Effects of HIP and Post Heat Treatment on the

Microstructures and Properties of Laser Direct Deposited

12CrNi2 Steels

J Liang

*

, Q Wang, R Hao, S Y Chen, C S Liu and Y H Chen

Key Laboratory for Anisotropy and Texture of Materials, Ministry of Education, Key

Laboratory for Laser Application Technology and Equipment of Liaoning Province,

School of Materials and Engineering, Northeastern University, Shenyang, 110819,

China

Corresponding author and e-mail: J Liang, liangj@atm.neu.edu.cn

Abstract. The process optimization of Hot Isostatic Pressing (HIP) and post-heat treatment

together with relative microstructure evolution of Laser Direct Deposited (LDD) 12CrNi2

steels for the crankshaft of emergency diesel generator using in nuclear power plants were

studied. Optical Microscopy (OM), X-Ray Diffraction (XRD), Scanning Electron Microscopy

(SEM), Transmission Electron Microscope (TEM) and electron microprobe together with the

microhardness tester and multipurpose material experiment machine were used to analyze and

evaluate the microstructures and the mechanical properties of the LDD 12CrNi2 specimens

under different post-heat treatment parameters. The stable microstructure in the centre of the

as-deposited LDD 12CrNi2 steel specimens is mainly composed of ferrite and granular

bainite. After HIPped at 820°C /2h/120MPa and solid solution treated at 860°C /10min with

oil quenching and tempering at 300°C /10min with AC, the microstructure obtained was

mainly tempered martensite. The average microhardness increased from 216.2HV

0.2

for the

as-deposited to 329.9HV

0.2

for the specimens with post heat-treatment. Though HIP and HT

afterwards, the yield strength and ultimate tensile strength of the 12CrNi2 steel tensile sample

reached 928.7 MPa and 1111.4 MPa respectively, and the elongation is up to 7.3%.

1. Introduction

Nuclear energy as a new generation of clean energy has attracted much attention in recent years.

Additional emergency power supply systems are needed to ensure the normal operation of the safety

automation systems for modern nuclear power plants [1]. High requirements for the power, start and

stop, speed regulation, reliability and service life of the emergency diesel generators have to be met

for nuclear power plants. The reliability of crankshaft and other parts in the generator must be

guaranteed first. The crankshaft of diesel generator required high hardness and wear resistance with

good contact fatigue strength for the surface

[2]. The materials used for the crankshaft normally are

medium carbon alloy steel, low alloy steel etc..The traditional crankshaft manufacturing method has

many difficulties, such as limitation in forming large and complex components, requirement for high

precision die, long manufacturing time and the large amount follow-up machining with the low ratio

of the materials utilization. Laser Direct Deposition (LDD) adopts a new "addition" process with

Liang, J., Wang, Q., Hao, R., Chen, S., Liu, C. and Chen, Y.

Effects of HIP and Post Heat Treatment on the Microstructures and Properties of Laser Direct Deposited 12Crni2 Steels.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 345-350

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

345

discrete layering and layer by layer addition, which can avoid the waste of materials in the "material

reduction" process, and do not need a die, so it can realize the rapid and full dense forming of high

performance complex components [3].

The composition, phases and the phase transition of alloy steels are complex, and the temperature

changing cycle in the process of laser direct deposition was restricted. It is necessary to study the

post-heat treatment for the LDD alloy steels to further regulate stress and microstructure to obtain

high-performance components. The study on the hot isostatic pressing (HIP) and post heat treatment

of LDD titanium alloys and superalloys showed that HIP with the heat treatment afterwards process

was superior to the direct heat treatment process by obtaining the same microstructure [4-5].G.A.

Ravi et.al. HIPped the LDD SC420 stainless steel also increased elongation from 2-3% for the

as-deposited condition to 9% for the HIPped specimen [6]. Xx He et. al. studied the effects of HIP

and HT post-process of IN718 superalloys in which the UTS increased 60-210MPa compared with

direct heat treatment without HIP, and the elongation increased 60%[7]. The specific influencing

factors for the improvement in elongation are not completely clear. In this paper, the effects of HIP

and related heat treatments afterwards on the microstructure and properties of LDD 12CrNi2 alloy

steels for emergency diesel generator crankshaft were studied.

2. Experimental procedure

Gas-atomized 12CrNi2 alloy steel powder was used in this study with the particles size varied from

50-150μm.The composition of the as-received 12CrNi2 powder was shown in Table 1. Laserline

LDF3000-60 system with Ar gas protecting box was used to fabricate the specimens

(100mm×30mm×20mm). The as-deposited 12CrNi2 samples were treated using hot isostatic press

(ABB company QIH-15 HIP tester in Southwest Jiaotong Univ.) under argon gas at 820-880°C and a

pressure of 120MPa for 2-4h with cooling rate 15°C /min. The Heat Treatment(HT) afterward was

860°C solution treatment for 10min and Oil Quenching(OQ) +300°C tempering for 10min and Air

Cooling(AC) (sample size 90mm×9mm×1mm). The samples for microstructure observation were

etched using 4% Nital solution. A Shimadzu-SSX-550 SEM was used to examine the microstructure

evolution of as-deposited and of HIPped and with HT afterwards specimens and the fracture surface

of the tensile test samples. TEM samples were examined a TECNAI G220 transmission electron

microscope. SAD pattern was recorded to identify the phases present in the microstructure. XRD

study was also performed for all the conditions using an X 'Pert Pro MPD-PW3040/60 X

diffractometer with Cu Kαradiation at 40kV and 40mA. Microhardness was tested on a Wilson

Wolpert 401MVD tester with the load of 200g and loading time 10s.Tensile tests were performed on

sample prepared as the standard (gauge length of 15±1mm, total length of 90mm and thickness of

1.0±0.1mm).The tests were carried out in a Shimadzu AG-X100KN at a strain rate 6.7×10-4/s.

3. Results and discussion

3.1. X-ray diffraction analysis and microstructure

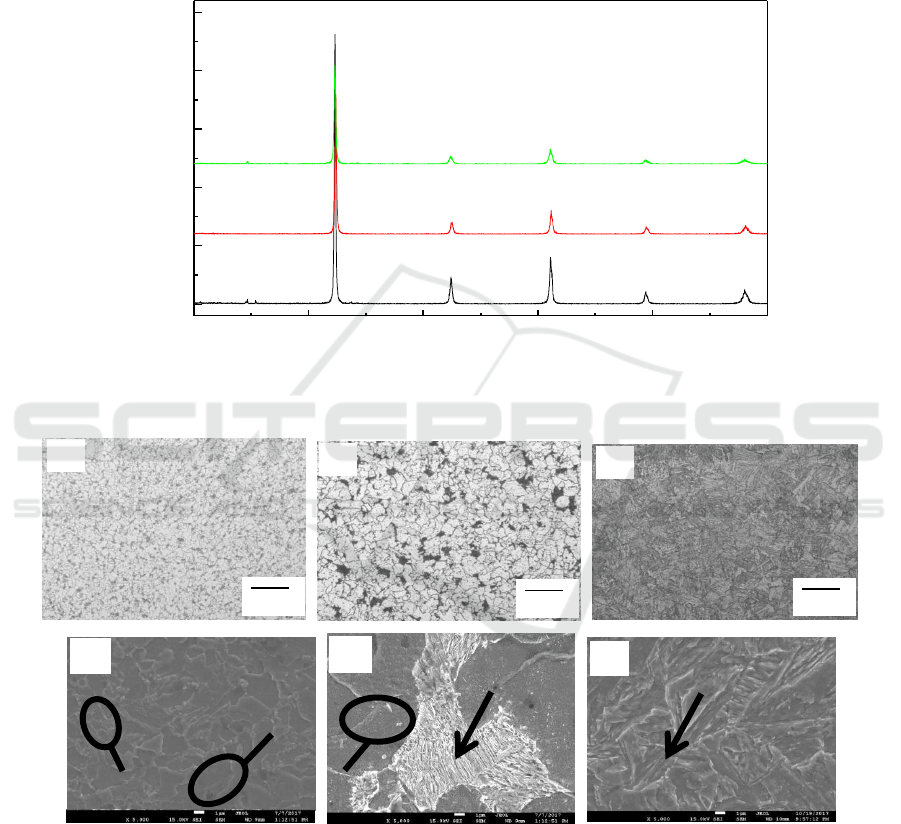

Figure 1 shows the results of XRD analysis of the as-deposited, HIPped and HIPped with post HT

samples. The alpha phase was identified without orientation. Figure 2 shows the optical and SEM

micrographs of the as-deposited and of HIPped and HIPped with post HT samples of 12CrNi2.

According to the XRD phase analysis above and microstructure observation below, it can be seen

that the optical morphology of the as-deposited sample contained mainly ferrite (white) and granular

bainite (see Figure 2a) [8-9]. The average size of the ferrite in the microstructure of as-deposited

sample was about 3μm-5μm. Carbon concentrated was observed alone grain boundary of a few

ferrite (see Figure 2g). In some as-deposited samples a few pores with size of 300μm-400μm was

found which lead to lower relative density of 98.3% compared with the wrought with density of 7.85

g/cm3. HIPping was performed at 860°C which higher than the measured AC3 of LDD 12CrNi2 and

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

346

the cooling rate during the HIPping cycle was slow(15°C /min) which led to microstructure

coarsening after HIPping (see Figure 2b). The microstructure of the HIPped samples composed of

ferrite (around 80%) and pearlite. The average size ferrite increased up to about 20μm. The pearlite

composed of lamellar structure of ferrite and cementite with the spacing 0.2117μm.Pores were not

observed in the HIPped sample with their relative density increased up to 99.3% which led to better

mechanical properties. SEM micrographs Figure 1g showed tempered martensite in the

microstructure of HIPped+HT samples.

Figure 1. X-ray diffraction analysis of 12CrNi2 alloy steel under different conditions (a)LDD

as-deposited,(b) HIPped (c) HIPped+post HT.

Figure 2. Optical and SEM micrographs of the LDD 12CrNi2 steels in different conditions (a)(d)

as-deposited; (b) (e) HIPped; (c) (f) HIPped +HT.

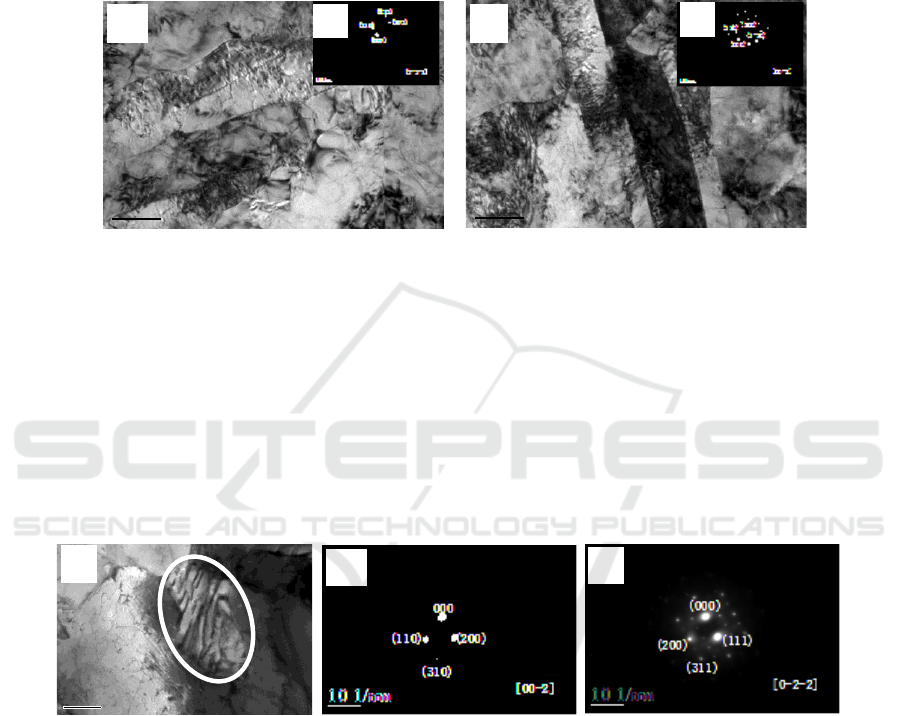

Figure 3 shows the TEM morphology and diffraction pattern in the surface layer of as-deposited

LDD 12CrNi2. The diffraction pattern for the stripe microstructure in Figure 3a is the body-centered

tetragonal structure along the crystal zone axis [3-3-1] of which identified as martensite phase

(Figure 3a). The diffraction pattern analysis of the black strip in Figure 3c, It is the body centered

cubic structure along the crystal zone axis [00-2] and determined to be the ferrite [10]. Therefore,

there is a few layers of martensite structure in the upper surface part of the as-deposited sample,

20 40 60 80 100 120

0

500

1000

1500

2000

2500

HIP+HT

HIP

α (310)

α (220)

α (211)

α (200)

α (110)

Intensity(CPS)

2°

LDD

a

20μm

b

20

μm

c

20μm

ferrite

granular

bainite

d

ferrite

pearlite

e

f

tempered

martensite

Effects of HIP and Post Heat Treatment on the Microstructures and Properties of Laser Direct Deposited 12Crni2 Steels

347

because the top layer cooling rate is higher which the heat dissipated through the air while for the

stable microstructure in the middle part of the as-deposited LDD 12CrNi2 contained ferrite and

granular bainite with lower cooling rate during the laser scanning thermal cycle. In the process of

LDD the thermal cycle when laser scanning each layer for the middle part layers resulted in the heat

accumulate on the existed previous deposited layer which led to lower cooling rate in the middle than

that of the surface layers thus stable proeutectoid ferrite and granular bainite structure was formed.

Figure 3. (a) (c) dark field TEM micrographs and (b)(d) select area diffraction (SAD) patterns of

martensite in the top and ferrite in the centre parts of LDD 12CrNi2 alloy steel respectively.

Figure 4 shows the TEM dark field micrographs and diffraction pattern of the microstructure in

the middle of LDD 12CrNi2 sample after HIPping under the conditions of HIPping pressure 120MPa,

HIPping temperature of 880°C holding time 4 hrs, cooling rate 15°C/min. Figure 4b is the standard

diffraction pattern of crystal zone axis [00-2] of body-centered cubic structure, which is determined

as ferrite phase (see the arrow on Figure 4a grayish-white flake), the diffraction pattern of the black

flake shown in Figure 4c was identified as crystal zone axis [0-22] of the complex orthogonal lattice

structure of cementite phase. Therefore, pearlite composed of ferrite and cementite lamellar are

shown in Figure 4a circle area, which is consistent with the previous SEM analysis.

Figure 4. (a) The dark field TEM micrographs and (b)(c) select area diffraction (SAD) patterns of

ferrite and cementite lamellar in the centre part of LDD 2CrNi2 sample after HIPping, respectively.

3.2. Mechanical properties of 12CrNi2 samples under different condition

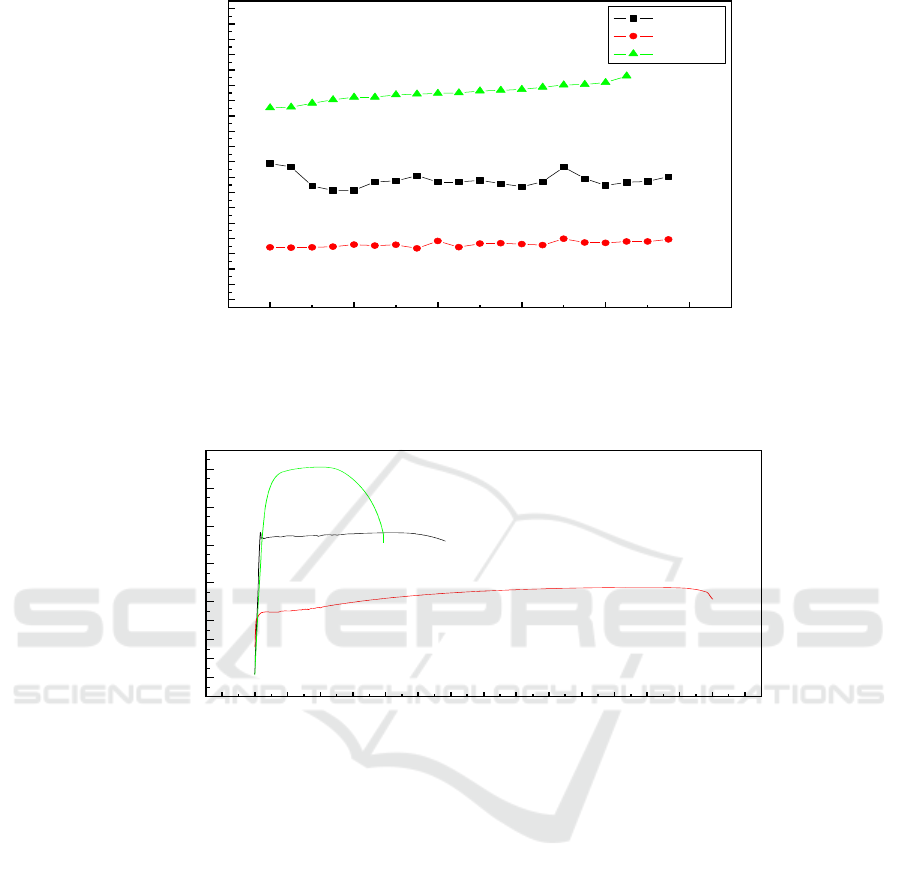

Figure 5 shows the microhardness distribution of the as-deposited LDD 12CrNi2, HIPped and

HIPped+HT samples respectively. The average microhardness of the as-deposited LDD 12CrNi2

samples is 216.2 HV. After hot isotactic pressing, pearlite appeared in the microstructure, the

microhardness decreased to 132.6HV. With the microstructure was transformed into tempered

martensite when quenching and tempering post heat treatment was applied after HIPping, the average

microhardness of HIPped+HT samples reached up to 329.9 HV which was higher than that of the

as-deposited sample with ferrite and granular bainite.

0.2 μm

diff-3

a

b

0.2 μm

diff-7

c

b

1 μm

1 μm

diff

diff-9

a

b

c

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

348

Figure 5. Microhardness distribution of 12CrNi2 alloy steel under different conditions (a)LDD

as-deposited (b) HIPped (c) HIPped+HT.

Figure 6. Tensile test curve of 12CrNi2 alloy steel under different conditions (a) LDD as-deposited

(b) HIPped (c) HIPped+HT.

The mechanical properties for the 12CrNi2 under different conditions were compared in the

Figure 6. It can be seen that the UTS and yield stress of the as-deposited condition decreased from

767.0 and 736.6MPa to 476.2 and 334.4MPa respectively while the elongation increased from 15%

up to 26.5%. The microstructure of as-deposited sample composed of proeutectoid ferrite and

granular bainite as discussed above. Therefore, decomposition products of austenite (M-A islands for

example) were distributed on the matrix of the ferrite, which played the role of strengthening the

granular bainite that improve the strength and toughness of the tensile test samples. Compared with

the ferrite in the microstructure of HIPped samples, proeutectoid ferrite in the as-depostied samples

formed under higher cooling rate with the smaller size offered higher strength and microhardness. At

the same time, the microstructure of HIPped sample contained a small amount of pearlite, its

performance is related to the lamellar spacing. For the sample HIPped and HT afterwards,because

tempered martensite is the supersaturated solid solution of C in α –Fe, it possessed high strength and

microhardness due to the solution strengthening and transformation strengthening in the process of

martensite transformation. Thus better comprehensive mechanical properties were obtained under the

HIPped+post HT condition which possessed 1111.4MPa for UTS and 928.7MPa for the yield stress

respectively with a moderate elongation of 7.3% that could with the requirement of the 12CrNi2

0 2 4 6 8 10

60

80

100

120

140

160

180

200

220

240

260

280

300

320

340

360

380

400

420

440

Hardness(HV)

Distance from the surface(mm)

LDD

HIP

HIP+HT

-2 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

-100

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

HIP

HIP+HT

Engineering stress/%

Engineering strain/%

LDD

Effects of HIP and Post Heat Treatment on the Microstructures and Properties of Laser Direct Deposited 12Crni2 Steels

349

alloy steels for emergency diesel generator crankshaft usage. The wear resistance and contact fatigue

strength for the surface of the crankshaft need further treatment by laser quenching or carburizing etc.

process.

4. Conclusions

LDD was successfully used in the forming of 12CrNi2 alloy steel samples. The effects of HIPping

and post-heat treatment on the microstructure Laser Direct Deposited (LDD) 12CrNi2 steels were

studied. The microstructure for the as-deposited sample was mainly composed of ferrite and granular

bainite while tempered matensite for the HIPping +HT. After HIPping, the porosity and the residual

stresses decreased in the sample, the relative density increased 1%. The optimal parameters for

HIPping and HT afterwards were obtained. Though HIPping and post HT better comprehensive

mechanical properties with the UTS and yield stress up to 1111.4MPa and 928.7MPa respectively

were achieved. The UTS and microhardness increased 45% and 53% respectivelycompared with that

of the as-depostied samples. The elongation reached up to 7.5% that could basically satisfied with the

requirement of the 12CrNi2 alloy steels for crankshaft usage.

Acknowledgements

This work was financially supported by the National Key R&D Program of China

(2016YFB1100203). The strong supports from the cooperative teams of the project on the

experiments and discussion were great appreciated.

References

[1] Borst A 1976 Standby and emergency power supply of German nuclear power plants J. Power

Apparatus & Systems IEEE Transactions on 95(4) 1080-1090

[2] Yang F, Ren X L and Cui J J 2017 Effect of Lightening Hole on Dynamic Characteristics and

Fatigue Life of Diesel Engine Crankshaft J. International Journal of Plant Engineering and

Management 22(2)

[3] Wang Y D, Tang H B, Fang Y L and et al 2010 Microstructure and mechanical properties of

laser melting deposited 1Cr12Ni2WMoVNb steel J. Materials Science & Engineering A

527(1) 4804-4809

[4] Zhang D X, Zhou S Y, Zhang Z Y and et al 2015 Application of HIP technology in improving

the densification of castings J. Powder metallurgy industry 25(1) 46-48

[5] Wang Y D, Tang H B, Fang Y L and et al 2010 Effect of heat treatment on microstructure and

mechanical properties of laser melting deposited 1Cr12Ni2WMoVNb steel J. Materials

Science & Engineering A 528(1) 474-479

[6] Ravi G A, Hao X J, Wain N and et al 2013 Direct laser fabrication of three dimensional

components using SC420 stainless steel J. Materials & Design 47(9) 731-736

[7] He S H 2011 Hot isostatic pressing of laser rapid forming IN718 Superalloy J. Hot working

process 40(22) 185-186

[8] Mei Z, Sha D and Yang D K 1987 Granular bainite in 12CrNi3 steel J. Ordnance Material

Science and Engineering (1) 3-10

[9] Kadiri H E, L Wang, Horstemeyer M F and et al 2008 Phase transormations in low-alloy steel

laser deposits J. Materials Science & Engineering A 494(1-2) 10-20

[10] Yadollahi A, Shamsaei N, Thompson S M and et al 2015 Effects of process time interval and

heat treatment on the mechanical and microstructural properties of direct laser deposited

316L stainless steel J. Materials Science & Engineering A 644 171-183

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

350