Analysis of Bolts’ Axial Corrosion Using Guided Waves

Based on FEM

P Ding

1,2, *

C Lu

3

, G F Ma

1

, T Li

1

, G F Yue

1

and X L Huang

1

1

Standard & Quality Control Research Institute Ministry of Water Resources. P.R.C,

Hangzhou, China

2

Key Laboratory of Research on Hydraulic and Hydro-Power Equipment Surface

Engineering Technology of Zhejiang Province, Hangzhou, China

3

Key Lab of Nondestructive Testing, Ministry of Education, Nanchang Hangkong

University, Nanchang, China

Corresponding author and e-mail: P Ding, qddp2008@126.com

Abstract. Bolts are widely used in water conservancy and hydropower engineering. There are

no good methods to test the corrosion defect of the bolts. Guided wave was used in this paper

to test the simulation axial defect in bolt based on FEM. The trend of the axial corrosion

coefficient and reflection coefficient of the guided wave was revelled. It shows that the

change trend of the defect reflection and wave type conversion of L (0, 1) mode and F (1, 1)

mode is consistent. The defect reflection of F (1, 1) is higher than the defect reflection of L (0,

1), both the defect reflection of F (1, 1) and L (0, 1) are no higher than 25%. And also it

verified the capability of low-frequency guided wave in detecting the small and medium

defects of bolts’ corrosion.

1. Introduction

Hydropower project transmission tower is an important facility to erect high-voltage transmission

lines. It is important to keep the tower fastness and reliable. The bolt is significant structure of

transmission tower, the safety and stability of bolt is in a very great degree affect the safety, stability

and service life of the transmission tower. Since the 1950s, China started using anchor in the coal

mine. And as support structure the anchor is widely used in the rock. With the development of

hydropower industry and the demand of the long-distance transmission, a large number of bolts have

been used in the cable of power transmission tower. These bolts are main load-bearing members,

which bear a large force and are used in bad environment. During the long term use, the effects of

cutting, fatigue and rainwater corrosion and the potential defects in the construction process easily

cause the failure, resulting in the occurrence of the accident. Not only does it cause enormous

economic losses, but it also results in casualties. Therefore, it is very important to use nondestructive

testing method to evaluate the operation condition and corrosion state of transmission tower. Guided

wave is a kind of ultrasonic wave which can be propagated in plates, rods and tubes, with the

advantages of small attenuation and long propagation distance. It has natural advantages for the

detection of transmission tower bolts defects such as rust.

616

Ding, P., Lu, C., Ma, G., Li, T., Yue, G. and Huang, X.

Analysis of Bolts’ Axial Corrosion Using Guided Waves Based on FEM.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 616-620

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All r ights reserved

2. Guided waves in bolt

The ultrasonic guided wave is caused by wave interference and dispersion due to multiple reflection

and scattering in the boundary of the propagation medium. The phase velocity is the rate at which the

phase of the wave propagates in space. This is the velocity at which the phase of any one frequency

component of the wave travels. The group velocity of a wave is the velocity with which the overall

shape of the wave's amplitudes-known as the modulation or envelope of the wave—propagates

through space. Guided waves are propagated by group velocity, and it have two characteristics:

dispersion characteristics and multimodal characteristics [1-7].

There are three modes of the ultrasonic wave propagating along the axial direction in the bolts, the

longitudinal axisymmetric mode L (0, m), the torsional mode T (0, m) and bending mode F (n,m).

The same frequency corresponds to several wave Numbers, that is, there are several different modes

at a certain frequency, and as the frequency increases, the number of modes becomes more and more.

Theoretically, in the low frequency range (< 100kHz) only exist L (0, 1) and F (1, 1) mode, and the

velocities of this two modes are quite different. The dispersion curve in theoretical draw by matlab of

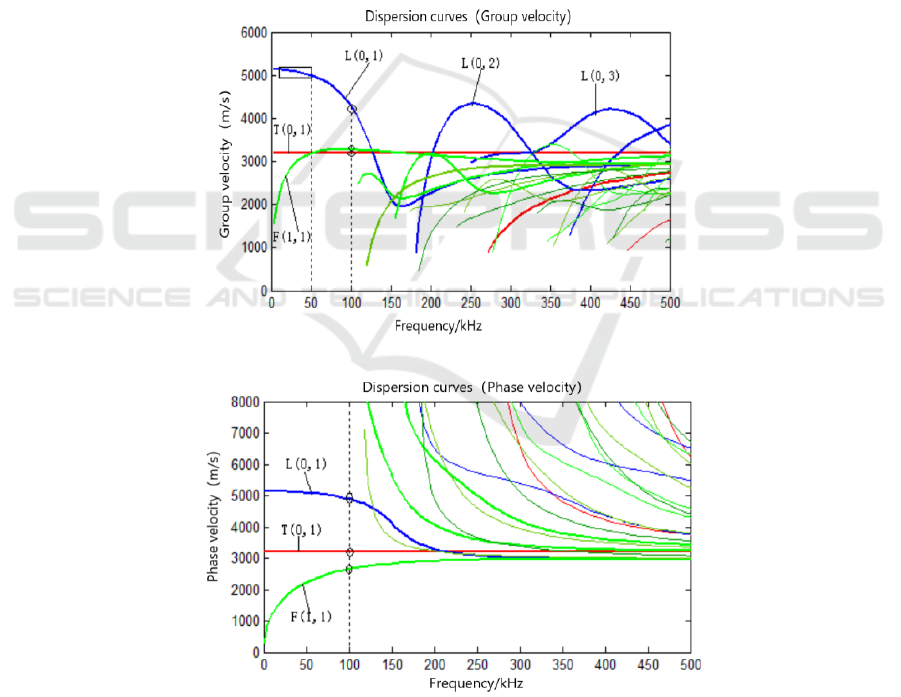

a solid cylinder with a diameter of 20mm and a length of 2m is shown in Figure 1.

(a) Dispersion curve of group velocity

(b) Dispersion curve of phase velocity

Figure 1. Dispersion curve of the solid cylinder with a diameter of 20mm and a length of 2m.

From the dispersion curve, it approves that when the frequency < 100kHz, there are only two

modes: the longitudinal mode L (0, 1) and the bending mode F (1, 1). So L (0, 1) mode and F (1, 1)

Analysis of Bolts’ Axial Corrosion Using Guided Waves Based on FEM

617

mode are selected to detect the corrosion of the bolts in order to avoid the other modes mask the

defect echo.

3. Simulation Model

According to the bolts’ size, the model is shown in Figure 2. In this model D=20mm, L=2m. The

length of the defect axis is indicated by a, and the axial corrosion coefficient (A) is defined as the

percentage of defect length(a) and wavelength. Reflection coefficient of ultrasonic guided wave R is

defined as R=B(ω)/A(ω), In this paper, B(ω) is the amplitude spectrum of the waveguide wave echo

at the end surface or the defect, A(ω) is the amplitude spectrum of the excitation signal wave. The

greater R is and the greater of the energy of reflected echo signal will be.

Figure 2. Bolt’s Model.

The material properties of the bolt are: Young’s Modulus E=206000Mpa; Poisson’s Ratio σ=0.30;

Mass Density ρ=7580kg/m3. ABAQUS/Explicit dynamic module was adopted in the simulation, and

the grid cell type was selected as C3D4, the length of the elements was set as 1/20 of the wavelength.

According to theory and simulation, guided wave excitation and acceptance point are set at the end

surface, and the waveguide frequency is 50kHz.

4. Result and Discussion

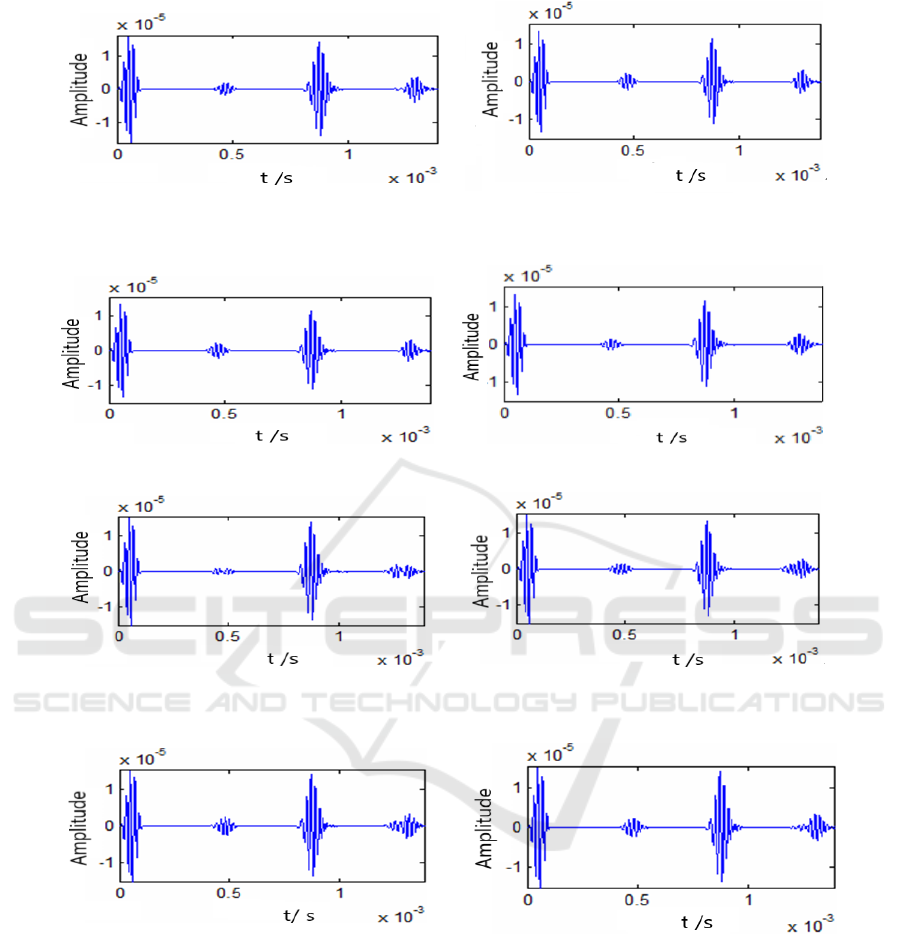

The defect depth is 1mm and distribution along the circumference, the axial length corrosion

coefficient(A) is 10%, 20%, 30%...90 percent to simulate. The results were shown from Figure 3 to

Figure 11.

From Figure 3 - Figure 11, it shows that the change of axial length coefficient is related to the

defect reflection coefficient. When axial length greater than or equal to 50%, the last time become

longer both the defect reflection L (0, 1) and wave type conversion F (1, 1). The transformation wave

pattern increases with the increase of axial length coefficient because that as the axial length

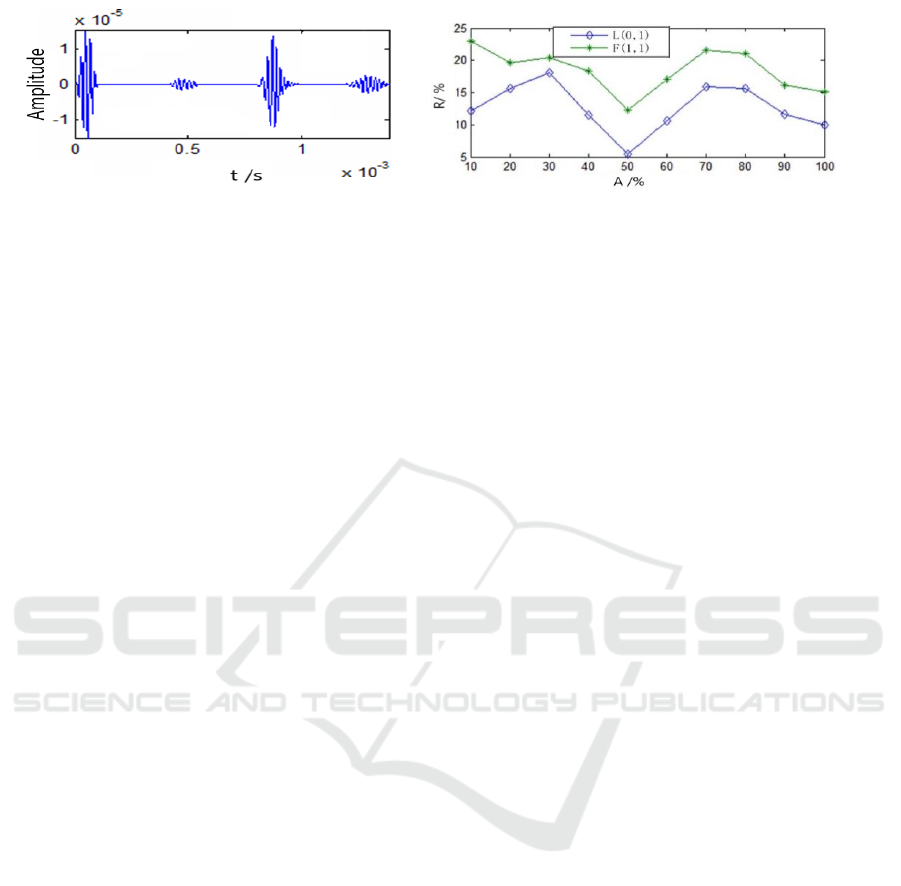

increases, the front and rear surfaces of the defect position are all reflected. Figure 12 shows the

relationship between the axial corrosion coefficient (A) and reflection coefficient (R). The change

trend of the defect reflection and wave type conversion of L (0, 1) mode and F (1, 1) mode is

consistent. The defect reflection of F (1, 1) is higher than the defect reflection of L (0, 1) mode, both

the defection of F (1, 1) and L (0, 1) are no higher than 25%.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

618

Figure 3. Waveform of A=10%. Figure 4. Waveform of A=20%.

Figure 5. Waveform of A=30%. Figure 6. Waveform of A=40%.

Figure 7. Waveform of A=50%. Figure 8. Waveform of A=60%.

Figure 9. Waveform of A=70%. Figure 10. Waveform of A=80%.

Analysis of Bolts’ Axial Corrosion Using Guided Waves Based on FEM

619

Figure11. Waveform of A=90%.

Figure 12. Trend of the Axial corrosion

coefficient and Reflection coefficient.

5. Summary

Through numerical simulation, the capability of low - frequency guided wave in detecting the small -

and - medium defects is verified. The reflection coefficient changes with the change of axial defect,

and it has good correspondence which provides a good reference for the guide wave detection of bolt

and other long straight bars, which are used in water conservancy and hydropower engineering.

Through further research and experiment, it is beneficial to the development of water conservancy

and hydropower engineering guided wave detection.

Acknowledgement

Thanks to the support of Science and Technology Project of Zhejiang Province (Nos. 2017C37062).

References

[1] Zeng G P 2017 Study on propagation characteristics of ultrasonic guided waves in arch

bridge suspender Zhejiang University.

[2] Rose J L 1999 Ultrasonic waves in solid Media Cambridge University Press

[3] Gazis D C 1959 Three dimensional investigation of the propagation of waves in hollow

circular cylinders Analytical Foundation J. of the Acoustics Society of America 31 pp568-

573

[4] Menachem Z and Tapuchi S 2013 Analyzing wave propagation in helical waveguides using

laplace, fourier, and their inverse transforms, and applications Intech: Wave Propagation

Theories and Applications

[5] Ahmed S R and Saka M 2000 A new ultrasonic angle-beam technique for sensitive evaluation

of closed cracks NDT&E International 33(4) pp 261-271

[6] Yang H 2013 Research on using ultrasonic guided wave NDT technique to detect the quality of

metal buffer rod cofferdam system North University of China

[7] Ivanovic A, Neilson R D and Rodger A A 2001 Numerical Modeling of single tendon ground

anchorage systems Geotech. Eng.142(2) pp 103-113

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

620