Influence Factors to Pipe Pressure on Cast-in Place Pile

Pouring

L Yu

*

, Z L Liu and G Q Zhang

Beijing Xin-Qiao Technology Development Co., LTD, China

Corresponding author and e-mail: L Yu, yuleimabel@163.com

Abstract. Transducer can be used to detect the interface between concrete and slurry by

detecting pressure along pipe. This interface is important to avoid pipe pulled out of concrete

and good for cast-in place p ile construction. But a lot of factors can affect the p ressures on

pipe. In order to detect pressure change around pipe and find out the reasons leading to pipe

pressure changed, some factors such as density, pouring velocity, concrete temperature and

concrete slump must be considered. By means of simu late cast-in place p ile construction in

lib rary, pressure along pipe were detected. Results shows that density and pouring velocity

are the main factors that can be effected on pipe pressure. Concrete temperature and slu mp

are not outstanding factors. From d ifferential pressure curve, interface position between

concrete and air can be found.

1. Introduction

During cast-in place pile construction, pipe is used to pouring concrete into pile hole. The interface of

concrete and slurry is very important. Pressures are different between concrete and slurry.

Transducers can be used to detect this interface by test pressure along pipe. But pressure around pipe

will be affected by different factors. To avoid pressure detecting disturbed and get rid of invalid data,

these factors should be found out. Refer to concrete form, the pressure around pipe may be affected

by pouring velocity, depth, density and temperature. In order to detect pressure change around pipe

and find out the interface of concrete and air, these factors must be considered.

2. Test equipment

Laboratory test was done to simulate pouring. A pipe was used to simulate pile hole. Two

transducers were tied on a steel stick. Put the stick into pipe and pouring concrete into pipe, the

pressure will be detected by transducers on stick. Test equipment is shown in figure 1. Fixed up

method of transducers is shown as figure 2.

The steel stick is divided into 10 parts by steel bars. Every pull stick out 10 centimeters, bars can

be put onto top cover of pipe and keep stick steady. Electronic on multi meter is steadier than handle

it.

Transducer output analog signal, pressure need to be calculated. The distance between

transducers is 30 centimeter.

Yu, L., Liu, Z. and Zhang, G.

Influence Factors to Pipe Pressure on Cast-in Place Pile Pouring.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 161-166

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

161

Figure 1. Test equipment for lab test Figure 2. Transducers arrangement

3. Test method

3.1. Test design for density factor

3.1.1. Test design.Three materials was made. They are concrete, mortar and slurry. Keep pouring

velocity, temperature and slumps constant. Just change materials. Detect pressure along pipe. Test

design is shown as table 1.

Table 1.Test parameter for density changing test

Density / kg/m

3

Depth / m

Velocity / L/min

Temperature / °C

Slumps / mm

concrete

1.2

37.68

8

200

mortar

1.2

37.68

8

200

slurry

1.2

37.68

8

200

3.1.2. Test steps. 45L materials were ready for pouring. Fill pipe with a bucket. Keep pouring

continuously. Take 1 minute to tank up the pipe. Keep steady for 5 seconds. Read the electric current

value by multi meter. And then pull out stick 10 centimeters by 10 centimeters. Every 10 centimeters,

read the electric current value until transducer on the bottom of stick is pull out of pipe.

3.2. Test design for pouring velocity factor

3.2.1. Test design. Design two pouring velocities. They are 5L/min and 10L/min. Keep density,

temperature and slumps constant. Just change velocity. Detect pressure along pipe. Test design is

shown as table 2.

Table 2.Test parameter for density changing test

Density / kg/m

3

Depth / m

Velocity / L/min

Temperature /°C

Slumps / mm

2300

1.2

5

8

200

2300

1.2

10

8

200

3.2.2. Test steps. 45L concrete was ready for pouring. Fill pipe with a 5L bucket. Take 1 minute for

pouring 1 bucket. Keep pouring continuously until the pipe was full. We think this pouring velocity

is 5L/min. Read the electric current value when there is display on the multi meter. For velocity of 10

L/min, use 10L bucket to pour the pipe.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

162

3.3. Test design for temperature factor

3.3.1. Test design. Design two temperatures of concrete. They are 8°C and 10°C . Keep density,

pouring velocity and slumps constant. Just change temperature of concrete. Detect pressure along

pipe. Test design is shown as table 3.

Table 3.Test parameter for density changing test

Density / kg/m

3

Depth / m

Velocity / L/min

Temperature /°C

Slumps / mm

2300

1.2

37.68

8

200

2300

1.2

37.68

22

200

3.3.2. Test steps.water with different temperature were used. The water from tap water pipe is 8°C .

For 22°C pouring temperature, mixing hot water and tap water for producing concrete is ok. Take 1

minute to fill pipe full with different temperature concretes respectively. Keep steady for 5 seconds.

Read the electric current value by multi meter. And then pull out stick 10 centimeters by 10

centimeters. Every 10 centimeters, read the electric current value until transducer on the bottom of

stick is pull out of pipe.

3.4. Test design for temperature factor

3.4.1. Test design. Design two level slumps. They are 300mm and 450mm. Keep density, pouring

velocity and temperature constant. Just change slump of concrete. Detect pressure along pipe. Test

design is shown as table 4.

Table 4. Test parameter for density changing test

Density / kg/m

3

Depth / m

Velocity / L/min

Temperature / °C

Slumps / mm

2300

1.2

37.68

8

300

2300

1.2

37.68

22

450

3.4.2. Test steps. 45L concrete was ready. The slump is changed by adding water reducing agent. Fill

pipe with a bucket. Keep pouring continuously. Take 1 minute to tank up the pipe. Keep steady for 5

seconds. Read the electric current value by multi meter. And then pull out stick 10 centimeters by 10

centimeters. Every 10 centimeters, read the electric current value until transducer on the bottom of

stick is pull out of pipe.

4. Results

4.1. Pressure changes by different materials

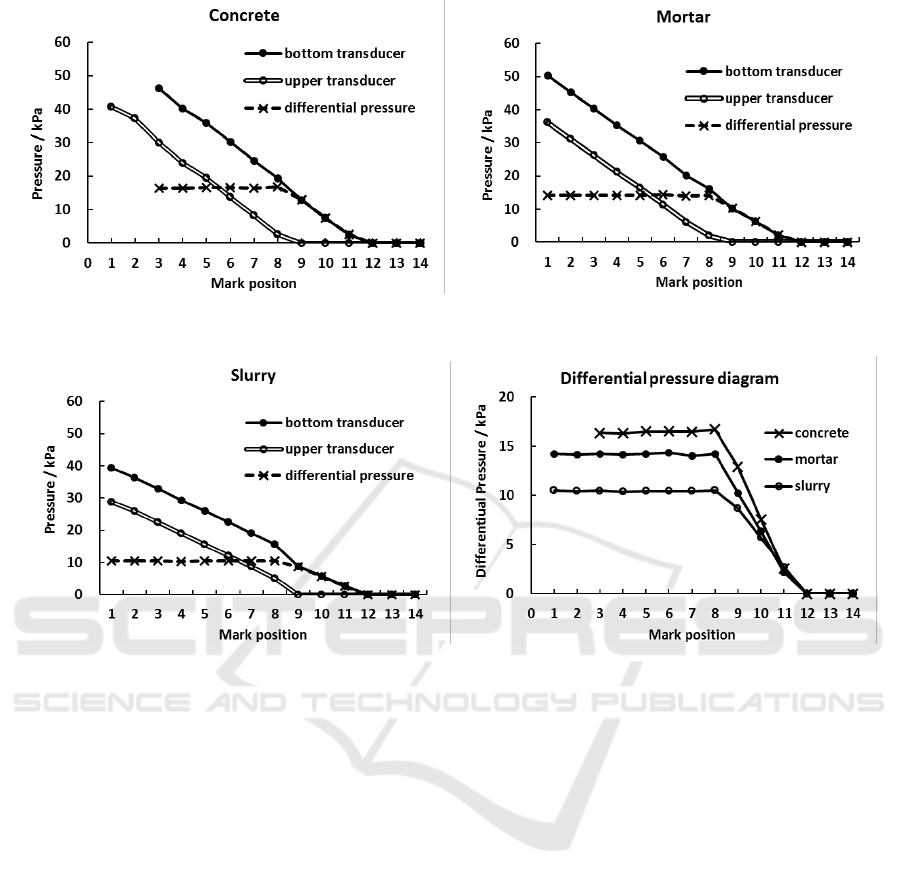

Figure 3 to figure 6 are about pressure along pipe for different density materials.

Influence Factors to Pipe Pressure on Cast-in Place Pile Pouring

163

Figure 3. Pressure along pipe for concrete Figure 4. Pressure along pipe for mortar

Figure 5. Pressure along pipe for slurry Figure 6. Differential pressure for different materials

The same change rule of pressure on pipe is shown by Concrete, mortar and slurry. Pressure from

transducers decrease by pulling out the stick. At the same mark position, the heavier density is, the

higher pressure is. From differential pressure figure, at point 8, the upper transducer is pull out of

materials into air. At point 12, the bottom transducer is also pull out of materials into air. The

interface of concrete and air is the 8 position.

4.2. Pressure changes by pouring velocity

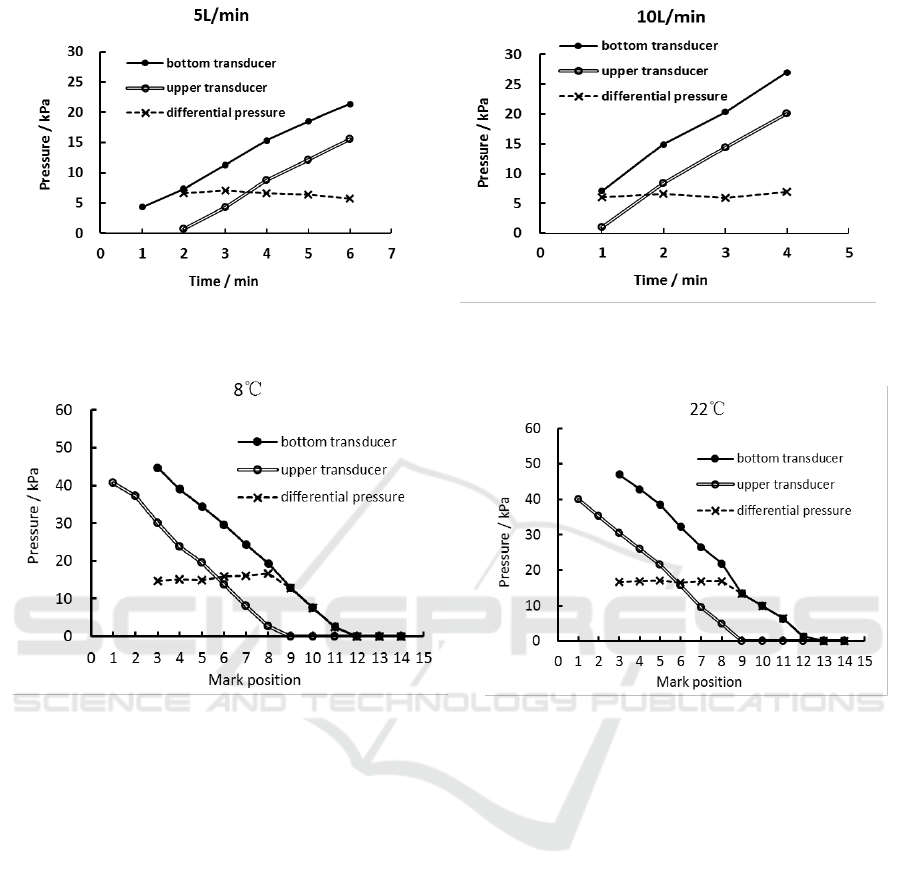

Figure 7 to figure 8 are about pressure along pipe for different pouring velocity.

At the same depth, the more quick pouring velocity is, the higher press is. This is because more

quick pouring velocity lead to liquid level of concrete higher. The higher of concrete is, the more

pressure is. For the same material, although pouring velocity is different, differential pressure is the

same.

4.3. Pressure changes by temperature

Figure 9 and figure 10 are about pressure along pipe for different temperature.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

164

Figure 7. Pressure for 5L/min pouring velocity Figure 8. Pressure for 10L/min pouring

velocity

Figure 9. Pressure for 8°C temperature Figure 10. Pressure for 22°C temperature

For 8°C and 22°C concrete temperature, at the same depth, for example mark position 3, pressure

are almost the same value. Differential pressure keeps constant no matter in 8°C or 22°C temperature.

Therefore, concrete temperature is not affect to pressure along pipe. From differential pressure curve,

interface of concrete and air can be found and that is point 8.

4.4. Pressure changed by slumps

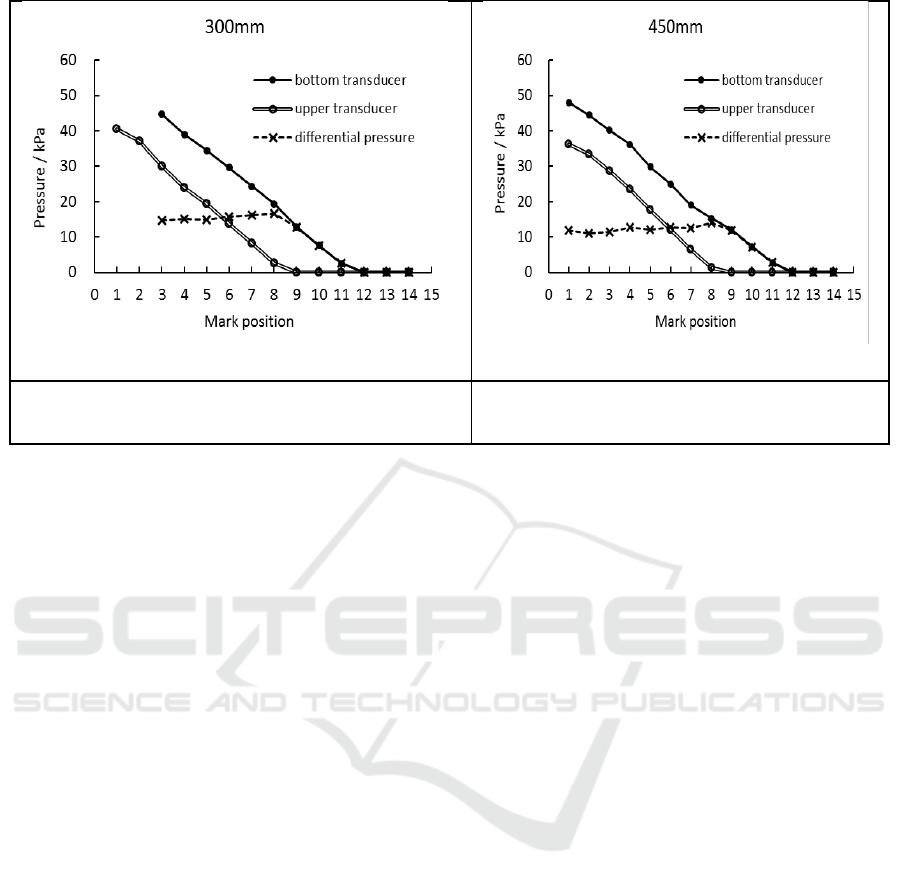

Figure 11 and figure 12 are about pressure along pipe for different concrete slumps.

Influence Factors to Pipe Pressure on Cast-in Place Pile Pouring

165

Figure 11. Pressure for 300mm concrete slump

Figure 12. Pressure for 450mm concrete

slump

At the same depth, pressure from high slump concrete is less than that from low slump concrete.

But the gap is not outstanding. Slump is not the main reason to lead to pipe pressure rising. From

differential pressure curve, interface of concrete and air can be found and that is point 8.

5. Conclusions

In order to detect pressure change around pipe and find out the reasons leading to wipe pressure

changed, some factors such as density, pouring velocity, concrete temperature and concrete slump

must be considered. By means of simulate cast-in place pile construction in library, pressure along

pipe were detected.

By changing materials, it can be seen that there should be a positive correlation between the

density and the hydrodynamic pressure. By changing pouring velocity, it can be seen that there

should be a positive correlation between pouring velocity and the hydrodynamic press. By changing

concrete temperature, it can be seen that concrete temperature is not effect to pressure along pipe. By

changing concrete slump with water reducing agent, the pressure gap between high slump and low

one is not outstanding. The inducements of pipe pressure changing are not the concrete temperature

and slump, but the density and velocity.

Acknowledgment

This work was supported by the Ministry of Communications and Enterprise Innovation Item [grant

numbers 2015 315 Q13 040].

References

[1] Zhang G Q, Yu L and Liu Z L 2017 Pouring simulation of cast-in place pile construction

Journal of Highway Communication technology 2 150-152

[2] Zhang Z M 2007 Pile foundation project Beijing: China Building Industry Press 10-25

[3] 2008 Technical code for safety of forms in construction JGJ 162-2008 Beijing: China building

industry press

[4] Yu L, Fu Y Y, Zhang J et al 2016 Test ans simulation on pull-out behavior of steelwire in

foam concrete, Journal of Harbin Institute of Technology 48 6 119-123

[5] Yuan S W 2014 Numerical simulation and experimental study of power-law fluid East China

University Of Science and Technology

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

166