Property Improvement of Wood by Organic-inorganic

Hybrid Polymer

J Wei

1,#

, R Zhao

1,#

, Z X Yang

1,#

, J L Fan

1

, C K Wang

1

, Y Sun

1

, B X Liu

2,*

, C H

Li

3

, X Y Dong

1,*

and Y F Li

1,*

1

Forestry College, Shandong Agricultural University, Taian 271018, China

2

Shandong Laucork Development Co., Ltd., Jining 272119, China

3

Sihong Inovo Wood Industry Co. Ltd, No.1 Industrial Park of Chengtou Town,

Suqian 223900, China

Corresponding author and e-mail: B X Liu, lyf288@hotmail.com; X Y Dong,

dxiaoying1982@163.com; Y F Li, 133997518@qq.com

#

These authors contributed equally

Abstract. Fast-growing wood plays an important role in addressing the contradiction

between supply and demand of wood. However, the low-quality of fast-growing wood limits

its wide applications as an alternative to high-quality wood. Consequently, we designs

organic-inorganic hybrid polymer as reinforcer to improve the mechanical properties and

thermal stability of poplar wood. Poly(ethylene glycol) dimethacrylate (PEG200DMA) as an

organic agent, tetraethoxysilane (TEOS) as an inorganic agent and γ-( methacryloxypropyl)

trimethoxy silane (KH570) as a coupling agent were employed to form organic -inorganic

hybrid polymer in wood via free radical polymerization and hydrolysis-condensation reaction,

in order to impart the high toughness of polymer, and high thermal stability of inorganic

matrix to wood. The modulus of rupture, compression strength, impact toughness and

hardness of the resulted wood is remarkably increased by 61%, 57%, 140% and 221% over

untreated wood, respectively.

1. Introduction

Wood has been a kind of raw material which is essential to human life since ancient times. It has

been widely used in the fields of construction, transportation, interior decoration and sports

equipment. However, in recent years, almost all the countries around the world have restricted timber

cutting. At the same time, the supply of high-quality wood is limited. On the other hand, people’s

pursuit of the quality of life requires an increasing supply of wood. Sharp contradictions between

supply and demand of wood have promoted the widespread cultivation of fast-growing species.

Although the fast-growing wood has eased the contradiction to some extent, it has the inherent

defects such as poor quality and poor strength. Consequently, it is difficult to substantially replace

high-quality wood, and thus effective modifications are urgently needed to overcome the defects of

the poor strength of the fast-growing wood[1-2].

The reported methods on wood modification include: 1) in-situ formation of polymer within wood

to form wood-polymer composites to increase the strength of the wood[3-8]; 2) in-situ formation of

630

Wei, J., Zhao, R., Yang, Z., Fan, J., Wang, C., Sun, Y., Liu, B., Li, C., Dong, X. and Li, Y.

Property Improvement of Wood by Organic-inorganic Hybrid Polymer.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 630-637

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

inorganic materials in wood to form wood-inorganic composites to improve the strength and thermal

stability of wood[9]; 3) compression treatment to increase the strength of wood[10]. However, all

these methods have certain fatal defects, and are difficult to make the modified wood being met the

practical requirements. For example, 1) although the strength of the wood-polymer composite is

significantly increased, the impact toughness is far lower than that of unmodified wood, suggesting

brittleness; 2) the strength of wood-inorganic composites are normally less improved and brittle; 3)

the strength of compressed wood are traditionally improved, but the thickness are easy spring-back in

wet condition. Although the dimensional stability could be improved by impregnating formaldehyde-

based resins, such treatment adversely results in significant reduction in the impact toughness of the

modified wood. In other words, it can not simultaneously increase strength and impact toughness.

As organic-inorganic hybrid nanocomposite possesses the strength and toughness of the organic

object and the rigidity, thermal stability and function of the inorganic object, indicating synergistic

enhancement of the hybrid compounds in nanoscale, it becomes the fourth generation of new

materials which are after one-component materials, composite materials and functional gradient

materials. It has become a hot research topic in the field of materials science.

In this context, this study attempts to use functional monomers with flexible chain unit and

polymerizable C=C double bond as the organic object, and tetraethoxysilane (TEOS) as the inorganic

agent, and duplicate silane as the coupling agent, to form organic-inorganic hybrid polymer within

the natural cell pores of wood. The purpose is to impart the high strength, high toughness of the

polymer and thermal stability of the inorganism to the untreated wood and accordingly form an

integrated wood .

2. Experiments and materials

2.1. Test materials

Glycidyl methacrylate(GMA) (Shanghai Yuanji Chemical Co. Ltd..) and 2,2-

Azobisisobutyronitrile(AIBN) (Shanghai Reagent 4 Factory) are analytical Reagents (AR).

Poly(ethylene glycol) dimethacrylate (PEG200DMA) (Yantai Yunkai Chemical Co., Ltd..) is

chemically purified (CP) agent. Tetraethoxysilane (TEOS)( Tianjin Komio Chemical Reagent

Development Cente) is analytical reagent(AR). γ-( methacryloxypropyl) trimethoxy silane (KH570)

(Nanjing Shuguang Chemical Group Co., Ltd..) is chemically purified agent. Laboratory chemical

reagents such as hydrochloric acid(38wt), tetrahydrofuran, acetone, anhydrous ethanol, deionized

water, are analytical reagent. All these chemical reagents can be used directly.

The wood species is Populus Ussuriensis Komarov, which was collected from Heilongjiang

Maoershan Forest Plant. The size of the wood plates is 25×300×2000 mm

3

(radial (R)×tangential (T)

×longitudinal (L)). After three-month adjustment at room temperature, the average moisture content

of the wood plate reached 10.4 wt%. Then the specimens are dried at 105

o

C for 24h to form an

average density of 0.35 g/cm

3

, and further stored for use afterward.

The experimental equipments and instruments include impregnation tank (home-made with size

of 300mm × 600mm (inner diameter × high) and maximum pressure of 1.7 MPa), vacuum oven

(DZF-6050 purchased from Shanghai Precision Instrument Instrument Co., Ltd.), WL-1 Particle Ball

Mill (Tianjin Computer Room Equipment Factory), Atomic-force microscopy (AFM, NaioAFM,

Nanosurf AG, Liestal, Switzerland) with tapping mode, QUANTA2000 Environmental Scanning

Electron Microscope (ESEM) (FEI Company), Magna IR 560 Fourier Transform Infrared

Spectroscopy (FTIR) (Nicolet Company in US), D/max2200 X-ray diffraction instrument (Rigaku

Corp., Tokyo, Japan) (XRD), and Thermogravimetric Analysis (TG/DTG, Q5000IR, TA Instrument,

New Castle, Delaware).

Property Improvement of Wood by Organic-inorganic Hybrid Polymer

631

2.2. Test methods

1) First, GMA and PEG200DMA were mixed into 100 mL tetrahydrofuran at a mass ratio of 20:1;

and then, AIBN, which accounts for 0.5 % of the total mass of the monomer, was added, followed by

KH570, which is 20 wt% of the total solution. The mixed solution was stirred for 15 min. Finally, the

condensation reaction was cycled at 65~70 °C for 70min, followed by severe stirring at room

temperature for 10 minutes. 2) At the same time, 0.3 M TEOS, 1.2 M deionized water, and a certain

amount of 38 wt% hydrochloric acid to make the mixed liquid with pH = 3.5 were employed to react

at 45 °C for 3h. 3) The above two kinds of solutions were mixed and stirred at room temperature for

30 minutes. Then, they were divided into two groups. One was poured into a glassware, which was

sealed and saved it for 5 days (room temperature). Then the pre-reacted samples were stored at 30-

35 °C for 2 days, and then at 45-50 °C for 2 days, and then at 70-80 °C for 1 day, and then at 105-

110 °C for 1 day to form completely polymerized hybrid polymer for comparison. The other one was

used to impregnate wood by the vacuum-pressure tank under the conditions of -0.8 MPa for 10min,

followed by 0.8 MPa for 10min. After being wrapped in aluminum foil, the treated wood samples

were stored at room temperature for 5 days, and then heated at 30-35°C for 2 days, and at 45-50 °C

for 2 days, and at 70-80 °C for 1 day, and at 105-110 °C for 1 day to finally obtain the wood-hybrid

polymer composite. With the same steps, the above amounts of GMA, PEG200DMA and AIBN was

mixed and impregnated into wood to form wood-polymer composite for comparison.

All the prepared samples were characterized by SEM, AFM, FTIR, XRD and TG/DTG

(Thermogravimetry/Differential Thermogravimetry). Before FTIR and TG experiments, the polymer was

extracted by THF for 24h.

The specimens’ preparation and test methods for the properties evaluation were conducted according

to the "national standard methods for testing wood physical and mechanical properties" (GB1928-2009).

The size of the specimens for modulus of rupture measurement is 20mm ×20mm × 300mm (R×T × L),

and the size of the specimens of the compression strength test is 20mm × 20mm × 30mm (R ×T × L), and

the size of specimen of the impact toughness test is 20mm × 20mm × 300mm (R ×T × L). Each

experiment was conducted in parallel for 5 times to obtain the mean value of the property.

3. Results and analysis

3.1. Microstructural morphology analysis

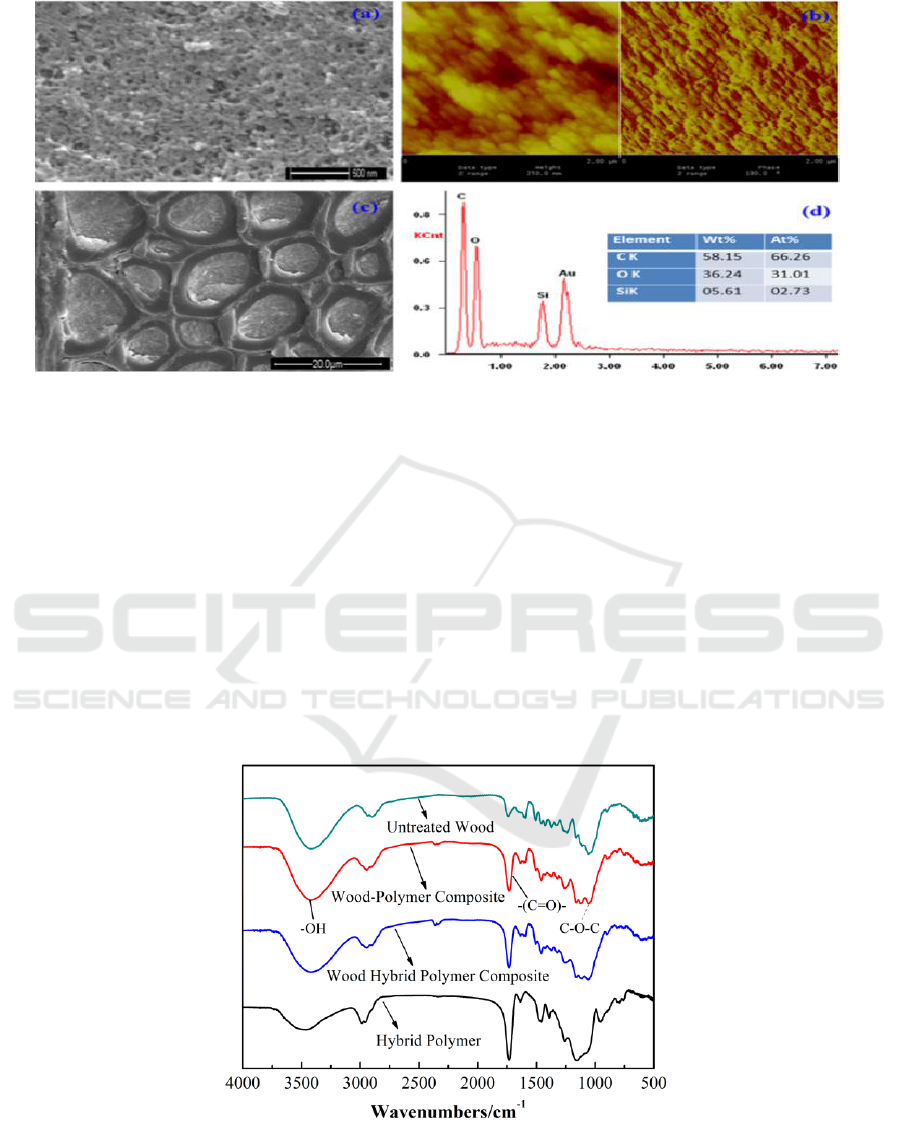

Figure 1a shows that there are nanoscale pores in the hybrid polymer and nanoparticles in the matrix.

Figure1b shows that the particle size in the hybrid polymer matrix is about 100nm, which is

consistent with the structure of figure 1a. The structure should be ascribed to the fact that 1) the

acidic hydrolysis condensation of ethyl silicate forms a granular spherical SiO

2

, and the particle size

can be controlled at the nanometer level when the conditions (pH, reaction time, etc.) are appropriate;

2) the particle size is linked by polymer chain, and the organic and inorganic objects are evenly

combined on nanoscale to form organic-inorganic hybrid polymer. Figure 1c clearly shows that the

polymer is densely packed in the wood cell lumen. Figure 1d further proves that the polymer in

Figure 1c is combined with silicon-containing compounds, suggesting that the wood-based organic-

inorganic composite is formed.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

632

Figure 1. Microstructural topography of Hybrid Polymer and Wood-Hybrid Polymer Composite: (a)

SEM morphology of Hybrid Polymer, (b) AFM morphology of Hybrid Polymer, (c) SEM photo of

the Wood-Hybrid Polymer Composite, (d) the EDX mapping of figure(c).

3.2. Fourier transform infrared spectrometry ( FTIR ) analysis

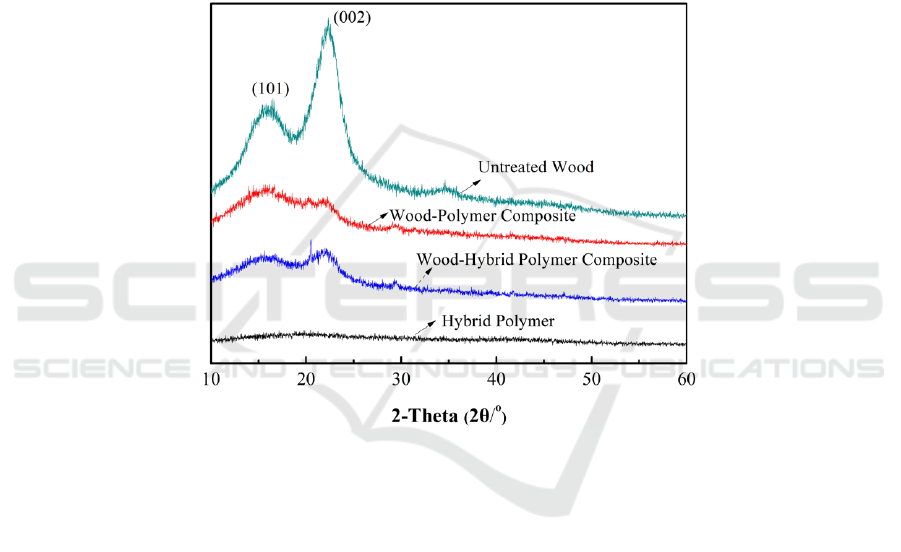

Figure 2 proves that the hybrid polymer, untreated wood, wood polymer composite and the wood-

hybrid polymer composite presents peaks at 3400cm

-1

,2960cm

-1

,2880cm

-1

,1730cm

-1

,1260cm

-1

,1160-

1060cm

-1

corresponding to the stretch vibration of -O-H, =C-H, -C-H, -C=O, -C(=O)- and -C-O (or

Si-O) groups, respectively. The stretch vibration of wood-hybrid polymer composite at 1260-1060

cm

-1

is more intensive than the that of wood-polymer composite and also untreated wood, suggesting

-C-O (or Si-O) groups formed in the hybrid polymer. In addition, same phenomena was observed at

1730cm

-1

, suggesting that the polymer and hybrid polymer grafted onto wood components.

In other words, the polymer can not only form chemical bonds with the wood component, but realize

the connection of polymer chain with the inorganic component through Si-O bond.

Figure 2. FTIR spectrogram of Untreated Wood, Hybrid Polymer, Wood-Polymer Composite and

Wood-Hybrid Polymer Composite.

Property Improvement of Wood by Organic-inorganic Hybrid Polymer

633

3.3. X-ray diffraction(XRD) analysis

Figure 3 shows that the hybrid polymer has no obvious crystal peak, indicating that it is an

amorphous material. The untreated wood presents obvious peak at 2θ=16.5° and 2θ=22.5° assigned

to the lattice plane of (101) and (002), respectively, which suggests crystal I form of the untreated

wood. The wood-polymer composite and wood-hybrid polymer composite present similar peaks at

2θ=16.5° and 2θ=22.5°, suggesting their same crystal form to that of untreated wood. However, their

peaks are quite lower than those of the untreated wood, which should be ascribed to the fact that the

amorphous polymer grafted onto wood components resulted in higher amorphous aggregation of the

treated wood and thus decreased by the crystallinity of the wood-polymer composite and the wood-

hybrid polymer nanocomposite. Such results proves the chemical grafting of the polymer onto wood

components.

Figure 3. XRD spectrogram of Hybrid Polymer, Wood - Polymer Composite and Wood-Hybrid

Polymer Composite.

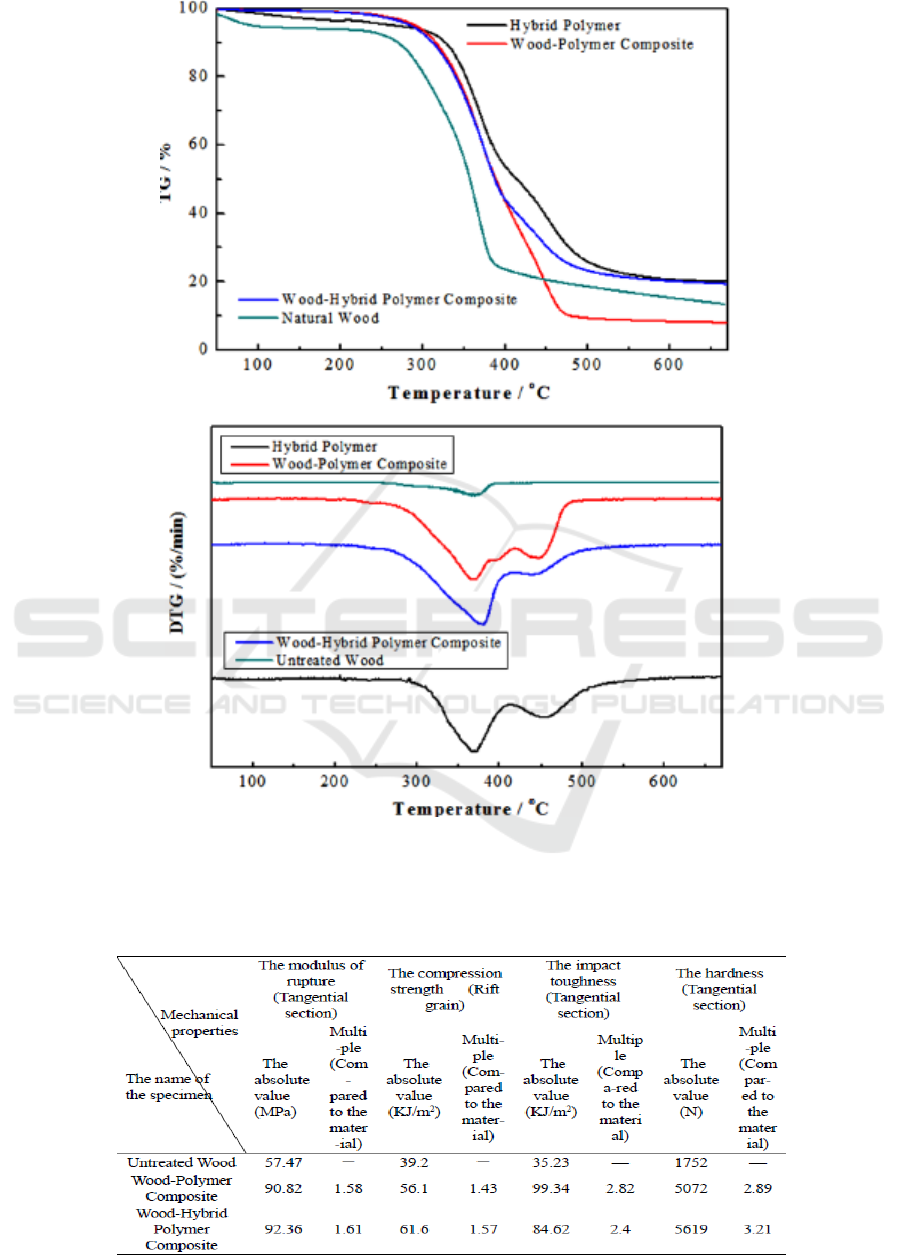

3.4. Thermgravimetry and differential thermgravimetry (TG/DTG) analysis

Figure 4 shows that the hybrid polymer begins pyrolysis at 300 °C, while the three wood materials

begin to undergo obvious pyrolysis at 275 °C, indicating that the wood materials are more likely to

begin degradation than the hybrid polymer. The untreated wood and the wood-polymer composite

present their maximum thermal decomposition temperatures at about 480 °C, while the hybrid

polymer and the wood-hybrid polymer composite are basically degraded at about 500 °C, suggesting

improved thermal stability of the wood-hybrid polymer composite due to its hybridization polymer

formed in wood. In addition, in terms of the weight loss, the descending order is wood-polymer

composite, untreated wood, wood-hybrid polymer nanocomposite and the hybrid polymer, indicating

that the hybrid polymer improved the thermal stability of wood.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

634

Figure 4. TG/DTG curves of Hybrid Polymer, Untreated Wood (i.e., Natural Wood), Wood-Polymer

Composite and Wood-Hybrid Polymer Composite.

Table 1. Comparison of mechanical properties of untreated wood and other two wood materials.

Property Improvement of Wood by Organic-inorganic Hybrid Polymer

635

*The polymer quality of all kinds of wood composites accounts for 70~ 100% of the quality of wood

materials.The test data is the mean of 5 parallel test results.The hardness number is the pressure value

when the head is pressed at depth of 2.81mm under the wood surface. The size of the specimen is about

50 × 50× 20 (mm) (L× R× T).

3.5. Performance analysis

According to the data shown in table 1, the modulus of rupture, compression strength, impact

toughness and hardness of the resulted wood is remarkably increased by 61%, 57%, 140% and 221%

over that of untreated wood, respectively. The results should be due to the hybrid composition of the

polymer and the inorganic object, which makes the molecular chains into stereo cross-linked form,

and accordingly improves the mechanical properties of wood. Interestingly, the thermal stability of

the hybrid wood is also improved. This consistence should be ascribed to the formation of the hybrid

polymer within wood that presents in cross-link form, which in turn contributes to enhanced stability

of the polymer as reinforcer of wood. The strong hybrid polymer consumes more energy of the

external loading and heating, enabling simultaneously improved mechanical properties and thermal

stability of wood.

4. Conclusions

1) The organic-inorganic hybrid polymer is produced in wood pores, and the wood-hybrid polymer

composite is synthesized by organic-inorganic hybrid technology. Among them, the inorganic

moiety is evenly distributed in the polymer matrix in situ formed within wood cell lumen, and the

nanoparticle size is around 100nm.

2) The succeeded composition of the hybrid polymer and wood obviously improves the thermal

stability of wood with enhancement of maximum pyrolysis temperature of about 20 °C over

untreated wood. And the modulus of rupture, compression strength, impact toughness and

hardness of the resulted wood is remarkably increased by 61%, 57%, 140% and 221% over

untreated wood, respectively.

Author contributions

Jie Wei, Ruo Zhao, Zhixing Yang, Baoxuan Liu, Jing Dong and Yongfeng Li designed the

experiment. Jie Wei, Ruo Zhao and Zhixing Yang performed the whole experiments. Jilong Fan,

Changkai Wang and Yun Sun helped to do some experiments. Baoxuan Liu and Canghai Li provided

the wood materials for the whole expriments. Jie Wei, Xiaoying Dong and Yongfeng Li wrote the

paper. Everybody comments on the final manuscript. Jie Wei, Ruo Zhao and Zhixing Yang

contributed equally to this work. Baoxuan Liu, Jing Dong and Yongfeng Li are corresponding

authors.

Acknowledgements

We acknowledge the financial supports from the Natural Science Foundation of Shandong Province,

Doctoral Branch (Grant. No. ZR2017BC042), and Innovation Project of Shandong Provincial

Forestry Science and Technology (Grant. No. 2018SDLY010), and Key Special Foundation for the

National Key Research and Development Program of China (Grant. No. 2016YFD0600704), and

National Natural Science Foundation of China (Grant. No. 31700497), and Project of the Shandong

Province Higher Educational Science and Technology Program (Grant. No. J15LC13).

References

[1] Xie Y J, Fu Q L, Wang Q W and Wang H Q 2012 Wood chemical modification: the

state of the art of technologies and commercialization. Scientia Silvae Sinicae 48(9)

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

636

pp 154-163. (in Chinese)

[2] Dong X, X Zhuo , Liu C, Wei J, Zhang G, Pan R T and Li Y F 2016 Improvement of

decay resistance of wood by in-situ hybridization of reactive monomers and nano-

SiO2 within wood. Applied Environmental Biotechnology 1 pp 56-62.

[3] Dong X Y, Sun T P, Liu Y X, Li C H and Li Y F 2015 Structure and properties of

polymer-impregnated wood prepared by in-situ polymerization of reactive

monomers. Bioresources 10(4) pp 7854-7864.

[4] Islam M S, Hamdan S, Rahman M R, Jusoh I, Ibrahim and N F 2010 Dynamic

Young’s modulus and dimensional stability of batai tropical wood impregnated with

polyvinyl alcohol. Journal of Materials Research 2(2) pp 227-236.

[5] Islam M S, Hamdan S, Jusoh I, Rahman M R and Talib Z A 2011 Dimensional

stability and dynamic young’s modulus of tropical light hardwood chemically

treated with methyl methacrylate in combination with hexamethylene diisocyanate

cross-linker. Industrial and Engineering Chemistry Research 50(7) pp 3900-3906.

[6] Li Y F, Liu Y X, Wang X M, Wu Q L, Yu H P and Li J 2011 Wood-polymer

composites prepared by in-situ polymerization of monomers within wood. Journal

of Applied Polymer Science 119 (6) pp 3207-3216.

[7] Dong X Y, Zhuo X, Wei J, Zhang G and Li Y F 2017 Wood-based nanocomposite

derived by in-situ formation of organic-inorganic hybrid polymer within wood via a

sol-gel method. ACS Applied Materials & Interfaces 9 pp 9070-9078.

[8] Stacy T, Shadi J and Mats J 2012 In situ polymerization of polyaniline in wood

veneers. ACS Applied Materials & Interfaces 4(3) pp 1760-1769.

[9] Zhuo X, Wei J, Xu J F, Pan R T, Zhang G, Guo Y L, Dong X Y, Long L and Li Y F

2017 Nanocellulose isolation from Amorpha Fruticosa by an enzyme-assisted

pretreatment. Applied Environmental Biotechnology 2 pp 34-39.

[10] Dick S, Peer H and Parviz N 2013 Thermo-hydro and thermo-hydro-mechanical wood

processing: An opportunity for future environmentally friendly wood products

Wood. Material Science and Engineering 8(1) pp 64-88.

Property Improvement of Wood by Organic-inorganic Hybrid Polymer

637