Design and Implementation of Mine Ventilating Safety Information

System

Ya Ban

1,*

, Jing Yuan

1

, Hongjing Liu

1

, Qian Xu

2

, Rui Wang

1

and Lu Luo

3

1

Chongqing Academy of Metrology and Quality Inspection, Chongqing 401120, China;

2

Beijing Aerospace Automatic Control Institute, Beijing 100854,China;

3

Chongqing Rato Power Manufacturing Corporation, Chongqing 402247, China.

Email:banya@whu.edu.cn

Keywords: 3D GIS, ventilation system, virtual reality, spatial analysis, decision support

Abstract: Mine ventilation system is one of important factors that affect mining safety. This paper combines GIS with

virtual reality and has constructed a mine ventilation safety information system based on 3D modelling

technology of ArcGIS Engine and 3ds Max, Google SketchUp. The system has achieved the 3D visual

management and auxiliary decision of mine ventilating system, which provides an integrated data

management and automatic management platform. The system includes many functions, such as mine data

management, ventilation network analysis, air simulation and security evolution, and provides the best

refuge and the rescue strategies according to the actual situation of mine accidents. The system has a certain

value and significance for mine production safety.

1 INTRODUCTION

Due to the complicated ventilation environment in

mining operations, many dangerous gases such as

gas and flue gas can easily cause ventilation

accidents. Timely monitor and technical measures

are the main ways to avoid and prevent mine

accidents according to different situations. Roadway

system is an important part of mine 3D virtual scene

and is the foundation to digital mine (Stothard, 2003;

Rossmann, 2003; ZHANG et al., 1998). At present,

software system of mine mainly focuses on

management and calculation. The expression of

three-dimensional laneway is not yet mature and has

limited functions in visualization and spatial

analysis. There is no MGIS (Mine Geographic

Information System) suitable for mine in our

country and three-dimensional spatial features of

mine are a big factor in limiting their growth (Niu et

al., 2007). In the literature (Li et al., 2004), an

OpenGL based 3D visual modeling system of

underground mine excavations was introduced and

key technique for developing the 3D visual

modeling system with OpenGL were presented,

including entity drawing, geometric transformation,

projective transformation, illumination and

rendering. GUO (Guo et al., 2005) has developed a

3D simulation system for the mine ventilation

network with visual basic6.0, which can show real-

time status of the mine ventilation dynamically and

veritably, feedback timely, intuitionistic a

dependable information of mine ventilation to mine

ventilation supervisors. In the literature (Wang and

Wang, 2009), under the VC++ development

environment, three dimensional tunnel’s in

computer two-dimensional surface hypothesized

demonstration is realized through OpenGL, and the

collision examination is implemented when you are

roaming in the tunnel three dimensional virtual

system. In the literature (Zhang et al., 2010), to

solve the problems in mine disaster rescue arising

from separate geological model and laneway model,

a multilayer 3D model was proposed, which

combined the geological model, laneway model and

3D visualization technique. ZHANG (Zhang, 2010)

constructed a TIN model of coal seam with grids

index algorithm according to drilling data, realized

3D visualization of coal seam by combining solid

modeling method and lighting rendering in OpenGL,

constructed 3D roadways model with SketchUp and

realized 3D visualization of roadway with

SceneControl in ArcEngine SDK.The tunnel cross-

section modeling method is put forward, and the

display of three-dimensional tunnel in two

dimensional plane of computer is realized based on

Ban, Y., Yuan, J., Liu, H., Xu, Q., Wang, R. and Luo, L.

Design and Implementation of Mine Ventilating Safety Information System.

In Proceedings of the International Workshop on Environment and Geoscience (IWEG 2018), pages 463-468

ISBN: 978-989-758-342-1

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

463

object-oriented program design and combined with

the Skyline (Li et al., 2015).In the literature (Wang

and Fu, 2015),the automatic modeling method is put

forward, mine roadway 2D representation ,data

extracting and organization, mine roadway model

3D building are studied, and two data organization

method to extract the mine roadway network data

are discussed and realized.

Mine ventilation safety intelligent analysis and

disposal decision-making research is in its infancy.

In the literature (Li and Li, 2007), evaluation factors

of the ventilation system in metal mines were

analyzed and selected according to the man-

machine-environment system, the member function

of the evaluation factors were formulated, and the

evaluation system was established. WANG (Wang

et al., 2007) proposed a new type of mine disaster

early warning and salvage technology system based

on GIS to form a complete set of perfect mine safety

management assurance system. CHANG (Chang et

al., 2018) established three-dimensional mine

ventilation system model to simulate ventilation

system present situation, the optimizing design, and

the roadway expedite and ventilation simulation

path, pollutant diffusion and avoid disaster

simulation, the 3D ventilation intelligent decision

analysis system. An intelligent monitoring and

control system for mine ventilation safety was

developed, which can real-timely monitor and

display ventilation safety parameters, such as air

speed, gas concentration, temperature, air pressure

and air volume, and the system can also

automatically adjust opening and closing state and

opening degree of air door when air volume is

insufficient or rich (Yang and Hao, 2017). Three-

dimensional simulation is an important information

technology for mine ventilation safety management

and evaluation. However, spatial analysis and

emergency decision of ventilation system are

bottlenecks in the promotion and application of mine

ventilation system in our country. GIS provides an

effective tool for the research in this field. Based on

actual needs of mine ventilation management, the

author uses VB.NET programming language and

ArcGIS Engine component GIS and Google

SketchUp 3D modeling tools to integrate all kinds of

ventilation safety information in the mine to realize

3D visual management and assistance of mine

ventilation system. The system provides an

integrated data environment and automated

management platform.

2 DESIGN OF MINE

VENTILATION SAFETY

INFORMATION SYSTEM

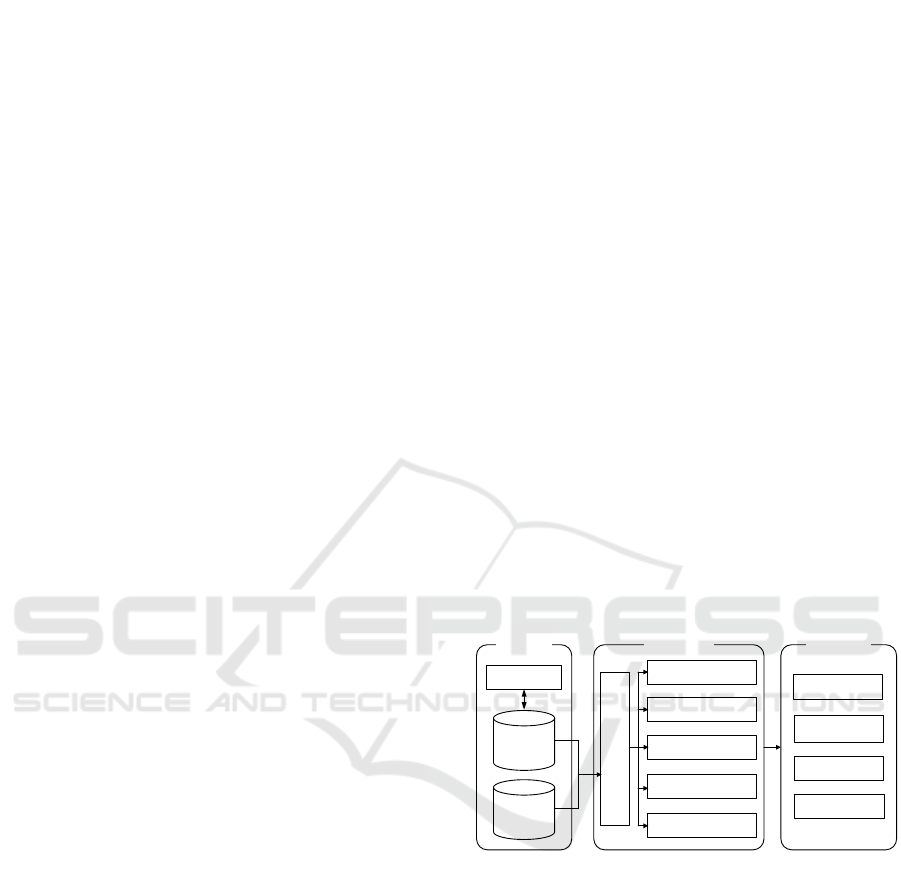

2.1 Design of Systematic Functions

The system is mainly divided into five modules:

ventilation information management, mine three-

dimensional modeling, ventilation network analysis,

ventilation system safety fuzzy comprehensive

evaluation and aided decision-making, as shown in

Figure 1. The system has constructed mine three-

dimensional scene and topological relations based

on measured structure data of mine. With monitors

as the real-time data source, dynamic changes of air

components such as air speed, air temperature and

gas are analyzed. When an indicator exceeds

standard value, air speed and air volume are

combined to determine the source of gas release.

The range of the roadway that is affected by the flow

of contaminated gas will be analyzed. After the

danger level is assessed, the system will be warned

and other intelligent ventilation devices will be

intelligently and fuzzily controlled to ensure

ventilation safety.

Ventilation

Information

Management

Real-time

Monitoring

Data

Data

Management

Ventilation

System Data

Structure

Spatial Analysis

Data Fusion

Safety grade assessment

Ventilation Network

Analysis

Gas Diffusion Analys is

Optimal Path Analysis

Assisted Decision

Making

System Output

3D Visualization

Safety Evaluation

Report

Thematic Map

Dynamic

Simulation

Figure 1: Systematic function diagram.

2.2 Mine Ventilation System Data

Organization and Topology

Topological relations are foundation of mine

ventilation simulation system, which is directly

related to functions and efficiency of mine

ventilation system. Through excavation, nodes,

structures, ventilation and power devices, flow

direction between each other to send messages,

topological relationships are built. Branches abstract

as a laneway, consists of beginning and end nodes.

Branches can be associated with many branches, but

the degree of nodes must be greater than or equal to

1. A structure or fan station belongs to only one

roadway, and one windward direction graphical

IWEG 2018 - International Workshop on Environment and Geoscience

464

object belongs to one laneway. Nodes are joints that

connect laneways in the mine ventilation system.

There are no isolated nodes in the mine ventilation

system and no isolated laneway exists. Data

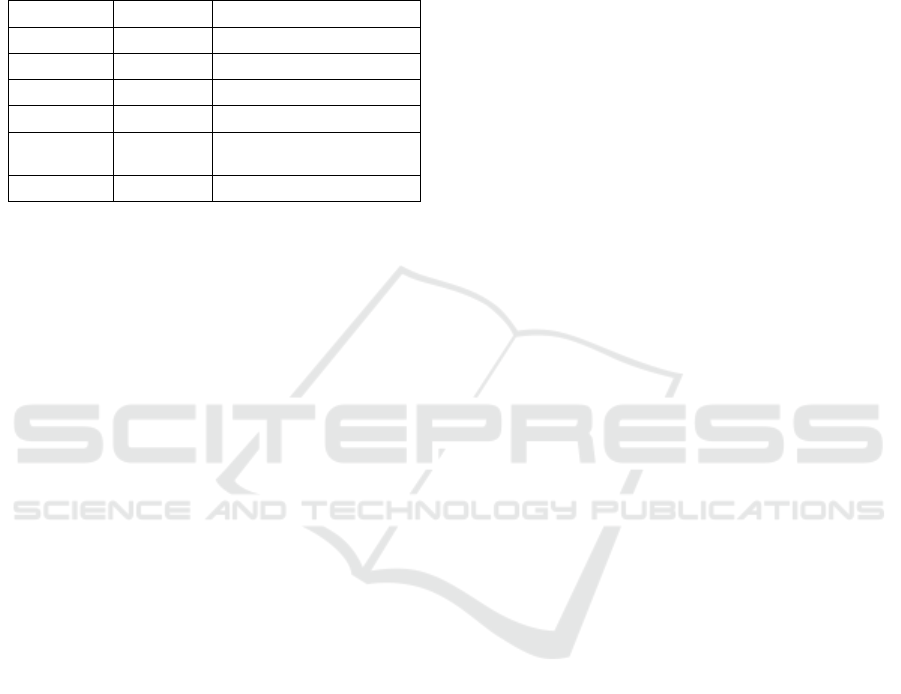

structure in the system is shown in Table 1.

Table 1: A table with headings spanning two columns and

containing notes.

Field Name Field Type Description

ID Integer branches ID

in_node Integer branches beginning node ID

out_node Integer branches end node ID

length Double branches length

type Integer branches type(Horizontal,

inclined shaft or shaft)

name String branches name

3 THREE-DIMENSIONAL

MODELLING OF MINE

VENTILATION SYSTEM

Mine ventilation system of three-dimensional

modelling includes three parts: three-dimensional

automatic ventilation system construction, three-

dimensional visual management and air dynamic

simulation. The 3D visualization management

model is used for ventilation system spatial

management and analysis. Based on improved

particle algorithm, dynamic airflow simulation

module can display ventilation parameters such as

direction of airflow, type of airflow and the amount

of airflow.

3.1 Ventilation System Topology

Relationship Establishment and

Management

Managers in management of mine ventilation

system can add and remove laneway, structures,

ventilation, power devices and direction of air flow,

and topological relationship of mine ventilation

system can automatically be established and

maintained. If a laneway is abolished, its

corresponding structures and ventilation units will

be removed or abolished. If a structure or ventilation

power plant is deleted, the topological relationship

between corresponding branches and deleted object

is unbound.

The attribute data of mine ventilation system is

managed by database. Only four kinds of objects,

such as branches, node, structure and fan station,

have attribute data in graphic entity of mine

ventilation system. The data in the system is

distributed storage using spatial graph data and

attribute data. Spatial data only contains spatial

location and the shape information of the

geographical object and is stored in the Geodatabase.

Attribute data stores attribute information, stored in

SQL Server database. Graph data and attribute data

establish real-time association by ID.

3.2 3d Mine Scene Construction

In construction of 3D mine, combined with three-

dimensional display of ArcGIS, spatial analysis

functions and 3D Max, fast and powerful 3D

modeling ability of Google SketchUp software, the

existing GIS data can be used to construct large-

scale and refined 3D scene quickly and efficiently.

3.2.1 3D Mine Symbol and Storage

In ArcGIS, three-dimensional surfaces are

represented in multipatch format, usually expressed

as Trianglestrips. This format records three-

dimensional coordinates of the points in the model

for spatial analysis. However, it is inconvenient to

draw 3D model through ArcGIS itself. Google

SketchUp can be used to draw beautiful 3D models

and convert them to multipatch recognized by

ArcGIS, making it quick and easy to work with and

beautiful models. Mine ventilation system is divided

into four types of graphical entities, namely,

branches, node, and structure and fan station. These

graphic entities have a lot of similarities. According

to the different types of the system, the system

draws the model in advance and automatically calls

it according to the requirement when drawing,

which can generate 3D graphics and 3D scene of

ventilation system flexibly and quickly.

3.2.2 Three-Dimensional Automatic

Construction of Laneway

Three-dimensional automatic construction of the

system is mainly the modeling of the laneway.

Spatial data and attribute data of the laneway are

stored in a fixed format, including starting point,

ending point coordinate of the laneway, and name.

When constructing a 3D scene, the system obtains

3D coordinates and attribute information of all the

laneways, nodes and structures by accessing

property database. After modeling different 3D

symbols, they can be transformed flexibly and mine

3D ventilation system can be automatically

Design and Implementation of Mine Ventilating Safety Information System

465

constructed. Users can freely browse three-

dimensional graphics built to observe and choose to

browse. After zooming in, the details of the laneway

can be clearly seen. The branches side and the arc-

shaped top surface can be seen in the scene of the

three-dimensional transportation laneway. Tracks in

the alley floor are used to transport equipment and

materials.

3.3 Air Dynamic Simulation

The direction of the air flow is indicated by an arrow

with a direction, the direction of the arrow indicating

the direction of the laneway. The system will read

the data of the branches from database according to

the user's choice, set direction, type, speed and

volume of air flow, and change the state to be air

flow dynamic simulation at the same time. In a

diffusion simulation of a laneway, the gas model is

continuously added along the laneway to be affected

in accordance with the direction of diffusion to

indicate the diffusion of flue gas. The tunnel is set to

be translucent to ensure that the simulated airflow

can be seen by the user.

4 MINE VENTILATION SAFETY

INFORMATION SYSTEM AND

APPLICATION

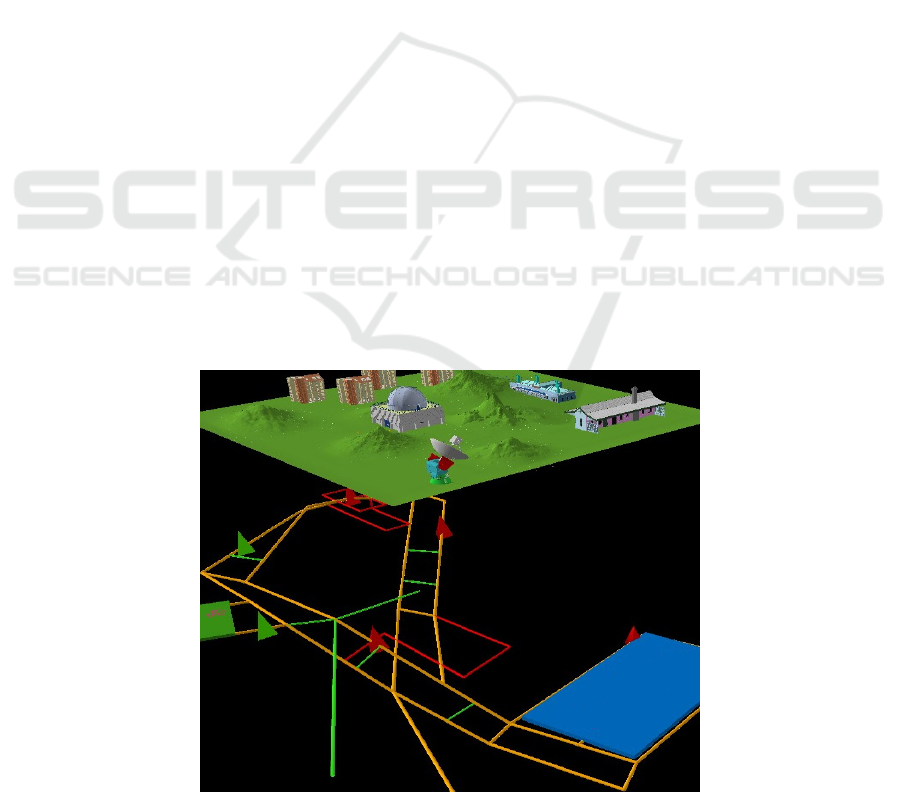

Taking a mine as an example, this paper uses

VB.NET programming language, applies ArcGIS

Engine component GIS and 3D Max, and Google

SketchUp 3D modelling tools to integrate various

mine safety ventilation information and establishes a

mining industrial square model and mine tunnel

model, a three-dimensional GIS mine ventilation

safety information system developed, main interface

of the system shown in Figure 2.

The mine has a total of 104 laneway branches,

93 nodes, 4 exits, and a number of structures. The

developed system can facilitate the management of

mine data conveniently and intuitively, analyze the

change of underground ventilation status, simulate

the ventilation safety accident and output the report,

which can help to improve mine ventilation

information management ability and decision level.

4.1 Mine Data Management

The data involved in the system includes two

aspects of ventilation system structure data and

monitoring data. Ventilation system structure data

includes laneway and node data, structure data and

ventilation and power unit data, and is managed

manually. Ventilation monitoring data (including

gas, coal dust, etc.) are collected in real time by gas

sensors in mine and workface. The data

communication equipment transmits information

such as total air pressure of the mine ventilator, air

volume and gas concentration to the ground

monitoring station. The coal mine monitoring master

station displays and manages the data collected by

the sensor and sends control instructions to

monitoring equipment to realize control functions.

Figure 2: Main interface of ventilation safety information system.

IWEG 2018 - International Workshop on Environment and Geoscience

466

The system has a good human-computer

interaction, the combination of spatial data and

attribute data, intuitively providing two-way

operation of the data to achieve visual management

of ventilation system data, three-dimensional spatial

attribute query, coordinate query, distance

measurement and two-dimensional three-

dimensional scene switching.

4.2 Ventilation Safety Analysis and

Gas Diffusion Simulation

Ventilation safety information modules mainly

include inspection and registration of ventilation,

fire prevention, gas emission prevention, and safety

inspection and ventilation safety equipment

management. Ventilation technical indicators are the

amount of air intake, return air volume, effective air

flow rate of mine, absolute gas emission, and

relative gas emission and so on. Specific to a point,

laneway technical indicators are into air speed, air

temperature, into air oxygen, gas and other

concentrations. At the same time, system can

monitor running status and fault of equipment in real

time. The system sends information to the man-

machine interface, visual display to monitoring staff.

The system, realizes simulation analysis of diffusion

of contaminated gas, predicts the influence scope,

makes decision of hedging and guides mine

ventilation safety based on powerful network

analysis function of GIS. Mine ventilation real-time

monitoring shown in Figure 3.

Figure 3: Mine ventilation real-time monitoring.

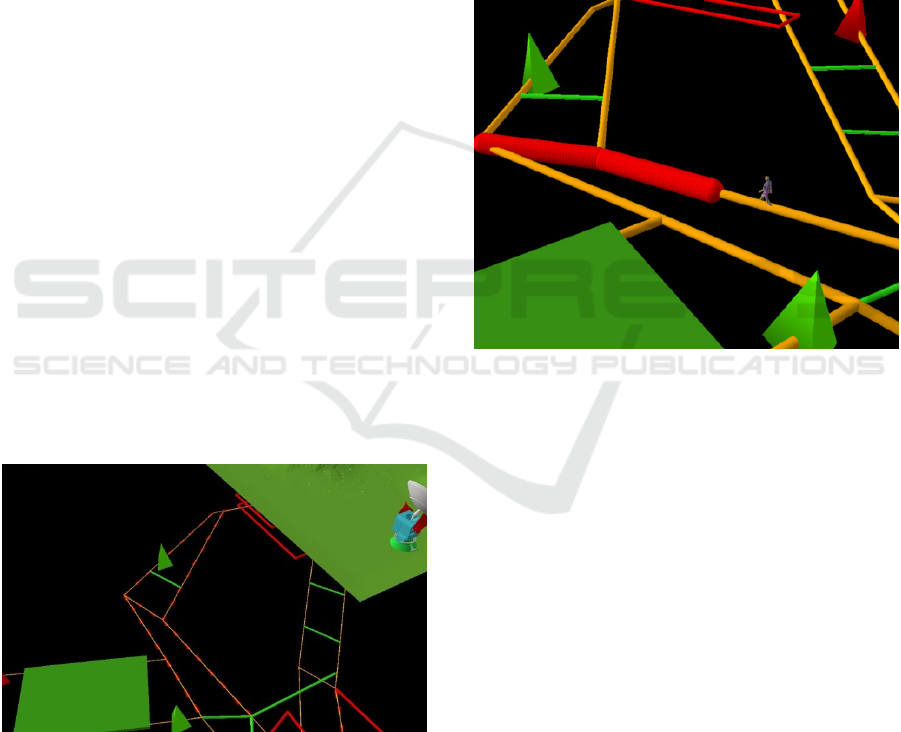

4.3 Mine Safety Emergency Decision-

Making

According to results of analysis of safety status, the

system conducts fuzzy comprehensive evaluation

and control based on expert knowledge and

disposition plan. Gas concentration in the lane

changes more frequently, so the design of its

boundary line alarm system uses theory of fuzzy

mathematics, that is, when the concentration value

in a certain range, the number and location of fans to

open will be different, the purpose of it is to prevent

fan jitter, and second, reduce the number of fans to

open and extend the life of the fan. When the fault is

not controllable, the system generates the disaster

prevention route and guides absenteeism. After the

disaster, hedge lines are shown in Figure 4.

Figure 4: Disaster prevention route planning.

4.4 Report Output and Thematic Map

Report and thematic map output module is the

ventilation safety and related data to the report or

thematic map output. Thematic map is formed by

setting different color, pattern or symbol according

to a particular value. Thematic map contain the

amount of air flow map, gas concentration map, etc.

We can know the monitoring point of the air volume

and gas concentration to reflect the safety of

underground conditions based on thematic map.

5 CONCLUSIONS

Based on the analysis of the current research status

of mine ventilation system, the solution to the spatial

analysis and visualization of mine ventilation system

is put forward based on GIS technology. Finally,

taking a mine as an example, a mine ventilation

safety information system based on 3D GIS has

Design and Implementation of Mine Ventilating Safety Information System

467

been developed. Based on real-time monitoring data,

the system comprehensively analyses and controls

ventilation, integrating data monitoring, analysis and

evaluation, and provides an integrated data

environment and visualization platform for mine

ventilation information management. Safe

production and mine disaster information to provide

intelligent technical support, the system has a certain

application value and market prospects in safe

production and mine disaster information to provide

intelligent technical support. System establishes a

comprehensive and stable algorithm, based on flow

of gas in the airway to carry out monitoring and

early warning. It can be extended to a variety of

tubular face ventilation system management and

monitoring analysis.

ACKNOWLEDGMENT

This work was financially supported by scientific

research project of Chongqing Bureau of Quality

and Technology

Supervision(No.CQZJKY2018004).

REFERENCES

Chang W Z,Ding Y L and Zhang L H 2018 The

Application of 3D Intelligent Analysis and Decision

Ventilation System in Ventilation Management Coal

Mine Modernization 1

Guo N Q,Huang G P and Wang H N 2005 Development

and Application of 3D Simulation System for the Mine

Ventilation Network China tungsten industry 5 20

Li C M,Li Z X and Seng D W 2004 OpenGL Based 3D

visualization of underground mining systems Journal

of university of science and technology Beijing 5 26

Li H,Li P F and Yu J Y 2015 Research on the Tunnel

Three Dimensional Modeling and Virtual Technology

Geomatics & spatial information technology 10

Li X L and Li C L 2007 Fuzzily Integrated Evaluation of

the Ventilation System in Metal Mines based on

Human-Machine-Environment China Mining

Magazine 1 16

Niu Y S,Cao R and Chen X X 2007 Design and

Implementation of 3D Visualized Simulation System

of Mine Ventilation Mental Mine 7 37

Rossmann M 2003 Planning, Simulation and Real-Time

Depiction of Coal-Mining Processes Using a Virtual

Reality System Gluechauf Mining Reporter 1

Stothard P 2003 The Feasibility of Applying Virtual

Reality Simulation to the Coal Mining Operations

Australasian Institute of Mining and Metallurgy

Publication Series. 5

Wang F L and Wang T B 2009 Research on the Tunnel

Three Dimensional Algorithm and Virtual Technology

Journal of Hunan University of Science &

Technology(Nature Science Edition) 1 24

Wang X B,Dong X P and Cao L G 2007 Mine Disaster

Warning and Rescue Technology System Safety in

Coal Mines 7 38

Wang Y J and Fu Y M 2015 Research on 3D Automatic

Modelling Method of Mine Roadway Geomatics and

information science of Wuhan University 4 31

Yang Z and Hao T 2017 Development of Intelligent

Monitoring and Control System for Mine Ventilation

Safety Industry & Mine Automation

Zhang C,Dai S X and Huang M 2010 Research and

Application of 3D Geological and Laneway Integrated

Model Journal of Geomatics science and technology 1

27

Zhang G L 2010 Research on 3-D Visualization of Coal

Seam based on OpenGL Coal mining Technology 4 15

ZHANG R X,REN T X and Schofield D 1998 Virtual

Reality and Its Application in mining engineering

Journal of China University of Mining & Technology 3

27

IWEG 2018 - International Workshop on Environment and Geoscience

468