Effects of Stress and Roughness on the Reflectivity of Blue

Light in ZnS/MgF

2

Multilayers

S Y Lian

1

, S H Xiao

1

, Y P Yu

1

, S H Lin

1

, H Y Zhang

2

, G Lin

2

, C K Xu

3

and J Y

Wang

1,

*

1

Department of Physics, Shantou University, Shantou, 515063, Guangdong, China

2

ShanTou Go World-Display Co. LTD, Shantou, 515065, Guangdong, China

3

Wuxi Xumatic Co., Ltd., Wuxi, 224200, Jiangsu, China

Corresponding author and e-mail: J Y Wang, wangjy@stu.edu.cn

Abstract. The influences of stress and interface roughness on the reflectivity of blue light in

the ZnS/MgF

2

multilayered film are evaluated quantitatively using the small deflection theory

of elastic mechanics and the index method. The simulated results show that upon the interface

roughness increasing, the reflectivity value of the blue light decreases but the shape of the

reflectivity curve does not change. The applied stresses do not change the shape of the

reflectivity curve. Depending on the compressive or tensile stress, the respective reflectivity

curve shifts to right or left as compared to the one without stress, but such a shift depends

strongly on the substrate thickness.

1. Introduction

The blue light that is part of the white light do have great harm to the human eye by damaging the

light-sensing cells of retina [1]. Many efforts have been made to design a suitable optical

multilayered film for filtering the blue light. To this end, the reflectivity of blue light in the prepared

multilayered film is often evaluated quantitatively in order to obtain an optimum layered structure.

On the other hand, to prepare a multilayered film on a foreign substrate, the interface roughness

between sublayers and the stress between film and substrate may be introduced into the multilayered

structure. Therefore, the effects of stress and interface roughness on the reflectivity of blue light in

the multilayered structure have to be taken into account in order to obtain a reliable simulated result.

It was found that the interface roughness has a significant influence on the reflectivity by

scattering losses, which has already been treated successfully both in theory and experiment [2].

Many papers in literature report the roughness effect on the optical properties for single layered

structure [3] and for multilayered structure. Stress in thin film associated with the lattice mismatch

and the difference of thermal expansion coefficient between film and substrate has also an impact on

the reflectivity of optical thin film [4-5]. The stress may cause film crack and even falling off

degrading the stability and the reliability of optical thin film. Currently, a couple of models have been

put forward for analyzing the stress [6-11] such as the finite element method [12-14] and the

boundary element method [15-16]. The stress in thin film is usually characterized by the curvature

method [17].

In this paper, the influences of stress and interface roughness on the reflectivity of the blue light in

478

Lian, S., Xiao, S., Yu, Y., Lin, S., Zhang, H., Lin, G., Xu, C. and Wang, J.

Effects of Stress and Roughness on the Reflectivity of Blue Light in ZnS/MgF2 Multilayers.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 478-485

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

the ZnS/MgF

2

multilayered film will be evaluated quantitatively using the index method and the

small deflection theory of elastic mechanics. The zinc sulfide and magnesium fluoride are chosen

because of the larger difference in their refractive index values.

2. Influence of interface roughness on the reflectivity

To simulate the reflectivity of an optical multilayered structure, a recursive method is often applied

using an equivalent interface [18].

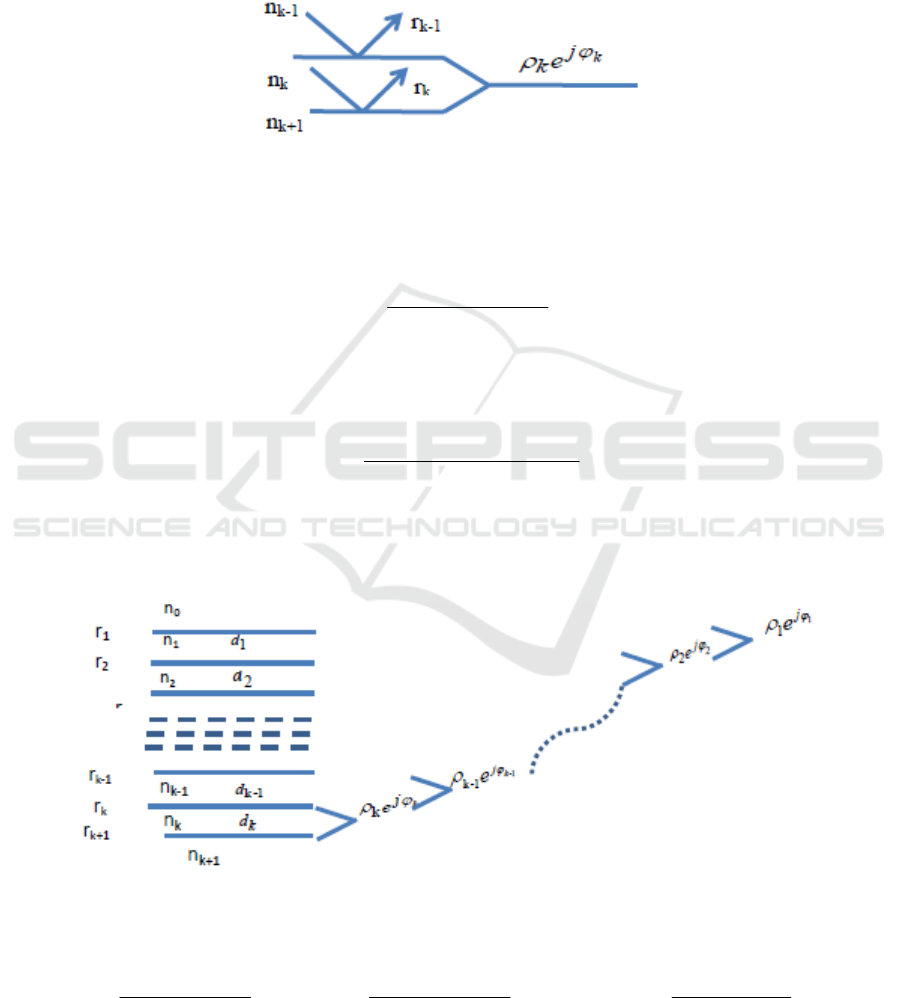

Figure 1. The equivalent interface of a single layer.

For a single layer, the equivalent interface is shown in Figure 1 and the corresponding reflection

coefficient of this single layer is given by

k

k

k

j

kk

j

kk

i

err

err

er

δ

δ

ϕ

ρ

2

1

2

1

k

1

−

+

−

+

+

+

==

(1)

where r

k

is reflection coefficient of the upper interface, r

k+1

is reflection coefficient of the lower

interface. The r

k

can be obtained by the Fresnel expression for S polarization as

tkik

tkik

k

nn

nn

r

θθ

θθ

coscos

coscos

1

1

+

+

+

−

=

(2)

where

θ

i

is the incident angle,

θ

t

is the refracted angle. According to the Snell’s law

(

sskk

nnn

θθθ

sinsinsin

00

==

), the incident angle or the refracted angle can be calculated.

n

k

is

the refractive index of the

k-th

layer.

Figure 2. The recursive method for obtaining the Fresnel coefficient.

For a multilayered structure as sketched in the left side of figure 2, the equivalent interfaces are

constructed as shown in the right side of Figure 2.

k

k

k

j

kk

j

kk

i

err

err

e

δ

δ

ϕ

ρ

2

1

2

1

k

1

−

+

−

+

+

+

=

1-

1-

1-

2

1-

2

1-

1-k

1

k

k

k

j

kk

j

kk

i

er

er

e

δ

δ

ϕ

ρ

ρ

ρ

−

−

+

+

=

......

1

1

1

2

21

2

21

1

1

δ

δ

ϕ

ρ

ρ

ρ

j

j

i

er

er

e

−

−

+

+

=

(3)

Effects of Stress and Roughness on the Reflectivity of Blue Light in ZnS/MgF2 Multilayers

479

where

jjjj

dn

θ

λ

π

δ

cos

2

=

and

d

j

are the phase difference and the thickness of the

j-th

layer,

respectively,

λ

represents the wavelength of incident light.

Then, the reflectivity of the multilayer can be calculated by

∗

⋅= rrR

(4)

To calculate the refraction index, the Sellmeier dispersion equation of equation (5) is used

()

2

2

λ

λ

B

An +=

(5)

where, for the investigated material MgF

2

, A=1.8976, B=0.01536 and for ZnS, A=5.013, B=0.2025.

When considering the effect of the interface roughness on the reflectivity of optical multilayers,

two methods may be applied: the stratified-interface method [19] and the index method [20]. In the

stratified-interface method, the rough interface is divided into different uniform thin layers, each

layer has a homogeneous interface. As long as the divided layer is thin enough, the

stratified-interface method can be used to describe well a rough continuous interface [19]. The index

method is to calculate the Fresnel reflection coefficient at each interface where the interface

roughness parameter is characterized by the real-structure model [21] and the Nevot-Croce model

[20].

In the index method, the reflection coefficient at each interface of a multilayered structure is given

by [20]

() ()

qMrqrr

jj 0

2

0

2

1

exp =

⎥

⎦

⎤

⎢

⎣

⎡

−=

σ

(6)

where

j

q

θ

λ

π

cos

4

=

,

()

qM

j

is called the Debye Waller factor, σ represents the interface roughness,

θ

j

is the incident angle,

r

0

is the Fresnel reflection of the perfect interface (

σ

= 0). This method is

applied to the case that the wavelength of the incident light is much large than the interface roughness

[22-23]. For considering the influence of interface roughness on the reflectivity, the equation (2) will

be replaced by the equation (6).

In the Real-Structure model [21], the interface roughness parameter is assumed to be increased

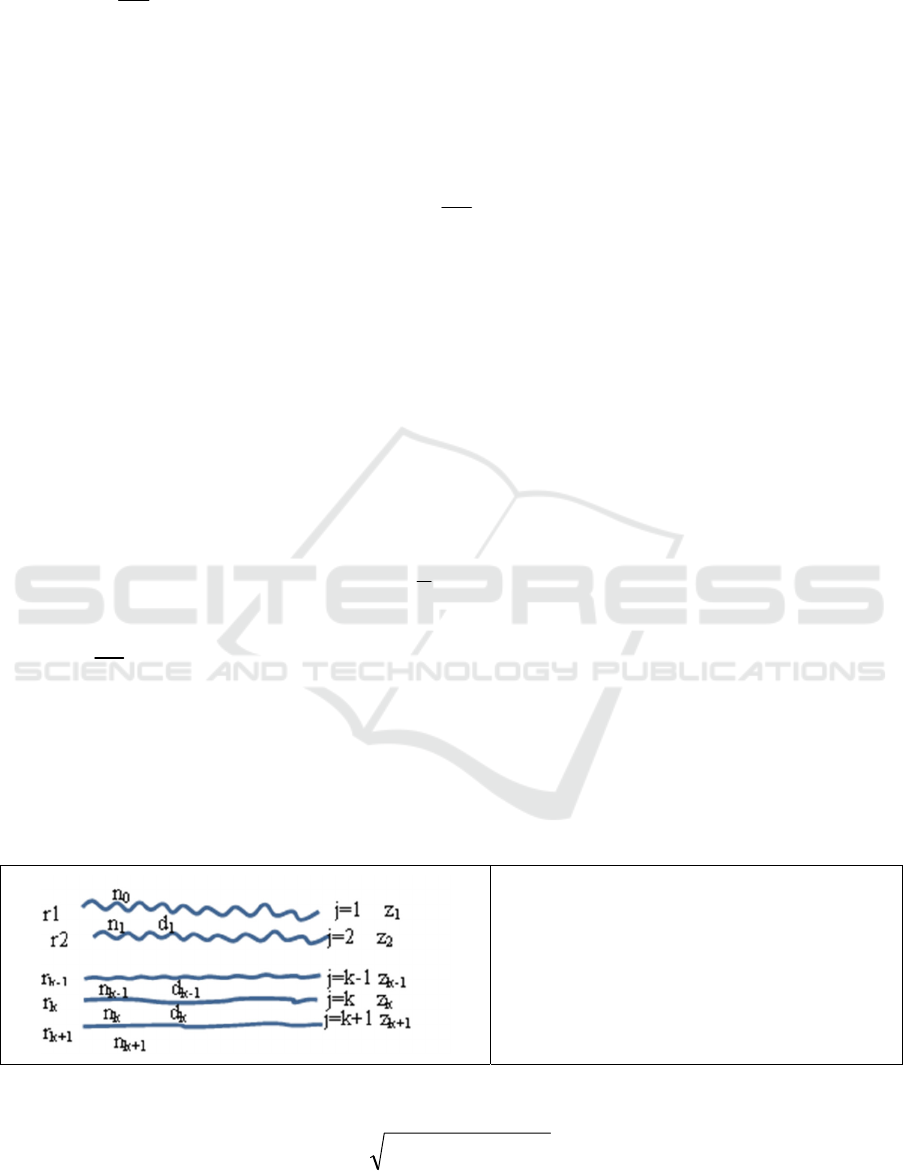

with the depth from the substrate to the surface as demonstrated in Figure 3.

Figure 3. The sketch of the divided

multilayer interfaces with different

roughness characteristics.

The j-th interface roughness between the j-th and (j +1)-th sublayers is assumed as [22]

()

jkkj

zzh −+=

++ 1

2

1

σσ

(7)

where

σ

k+1

is the surface roughness of the substrate, z

k+1

and z

j

represent, respectively, the coordinate

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

480

values of the substrate’s surface and the j-th sublayer’s surface as shown in figure 3, h is a constant

defined as the increase rate of interface roughness.

The factor Mj (q) is given by

⎥

⎥

⎦

⎤

⎢

⎢

⎣

⎡

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

−=

+1

2

coscos

4

2

1

exp

jj

j

j

M

θθ

λ

πσ

(8)

For h = 0 and

σ

k+1

= 0, it corresponds to an ideal interface.

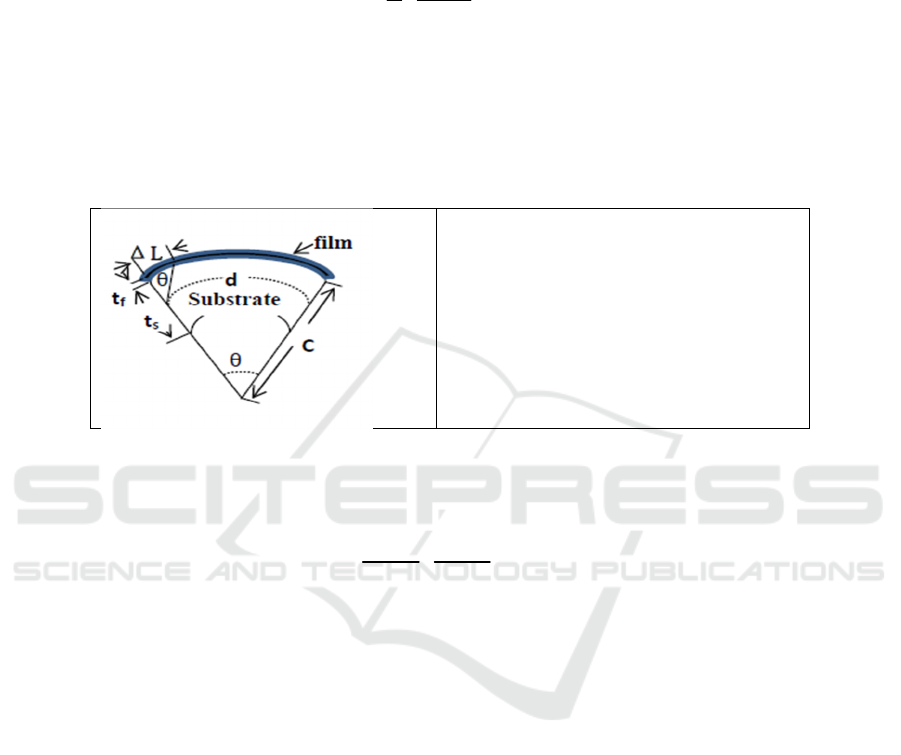

3. Stress characterization

Due to the lattice mismatch between the film and the substrate, the film is constrained as shown in

Figure 4.

Figure 4. The sketch of the constrained

film with the substrate. t

f

is the film

thickness, t

s

is the thickness of the

substrate. The middle plane of the

substrate indicated as dashed line as no

stress plane.

Assumed that t

s

is much larger than t

f

, and the stress in the film is regarded as a uniform

distribution, the Stoney equation is expressed as [20]

f

s

s

s

f

Ct

tE

61

2

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

−

=

ν

τ

(9)

where τ

f

is the stress of surface, and C is the radius of curvature. In the z plane, the strain of xy plane

is proportional to the distance z. Assuming that the Poisson's ratios of the film and the substrate are

equal, namely, ν

s

= ν

s

= 0.25. While, for the glass substrate, the Es is equal to 55GPa. The packaging

density P [24] is then described as

()

1

0

421

−

−+= kZkZPP

ν

(10)

where k=1/C. Upon the curvature change, the refractive index can be rewritten as

()()

1421421

11

0

+−+−−+=

−−

kZkZkZkZnn

νν

(11)

where n

0

is the refractive index of thin film material without stress. The equation (11) shows that the

refractive index is associated with the distance Z from the middle plane of the substrate to the

interface. Assuming that the substrate thickness is greater than that of the film and the refractive

index of each sublayer is regarded as the same. Applying the equation (6) and (11) into the equation

(2), the reflected coefficient of the multilayer can be calculated for considering the influences of both

interface roughness and stress on the reflectivity.

4. Result and discussion

For the investigated refractive index materials, zinc sulfide and magnesium fluoride, using the

Effects of Stress and Roughness on the Reflectivity of Blue Light in ZnS/MgF2 Multilayers

481

Genetic algorithm and truncation selection strategy, the optimum 4x ZnS/MgF

2

multilayered

structure for the anti-reflectivity of the blue light is determined as 149, 29, 74, 31, 80, 33, 249 and

127 nm thick, respectively. In the following, the reflectivity of the above optimum multilayered

structure will be calculated assuming that the incident light is perpendicular to the surface/interface,

i.e.

θ

0

= 0.

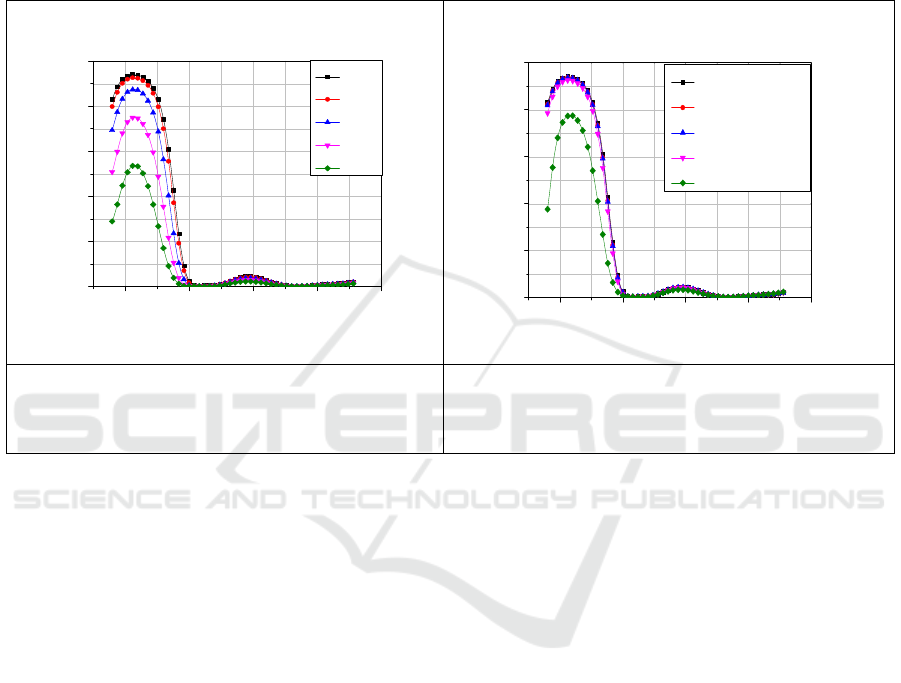

4.1. Effect of roughness

400 500 600 700 800

0.0

0.2

0.4

0.6

0.8

1.0

Reflectivity

Wavelength/nm

σ=0

σ=10

σ=20

σ=30

σ=40

400 500 600 700 800

0.0

0.2

0.4

0.6

0.8

1.0

Reflectivity

Wavelen

g

th/nm

No Roughness

h=0.002

h=0.02

h=0.2

h=2

Figure 5. The reflectivity for different

substrate roughness values with the same h

value of 0.002.

Figure 6. The reflectivity for the different h

values with the same substrate roughness of

5nm.

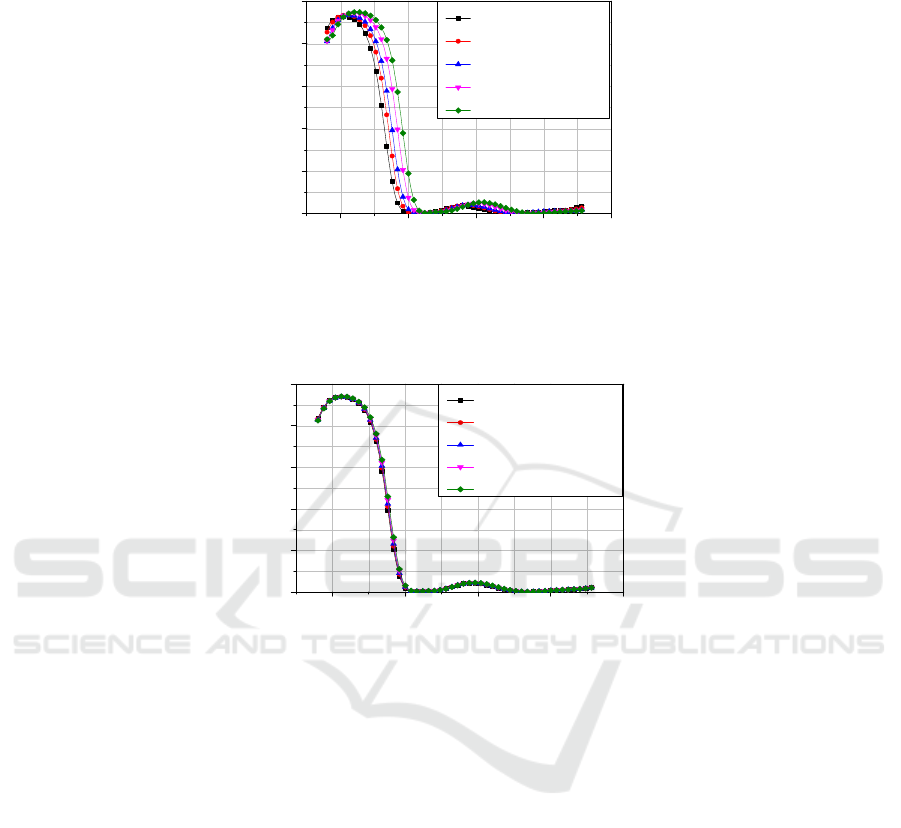

Figure 5 shows that, with increasing the substrate roughness for the same h value of 0.002, the

reflectivity of this multilayer is reduced. When the substrate roughness is less than 10 nm, the effect

of roughness on the reflectivity can be ignored. However, when the substrate roughness is more than

40 nm, the maximum value of the reflectivity of the blue light is dropped significantly about 39% as

compared to the ones for the roughness less than 10 nm. Upon the interface roughness increasing, the

reflectivity value of the blue light decreases but the shape of the reflectivity curve does not change.

Figure 6 shows that, for the substrate roughness of 5 nm, the maximum reflectivity value

decreases gradually with increasing of h value (the increase rate of interface roughness). But the

interface roughness does not affect the reflectivity curve when the h value is less than 0.2. However,

when the h value is of 2, the maximum reflectivity reduces about 15% but the shape of reflectivity

curve does not change.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

482

4.2. Effect of stress

400 500 600 700 800

0.0

0.2

0.4

0.6

0.8

1.0

Reflectivity

Wavelen

g

th/nm

stress=200GPa

stress=100GPa

stress=0GPa

stress=-100GPa

stress=-200GPa

Figure 7. The reflectivity for different stress values with the same glass substrate thickness of 0.1

mm.

400 500 600 700 800

0.0

0.2

0.4

0.6

0.8

1.0

Reflectivity

Wavelen

g

th/nm

stress=200GPa

stress=100GPa

stress=0GPa

stress=-100GPa

stress=-200GPa

Figure 8. The reflectivity for different stress values with the substrate thickness of 1 mm.

In practice, stress value generally will not more than a few Gpa. The stress value here was set to

200 Gpa to show the impact of stress on the spectrum value. Figure 7 shows, when the glass substrate

thickness is of 0.1 mm (the corresponding Young's modulus is 55 Gpa and the Poisson's ratio is 0.25),

upon increasing the compressive or tensile stress value, the respective reflectivity curve shifts to the

right or left as compared to the one without applied stress, but the shape the reflectivity curve

remains the same.

However, when the substrate thickness increases to 1 mm, and all the other parameters including

the applied stress values as indicated in Figure 7 remain the same, the reflectivity curve shown in

Figure 8 does not change at all. It concludes that the influence of the applied stress on the reflectivity

strongly depends on the substrate thickness. If the substrate thickness is thick enough, the applied

stress in the multilayered film has no significant influence on the reflectivity of the blue light.

5. Conclusions

(1) Upon increasing the interface roughness, the reflectivity value of the blue light decreases, but

the shape of reflectivity curve does not change;

(2) With increasing of the stress, the reflectivity curve shifts to the right or left as compared to the

one without applied stress, but the shape of reflectivity does not change;

(3)The effect of stress on the reflectivity of the blue light could be ignored when the substrate

thickness is thick enough.

Effects of Stress and Roughness on the Reflectivity of Blue Light in ZnS/MgF2 Multilayers

483

Acknowledgement

The authors gratefully thank the support of Science and Technology Planning Project of GuangDong

Province, China (Grant NO.2017A010103021).

References

[1] Keller C, Grimm C, Wenzel A, Hafezi F and Reme C 2001 Protective effect of halothane

anesthesia on retinal light damage:inhibition of metabolic rhodopsin regeneration Invest

Opthalmol Vis Sc. 42 475-480

[2] Carniglia C K 1979 Scalar scattering theory for multilayer optical coatings Opt. Engin. 18

104-115

[3] Ferre-Borrull J, Duparre A and Quesnel E 2000 Roughness and light scattering of

ion-beam-sputtered fluoride coatings for 193 nm Appl. Optics 39 5854-5864

[4] Whitman C S and Chung Y W 1991 Thermomechanically induced voiding of Al-Cu thin films

J. Vac. Sci. Technol. A9 2516-2522

[5] Windischmann H 1992 Intrinsic stress in sputter-deposited thin films Crit. Rev. Solid State 17

547-596

[6] Kinosita K, Maki K, Nakamizo K and Takeuchi K 1967 Stress in vacuum deposited films of

silver Jpn. J. Appl. Phys. 6 42-53

[7] Klokholm E and Berry B S 1968 Intrinsic stress in evaporated metal films J. Electrochem. Soc.

115 823-826.

[8] Hoffman R W 1976 Stresses in thin films: the relevance of gain boundaries and impurities

Thin Solid Films 34 185-190

[9] Alexander P M and Hoffman R W 1976 Effect of impurities on intrinsic stress in thin Ni film

J. Vac. Sci. Tech. 13 96-98

[10] Heurle F M D 2008 Aluminum films deposited by RF sputtering Metal. Mater. Trans. B 1

725-732.

[11] Muller K H 1987 Stress and microstructure of sputter deposited thin films: molecular

dynamics investigation J. Appl. Phys. 62 1796-1799

[12] Ward D J and Arnell R D 2002 Finite element modeling of stress development during

deposition of ion assisted coating Thin Solid Films 420-421 269-274

[13] Souza R M, Mustoe G G W and Moore J J 1999 Finite element modeling stress and fracture

during the indentation of hard elastic films on elastic-plastic aluminum substrate Thin Solid

Films 355-356 303-310

[14] Souza R M, Mustoeb G G and Moore J J 2001 Finite element modeling of stresses, fracture

and delamination during the indentation of hard elastic films on elastic-plastic soft

substrates Thin Solid Films 392 65-74

[15] Luo J F, Liu Y J and Berger E J 2000 Interfacial stress analysis for multi-coating systems

using an advanced boundary element method Comput Mech. 24 448-455

[16] Luo J F, Liu Y J and Berger E J 1998 Analysis of two dimensional thin structures (from

micro-to-nano-scales) using the boundary element method Comput Mech. 22 404-412

[17] Tian M B and Liu D L 1991 Handbook of thin film science and technology (Beijng: China

Machine Press) p 144-146

[18] Rouard P 1937 Optical properties of very thin metallic films Annales de Physique 7 291

[19] Zhou X L and Chen S H 1995 Theoretical foundation of X-ray and neutron reflectometry Phys

Rep 257 223-348

[20] Nevot L and Croce P 1980 Caracterisation des surfaces par reflexion rasante de rayons X.

Application a l’etude du polissage de quelques verres silicates Rev Phys Appl. 15 761-779

[21] Pleshanov N K 2004 Algorithm for the real-structure design of neutron supermirrors Nuclear

Instruments and Methods in Physics Research A. 524 273-286

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

484

[22] Marquart D W 1963 An algorithm for least-squares estimation of nonlinear parameters J. Soc.

Ind. Appl. Math. 11 431-441

[23] Bevington P R, Robinson D K, Blari J M, Mallinckrodt J and Mckay S 1993 Data reduction

and error analysis for the physical science Computer in Physics 7 415

[24] Rastogi R, Dharmadhikari V and Diebold A 1991 Stress variation with temperature/time and

its correlation to film structure and deposition parameters Journal of Vacuum Science and

Technology A 9 2453-2458

Effects of Stress and Roughness on the Reflectivity of Blue Light in ZnS/MgF2 Multilayers

485