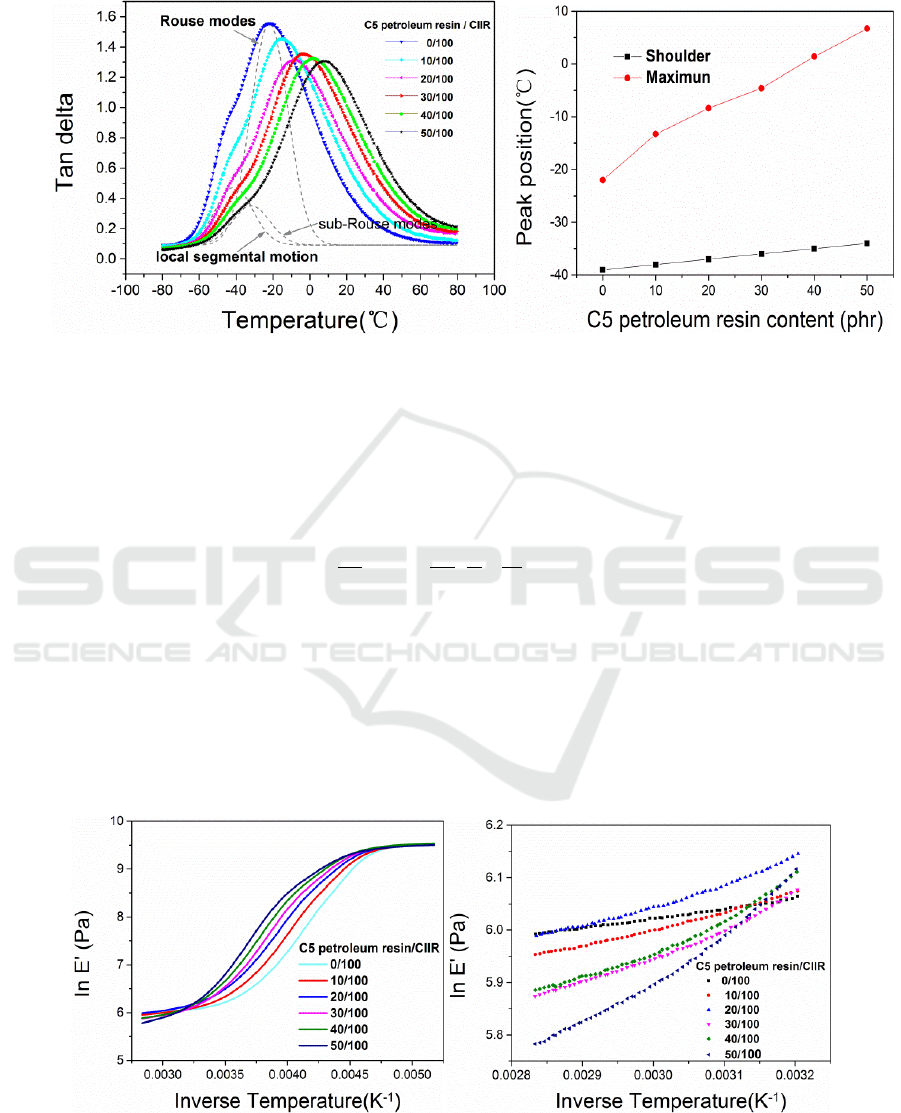

3.1.2. DMA analysis of C5 petroleum resin/CIIR composites. The damping properties and the

changes of molecular dynamics of polymer of C5 petroleum resin/CIIR have been studied by DMA

experiments [14]. The damping performance is shown in Figure 5(a). It shows that the T

g

and ΔT

increase gradually with increasing C5 petroleum resin content. Generally, the T

g

values of CIIR can

be extracted from the peak temperatures in the tan δ curves. But it is found that the tan δ curve of

CIIR displays an asymmetrical peak with a shoulder peak at about -38°C and a maximum peak at -

22°C . According to reports in the literature [15], tan δ curve may be divided into three peaks which

can be correspond to the local segmental, sub-Rouse mode and Rouse mode peaks respectively. The

local segmental, which is a cooperative motion of neighboring chains each involve several repeat

units, is the enthalpic and related with the glass transition temperature. Meanwhile the Rouse mode,

which is based on the motions of Gaussian sub-molecules formed by sufficient number of repeat

units in each chain, is entropic in nature. As Figure 5 shows that both the maximum and the shoulder

of the tan δ peak of CIIR move to the higher temperature with the increase of C5 petroleum resin

content, which indicating C5 petroleum resin limits the space for CIIR due to intermolecular

interaction between C5 petroleum resin and CIIR. Meanwhile, it is noted that C5 petroleum resin

Study on the Damping Mechanism of Chlorinated Butyl Rubber/C5 Petroleum Resin Composites by Experimental and Molecular Dynamics

Simulation

647

limits these two relaxation modes (local segmental motion and Rouse modes relaxation) to different

extents.

(a) (b)

Figure 5.(a) Temperature dependence of loss factor (tan

) for C5 petroleum resin/CIIR composites,

and (b) Peak position of different modes of C5 petroleum resin/CIIR composites with different C5

petroleum resin content.

The activation energy (E

a

) is introduced to quantify the internal friction. According to the storage

modulus (E’)–temperature curves presented in Figure 6 (a). E

a

can be calculated through the

following Arrhenius-type equation [16]:

00

11

exp[( ( )]

a

E

E

E R T T

(1)

Where E’ is the storage modulus at temperature T, E

0

is the storage modulus at reference

temperature T

0

and R is the universal gas constant. Based on Eqn (1), the logarithm of the storage

modulus is almost linear with the inverse temperature, which the result is shown in Figure 6 (b). It

can be seen that the E

a

is almost proportional to the slope of the straight line. For the 50/100 system,

the deviation occurs at a low temperature which may be owed to aggregations of the C5 petroleum

resin. Table 2 listed the results of the E

a

, showing that E

a

of CIIR chains increase gradually with

increasing C5 petroleum resin content. It indicates that more energy is required to overcome internal

friction of CIIR chains, which is consistent with the result of MSD.

(a) (b)

Figure 6.(a) Storage modulus in temperature sweep for C5 petroleum resin/CIIR composites, and (b)

logarithm of storage modulus against inverse temperature for C5 petroleum resin/CIIR composites.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

648

Table 2.Damping properties of CIIR and C5 petroleum resin/CIIR composites

Mass

ratios of

C5 petroleum

resin/CIIR

tan δ

max

tan δ > 0.3

Value

T

g

(°C)

T

1

a

(°C) T

2

a

(°C)

ΔT

a

(°C) E

a

(kJ mol

-1

)

0/100

1.56

-22.00

-57.70 29.45

-54.10 38.25

-50.35 45.60

-45.35 52.10

-44.50 56.45

-39.45 62.40

87.15 1.53

10/100

1.45

-13.30

92.35 2.70

20/100

1.31

-8.40

95.95 3.38

30/100

1.35

-4.60

97.45 4.32

40/100

1.32

1.40

100.95 4.86

50/100

1.31

6.70

101.85 7.27

a.T

1

, T

2

is the starting and ending temperatures with the loss factor tanδ 0.3 range. ΔT is the difference value

from T

1

to T

2

.

4. Conclusions

The damping mechanism of C5 petroleum resin/CIIR composites was studied by combining

experimental and molecular dynamic simulations. With the increase of C5 petroleum resin content,

the damping parameters (T

g

and ΔT) gradually increase, which shows C5 petroleum resin improve

the damping performances of the composites. As the two relaxation processes need different free

volume, the local segmental motion and Rouse mode have different responses to the space limited

from DMA experiments. The simulation parameters (FFV, MSD) are getting smaller, which shows

the C5 petroleum resin plays a key role like anti-plasticizer in decreasing the free volume fraction of

the blends. The presence of C5 petroleum resin slightly confines the molecular mobility of the local

segmental motion of CIIR, but greatly confines the molecular mobility of Rouse mode of CIIR.

Acknowledgements

The authors acknowledge the National Natural Science Foundation of China (Grant No. 51473012).

References

[1] Zhao X, et al, 2016 Molecular-level insight of hindered phenol AO-70/nitrile-butadiene rubber

damping composites through a combination of a molecular dynamics simulation and

experimental method. RSC Advances. 6(89) 85994-86005

[2] Wu J, et al, 2011 Molecular dynamics in chlorinated butyl rubber containing organophilic

montmorillonite nanoparticles. Journal of Polymer Research. 18(6) 2213-2220

[3] Plazek D J, et al, 1995 Viscoelastic properties of polymers. 4. Thermorheological complexity

of the softening dispersion in polyisobutylene. Macromolecules. 28(19) 6432-6436

[4] Wu, J., et al., 2011 Detecting different modes of molecular motion in polyisobutylene and

chlorinated butyl rubber by using dielectric probes. Soft Matter. 7(19) 9224-9230

[5] Zhang, F., et al., 2015 The damping and flame ‐ retardant properties of poly(vinyl

chloride)/chlorinated butyl rubber multilayered composites. Journal of Applied Polymer

Science. 132(2) 41259

[6] Zhu, J., et al., 2018 Quantitative relationships between intermolecular interaction and damping

parameters of irganox‐ 1035/NBR hybrids: A combination of experiments, molecular

dynamics simulations, and linear regression analyses. Journal of Applied Polymer Science,

135 46202

[7] Yang, D., et al., 2016 Investigation of the damping properties of hindered phenol AO-

80/polyacrylate hybrids using molecular dynamics simulations in combination with

experimental methods. Journal of Materials Science. 51(12) 5760-5774

[8] Wu, W., et al., 2017 Extraction resistance and mechanism of a macromolecular hindered

phenol antioxidant in natural rubber. Journal of Applied Polymer Science. 134 44905

Study on the Damping Mechanism of Chlorinated Butyl Rubber/C5 Petroleum Resin Composites by Experimental and Molecular Dynamics

Simulation

649

[9] Jin, K.K., Y.R. Du, and K.H. Lee, 2000 The aromatic hydrocarbon resins with various

hydrogenation degrees Part 1. The phase behavior and miscibility with polybutadiene and

with polystyrene. Polymer. 41(14) 5195-5205

[10] Liang, J., S. Chang, and N. Feng, 2013 Effect of C5 petroleum resin content on damping

behavior, morphology, and mechanical properties of BIIR/BR vulcanizates. Journal of

Applied Polymer Science. 130(1) 510-515

[11] Song, M., et al., 2014 Molecular dynamics simulations and microscopic analysis of the

damping performance of hindered phenol AO-60/nitrile-butadiene rubber composites. RSC

Advances. 4(13) 6719

[12] Wang, W., et al., 2014 Bromination of butyl rubber in rotating packed bed reactor. Chemical

Engineering Journal. 240(6) 503-508

[13] Zhao, X.Y., et al., 2007 Nitrile butadiene rubber/hindered phenol nanocomposites with

improved strength and high damping performance. Polymer. 48(20) 6056-6063

[14] Ngai, K.L., D.J. Plazek, and I. Echeverría, 1996 Viscoelastic Properties of Amorphous

Polymers. 6. Local Segmental Contribution to the Recoverable Compliance of Polymers.

Macromolecules. 29(24) 7937-7942

[15] Zhang, F., et al., 2014 The molecular dynamics of different relaxation modes in asymmetric

chlorinated butyl rubber/petroleum resin blends. RSC Adv. 4(40) 20620-20625

[16] Luo, Y., et al., 2016 Experimental study and molecular dynamics simulation of dynamic

properties and interfacial bonding characteristics of graphene/solution-polymerized styrene-

butadiene rubber composites. RSC Advances. 6(63) 58077-58087

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

650