Effect of Transverse Pre-Rolling before Drawing on the Anti-

Ridging Properties of 17%Cr Ultra-Purified Ferritic

Stainless Steel

X W Li

1

, X Gao

2

, M F Qi

2

, J Y Li

2,*

and D Tang

1

1

Institute of Engineering Technology, University of Science and Technology

Beijing, Beijing 100083, China

2

School of Materials Science and Engineering, University of Science and

Technology Beijing, Beijing 100083, China

Corresponding author and e-mail: J Y Li, lijy@ustb.edu.cn

Abstract. Cup-drawing test was performed to study the effect of transverse pre-rolling by

2%, 4% and 6% reduction on the surface anti-ridging properties during deep drawing of

17%Cr ultra-purified ferritic stainless steel cold-rolled annealed sheets. The shape and size of

the grains in the tested sheets after transverse pre-rolling were analyzed by optical microscope

(OM), and the evolution of textures and grain colonies in the tested sheet were analyzed by

electron back-scatter diffraction (EBSD) and X-ray diffraction (XRD). The results show that

transverse pre-rolling does harm to the anti-ridging properties of the experimental sheet, and

the height of ridging increases with rising of rolling reduction. After transverse pre-rolling, γ-

fiber texture grain colonies are not deflected and its width increases. The content of γ-fiber

texture and α-fiber texture increase and the texture strengths are more concentrated in the

standard orientation of {111} line, which lead to the degradation of anti-ridging property.

1. Introduction

Ferritic stainless steels have advantages of low cost and outstanding sheet metal formability,

therefore it can replace austenitic stainless steel under certain conditions [1, 2]. During deep forming,

high plastic strain ratio and low earing rate are acquired, but the surface quality of drawing parts is

unsatisfactory. A rather serious problem is that distribution of high and low undulating strip defects

appears along the original rolling direction on the surface of sheet after deep drawing. It’s so called

ridging [2, 3]. The mechanisms of surface ridging of annealed ferritic stainless steel sheet during

tensile or drawing were studied [4, 5]. Chao et al. [6] argued that ridging was caused by {111}//ND

and {100}//ND textures with different plastic strain ratios. Takechi et al. [7] proposed that the shear

deformation would be introduced by asymmetrical slippage between the RD//<110> texture

components and the difference of shear deformation between the different components resulted in

ridging when the plate is tensioned. However, Brochu et al. [8] found that the peaks and valleys were

located in the same position in the top and bottom surface of ferritic stainless steel after tensile

deformation, which is inconsistent with the deformed surface profiles measured by Chao [6].

336

Li, X., Gao, X., Qi, M., Li, J. and Tang, D.

Effect of Transverse Pre-Rolling before Drawing on the Anti-Ridging Properties of 17%Cr Ultra-Purified Ferritic Stainless Steel.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 336-344

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

In addition, many researches on improving ridging resistance have been reported. Gao et al. [9,10]

proved that low temperature finish rolling contributes to reduce the ridging height of ferritic stainless

steel. Huh et al. [11] found that the recrystallization texture was notably shifted towards {334}<483>

and {554}<225> instead of forming the {111}//ND γ-fiber texture typical of recrystallized ferritic

steel sheets when introducing intermediate annealing during cold rolling of 430 ferritic stainless steel.

We have reported transverse pre-stretching before deep drawing can improve the surface ridging

resistance of ferritic stainless steel effectively [12]. In order to find a more efficient process than pre-

stretching, the researches on transverse pre-rolling were performed. Microstructural evolution during

pre-rolling and surface roughness after drawing were observed in this study.

2. Experimental

Table 1 lists the chemical composition of the 17%Cr ultra-purified ferritic stainless steel sheet. The

sheets were rolled along the transverse direction by 2%, 4% and 6% reduction before drawing, which

was named as transverse pre-rolling. The as-received sheet was marked as 0#, and the pre-rolled ones

were marked as 1#, 2# and 3# corresponding to 2%, 4% and 6% reduction, respectively. Then the

sheets were cut into disc specimens with the diameter of 78mm. The cup drawing test was carried out

by the sheet metal forming machine BCS-30D with film lubrication. The surface ridging was tested

by laser scanning confocal microscope LEXT OLS4000. Microstructural observations were

performed by optical microscopy (OM, Leica DM2500). Macro-textures were tested by X-ray

analysis (Bruker D8 X-ray diffractometer). Orientation distribution functions (ODF) were calculated

from incomplete pole-figures measured in back-reflection. Micro-texture and spatial orientation

distribution were measured by a ULTRA55 field emission scanning electron microscope equipped

with an EBSD detector.

Table 1. Chemical composition of the studied steel.

C Si Mn S P Cr N Nb Ti Fe

0.01 0.58

0.1

7

0.001 0.019 16.51 0.008 0.144 0.159 Bal.

3. Results

3.1. Surface ridging after drawing

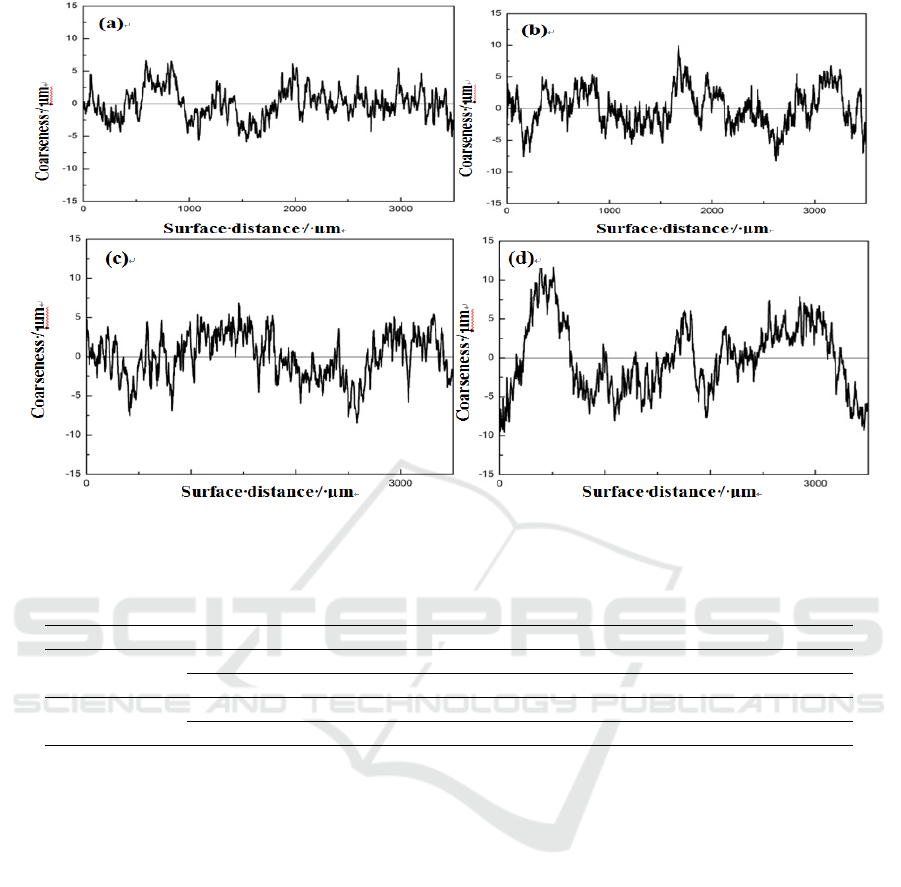

Figure 1 shows the profile roughness curves of surface on the side wall of cups. It can be seen that

the distance of curve peaks on sample 0#, 1#, 2# and 3# were 500, 600, 700 and 1000 μm,

respectively. It indicated that transverse pre-rolling made the ridging becoming wide.

Table 2 lists the values of roughness with vertical pattern or U shape pattern on the side wall of the

drawn cup. Here, Ra represents the arithmetic mean of the vertical distance between the profile and

the center line in the evaluation length, while the Rz indicates the difference between the average

value of the five highest contour peaks and the average value of the five deepest valleys. It indicated

that the roughness of tested samples after transverse pre-rolling were bigger than those original

annealed sheet.

Effect of Transverse Pre-Rolling before Drawing on the Anti-Ridging Properties of 17%Cr Ultra-Purified Ferritic Stainless Steel

337

Figure 1.Roughness profiles of vertical pattern of deep drawing products for different transverse

pre-rolling reductions: (a) annealed state, (b) 2%, (c) 4%, (d)6%

Tab le 2. Roughness values of deep drawing products for different transverse pre-rolling reductions.

0# 1# 2# 3#

Vertical ridge

Rz 3.533 3.983 4.142 4.179

Ra 0.676 0.755 0.748 0.830

U shape ridge

Rz 3.161 3.039 3.127 3.242

Ra 0.539 0.548 0.543 0.552

The above results revealed that transverse pre-rolling cannot improve the surface ridging

resistance of ferritic stainless steel, which was contrary to our previous research on transverse pre-

stretching [12]. The evolutions of microstructure and texture as below were studied to explain the

distinct difference.

3.2. Microstructures after transverse pre-rolling

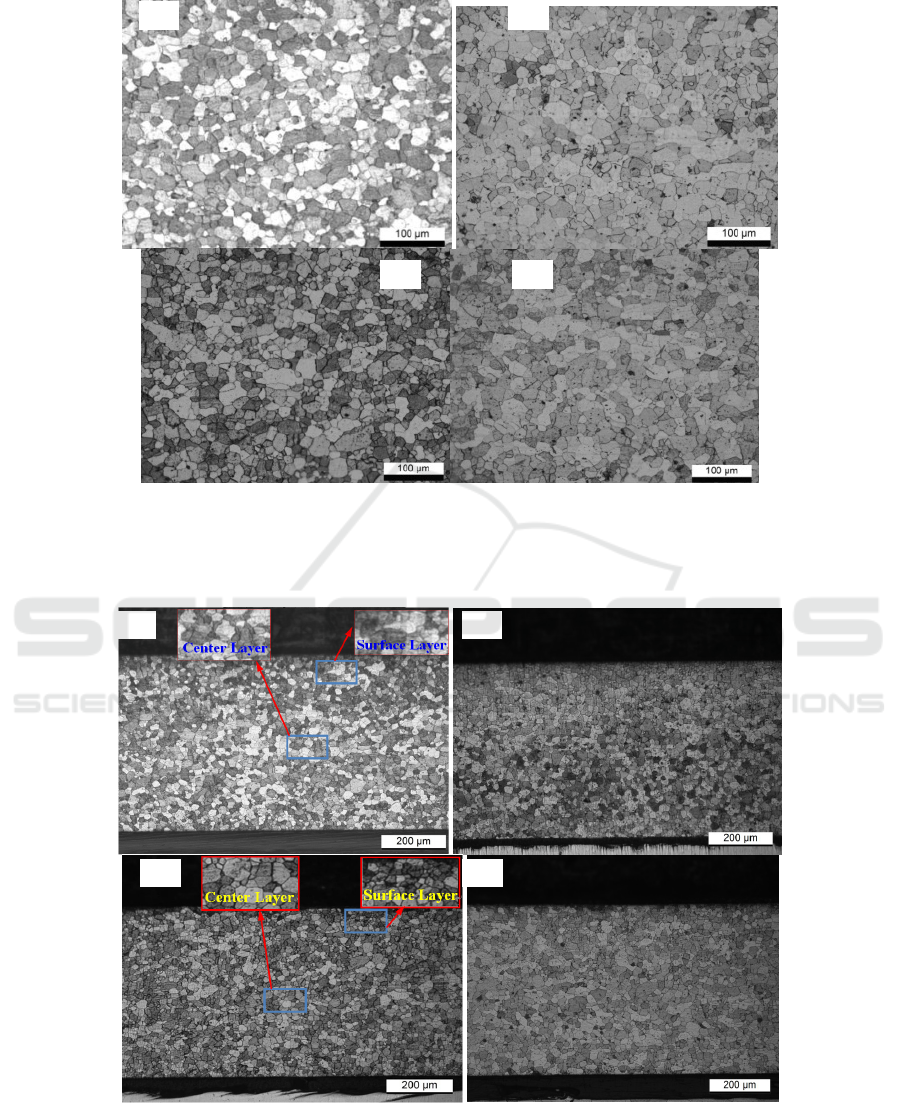

Figure 2 shows the microstructures of the sheets. It can be seen that the grains of annealed sheet were

uniformly with the average size of 26 μm and the grains were just slightly elongated along the rolling

direction after transverse pre-rolling.

The major difference of microstructures between samples with and without transverse rolling was

the uniformity of grain size. The grain size on the surface and center layers were similar in annealed

samples (Figure 3 a), However, the grain on the surface layer was greatly finer than that in the center

when samples were transverse rolled for 2~6% reduction (Figures 3 b-d), which caused by the

friction between the roller and sheet surface, and the shearing stress refined the grain in the surface

layer [3, 9].

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

338

Figure 2. Microstructures of 17%Cr ultra-pure ferritic stainless steel sheet on transverse direction

(ND) section after various transverse pre-rolling reductions: (a) annealed state, (b) 2%, (c) 4%, (d)

6%.

Figure 3. Microstructures of 17%Cr ultra-pure ferritic stainless steel sheet on transverse direction

(TD) section after various transverse pre-rolling reductions: (a) annealed state, (b) 2%, (c) 4% and (d)

6%.

(a) (b)

(d)(c)

(a) (b)

(c) (d)

Effect of Transverse Pre-Rolling before Drawing on the Anti-Ridging Properties of 17%Cr Ultra-Purified Ferritic Stainless Steel

339

3.3. Grain clusters after transverse pre-rolling

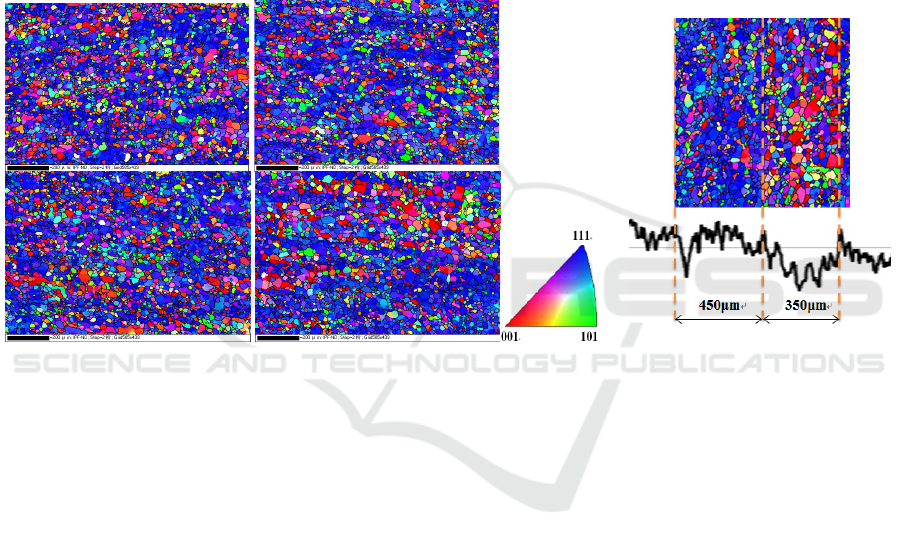

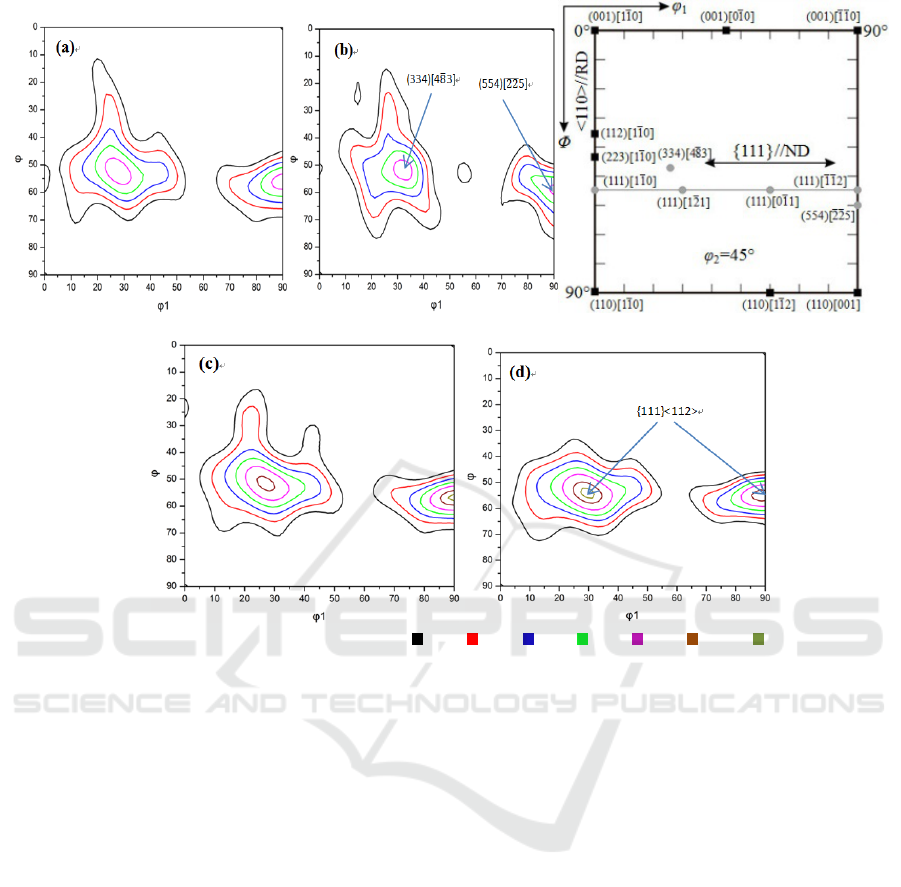

Figure 4 shows the grain distribution of normal direction (ND) for the sheets under different

transverse pre-rolling reductions. The blue, red and purple grains represent {111}ND, {001}ND and

{112}ND, respectively. It indicated that all samples have very strong {111} texture, which formed

clear grain colonies. The width of {111} grain clusters rises slightly with the increase of the

deformation of transverse rolling. The grain clusters and profile curves of sample 2# are shown in

Figure 5. It can be seen that the width of grain clusters and ridging on stamping surface was

consistent, compared with the stamping surface profile as mentioned in Figure 1.

Grain clusters with same orientation were the decisive factor for the ridging of stamping surface,

were widely used for explaining the ridging phenomenon on stamping of ferritic stainless steel sheets

[6, 13]. Grain clusters were not narrowed greatly after transverse pre-rolling in this work. It indicated

that there was no improvement in decreasing the ridging phenomenon by transverse pre-rolling.

Figure 4. Grains distribution of normal direction (NT) for

transverse pre-rolling reductions of (a)annealed state, (b)2%, (c)4%

and (d)6%.

Figure 5. Grain clusters and

profile curves of sample 2#.

3.4. Micro orientations of grains after transverse pre-rolling

The grain orientation and texture were regarded as the most important affect factors for ridging of

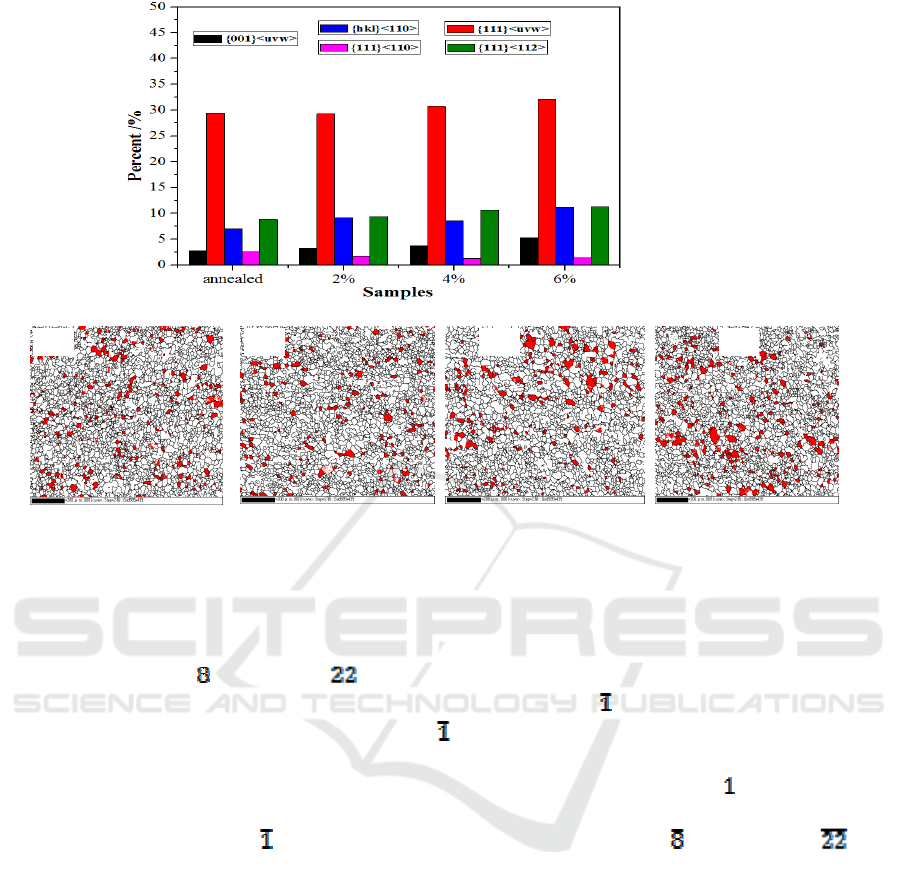

ferritic stainless steel. Figure 6 shows the contents of various grain orientations in the tested steel

sheet at as-received state and after transverse pre-rolling. It can be seen that {111} <uvw> was the

primary orientation in all tested samples, which is the typical recrystallization texture for ferritic

steel. It should be noted that the contents of all typical texture, {111}, {001} and <110> increased

with the increasing of pre-rolling, which might lead to texture gradient and inhomogeneity of grain

orientation.

Figure 7 shows the distributions of the specific oriented grains in the center layer of the sheets and

in which the red zone represented grains with orientation of {001}//ND. The content of grains with

{001}<uvw> was lower than 8% and cluster was not found in all the tested sheet. Thus, though Chao

[6] and others believed that the difference of plastic strain ratio between {001}//ND texture and other

textures components lead to the ridging phenomenon, the tested 17%Cr ultra-pure ferritic stainless

steel sheet was not fit to Chao model because of little content of {001} texture and no texture cluster.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

340

Figure 6.

Contents of

typical grain

orientation in

tested sheets.

Figure 7. Grains distribution of {001}ND (normal direction) for different transverse pre-rolling

reductions: (a) annealed state, (b) 2%, (c) 4%, (d) 6%.

3.5. Macro texture after transverse pre-rolling

Figure 8 shows ODF of the sheets with different transverse pre-rolling reductions. The annealed

sheet formed strong γ fiber texture and the texture strengths slightly deviated from {111} line to

orientation of (334)[4

3] and (554)[ 5] with the orientation density of 6.4 due to high content of

Cr. Meanwhile, α fiber texture and rotated cube texture (001) [1

0] were relatively low, and the

strength of α fiber texture was located in (111)[1

0] with the orientation density of 2.2 (Figure 8. a).

When the transverse rolling of deformation was applied, the grain orientation was rotated. There was

no obvious change in texture and α fiber texture slightly moved to (445) [1

0] for 2% rolling

reduction (Figure 8. b). After rolling reduction of 4%, intensity of γ texture increased, α fiber texture

continues move to (113)[1

0] and the strength moved from (334)[4 3] and (554)[ 5] to

{111}<112>, with the orientation density of 7.1 (Figure 8. c). As the rolling reduction increased to

6%, intensity of γ texture continued to increase and the strengths moved to the position of {111}

<112> with the orientation density of 7.7 (Figure 8. d).

(a) (b) (c) (d)

Effect of Transverse Pre-Rolling before Drawing on the Anti-Ridging Properties of 17%Cr Ultra-Purified Ferritic Stainless Steel

341

Grain orientation density:2.0 3.0 4.0 5.0 6.0 7.0 7.50

Figure 8. ODF of tested steel with different transverse pre-rolling reductions: (a) annealed state, (b)

2%, (c) 4%, (d) 6%.

The ODF maps of each sample were consistent with the results of grain orientation. γ fiber texture

was gradually strengthened with the increase of rolling reduction, mainly lied in the increase of

texture intensity of {111}<112>. The reason is that it formed {111}<110> rolling texture along the

rolling direction, and the grain orientation performed as {111}<112> during the transverse rolling

when it was observed along the original rolling direction. The conclusion that {hkl}<110> increased

by a certain strength was not obvious. But it can be seen that although there was no obvious

discipline of α peak changed, the texture distribution on α orientation line is more uniform with the

increase of rolling reduction, and the amount of α texture increased. α texture is mainly caused by

rolling. After transverse rolling, {001}<110> texture formed in the transverse direction, and it also

performed as {001}<110> texture along the original rolling direction, thereby {001}<110> texture

strengthened with the rolling reduction increased. The α texture downward extended along the

orientation line, and the lower position was the larger deviation angle between the transverse

direction and the original rolling direction was, until it move down to {111}<110>, the deviation

angle reached 90°. {111}<110> as the main rolling texture increased along the rolling direction after

cold rolling, but it performed as {111}<112> along the original rolling direction, so {111}<110>

decreased in the original rolling direction, as shown in Table 2 by the measured results.

4. Discussions

In the stretching process, the grains of {hkl} <112> orientation along the stretch direction

continuously turn to {hkl} <110> along the slip plane until the grains of {hkl} <112> absolutely turn

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

342

to {hkl} <110> orientation, and at this time it has reached the deformation limit that the grains can

bear. Meanwhile, the content of {111} <uvw> oriented grains decreased gradually. Thus, in the

transverse pre-stretching process [12], the content of {hkl}<110> and {hkl}<112>grains decreased

and increased respectively along the rolling direction because the stretching and the cold rolling

directions were perpendicular. Also, {111} <uvw> oriented grains were easily to slide and rotate

continuously in the process of stretching, so the texture distributed wider and more uniformly, and

the content of γ fiber decreased.

However, after rolling, both the intensity of α and γ fiber textures increases, that is, both the

{hkl}<110> and the {111}<uvw> textures increases. In this experiment, after transverse rolling (the

rolling direction perpendicular to the original cold rolling direction), the {111} <uvw> texture raised

slightly, the {111} <112> texture raised significantly (caused by the increase of {hkl}<110> texture

along transverse direction), and the {111}<110> texture decreased a little.

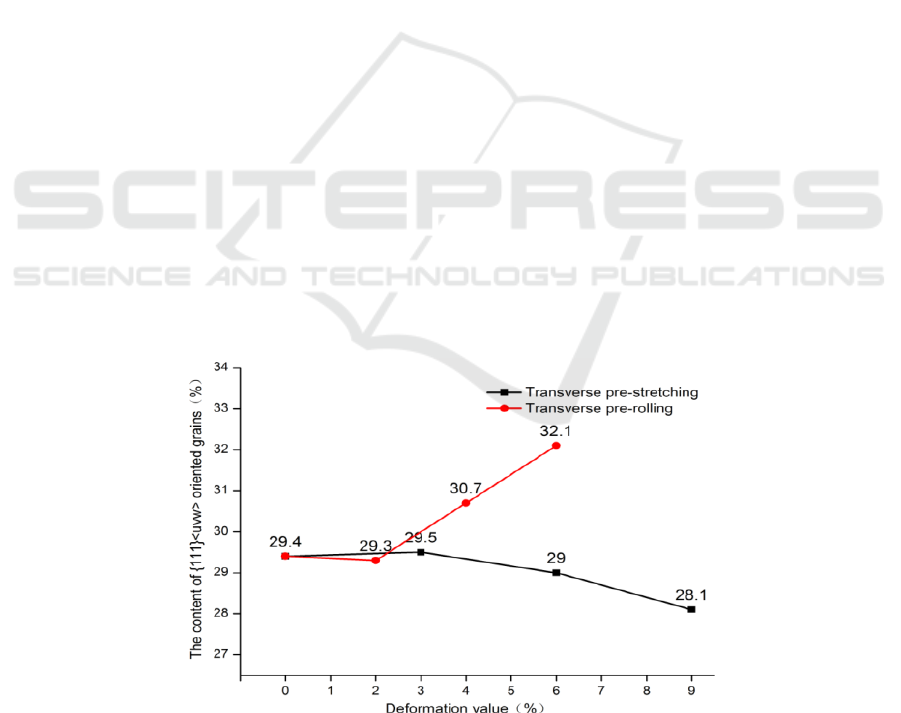

The quantities of {111} <uvw> oriented grains were measured by EBSD. When the deviation

angle was 15°, no matter transverse stretching or transverse rolling, the quantities of the oriented

grains were increased. When the deviation angle was 10°, the quantities of the grains were decreased

and increased after transverse stretching and transverse rolling respectively, as shown in Figure 9.

Transverse stretching make the distribution of the γ texture more uniform in ODF map, that is, the

grains of γ fiber texture gradually shift to other orientations, so the typical {111} oriented grains

decrease. With the increase of deformation, both the γ fiber texture and the deflection angle to the

{111} orientation line changed obviously, the deflection range of main texture component increased

along Φ in ODF map. On the contrary, transverse rolling made the γ texture distribute more compact

along Φ in ODF map, it was more focused on the typical {111} orientation line. In the analysis of

macro texture results by ODF, the texture strengths of 0# and 1# were located in {334}<483> and

{554}<225>, and with the reduction of transverse rolling increased, the texture strengths of 3# had

already moved to the standard position {111}<112> of γ fiber texture. Some studies [11, 14] have

indicated that the two factors mentioned above would enhance the ridging phenomenon of ferritic

stainless steel.

Therefore, it can be seen that the opposite influence on the ridging phenomenon of ferritic

stainless steel by transverse stretching and transvers rolling, is due to that the intensity and strengths’

position of α and γ fiber texture change differently after transverse stretching and transvers rolling.

Figure 9. The content of {111}<uvw> oriented grains in the test site.

Effect of Transverse Pre-Rolling before Drawing on the Anti-Ridging Properties of 17%Cr Ultra-Purified Ferritic Stainless Steel

343

5. Conclusions

Transverse pre-rolling by 2~6% reduction before drawing will enhance the surface riding

phenomenon of 17%Cr ultra-pure ferritic stainless steel, and deteriorate its anti-ridging property. The

conclusions are summarized as follows:

1. The surface grains are refined by transverse pre-rolling, but the morphology of the central layer

grains is less affected. Also, the increases of the width of <uvw> {111} grain clusters do not lead to

deflection of the grain clusters by transverse pre-rolling.

2. EBSD and XRD analysis revealed that the content of α fiber texture and γ fiber texture were

respectively increased slightly and obviously by transverse pre-rolling. Furthermore, the γ texture

distribution, assembled along Φ in ODF map, is more focused on the typical {111} orientation line.

Those results produced by transverse rolling is greatly different from transverse stretching process,

which formed more dispersive γ texture and made the strengths of texture deviate from the typical

{111} orientation line of γ texture. In conclusion, the anti-ridging property of the experimental plate

was reduced under the united effect of these textures.

Acknowledgements

Project supported by National Key Technology Research and Development Program of the Ministry

of Science and Technology of China during the Twelfth Five-Year Plan Period(2015AA03A502)

References

[1] Li X B 2006 J. Plasticity Eng. 3 35

[2] Chen P D, Zhang Z F, Ma Z W, Wang H X 2011 J. Univ. Sci. Technol. B. S1 46

[3] Costa Viana C S D, Pinto A L, Candido F S 2006 Mater. Sci. Technol. 22(3) 293

[4] Wright R N 1972 Metall. Trans. 3(1) 83

[5] Lefebvre G 2014 Electronic Theses and Dissertations (ETDs) 9 306

[6] Chao H C 1967 Trans. Am. Soc. Met. 60(1) 37

[7] Takechi H, Kato H, Sunami T 1967 Trans. Jpn. I. Met. 8(4) 233

[8] Brochu M, Yokota T, Satoh S 1997 Isij Int. 37(9) 872

[9] Gao F, Liu Z, Liu H 2013

J. Alloys Compd. 567(31) 141

[10] Gao F, Liu Z, Liu H 2013 Mater. Character. 75(1) 93

[11] Huh M Y, Engler O 2001 Mater. Sci. Eng. A 308(1-2) 74

[12] Xiong Q, Chen Y L, Li J Y 2015 Chin. J. Eng. 9 1149

[13] Engler O, Huh M Y, ToméC N 2005 Metall. Mater. Trans. A 36(11) 3127

[14] Zhang C, Liu Z, Wang G 2011 J. Mater. Process. Technol. 211(6) 1051

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

344