Sensitivity Analysis of Design Parameters on Fluidlastic

Isolators Performance

J H Deng and Q Y Cheng

*

Science and Technology on Rotorcraft Aeromechanics Laboratory, China Helicopter

Research and Development Institute, Jingdezhen 333001, China

Corresponding author and e-mail: Q Y Cheng, qy_cheng@163.com

Abstract. Control of vibration in helicopters has always been a complex and challenging task.

The fluidlastic isolators become more and more widely used because the fluids are non-toxic,

non-corrosive, nonflammable, and compatible with most elastomers and adhesives. In the

field of the fluidlastic isolators design, the selection of design parameters is very important to

obtain efficient vibration-suppressed. Aiming at getting sensitivity of property of fluidlastic

isolator to design parameters, a dynamic equation is set up based on the theory of dynamics.

The orthogonal experimental method is used to analyze the parametric sensitivity of the

design parameters on the property of fluidlastic isolator. Two control indexes for design are

taken as the experimental indexes, and five parameters influencing the property of the isolator

are taken as the experimental factors. Arranged for the tests based on the orthogonal

experiment table, 2 indexes 6 factors orthogonal experiment is carried out. Range analysis is

adopted to study the sensitivity. The results show that for the combustion efficiency of

dynamic stiffness of fluidlastic isolator, the order of significance levels in turn decreases with

η, K

1

, c , L, ρ and K

2

respectively. For the combustion efficiency of dynamic stiffness of

fluidlastic isolator, the order of significance levels in turn decreases with η, K

1

, c, K

2,

ρ and L

respectively.

1. Introduction

Helicopter vibration is a critical aspect of helicopter design and a major reason for extended lead time

during the aircraft development phase. Control of vibration in helicopters has always been a complex

and challenging task. Increasing demands for expanding the flight envelop of helicopters, such as nap

of earth flying, high speed, high maneuvers, coupled with the need to improve system reliability and

reduce maintenance costs has resulted in more stringent vibration specifications.

Various methods have been applied to vibration control in the engineering field [1-5].

Traditionally, passive isolators and dampers are used to attenuate mechanical vibrations. The

traditional approach to passive vibration isolation is to install relatively soft springs or elastomeric

isolators to provide a primary low natural frequency [6-9]. These isolators would also incorporate

sufficient damping to control resonant response. Soft systems with primary natural frequencies well

below the N/rev exciting frequency are required to achieve isolation. Such systems result in large

relative motion between the pylon and the airframe due to static loads. Natural frequencies low

enough to isolate N/rev vibration would have static (1G) deflections up to 0.50 inches. Since flight

64

Deng, J. and Cheng, Q.

Sensitivity Analysis of Design Parameters on Fluidlastic Isolators Performance.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 64-70

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

controls and power transmission drive shafts cross this interface it is advantageous to keep the

relative motion as small as practical. An effective method for isolating the N/rev vibration that did

not allow large relative motions between the pylon and airframe was needed.

There are many design parameters such as the density of fluid, area coefficient (R

1

), and rubber

performance that can affect the property of fluidlastic isolator [10-12]. Each of these parameters is

important considerations in the design of a fluidlastic isolator and affects property of fluidlastic

isolator to a greater or lesser degree. A key ingredient in developing reliable and efficient procedures

for design optimization of fluidlastic isolator is sensitivity analysis.

The paper discusses the sensitivity of property of fluidlastic isolator to design parameters such as

the density of fluid, rubber performance. These parameters are important consideration in the design

of a fluidlastic isolator and affects performance to a greater or lesser degree. The dynamic equation is

set up based on the theory of dynamics. The dynamic analysis is carried out. The effects of design

parameters on property of fluidlastic are studied by orthogonal experimental method.

2. Mathematical model

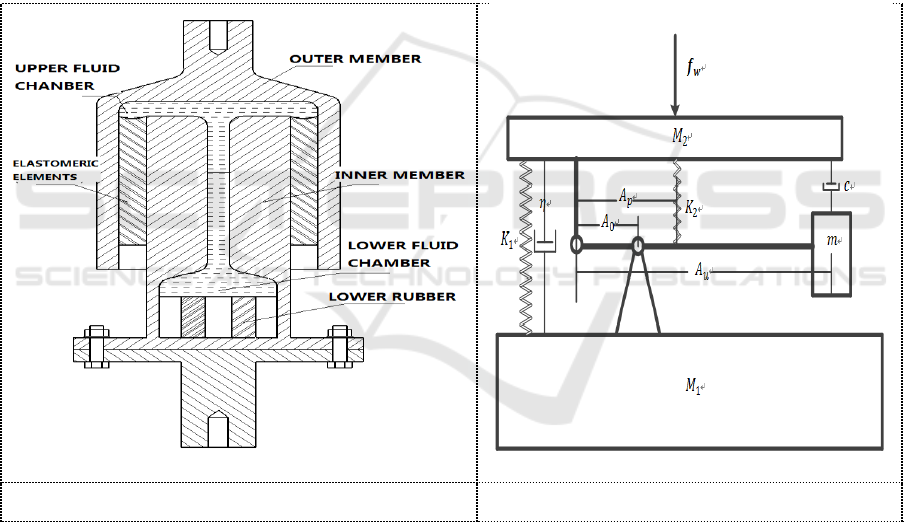

Figure 1 and Figure 2 show the cross-section and the mechanical model of Fluidlastic Isolator.

Figure 1. Cross-section of Isolator.

Figure 2. Mechanical model of Isolator.

According to the Figure 1 and Figure 2, the equations of motions (EOM) for the fluidlastic tuned

isolator can be expressed as:

d

xKxcxxmfxxiKxM

202021111

1

(1)

wd

fxcxKfxxiKxM

0221122

1

(2)

0020020

)( fAAAxKAAxcxxm

pdu

(3)

Where, c is the Viscosity coefficient of liquid, ηis Loss coefficient of rubber, f is the load that the

M

2

imposed on the lever mechanism. The A

p

, R

1

and R

2

is defined as:

Sensitivity Analysis of Design Parameters on Fluidlastic Isolators Performance

65

dup

AAAA /

0

(4)

21

0

0

1

xx

x

A

A

R

u

(5)

d

d

x

x

A

A

R

0

0

2

(6)

When the vibration load is a harmonic excitation, the load and displacement can be written as

follows:

tj

tj

tj

w

eXx

eXx

Fef

22

11

(7)

The Transmissibility of vibration can be written as (8):

2

21

2

21

22

2

2

1

2

12

2

2

22

2

21

2

2

2

1

2

12

2

211

2

2

1

1

11

1

RiKRMRRjcRKRmR

RiKRRjcRKRRRm

X

X

T

(8)

When

,,,

11

cX

are all equal to zero, the frequency of undamped isolation system can be

obtained:

2

1

2

211

2

12

2

21

1

mRRR

RKRK

iso

(9)

The amplitude of vibration can be written as:

2

2

2

1

22

2

2

1

2

12

2

21

2

1

11

2

RjcRRRmRKRiK

FRR

X

(10)

From the equation (7), the dynamic stiffness of isolation system can be obtained:

2

2

2

2

1

22

2

2

1

2

12

2

21

2

11

R

RjcRRRmRKRiK

X

F

K

D

(11)

According to the static equation, the static stiffness of isolation system can be also obtained:

2

2

2

1

21

R

R

KKK

(12)

3. Parameter sensitivity analysis

Table 1 gives the design parameters of fluidlastic including the density of fluid, viscosity coefficient

of fluid, tuning port lengh, stiffness of rubber, loss coefficient of fluid, stiffness of (K

2

). The

boundary values of K

1

, K

2

, ρ, L, c and η are set at 5e6 to 1.5e7, 1e4 to 8e4, 1e3 to 5e3, 0.1 to 0.3,

0.05 to 5 and 0.05 to 5.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

66

Table 1. Design parameters of fluidlastic.

level

K1

K2

ρ

L

c

η

1

5e6

1e4

1e3

0.1

0.05

0.05

2

8e6

3e4

1.5e3

0.12

0.1

0.1

3

1e7

4e4

1.8e3

0.2

0.5

0.5

The sensitivity analysis of design parameters on property of fluidlastic are studied through

orthogonal experimental method. Five relevant factors including the density of fluid, viscosity

coefficient of fluid, tuning port length, stiffness of rubber, loss coefficient of fluid, stiffness of (K

2

)

are studied. The orthogonal table L

25

(5

6

) is designed and show in Table 2 based on five investigation

factors and five corresponding levels.

Table 2. Design of orthogonal table L

25

(5

6

) and analysis results.

No

K

1

K

2

ρ

L

c

η

T

K

D

/23.87

1

5e6

1e4

1e3

0.1

0.05

0.05

0.122

90.106

2

5e6

3e4

1.5e3

0.12

0.1

0.1

0.050

62.935

3

5e6

4 e4

1.8e3

0.2

0.5

0.5

0.143

138.419

4

5e6

5 e4

3 e3

0.25

1

1

0.342

253.485

5

5e6

8 e4

5 e3

0.3

5

5

0.532

474.724

6

8e6

1e4

1.5e3

0.2

1

5

0.205

743.486

7

8e6

3e4

1.8e3

0.25

5

0.05

0.199

146.667

8

8e6

4 e4

3 e3

0.3

0.05

0.1

0.316

156.815

9

8e6

5 e4

5 e3

0.1

0.1

0.5

0.173

969.695

10

8e6

8 e4

1e3

0.12

0.5

1

0.462

2504.493

11

1e7

1e4

1.8e3

0.3

0.1

1

0.345

3161.499

12

1e7

3e4

3 e3

0.1

0.5

5

0.279

1857.246

13

1e7

4 e4

5 e3

0.12

1

0.05

0.123

103.191

14

1e7

5 e4

1e3

0.2

5

0.1

0.392

596.747

15

1e7

8 e4

1.5e3

0.25

0.05

0.5

0.218

2251.392

16

1.2e7

1e4

3 e3

0.12

5

0.5

0.473

2930.703

17

1.2e7

3e4

5 e3

0.2

0.05

1

0.413

5674.165

18

1.2e7

4 e4

1e3

0.25

0.1

5

0.442

3353.537

19

1.2e7

5 e4

1.5e3

0.3

0.5

0.05

0.100

399.778

20

1.2e7

8 e4

1.8e3

0.1

1

0.1

0.478

944.904

21

1.5e7

1e4

5e3

0.25

0.5

0.1

0.335

551.430

22

1.5e7

3e4

1e3

0.3

1

0.5

0.613

5074.972

23

1.5e7

4 e4

1.5e3

0.1

5

1

0.949

10439.771

24

1.5e7

5 e4

1.8e3

0.12

0.05

5

0.743

5570.818

25

1.5e7

8 e4

3 e3

0.2

0.1

0.05

0.083

606.392

The range analysis is applied to clarify the sensitivity of design parameters on the property of

fluidlastic isolator including dynamic stiffness and transmissibility of vibration. First, the average

value of each experimental index of factors at five levels is calculated. Next, the range of each factor

of at five levels is also calculated. The influence coefficient of these six factors can be confirmed by

comparison with the value of range. The bigger the range is, the more the influence will be.

4. Results and discussion

A civil helicopter is chosen for this study. The N/rev frequency of this helicopter is close to 25Hz.

High loads and very small motions of high stiffness isolators are even more challenging.

Effectiveness of a tuned isolator in a system can be estimated by measuring the dynamic stiffness

Sensitivity Analysis of Design Parameters on Fluidlastic Isolators Performance

67

(K

D

) over the frequency range of interest. The K

D

value at the tuned (N/rev) frequency is a good

indicator of the effectiveness of the isolator in the system.

Fluidlastic isolators must also be designed to handle a specific range of input motions. The

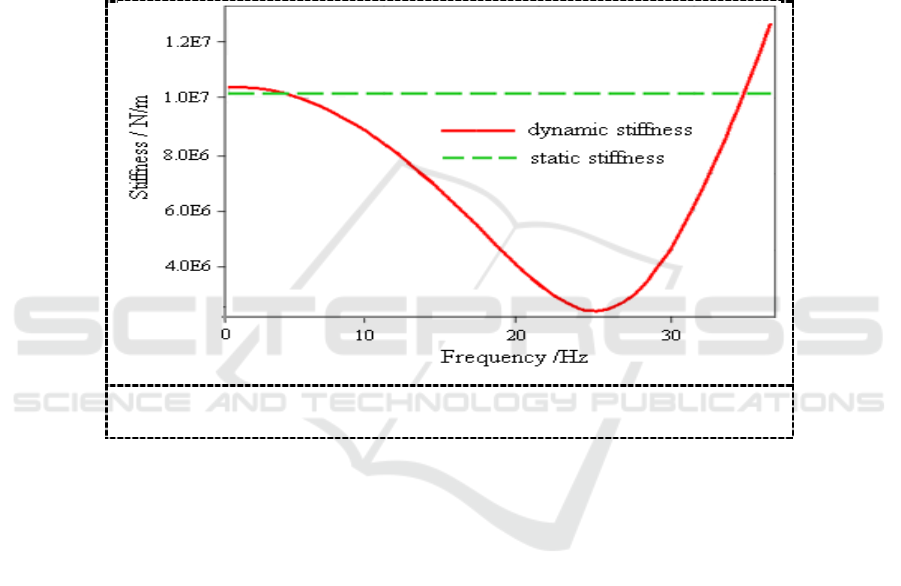

dynamic stiffness versus frequency curve is shown in Figure 3. The dynamic stiffness varied with the

frequency. The dynamic stiffness varies from nominally 1.03E7 N/m statically (f = 0 Hz) to

approximately 1.91E6 N/m at 25 Hz. Effective dynamic stiffness at 25Hz is less than 20% of the

static stiffness. So, the “rigid” isolator can still provide effective performance. However, the static

stiffness is relatively high. It is advantageous to keep the relative motion between the pylon and

airframe as small as practical.

Figure 3. Fluid isolator stiffness versus frequency.

The range analysis is applied to clarify the sensitivity of design parameters on the property of

fluidlastic isolator including dynamic stiffness and transmissibility of vibration.

According to Table 2, it is showed that the design parameters have obvious influence on the

performance of isolator. The value of dynamic stiffness and transmissibility of vibration varies

widely at different assembly of design parameters. The result of transmissibility is in the range 0.05

to 0.949. Dynamic analysis has shown that fluidlastic isolator can reduce the vibration effectively.

The integration of these parameters is very important when selecting parameters for fluidlastic

isolators design.

The range analysis of sensitivity of design parameters on dynamic stiffness is shown in Table 3.

Table 3 summarizes the range analysis of the effect of different factor on the dynamic stiffness.

According to the results of constricting the R values of different factors, the significant sequence of

all the investigated influencing factors of design parameters was in turn. For the combustion

efficiency of dynamic stiffness of fluidlastic isolator, the order of significance levels in turn

decreases with η, K

1

, c, L, ρ and K

2

respectively.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

68

Table 3. Range analysis of influencing factors for T.

level

K1

K2

ρ

L

c

η

1

0.093

0.093

0.100

0.110

0.106

0.036

2

0.082

0.090

0.089

0.093

0.062

0.092

3

0.077

0.119

0.096

0.076

0.079

0.088

4

0.106

0.094

0.114

0.120

0.119

0.184

5

0.149

0.111

0.125

0.130

0.165

0.129

R

0.104

0.055

0.057

0.085

0.144

0.203

Sensitivity: η> K

1

> c >L>ρ>K

2

The range analysis of sensitivity of design parameters on transmissibility of vibration is shown in

Table 4. Table 4 summarizes the range analysis of the effect of different factor on the transmissibility

of vibration. According to the results of constricting the R values of different factors, the significance

sequence of all the investigated influencing factors of design parameters was in turn. For the

combustion efficiency of dynamic stiffness of fluidlastic isolator, the order of significance levels in

turn decreases on η, K

1

, c, K

2

, ρ and L respectively.

Table 4. Range analysis of influencing factors for K

D.

level

K1

K2

ρ

L

C

η

1

204

1495

2324

2860

2749

269

2

904

2563

2779

2234

1631

463

3

1594

2838

1992

1552

1090

2273

4

2661

1558

1161

1311

1424

4407

5

4449

1356

1555

1854

2918

2400

R

6369

2954

2418

2340

3484

6386

Sensitivity: η>K

1

>c>K

2

>ρ>L

Referring to the Table 2, Table 3 and Table 4, it should be noted that the property of fluidlastic

isolators can be affected by design parameters obviously. But the property of rubber (loss coefficient

of rubber and stiffness of rubber) is, by far, the most significant design driver.

However, six parameters are analyzed only in this paper. The intercoupling among different

parameters has not been considered. In order to obtain more accurate results, more parameters such

as tuning port length, area coefficient should be considered in the next study. The interrelationship

among these parameters will be also analyzed.

5. Conclusions

The dynamic equation is set up based on the theory of dynamics. The orthogonal experimental

method is used to analyze the parametric sensitivity of the design parameters on the property of

fluidlastic isolator. Findings are listed below:

(1) The fluidlastic isolator can reduce the vibration effectively. The integration of these

parameters is very important when selecting parameter for fluidlastic isolators design.

(2) The property of fluidlastic isolators can be affected by design parameters obviously. But the

property of rubber (loss coefficient of rubber and stiffness of rubber is, by far, the most significant

design driver.

(3) The order of significance levels in turn decreases with η, K

1

, c, L, ρ and K

2

respectively. For

the combustion efficiency of dynamic stiffness of fluidlastic isolator, the order of significance levels

in turn decreases with η, K

1

, c, K

2

, ρ and L respectively.

Sensitivity Analysis of Design Parameters on Fluidlastic Isolators Performance

69

References

[1] Strehlow H, Mehlhose R, Znika P and Roth D 1990 Review of MBB’s passive and active

vibration control activities The Royal Aeronautical Society in London January

[2] Narayana Rao K S, Pranesh B and Ravindranath R 1998 Design development and validation of

an anti-resonant isolation system for advanced light helicopter 24th European Rotorcraft

Forum Marseille France September

[3] John H, Doug S and Askari B A 2003 Vibration attenuation through the use of active frahms

American Helicopter Society 59th Annual Forum Phoenix Arizona May 6-8

[4] Hugin C T and Hatch C 2006 Global control of helicopter vibrations using a semi-active

vibration control system 47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural

Dynamics, and Materials Con 1-4 May Newport Rhode Island

[5] Brown T J and Mccloud J L 1980 Multicyclic control of a helicopter rotor considering the

influence of vibration, load, and control motion In: 36th annual National Forum of the AHS

Washington D C: 72

[6] Gupta B P, Logan A H and Wood E R 1984 Higher harmonic control for rotary wing aircraft

In: AIAA/AHS/ASE Aircraft Design Systems and Operations Metting San Diego California

New York: AIAA 1984 2484

[7] Halwes and Dennis R 1975 Nodal beam inertial flexure U.S. Patent 3 858 831

[8] Flannelly W G 1964 Dynamic anti-resonant vibration isolator U.S. Patent 3 322 379

[9] Smith M R and Redinger W S 1999 The model 427 pylon isolation system American

Helicopter Society 55th Annual Forum Montreal Quebec Canada

[10] McGuire and Dennis P 1994 Fluidlastic dampers and isolators for vibration control in

helicopters. American Helicopter Society 50th Annual Forum Washington DC

[11] Dennis P and McGuire 2006 Active vibration control using fluidlastic pylon struts American

Helicopter Society 62nd Annual Forum Phoenix Arizona

[12] Cheng Q Y, Deng J H, Qian F, Feng Z Z and Zhu Y 2017 Dynamic performance analysis and

design for a fluidlastic isolator CMAME 2017 Guangzhou

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

70