Investigation of Thermal Decomposition Kinetic of

Polyethylene 100 Compounds with Kissinger Model

G J Huang

*

, S P Li, W W Ye, B Yang, M D Li and M L Xin

Guangzhou special pressure equipment inspection and research institue, Guangzhou

510663, China

Corresponding author and e-mail: G J Huang, huangguojia@163.com

Abstract. The thermal stability and non-isothermal degradation kinetics of the polyethylene

100(PE100) compounds were studied by thermogravimetric(TG) and derivative

thermogravimetric(DTG) analyses using multiple heating rates (2, 5, 10, 20 °C/min) under

nitrogen gas atmosphere. The thermal features of PE100 compounds was examined and the

average activation energy(Ea) thus obtained with Kissinger method is 333.79 kJ/mol.

1. Introduction

With the development of modern energy, the use of natural gas to replace coal-fired fuel in

production and life is becoming more and more widespread, and the scale and number of gas pipeline

networks are also rapidly increasing[1-2]. As an important part of the distribution system, the

performance of the natural transmission pipeline is related to the safety of the entire system. Among

the medium and low-pressure gas transmission and distribution pipelines in cities and towns,

polyethylene (PE) has become a preferred material as gas pipe because of its good welding

performance, chemical resistance, toughness and weather resistance, and good resistance to rapid

crack propagation[3-4]. The development and application of polyethylene pipes have undergone four

stages. In the 1940s, in order to replace the traditional metal pipe, people produced the first

generation polyethylene pipe material PE63 with corrosion resistance, but its environmental stress

crack resistance was poor. In the 1960s, as the relative molecular mass and the content of comonomer

were increased, the second-generation polyethylene pipe PE80 with long-term service life was

developed with slow crack resistance. However, it has been found that the relative molecular mass is

too high to reduce the processing performance of the material, while the increase in the comonomer

content leads to a decrease in the rigidity of the material. In order to take into account both

processing and use properties, the PE100, a third generation PE pipe material, was developed. The

important performance of gas-fired polyethylene pipes is long-term service life. In the past decade or

more, one of the developments in PE pipe materials has been to lock in with slow crack growth or

stress cracking resistance in search of new applications. Based on the third-generation PE100, the

fourth-generation PE pipe material, PE100RC, was further developed through molecular structure

design to improve the resistance to slow cracking. The representative product is a bimodal molecular

weight distribution of hexene copolymerized PE100-RC.

Huang, G., Li, S., Ye, W., Yang, B., Li, M. and Xin, M.

Investigation of Thermal Decomposition Kinetic of Polyethylene 100 Compounds with Kissinger Model.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 183-188

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

183

Polyethylene pipeline contains a flammable special medium such as natural gas, and several gas

fire accidents have occurred in life [5-6]. Once a fire breaks, polyethylene will burn and decompose

at high temperatures, and the remaining pipes will also become garbage. How to understand the

thermal decomposition mechanism of polyethylene pipe materials is of great significance to the

safety protection of pipes and the reuse of waste polyethylene. Its efficient reutilization has a growing

importance these years due to the increased demand for resource recycling and environmental

protection. In general, plastic waste has been mainly disposed of by landfill or incineration, but these

processes are not fully acceptable under current international policy, which focuses on efficient

recovery of raw material and energy. Pyrolysis and gasification processes are promising routes for

optimal upgrading from waste. Moreover, pyrolysis of plastic, based on the decomposition of

polymers at different temperatures, allows the treatment of polymers with simultaneous

decomposition and separation [7-8].

Thermal degradation of polymers has great interest as an alternative source of energy or chemical

raw materials, as well as it contributes to the solution of environmental problems [9]. The

determination of the parameters of the thermal decomposition process by means of TG techniques

allows the development of the recycling process of these materials in an industrial scale. Thermal

behavior of plastics can be improved by knowing thermal degradation kinetic [10-11]. Pyrolysis of

plastic can transform it into valuable chemicals [12], and it becomes a popular way to dispose waste

plastics. Meanwhile, thermal degradation is usually occurring during the polymer processing.

Designing and implementation of the pyrolysis or process for polymers depends primarily on kinetic

analysis [13]. Precised kinetics heavily relies on the reliable kinetic triplets, activation energy (Eα),

preexponential factor (A) and reaction model (f (α)) [14]. A thermogravimetric analysis technique is

an excellent way for studying the kinetics of thermal degradation. TG provides the pathway to

determine the macroscopic kinetics of these processes such as the information on activation energy

and kinetic model [15].

In this work, the thermogravimetric study of polyethylene compounds was realized using

non-isothermal method in order to determine the apparent activation energy with Kissinger model.

2. Measurement and method

2.1. Measurement

The PE100 compound (Borstar® HE 3490LS) was purchase from Borouge company. PE100 samples (~10

mg) were subjected to TG analysis in an inert atmosphere of nitrogen. NETZSCH 209 F1 TG

analyzer was used to measure and record the sample mass change with temperature over the course

of the decomposition reaction. TG curves were obtained at four different heating rates (2, 5, 10,

20 °C /min) from room temperature 700 °C.

2.2. Kinetic analysis method

Kinetic analysis of a thermal decomposition process is usually expected to produce a satisfactory

kinetic description in terms of the reaction model and the Arrhenius parameters. Typically, the

generalized form of kinetic equation can be expressed as Eq.1

(1)

Where α is the degree of conversion and it ranges from 0 to 1. Where k(T) and f(α) are

temperature dependent rate constant and mass dependent reaction model. The rate constant k(T) is

assumed to follow the Arrhenius law such as k(T)=Aexp(-E

a

/RT), where the temperature and time

coordinates are related as T= T

0

+βt. Eq.1 can be written as following

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

184

(2)

T where A is the pre-exponential factor (1/min-) and Ea is the apparent activation energy (kJ/mol),

respectively, R is the gas constant (8.314 J/mol/K). The differential isoconversional method

suggested by Kissinger [16] is based on Eq. 2 given by the following relation:

(3)

Where T

p

is the peak temperature at the maximum reaction rate. Plot of

versus

should give straight lines, and E

a

is calculated from the slope of the fitted straight line.

3. Results and discussion

3.1. Thermal features of PE100

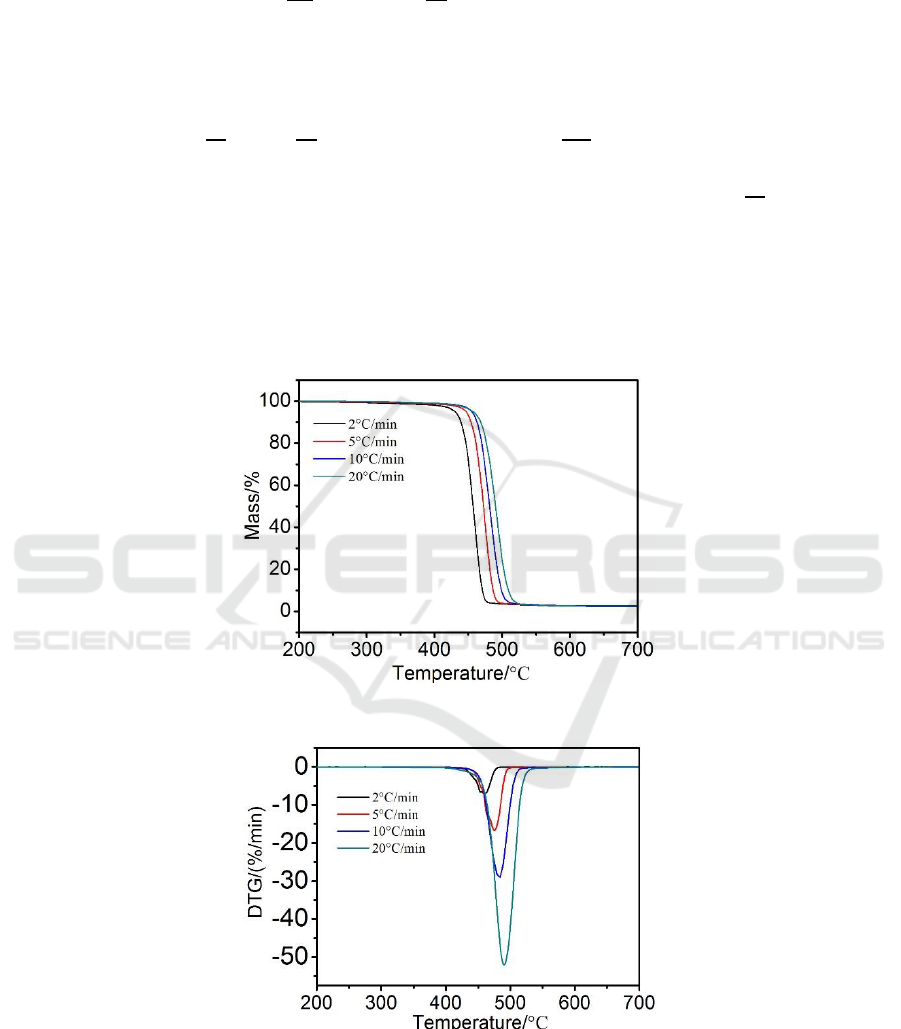

Figure 1.TG profiles of PE100 at four heating rates (2, 5, 10 and 20°C/min).

Figure 2.DTG profiles of PE100 at four heating rates (2, 5, 10 and 20°C/min).

The TG and DTG curves of PE100 at a heating rate of 2, 5, 10 and 20 °C/min in N2 are shown in

Figure 1 and Figure 2 respectively. From TG curves it can be observed that the shape of the weight

loss curve does not change with the variation of heating rate. The TG characteristic temperatures of

PE100 at the different heating rates are illustrated in Table 1. Tp and the decomposition temperature

Investigation of Thermal Decomposition Kinetic of Polyethylene 100 Compounds with Kissinger Model

185

at 5% weight loss (T

5%

) shift to higher temperature with increasing from 2 to 20 °C/min is mainly

due to the time and temperature history subjected to the materials. At higher heating rates, the time

required to reach the decomposition temperature becomes shorter, causing the temperature difference

between the sample inside and outside turning to be larger as well, and subsequently causes thermal

lagging which may delay the sample inside thermal decomposition. It can be seen from Figure 2 that

the DTG peak becomes stronger and wider as heating rate increases from 2 to 20 °C/min, and in the

meantime Tp is promoted from 460 to 490 °C.

Table 1.Characteristic temperatures of thermal degradation of the PE100 compound (HE 3490LS).

T

5%

: the decomposition temperature at 5% weight loss.

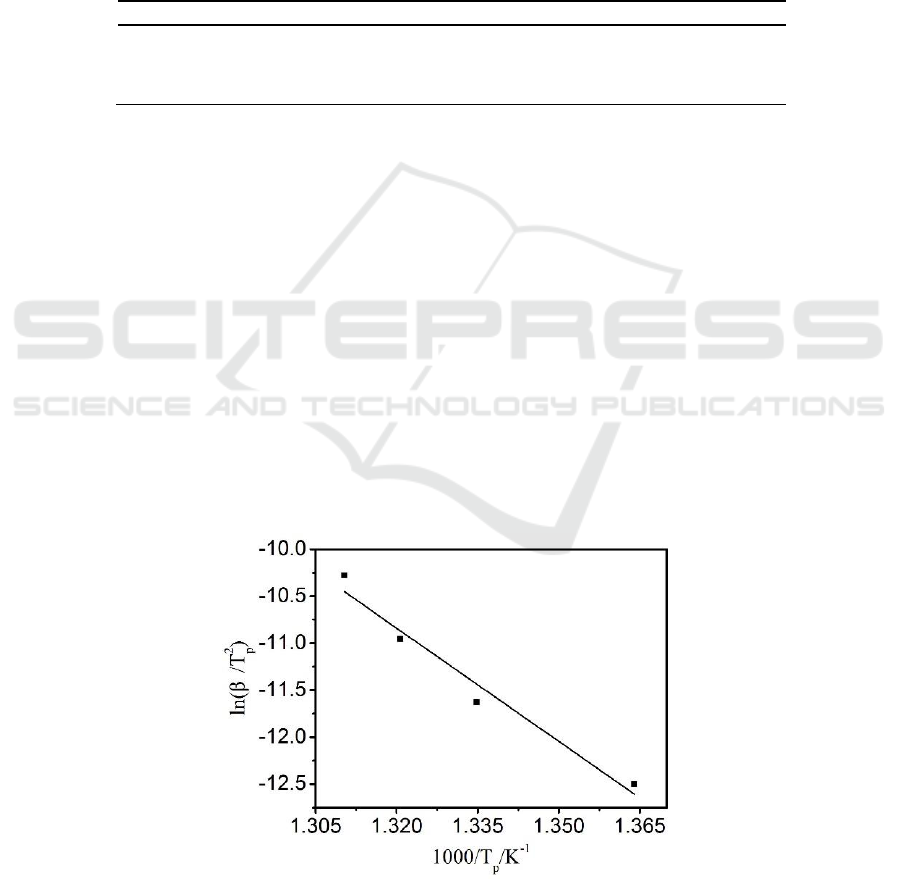

3.2. Kinetic analysis with Kissinger method

This method derives from the correlation between the peak temperature (T

p

) and . Suited for more

than four thermal analytical curves of the derivation type, it is an efficient model-free differential

method. According to Eq.3, the linear fitted plots between

versus

obtained for

PE100 are shown in Figure 3. The results show that the activation energy(Ea) is 333.79 kJ/mol.

Westerhout has examined the pyrolysis kinetics of low-density polyethylene below 450 °C, and also

made a comparison of activation energy(Ea) with literature models and data[17]. The thermal

decomposition Ea for low-density polyethylene varied from 201 to 330 kJ/mol,all of which is lower

than that of PE100 compound with Kissinger method. The above results may be due to the higher

molecular weight. As proper selection of the conversion function is extremely important to formulate

a self-consistent global pyrolysis kinetic model that performs uniformly well in a practically

realizable range heating rates occurring in polymer combustion[18], Kissinger method gives an

average Ea overall the decomposition process.

Figure 3.Kissinger method plots of

versus

.

(°C/ min)

2

5

10

20

T

5%

T

P

241

460

290

476

329

484

336

490

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

186

4. Conclusions

In this work, thermal decomposition kinetics of the PE100 compounds has been investigated, and the

measurements were carried out under N

2

atmosphere at different heating rates. TG and DTG results

show that the thermal features of PE100 compounds are strongly depend on the heating rates with a

single decomposition step. With the Kissinger method, the apparent activation energy (Ea) of PE100

compounds during thermal degradation is 333.79 kJ/mol.

Acknowledgement

The authors would like to thank the Science and Technology Research Programs of Guangzhou City

(Grant No. 201607010258); the Scientific and Technological Project of Guangzhou Quality and

Technical Supervision Bureau (Grant No. 2017KJ21); the Scientific and Technological Project of

Guangdong Provincial Quality and Technical Supervision Bureau (Grant Nos. 2016CT14,

2017CT29).

References

[1] Wei L and Geng P 2016 A review on natural gas/diesel dual fuel combustion,emissions and

performance [J]. Fuel Processing Technology 142 264-278

[2] Hao H, Liu Z, Zhao F, et al. 2016 Natural gas as vehicle fuel in China: A review [J].

Renewable and Sustainable Energy Reviews 62 521-533

[3] Almeida J C, Macieski G C, Zanette L A, Almeida J C, Macieski G C, & Zanette L A, 2015

General guidelines for developing executive design of natural gas urban pipeline networks

and using hdpe valve [J]. Brazilian Journal of Petroleum & Gas 9(1) 19-26

[4] Hua Y, Wu Z J, Xiong Z M,et al. 2014 The developing trends of polyethylene (PE) gas piping

systems[J]. Total Corrosion Control 4 34-40

[5] Brandt A R, Heath G A, Kort E A, et al. 2014 Methane leaks from North American natural gas

systems [J]. Science 343(6172) 733-735

[6] McKain K, Down A, Raciti S M, et al. 2015 Methane emissions from natural gas infrastructure

and use in the urban region of Boston, Massachusetts[J]. Proceedings of the National

Academy of Sciences , 112(7) 1941-1946

[7] Marongiu A, Faravelli T, Bozzano G, Dente M and Ranzi E 2003 Thermal degradation of

poly(vinyl chloride) Journal of Analytical and Applied Pyrolysis 70 519-53

[8] Kiran N, Ekinci E and Snape CE 2000 Recyling of plastic wastes via pyrolysis Resoure

Conservation Recycle 29 273-83

[9] Yang J, Miranda R and Roy C 2001 Using the DTG curve fitting method to determine the

apparent kinetic parameters of thermal decomposition of polymers Polymer Degradation

Stability 73 455–61

[10] Vyazovkin S and Wight C A, 1998 Isothermal and non-isothermal kinetics of thermally

stimulated reactions of solids International Reviews in Physical Chemistry 17 407-433

[11] Friedman H L, 1964 Kinetics of thermal degradation of char-forming plastic from

thermogravimetry.application to a phenolic plastic [J]. Journal of Polymer Science Part C,

6 183-195

[12] Demirbas A 2004 Pyrolysis of municipal plastic wastes for recovery of gasoline-range

hydrocarbons [J]. Journal of Analytical and Applied Pyrolysis 72(1) 97-102

[13] Das P and Tiwari P 2017 Thermal degradation kinetics of plastics and model selection

[J].Thermochimica Acta 654 191-202

[14] Collazzo G C, Broetto C C, Perondi D, et al. 2017 A detailed non-isothermal kinetic study of

Elephant Grass Pyrolysis from different models[J].Applied Thermal Engineering 110

1200-1211

Investigation of Thermal Decomposition Kinetic of Polyethylene 100 Compounds with Kissinger Model

187

[15] Aboulkas A, Harfi K E 2010 A E Bouadili. Thermal degradation behaviors of polyethylene

and polypropylene Part I: Pyrolysis kinetics and mechanisms [J]. Energy Conversion &

Management 51(7) 1363-1369

[16] Kissinger H E 1957 Reaction Kinetics in Differential Thermal Analysis[J]. Analytical

Chemistry 29(11) 1702-1706

[17] Westerhout R W J, Waanders J, Kuipers J A M et al 1997 Kinetics of the Low-Temperature

Pyrolysis of Polyethene, Polypropene, and Polystyrene Modeling, Experimental

Determination, and Comparison with Literature Models and Data [J]. Industrial &

Engineering Chemistry Research 36(6) 1955-1964

[18] Snegirev A Y, Talalov V A, Stepanov V V et al 2017 Autocatalysis in thermal

decomposition of polymers [J]. Polymer Degradation & Stability 137 151-161

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

188