Size Effect of Bending Properties of Zirconia Ceramics Based

on Cosserat Theory

Y Q Xu

1,*

, M M Li

2

and X Huo

1

1

Department of Civil Engineering, Beijing jiaotong University, Beijing 100044,

China.

2

Beijing NO.6 Construction Engineering Quality Test Department CO.,LTD. No.1

Xinhua Road, Fengtai District, Beijing 10076,China.

Corresponding author and e-mail:Y Q Xu, yqxu@bjtu.edu.cn

Abstract. In order to study the size effect of zirconia ceramics flexural properties , based on

the Cosserat generalized continuum theory, the zirconia ceramic flexural specimens with

different heights were numerically simulated, and the intrinsic size parameters of zirconia

ceramics were determined by comparing with expe rimental data. Compared with the classical

continuum theory, it is verified that the calculated value of bending strength based on

Cosserat theory is closer to the experimental results, which proves that Cosserat theory can

explain the size effect of zirconia ce ramics flexu ral strength. The equation of size effect of

nominal bending strength and nomina l bending stiffness is obtained by numerica l regression

based on the theoretical values of classical continuum.

1. Introduction

Zirconia ceramics have many advantages, such as high hardness, high strength, and corrosion

resistance and wear resistance. They are widely used in the field of micro forming. The experimental

results show that the flexural properties of zirconia ceramics increase with the decrease of specimen

height, showing obvious size effect [1].

The classical continuum mechanics considers an object to be composed of a continuous

distribution of particles without a geometric size. It is believed that the state of any point of matter

depends only on the point or the history of the point, without the influence of other material points.

Therefore, there are obvious limitations in describing the bending properties of zirconia ceramic

specimens with different heights, which can’t explain the bending property size effect caused by the

change of beam height. From a statistical point of view, it is reasonable to assume that an object is

made up of an ideal continuous medium when the macroscopic size of an object is much larger than

the characteristic size of the material microstructures. But when the macroscopic dimension of the

object is close to the characteristic size of the material microstructure, such assumption will cause a

larger deviation.

In fact, any material is made up of material points with geometric dimensions. In 1909, French

scientists Cosserat E. and F. two brothers, based on the classical continuum theory, put forward

generalized continuum mechanics [2], which considered objects to be composed of continuous rigid

particles of a certain size. Each particle can be both translational and rotatable. And the couple stress,

rotational gradient and intrinsic size of the material are introduced into the basic equations. Therefore,

Xu, Y., Li, M. and Huo, X.

Size Effect of Bending Properties of Zirconia Ceramics Based on Cosserat Theory.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 371-377

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

371

Cosserat theory can explain the scale effect phenomenon of materials at different scales in a

phenomenological way [3]. Many scholars have applied the Cosserat theory to explain the size effect

of metal and polycrystal [4-7] in micro scale, but the size effect of the mechanical properties of brittle

materials in the macro scale is very little. The study on the size effect of zirconia ceramic bending

performance based on Cosserat theory is still blank. In this paper, the size effect of the bending

properties of zirconia ceramics is studied by the comparison of the numerical simulation analysis and

model test based on the Cosserat theory.

2. Basic equations of plane Cosserat theory

The basic unknown quantities of the plane Cosserat theory are: two line displacements u, v and one

rotational displacement

; two normal stresses

and

, two shear stresses

and

, two

couple stresses

and

; two normal strains

and

, two shear strains

and

and two even

strains

and

.

2.1. Equilibrium differential equation

Compared with the classical elasticity theory, due to the consideration of couple stress, when the

physical forces are not considered, the equilibrium differential equations of plane problems are as

follows [2].

0 0 0

yx y xy y

xx

xy yx

x y y x x y

, ,

(1)

From the above equilibrium, it is known that due to the existence of couple stress, shear stress

and

are no longer equal to each other.

2.2. Geometric equation

Considering the angle and curvature, the geometric equation is shown as follows:

x yx x

yy

xy

uu

x y x

v

v

yy

x

, ,

(2)

2.3. Physical equation

For ideal elastomers, the stress and deformation conform to Hooke's law.The relationship between

normal stress and normal strain is the same classical elasticity theory. Its relationship is shown as

follows on the plane stress condition:

11

( ) ( )

x x y y y x

EE

,

(3)

Because the shear stress is no longer equal to each other, the relationship between shear stress and

shear strain is different from that of classical elasticity theory. Based on the assumption of linear

elasticity and isotropy, the relationship between shear stress and shear strain can be expressed as

xy xy yx

ab

,

yx xy yx

ba

(4)

In the formula, a and b are the undetermined constants, and half of the sum of the formula (4) two

is

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

372

2 2 2

xy yx

xy yx

a b a b v u

xy

(5)

This is the normal symmetrical part of shear stress, which will cause shear deformation

xy

uv

yx

, which is consistent with classical elasticity theory and its coefficient

=

2

ab

G

.G is

the first shear modulus of the material. Half of the difference of type (4) two is

2 2 2

xy yx

xy yx

a b b a v u

xy

(6)

This is the antisymmetric part of the shear stress, which will cause the macroscopic angle

0

1

2

vu

xy

and its coefficient

c

=

2

ba

G

. G

c

is the second shear modulus of the material.

Therefore, for plane stress conditions, the relationship between shear stress and shear strain can be

expressed as

cc

cc

( ) ( )

()

xy xy yx

yx xy yx

G G G G

G G G G

(7)

For the relationship between the couple stress and the even strain, in order to maintain the unity of

dimension, the intrinsic size parameter of the material is introduced. The expression is given in the

paper [8].

22

44

x c x y c y

Gl Gl

,

(8)

In the above equation,

2

4

c

Gl

is the bending stiffness of the material, in which

c

l

is the intrinsic

size of the material, which depends on the characteristic length of the material microstructures, such

as the modulus of elasticity and the Poisson's ratio, which are important parameters to measure the

properties of the material, and are not affected by the macro size, load and constraint conditions of

the structure. Although the intrinsic size is the dimension of the length, it is not equal to the particle

size of the material, so it can’t be obtained directly through the test. The determination of intrinsic

size parameters is the key to solve many mechanical problems by using Cosserat's basic equations

and boundary conditions. However, up to now, there has not been a search for the study of the

intrinsic parameter values of zirconia ceramics, there are no test standard and operation specification

can be referred to get through experiment.

3. Determination of intrinsic dimensional parameters of zirconia ceramics

The Cosserat theory of plane problem contains fifteen unknown functions and fifteen differential

equations, but its analytical solution is very difficult to obtain, and can only be solved by numerical

method. Therefore, this paper adopts Cosserat finite element mode [9]

numerical simulation and

existing test data combination method to study the intrinsic parameters of zirconia ceramics.

3.1. Experimental data on size effect of bending strength of zirconia ceramics[1]

The samples were made of 6 kinds of sintered samples, the width of all was 4.7mm, and the height

was 92μm, 191μm, 289μm, 378μm, 474μm, 568μm respectively. The three point bending test was

carried out and the calculated span was 30mm.The formula for calculating the bending strength is

Size Effect of Bending Properties of Zirconia Ceramics Based on Cosserat Theory

373

2

3

2

f

Fl

bh

(9)

The

f

is nominal bending strength, F is the ultimate load, l is the calculation span, h is the

section height of the specimen, and b is the section width of the specimen. The bending strength of

specimens at different heights tested is shown in Table 1 [1].

Table 1. Material parameters of zirconia ceramics.

h/μm

F/N

f

/ MPa

92

0.88

998

191

3.39

890

289

6.80

780

378

9.40

630

474

12.67

540

568

18.20

540

It can be seen from Table 1 that the bending strength of zirconia ceramics decreases with the

increase of specimen height, showing obvious size effect.

3.2. Bending failure criterion of brittle materials

Because the tensile capacity of brittle materials is far less than its compressive capacity, when the

brittle material is bent, the damage occurs at the tensile fracture of the lower side fiber in the middle

cross section, and destroy all of a sudden with no significant deformation. Therefore, according to the

linear elastic failure characteristics of brittle materials, the maximum tensile stress failure criterion is

adopted to simulate the bending specimens of zirconia ceramics.

The maximum tensile stress criterion holds that, no matter what stress state of the material is in, as

long as the maximum tensile stress

of the element is reached to the strength

of the material,

the brittle fracture will be occurred. According to this criterion, the failure condition of material

fracture is

(10)

It can be seen from table 1, the bending strength of the specimen tends to be stable as the height of

the specimen increase. Therefore, the bending strength obtained from the specimen with the height of

568 μm is regarded as the flexural tensile ultimate strength of zirconia ceramics, which is

=540

b

MPa.

3.3. The determination of intrinsic dimensional parameters

Numerical analysis of zirconia bending specimens at different heights is carried out with different

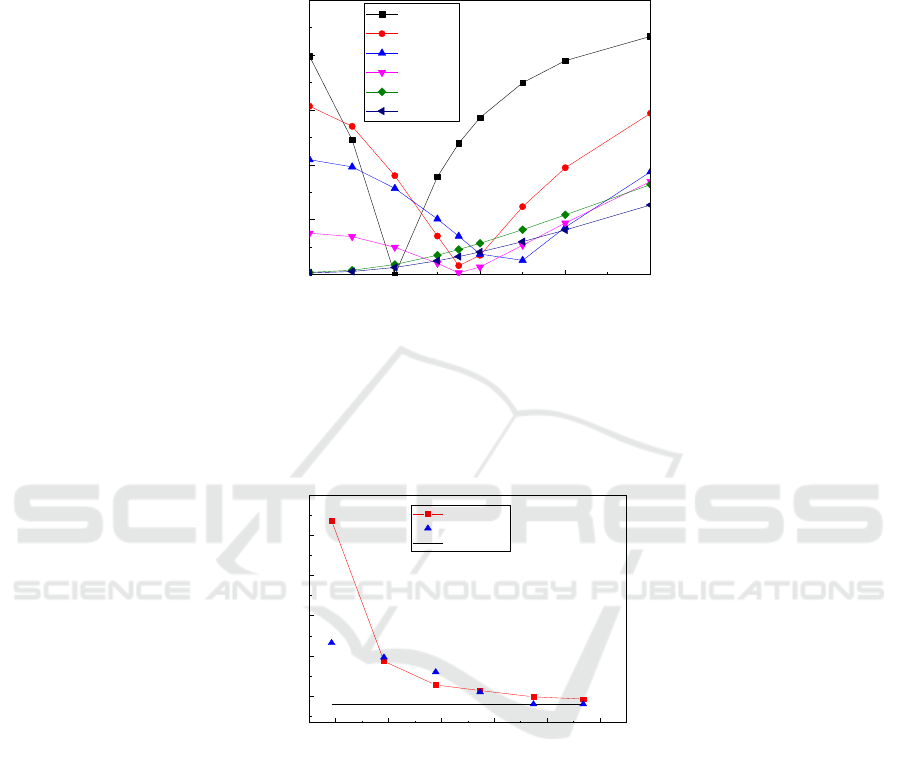

intrinsic sizes. The calculated values are compared with the experimental values, as shown in Figure

1.

As shown in Figure 1, when the intrinsic size is 0, the calculated value is the theoretical solution

of the classical continuous medium. The deviation from the test results increases with the decrease of

the specimen’s height, and the deviation of the specimen is 84.8% when the specimen height is 92μm.

When the intrinsic size is between 20~40μm, the deviation between calculated value that based on

Cosserat theory and experimental value is relatively small. It can be seen that the intrinsic size of

zirconia ceramics should be in the range of 20~40μm. In addition to the specimens with height of

92μm, the deviation of the numerical solution and the test value are basically the smallest, when the

other height specimens are basically the same intrinsic size as 35μm. When the intrinsic size of the

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

374

specimen with height of 92μm is 20μm, the deviation from the test value is the smallest, which may

be because the height is smaller, the pores in sintering are easier to discharge, the internal porosity

decreases, the sintering of the sample is more compact, and the internal defects of the material are

less, resulting in the decrease of the intrinsic size.

0 20 40 60 80

0

20

40

60

80

100

Deviation between numerical solution

and experimental value /%

intrinsic size /mm

h=92 m

h=191m

h=289m

h=378m

h=474m

h=568m

Figure 1. Deviation between numerical solution and experimental value with different intrinsic sizes.

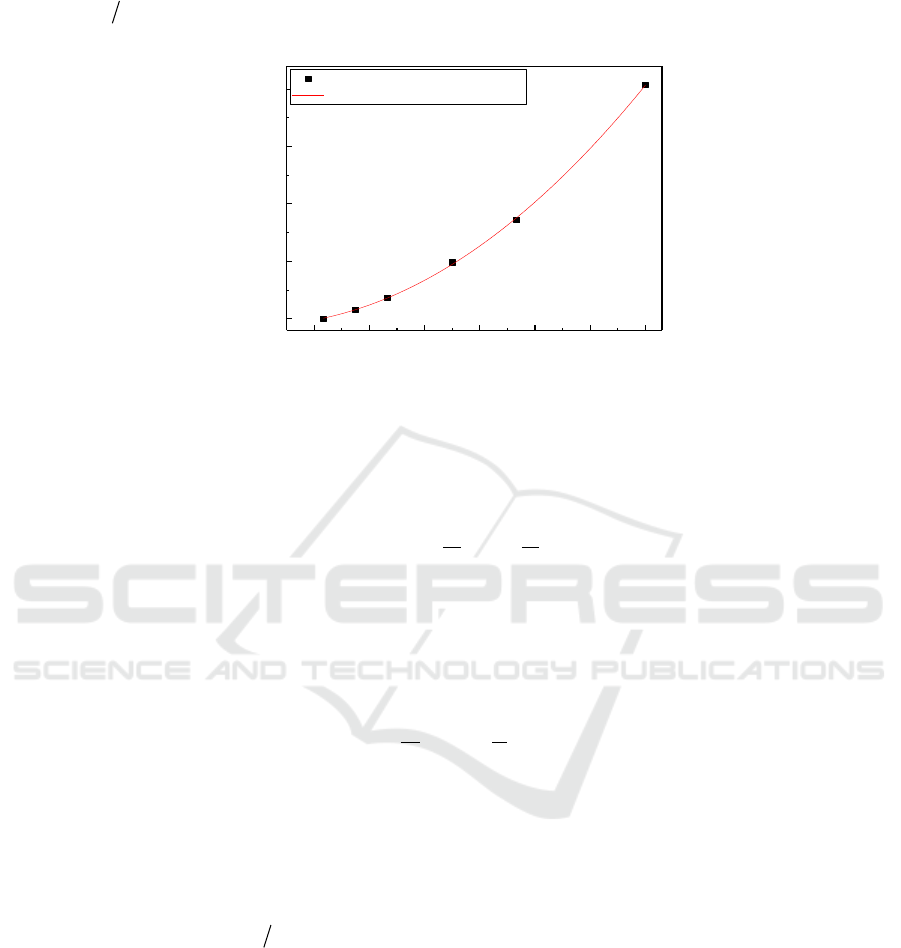

The intrinsic dimension of zirconia ceramics is equal to 35μm, and the three point bending

loading test is simulated numerically. The experimental values, classical continuum mechanics

solutions and numerical solutions based on Cosserat theory are compared and analyzed, and the

variation of nominal bending strength with the height of the specimen is shown in Figure 2.

100 200 300 400 500 600

600

900

1200

1500

1800

2100

Nominal bending strength /MPa

Specimen height /mm

Cosserat

Test

Classic

Figure 2. The variation of nominal bending strength with the height of the specimen.

It can be seen from Figure 2 that the bending strength of zirconia ceramics obtained by the

classical continuum theory is constant, which is independent of the size of the specimen, and can’t

explain the size effect of the bending strength of the specimens at different heights. The calculation

value of bending strength based on Cosserat theory and the test value are relatively closer, both are

increased with the decrease of the specimen’s height. When the specimen is high, the value of the

two is close to the theoretical value of the classical continuous medium, which shows that the size

effect of the bending strength is no longer obvious when the specimen is large enough.

4. The rule of size effect on the bending properties of zirconia ceramics

4.1. The rule of size effect of bending strength

In order to study the size effect of bending strength of zirconia ceramics, considering the influence of

the span and width is less, the span and width of the specimen are kept unchanged, and the three

Size Effect of Bending Properties of Zirconia Ceramics Based on Cosserat Theory

375

point bending loading test is simulated with the Cosserat finite element model. When the relative

dimension

c

lh

is different, the ratio of the nominal bending strength

Nb

to the classical theoretical

solution

b

is shown in Figure 3.

0.05 0.10 0.15 0.20 0.25 0.30 0.35

1.0

1.5

2.0

2.5

3.0

Cosserat

Polynomial regression curve

Ratio of bending strength

Nb

/

b

l

c

/h

Figure 3. The dimensionless size effect law of bending strength.

The regression equation for the nominal bending strength

Nb

of zirconia ceramicsis obtained by

regression analysis of the numerical data:

2

= 1 0.1 17

cc

Nb b

ll

hh

(11)

4.2. The rule of size effect of bending stiffness

For the three point bending beam, according to the classical continuum theory, the bending stiffness

of the beam is as follows:

3

=4

b

Fh

k Eb

l

(12)

The formula (12) shows that when the elastic modulus of the material, the width of the specimen

and the high span ratio are certain, the bending stiffness of the beam calculated by the classical

continuum theory is constant.

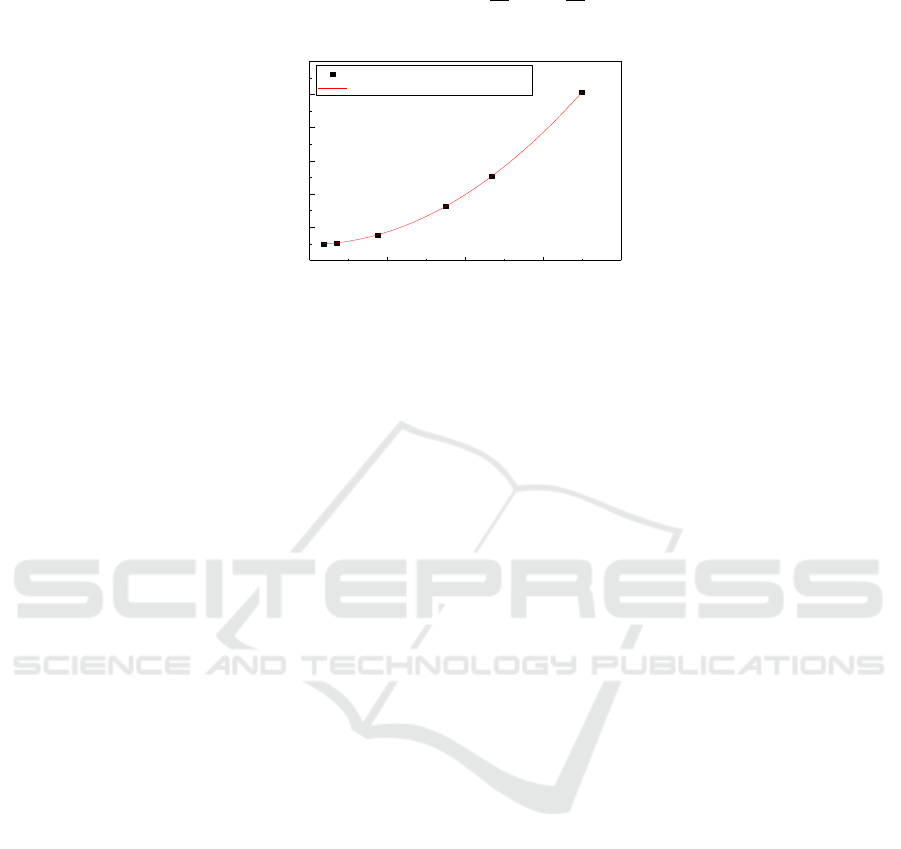

In order to study the size effect law of the bending stiffness of zirconia ceramics, the Cosserat

finite element model is used to simulate the three point bending beam with a height span ratio of

0.01.When the relative size

c

lh

takes different values, the ratio of the nominal bending stiffness

Nb

k

of the specimen to the classical theoretical solution

b

k

is shown in Figure 4.

As shown in Figure 4, the nominal bending stiffness of zirconia ceramics increases with the

decrease of specimen height, and the bending stiffness exhibits obvious size effect. When the height

of the specimen is far greater than the intrinsic size of the material, the nominal bending stiffness

calculated by Cosserat theory is closer to the classical continuum theory, and the size effect is no

longer significant. By regression to the numerical simulation data, the equation of the nominal

bending stiffness

Nb

k

of zirconia ceramic with size is obtained as follows:

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

376

2

1 0.02 18( )

cc

Nb b

ll

kk

hh

(13)

0.0 0.2 0.4 0.6 0.8

0

2

4

6

8

10

12

Cosserat

Polynomial regression curve

Nominal bending strength

k

Nb

/k

b

l

c

/h

Figure 4. The dimensionless effect law of bending stiffness.

5. Conclusions

On the basis of Cosserat theory, the range of intrinsic size parameters of zirconia ceramics is

determined by combining numerical simulation with flexural performance test data. The size effect

law of the bending properties of zirconia ceramics is proposed. The conclusion is as follows:

1) The intrinsic size of zirconia ceramics is deter-mined to be 20~40μm by comparison of theory

and experiment;

2) Considering the intrinsic dimensional parameters of the material, the bending strength of

zirconia ceramic based on Cosserat theory is in good agreement with the experimental results, and it

can explain the size effect of bending strength at different height beams;

3) The nominal bending strength and bending rigidity of zirconia ceramics increase with the

decrease of beam height.

4) The nominal bending strength of zirconia ceramics and dimensionless size effect equation of

nominal bending rigidity are obtained by numerical simulation regression analysis.

References

[1] Yang L, Tian S Y, Xia F and et al 2017 Size Effect of Flexural Strength of Zirconia Ceramics

Bulletin of the Chinese Ceramic Society vol 36(9) 3125-2127

[2] Cosserat E and Cosserat F 1909 Théorie des corps déformables Hermannet and Fils Paris

[3] Dai T M 1981 Brief Comments on the Development of the Cosserat Continuum Theory

Chinese Journal of Solid Mechanics vol 1 129-132

[4] Asmahana Z, Samsuel F, Anne F G and et al 2005 Cosserat continuum modelling of grain size

effects in metal polycrystals PAMM. Proc. Appl. Math. Mech vol 5 79-82

[5] Tang H X and Hu Z L 2013 Three Dimensional Cosserat Continuum Model and Finite

Element Analysis for the Size Effect of Micro-structure Chinese Journal of Computational

Mechanics vol 30(3) 399-405

[6] Amir M A, Seyed M S, Ghader R and et al 2015 Modelling the Size Effects on the Mechanical

Properties of Micro/Nano Structures Sensors vol.15 28543-28562

[7] Zhao B, Zheng Y R and Chen C Finite element method implementation of Cosserat theory and

scale effect simulation of micro-beam. 2010 Journal of Changsha University of Science and

Technology (Natural Science), vol 7(4), 37-42

[8] Mindlin R D 1962 Influence of couple-stress on stress concentrations Experimental Mechanics

vol 3(1) 1-7

[9] Li M M 2017 Establishment of Finite Element Model and Study on Size Effect of Concrete

Flexural Strength Based on Plane Cosserat Theory Beijing jiaotong University

Size Effect of Bending Properties of Zirconia Ceramics Based on Cosserat Theory

377