Stearic Acid Grafted Carboxymethyl Chitosan and Its

Nanoencapsulation of Macadamia Oil

H Wang

1,2

, Z M Yang

2

, S D Li

2,3

, Y Z Xia

4

, B B Wang

4

, C Zhou

2

, C Wang

2

and P

W Li

2, *

1

College of Food Science & Technology, Huazhong Agricultural

University,Wuhan ,430070, China

2

Agricultural Products Processing Research Institute, Chinese Academy of Tropical

Agricultural Sciences, Zhanjiang, 524001, China

3

College of Chemistry and Environment, Guangdong Ocean University, Zhanjiang,

524088, China

4

Collaborative Innovation Center for Marine Biomass Fibers, Materials and Textiles

of Shandong Province, Qingdao University, Qingdao, 266071, China

Corresponding author and e-mail: P W Li,1520102069@qq.com

Abstract. This work is aims to synthesize a novel stearic acid (SA) grafted N,O-

carboxymethyl chitosan (NOCC), and then use it as a wall material to nanoencapsulation

macadamia oil. The grafted copolymer is a amphiphilicity sample. By the catalysis of 1–(3-

dimethyl amino propyl)-3-ethyl carbodiimide hydrochloride (EDC·HCl) and N-hydroxy

succinimide(NHS), we got hydrophilic and hydrophobic NOCC-SA polymers via the

condensation reaction between the carboxyl of arboxymethyl chitosan and the carboxyl of

stearic acid in a water bath. Macadamia oil has significant effect on whitening and spotting,

also as a bioactive compound with health beneficial potential, which are used as safe

additives in food , medicine, cosmetics. However Macadamia oil is sensitive to light, thermal

condition and oxidation. Nanoencapsulation could be an adequate technique to overcome

these challenge. Here, we obtained the analysis by scanning electron microscope and

grainsize analyzer that most nanocapsules sizes ranged from 130.2 to 200.8 nm. To sum up,

this study showed that amphiphilic chitosan were a kind of potential carrier. It could increase

the solubility of hydrophobic substances and make it sustained release by nanoencapsulation.

1. Introduction

Macadamia integrifolia, also known as Australian walnuts, Queensland fruits and macadamia nuts,

belong to evergreen trees and dicots. Among many dried fruits in the world, macadamia integrifolia

have high nutritional and medicinal value, and therefore it have the highest economic value, and

always been regarded as the “king of dried fruit” [1]. The main fatty acid content of macadamia oil is

mainly composed of unsaturated fatty acids such as oleic acid, palmitic acid and stearic acid, and a

small amount of linoleic acid. Among them, macadamia integrifolia contain more than 80% of

unsaturated fatty acids, making macadamia oil with lower blood pressure, blood lipid regulation, and

can be used as an effective additive in food and drugs. However, it can also be used as an effective

Wang, H., Yang, Z., Li, S., Xia, Y., Wang, B., Zhou, C., Wang, C. and Li, P.

Stearic Acid Grafted Carboxymethyl Chitosan and Its Nanoencapsulation of Macadamia Oil.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 297-301

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

297

additive for moisturizing, nourishing and whitening products [2]. It can be applied directly to the

basal layer of the skin and very widely used in cosmetics, skin care products. Because of the high

ratio of unsaturated fatty acids, Macadamia oil is extremely susceptible to oxidation, which is

affecting the storage quality and transport of the oil. Therefore, nanoencapsulation technique might

be a suitable solution to solve these problems. In order to protect sensitive ingredients,

nanoencapsulation technology allows “wall material” enveloped these ingredients or “core” materials

from adverse reactions, volatile loss, or nutritional deterioration [3]. In this research, stearic acid

grafted N,O-carboxymethyl chitosan as a amphiphilicity polymer because of its ability to control the

release of sensitive ingredient, and cross-linking to form nanocapsulates. Nanocapsules based on

chitosan and modified starch as a wall material to enveloped Macadamia oil as an active ingredient

by freeze-drying. In their study, the sizes of most nanocapsules ranged from 339.3 to 553.3 nm and

chitosan: Hicap is 1.5: 8.5%, which showed the lowest oil release. In another study, Abreu [4] use

chitosan and cashew gum nanogel for L.sidodies oil encapsulation systems. Few studies have used

amphipathic modified chitosan as a wall material to deliver hydrophobic substances (such as plant

essential oils)[5]. The amphiphilic NOCC-SA polymers were prepared by stearic acid grafted N,O-

carboxymethyl chitosan, which nanocapsulation macadamia oil can improve the biological activity

and utilization of macadamia oil, making it more versatile and greatly increase its economic value.

What’s more amphiphilic NOCC-SA polymers can be a meaningful hydrophobic substances model,

provide new ideas for following related research.

2. Materials and methods

2.1. Materials and reagents

chitosan was purchased from Aladdin Industrial Co. Ltd. (Shanghai,China). The degree of

deacetylation and viscosity of chitosan were determined as 95% and 100-200 mpa.s, respectively.

stearic acid (SA), 1–(3-dimethyl amino propyl)-3-ethyl carbodiimide hydrochloride (EDC·HCl), N-

hydroxy succinimide(NHS) were all purchased from J&K Scientific LTD. (Beijing, China). All

other reagents were of analytical grade.

2.2. Synthesis of N,O-carboxymethyl chitosan (NOCC)

NOCC was prepared according to the previous report by Chen [6] with some modifications. Briefly,

5 g chitosan dispersed and mixed thoroughly in 500 mL of isopropyl alcohol flask at room

temperature. Then, the solution comprising 35 g monochloroacetic acid and 10 mL of 10 M NaOH

was dropwise added to the stirred slurry over a period of 30 min. The alkaline slurry was stirred for

additional 20 min. The resulting mixture was heated at 60

o

C for 3 h. And then, dialyzed against

distilled water with 7000 Da molecular weight cut-off membrane for 48 h. Finally, the dialyzate was

freeze-dried to afford NOCC [7].

2.3. Preparation of stearic acids grafted NOCC

The preparation of NOCC grafted coplymers were preformed by using stearic acid (SA). Briefly, 500

mg NOCC was dissolved in 50 mL of distilled water to make solution I. And then, 500 mg stearic

acids was dissolved in 40 mL of hot ethyl alcohol absolute, and add 1.5 times the molar amount of

EDC·HCl and NHS were stirred at 65°C until completely dissolved to prepare solution II.

Subsequently, Solution II was added to solution I under vigorous stirring conditions. The reaction

was carried out at 60°C for 5 h, dialyzed against distilled water for 48 h, and freeze-dried for 2 d.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

298

O

O

O

OH

OH

NH

2

NH

2

O

HO

HO

n

Chitosan

IPA/NaOH

monochloroacetic acid

O

O

O

OH

OCH

2

COO

-

NH·

NHCH

2

COO

-

O

HO

HO

n

NOCC

O

O

O

OH

OCH

2

COO

-

NHR

NHCH

2

COO

-

O

HO

HO

n

NOCC-SA

stearic acid (SA)

EDC·HCL/NHS

R =

OH

O

Figure 1. The proposed mechanisms for the synthesis of stearic acids grafted NOCC.

2.4. Preparation of NOCC-SA nanocapsulation Macadamia oil

NOCC-SA nanocapsulation macadamia oil were prepared with slight modification of previous

studies [8-9]. Briefly, 500 mg NOCC-SA was dissolved in 50 mL of distilleded water, after it was

completely dissolved. The macadamia oils was added in a 1:4 ratio (w/w, macadamia oils/ NOCC-

SA solution) to the solution. The resulting mixture flask at room temperature for 1d, and dialyzed

against distilled water with 7000 Da molecular weight cut-off membrane for 48 h. Then, dialysate

was treated three times with probe-type ultrasonic cell crusher: Power 80 W; Pulse on 2.0 s; Pluse off

3.0 s; Time 2 min, over 0.8 μm filter. Finally, the dialyzate was freeze-dried into nanocapsule powder.

2.5. Characterization of the products

Morphology of the freeze-dried nanocapsules was examined to study the surface structures of

powders by scanning electron microscopy (SEM; S-4800, HITACHI, Tokyo, Japan). The samples

were glued onto an adhesive tape mounted on the specimen stub, and particles were covered with

gold-palladium prior to analysis. Preparation a suitable concentration of NOCC-SA macadamia oil

nanocapsules solution, add 2 mL of nanocapsules solution to the cuvette, and measure the

nanocapsules size with a laser particle size analyzer.

3. Results and discussion

3.1. Preparation of phenolic acids grafted NOCC

In this study, stearic acid (SA) grafted NOCC were synthesized by using EDC·HCl and NHS as

catalyst. The possible mechanism for the stearic acid grafted NOCC was proposed in Figure 1. Firstly,

NOCC was synthesized in isopropyl alcohol/NaOH/ monochloroacetic acid system. And then, The

use the EDC·HCl and NHS as catalyst, which can catalyzes the reaction of the carboxyl group on SA

with the amino group on NOCC. During the reaction, EDC·HCl is used to activate the carboxyl

group and NHS is used to assist the reaction. NOCC and SA are linked together by amide bonds. The

obtained NOCC-SA grafted coplymers were amphiphilic samples.

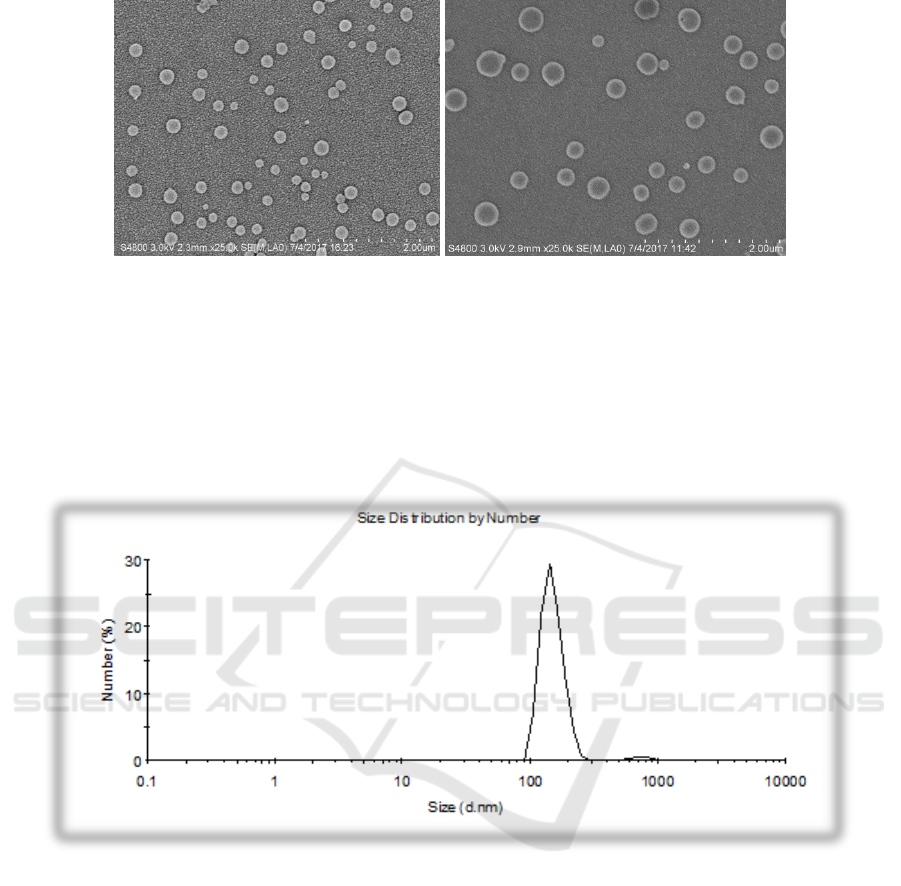

3.2. Morphology

Scanning electron microscope (SEM) is based on the interaction between electrons and substances to

obtain the physical properties and chemical properties of the tested sample. SEM images of the

NOOC-SA macadamia oil nanocapsules are shown in follow Figure 2.By the analysis of represented

by Scanning electron microscope images, we know that the obtained nanocapsules showed a

spherical shape surface without rough.

Stearic Acid Grafted Carboxymethyl Chitosan and Its Nanoencapsulation of Macadamia Oil

299

Figure 2. The SEM images of NOCC-SA macadamia oil nanocapsules.

3.3. Particle size

The hydrodynamic size of nanocapsules were determined by Malvern 3000HS (Malvern Instruments

Ltd., UK). In order to quantitatively determine the nanoparticle size of NOOC-SA macadamia oil

nanocapsules, set the detection angle to 90°, 25°C, and λ=532 nm. Most nanocapsules sizes ranged

from 130.2 to 200.8 nm. Particle size analysis chart of NOOC-SA macadamia oil nanocapsules as

shown Figure 3:

Figure 3. The size distribution of NOOC-SA macadamia oil nanocapsules.

4. Conclusions

The preparation, characterization of stearic acids grafted NOCC were investigated in the study.

Results suggested that the stearic acids could be easily grafted into NOCC by using EDC·HCl and

NHS as catalyst. In addition, the nanocapsules showed a Spherical and smooth surface by SEM

images. In conclusion, NOCC-SA is the promising coat material for developing delivery systems for

the hydrophobic substances. The findings obtained from the study suggest that NOCC-SA is

amphiphilicity which had a great potential to improve the stability of macadamia oil for its

utilization in perfumery, food industries, antimicrobial and antiseptic products.

Acknowledgment

This work was supported by the Natural Science Foundation of Guangdong Province (No.

2016A030307003), and the Central Public-interest Scientific Institution Basal Research Fund for

Chinese Academy of Tropical Agricultural Sciences (No.1630122017011, No.1630122017009).

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

300

References

[1] Navarro S L B and Rodrigues C E C 2016 Macadamia oil extraction methods and uses for the

defatted meal byproduct J. Trends in Food Science & Technology 54 148-154

[2] Chen Y, Tang H, Liu Y and et al 2016 Preparation and study on the volume phase transition

properties of novel carboxymethyl chitosan grafted polyampholyte superabsorbent

polymers J. Journal of the Taiwan Institute of Chemical Engineers 59 569-77

[3] Liu J, Lu J F, Kan J and et al 2013 Preparation, characterization and antioxidant activity of

phenolic acids grafted carboxymethyl chitosan J. International Journal of Biological

Macromolecules 62(2) 85-93

[4] Abreu F O, Oliveira E F, Paula H C and et al 2012 Chitosan/cashew gum nanogels for

essential oil encapsulation J. Carbohydrate Polymers 89(4) 1277-82

[5] Donsì F, Annunziata M, Sessa M and et al 2011 Nanoencapsulation of essential oils to enhance

their antimicrobial activity in foods J. LWT - Food Science and Technology 44(9) 1908-14

[6] Kusuma H S, Al-Sa’Bani A F and Darmokoesoemo H N 2015 O-Carboxymethyl chitosan: an

innovation in new natural preservative from shrimp shell waste with a nutritional value and

health orientation J. Procedia Food Science 3 35-51

[7] Jung B O, Chung S J and Sang B L 2006 Preparation and characterization of eugenol-grafted

chitosan hydrogels and their antioxidant activities J. Journal of Applied Polymer Science

99(6) 3500–06

[8] Stefan D, Dima C and Iordăchescu G 2015 Encapsulation of Functional Lipophilic Food and

Drug Biocomponents J. Food Engineering Reviews 7(4) 417-438

[9] Bahreini E, Aghaiypour K, Abbasalipourkabir R and et al 2014 Preparation and

nanoencapsulation of l -asparaginase II in chitosan-tripolyphosphate nanoparticles and in

vitro, release study J. Nanoscale Research Letters 9(1) 340

Stearic Acid Grafted Carboxymethyl Chitosan and Its Nanoencapsulation of Macadamia Oil

301