Experimental Research on Current-carrying Efficiency of

Arc under Different Polarities

H Y Yan

1,*

, L M Song

1

, R H Zhang

1

and L X Jia

1,2

1

Department of Materials Science & Engineering, Luoyang Institute of Science and

Technology, Henan Luoyang 471023, China

2

National United Engineering Laboratory for Advanced Bearing Tribology, Henan

University of Science and Technology, Henan Luoyang, 471023

Corresponding author and e-mail: H Y Yan, yanhongyan@126.com

Abstract. Current-carry ing arc got contact surface worse and influenced the transmission of

electric energy. Arc burning process and arc characteristics and arc erosion and current -

carrying efficiency were tested on a home-made single asperity current-carrying tester under

different polarities conditions. Experimental results show: when W probe is anode and copper

specimen is cathode, arc mainly belongs to metallic vapour state and arc has long burning

times and high arc energy and lo w electric field intensity. Current -carrying efficiency is high.

When W probe is cathode and copper specimen is anode, arc main ly belongs to gas state and

arc has short burning times and low arc energy and high electric field intensity. So arc erosion

is light and current-carrying efficiency is low.

1. Introduction

Pantograph-catenary system is friction pair which can transmit electric energy during their sliding

relatively. When contact surface breaks between pantograph and catenary at high voltage and heavy

electric current, current-carrying arc generates inevitably. Current-carrying arc with high temperature

could burn and damage the material and makes contact surface worsen, while it can transmit electric

energy to satisfy with energy supply of high-speed train because of its electrical conductivity. So

pantograph-catenary arc takes on double properties [1-2]. It is necessary to research influence of arc

characteristics on arc erosion and arc current-carrying efficiency.

In recent technological developments of current-carrying friction pair, major efforts have been

devoted to research of friction-wear property and current-carrying quality. Experimental results show

current-carrying arc play an important role. All above researches were carried out on the pin-on-disk

tester which kept pin and disk contact all the time, thus friction heat and resistance heat and arc heat

damaged commonly materials and electric current transmitted in contact conductivity and arc

conductivity manners [3-10]. It is rare that mere arc cause damage and change of electric

conductivity quality. Current-carrying arc occurs at random and instantaneously, so it is difficult to

control and catch and measure it. To solve above problems a current-carrying tester of a single

contact peak has been developed on which arc burning process and arc characteristics were observed

and analyzed under different polarities.

386

Yan, H., Song, L., Zhang, R. and Jia, L.

Experimental Research on Current-carrying Efficiency of Arc under Different Polarities.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 386-391

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

In this paper, arc burning processes were photographed separately under two polarities conditions

and arc states were obtained by observing and analyzing pictures. The aviations of arc burning time

and arc energy and electric field intensity against voltage were gotten to study on arc characteristics.

Microstructure and element distribution on the erosion surface of material were available by SEM

and arc erosion mechanism were discussed. Based on arc burning process and arc characteristics, arc

erosion and current-carrying efficiency were researched and a method of alleviating arc erosion was

put forward.

2. Experimental apparatus and experimental procedure

2.1. Principal of experimental apparatus

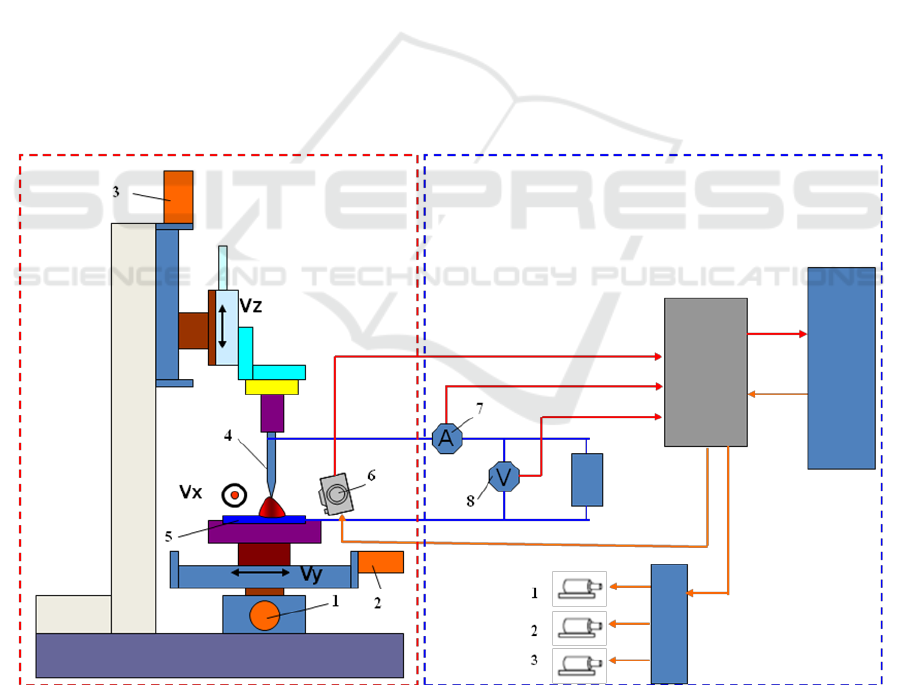

Experiment was carried out on the current-carrying tester of single contact peak whose principle was

shown in Figure 1. The tester consists of mechanical and measure-control systems. In the mechanical

system probe moves up and down at certain speed by adjusting rotation rate and orientation of

stepping motor of Z direction, meanwhile specimen moves back and forth at certain speed by

adjusting rotation rate and orientation of stepping motor of X direction. When probe slides with

specimen, probe and specimen and electric source form a closed electric circuit and current

transmission is by the contact surface between probe and copper. When probe separates with

specimen, probe and arc and specimen and electric source form a closed electric circuit and current

transmission is by arc. In measurement-control system voltage sensor and current sensor and high-

speed camera catch respectively arc voltage and arc current and arc pictures of burning process, in

addition all these data are collected synchronously and are displayed on the computer screen after

treatment of software.

1 stepping motor of X direction 2 stepping motor of Y direction 3 stepping motor of Z direction

4 probe 5 specimen 6 high-speed camera 7 current sensor 8 voltage sensor

Figure 1. Principle diagram of current-carrying tester of the single contact peak.

Arc photograph

Arc current

Arc voltage

Computer

Data

acquisition

Motion control

Synchronous trigger signal

Measurement and control part

Mechanical

part

Experimental Research on Current-carrying Efficiency of Arc under Different Polarities

387

2.2. Experimental procedure

In the experiment probe adopts tungsten alloy which is made up of W and ThO

2

and the content of

ThO

2

is 0.7~0.99%. W probe is 2.4mm in diameter and 45mm in length and its end is processed into

cone which is 30 degree in angle and 5mm in length. Specimen adopts copper which is 80mm in

length and 40mm in width and 8mm in thickness and copper specimen will be treated with #800

metallographic abrasive papers. Electric source adopts JP50100D source of direct current which can

supply constant current or voltage. Experimental current is set 20A and experimental voltage is set at

25V, 30V, 35V, 40V, 45V and copper specimen moves back and forth at 15mm/s along X direction

and W probe moves up and down at 3mm/s along Z direction. All above parameters will be preseted

before experiment.

2.3 Measurement of experimental results

Arc current and arc voltage is respectively attained by current sensor and voltage sensor. Arc pictures

are shot by high-speed camera. Arc burning time is obtained in term of variation regularity of arc

current and arc voltage. Arc energy is gotten by product of arc current and arc voltage and arc

burning time. Electric field intensity is gained by division of arc voltage and the distance between W

probe and copper specimen at this point. The current-carrying efficiency, η, is expressed as:

%100 II

(1)

Where is average current during arc burning steadily time and I is normal electric current.

3. Experimental results

3.1. Arc current transmission at different polarities

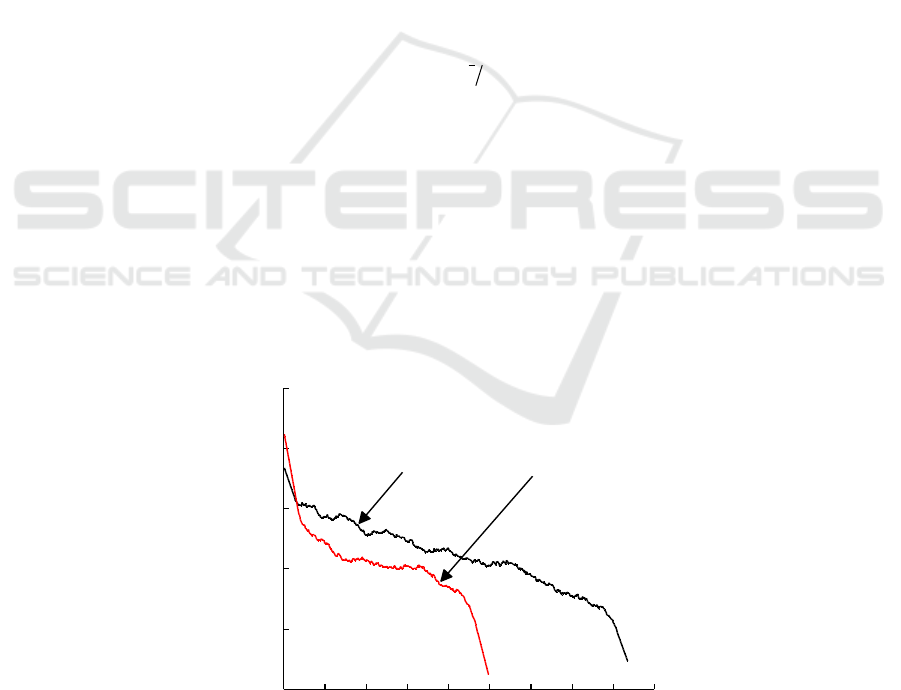

Authors should try to make economical use of the space on the page; for example: Electric

transmission quality is reflected by efficiency and stability of electric transmission during arc burning.

Because current-carrying arc is mobile, waveform of arc current contains many interference signals

which are shown in Figure 2. Figure 2 shows change of arc current with time which decreases at first

quickly and then slowly and quickly again at last.

0 100 200 300 400 500 600 700 800 900

0

5

10

15

20

25

W probe: anode

W probe: cathode

Arc current

I(A)

Time t(ms)

Figure 2. Change of arc current with time at different polarities.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

388

3.2. Arc burning characteristics under different polarities condition

3.2.1. Arc burning characteristics

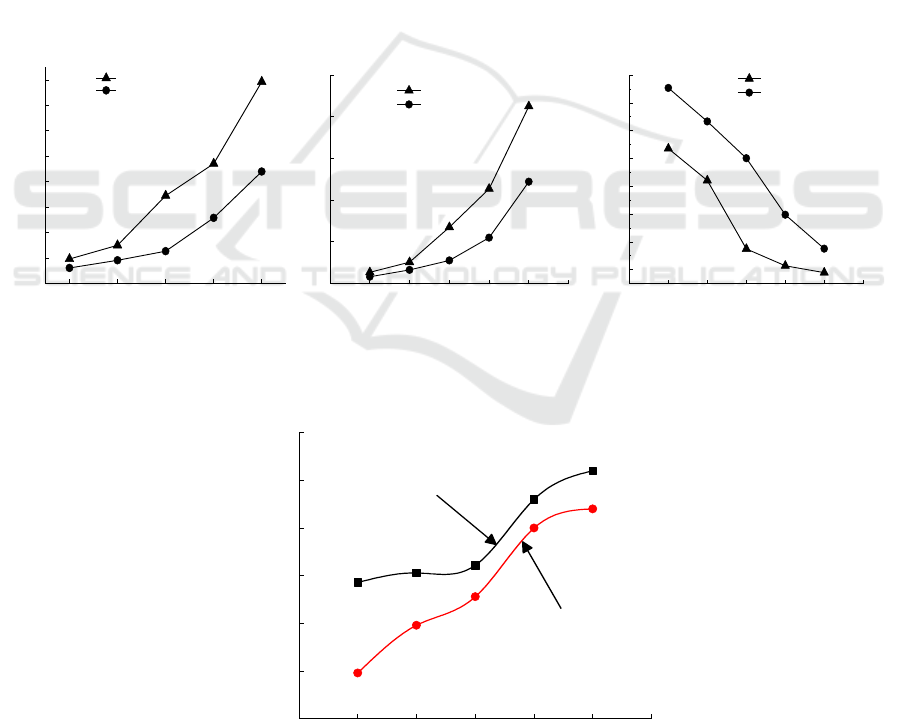

Arc burning time stands for ability to keep burning. Figure 3 (a) shows the variation of arc burning

time against voltage, which is arc burning time increases when voltage increases. But the arc burning

time is longer when W probe is anode than W probe is cathode, so the ability to keep burning is

better when W probe is anode than W probe is cathode.

Arc energy is the accumulated discharge energy which reflects heat energy in arc. The more arc

energy is, the higher arc temperature is. Figure 3 (b) shows the variation of arc energy against voltage,

which is arc energy increases when voltage increases. The arc energy is more when W probe is anode

than W probe is cathode.

Arc burning process essentially is charged particles move directionally and collides with each

other under the action of electric field intensity, thus electric energy turns into kinetic energy and

then into heat energy which makes arc temperature go up. At the given electric current and voltage

the higher the electric field intensity is, the more difficultly the arc keeps burning, and vice versa.

Figure 3 (c) shows the variation of electric field intensity against voltage, which is electric field

intensity decreases when voltage increases. The electric field intensity is lower when W probe is

anode than W probe is cathode, so the ability to keep burning is better when W probe is anode than

W probe is cathode.

(a) Arc burning time; (b) arc energy; (c) electric field intensity

Figure 3. Arc burning characteristics at different polarities.

20 25 30 35 40 45 50

0.30

0.35

0.40

0.45

0.50

0.55

0.60

W probe: cathode

Efficiency of current-carrying

Voltage U(V)

W probe: anode

Figure 4. Changes of current-carrying efficiency with voltages at different polarities.

(c)

20 25 30 35 40 45 50

400

600

800

1000

1200

1400

1600

1800

Electrical field intensity /V/cm

Voltage /V

W probe: anode

W probe: cathode

(b

)

20 25 30 35 40 45 50

0

50

100

150

200

250

Arc energy /J

Voltage /V

W probe:anode

W probe:cathode

(a)

25 30 35 40 45

0

200

400

600

800

1000

1200

1400

1600

Arc peroid/ms

Voltage/V

W probe: anode

W probe: cathode

Experimental Research on Current-carrying Efficiency of Arc under Different Polarities

389

3.2.2. Current-carrying efficiency under different polarities condition

Variation of current-carrying efficiency against voltage is shown in Figure 4, which is known that

current-carrying efficiency increases when voltage increases and the current-carrying efficiency is

higher when W probe is anode than W probe is cathode.

4. Discussions

4.1. Analysis of arc burning process and characteristics under different polarities condition

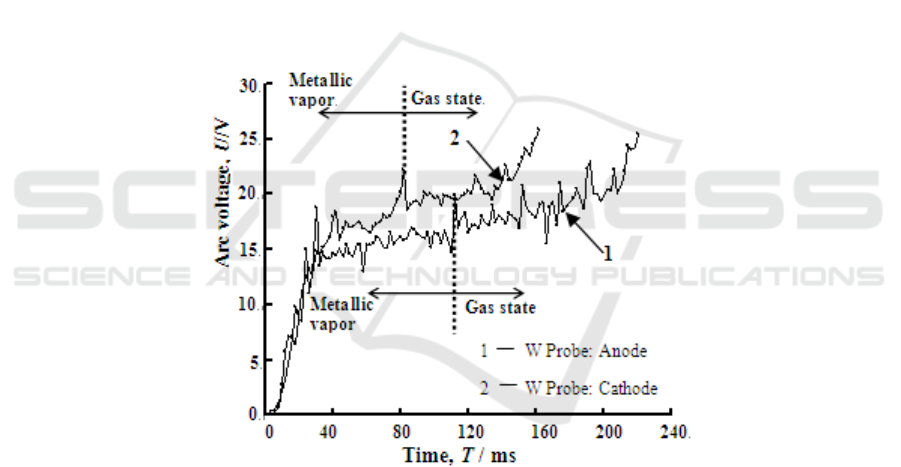

Boddy et al scholars found that arc between switch contacts would undergo two stages. The first

stage was described as metallic vapor state arc which mainly burned in metallic vapors, while the

second stage was described as gas state arc which burned in little metallic vapors and air ionizing

took part in arc burning. When arc transferred from metallic vapor state to gas state, arc voltage

would jump [11]. When arc is in metallic vapor state, arc motion is slow as charged particles are

heavy. When arc is in gas state, arc motion is quick as charged particles are light.

Figure 5 shows variations of arc voltages against arc burning time at 15 voltages under different

polarities condition. It is found that time in metallic vapour state is longer when W probe is anode

and copper specimen is cathode than W probe is cathode and copper specimen is anode.

Figure 5. Aviations of arc voltages at 15V under different polarities.

4.2. Analysis of electric conductivity of arc

Document [12] expressed electric conductivity of arc is related with movement of charged particles.

Under electric field force movements of electrons and cations in arc form electrons stream and

cations stream respectively which form commonly arc currents. Because cations are much heavier

than electrons and then cations move much more slowly than electrons, arc currents mainly are made

up of electrons. Under the action of electric field force, electrons move in direction of electric field

force and meanwhile electrons can collide with each other to move irregularly. Irregular motion of

electrons form thermal motion currents and direct motion of electrons form electric field currents.

Thermal motion currents are 100 times or so as much as electric field currents, that is, arc currents

mainly consist of thermal motion currents. Arc energy is high when W probe is anode and copper

specimen is cathode, thus charged particles are not only a great quantity but also at high speed. All

these cause much more thermal motion currents and high current-carrying efficiency. Arc energy is

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

390

low when W probe is cathode and copper specimen is anode, thus charged particles are not only little

but also at low speed. All these cause much less thermal motion currents and low current-carrying

efficiency.

5. Conclusions

when W probe is anode and copper specimen is cathode, arc mainly belongs to metallic

vapor state and arc has long burning times and high arc energy and low electric field

intensity. Current-carrying efficiency is high.

When W probe is cathode and copper specimen is anode, arc mainly belongs to gas state and

arc has short burning times and low arc energy and high electric field intensity. So arc

erosion is light and current-carrying efficiency is low.

References

[1] Shang G B 2010 Study on damage mechanisms of the materials under coupling condition of

current carrying and friction D. Xi’an: Xi’an Jiaotong University

[2] Yang Z H, Zhang Y Z, Zhao F and et al 2016 Dynamic variation of arc discharge during

current-carrying sliding and effect on directional erosion J. Tribology International 94 71-

76

[3] Argibay N, Bares J A and Liu J 2010 Asymmetric wear behavior of self-mated copper fiber

brush and slid-ring sliding electrical contacts in a humid carbon dioxide environment J.

Wear 268 455-463

[4] Zheng R G, Zhan Z J and Wang W K 2010 Wear behavior of Cu-La2o3 composite with or

without electrical current J. Wear 268 72-76

[5] Ding L, Chen G X, Zhu M H and et al 2007 Wear mechanism of aluminum-stainless steel

composite conductor rail sliding against collector shoe with electric current J. Wear 263

598-603

[6] Bouchoucha A, Chekroud S and Paulmier D 2004 Influence of electrical sliding speed on

friction and wear processes in an electrical contact copper-stainless steel J. Applied Surface

Science 223 330-342

[7] Wang Y, Liu Z G, Fan F Q and et al 2013 Review of research development of pantograph-

catenary arc model and electrical characteristics J. Journal of Material Engineering 35(8)

35-43

[8] Jia L X, Zhang Y Z, Li J and et al 2008 Research on tribology property of carbon soaked by

metal with current J. Journal of Material Engineering 12 11-18

[9] Han W F, Gao G Q, Liu X N and et al 2015 MHD model of pantograph-catenary arc J.

Journal of the China Railway Society 37(5) 21-22

[10] Jia L X, Zhang Y Z, Sun L M and et al 2010 Friction and wear characteristic comparison of

two kinds of carbon material under condition of current-carrying J. Journal of Material

Engineering 9 91-95

[11] Rong M Z 1999 Electric contacts theory M.Beijing: China Machine Press 38-45

[12] Hirohira A and Mitsuo H 1985 Welding arc phenomena M. Beijing: China Science Press 120-

122

Experimental Research on Current-carrying Efficiency of Arc under Different Polarities

391