Nitrogen Foam Profile Control Improves Steam Huff and Puff

Development Effect

Jicheng Zhang

1

, Qingqing Li

1,*

, Xinyu Chen

1

, Guangfu Lu

1

and Li Liu

2

1

Northeast Petroleum University, School of Petroleum Engineering, Daqing, Heilongjiang;

2

Department of Flow in Porous Media & Fluid Dynamics, Research Institute of Petroleum Exploration & Development,

Langfang, Hebei.

Email: 1525841456@qq.com.

Key words: Steam huff and puff, nitrogen foam, profile control, heavy oil, remaining oil

Abstract. After the XQ-45 block entering the multiple rounds of steam huff and puff, it is affected by faults, reservoir

properties, edge water and other factors. The remaining oil distribution is complex, and steam huff and puff

effect is getting worse. According to the reservoir dynamic data, this block is selected as a test block to

improve the steam huff and puff development effect of nitrogen foam. The 79 wells in this block are divided

into different types of heavy oil wells according to the remaining oil saturation parameters. Aiming at the

high-level intervals in the oil wells with different layers, then take nitrogen foam profile control measures to

adjust the suction profile, and optimize the optimal nitrogen foam injection parameters are: nitrogen foam

injection volume is 0.2pv, foam concentration is 0.5%, gas liquid ratio is 2: 1, cycle steam injection volume

is 100t/m. The results show that the oil production is the largest in the second round of profile control, the

average daily oil production is 3.89t, and the cycle oil-gas ratio reaches 0.32. On this basis, continue to

increase the profile control round, after the profile control 5 rounds, the average daily oil production is

3.18t, the average oil-gas ratio is 0.26, the cycle of cumulative oil production is 1431.23t, and the program

implementation effect is getting better.

1 INTRODUCTION

At home and abroad the application of foam fluid

has nearly 30 years of history in oil field. The

composition form of foam fluid is also evolved from

single ordinary foam flooding to current compound

nitrogen foam flooding (Zhao et al., 2009; Yang,

2014; Huseyin, 2013). After the 80’s, domestic oil

field has made a major breakthrough in the

application of foam fluid technology. The foam is

gradually recognized as main mechanism to improve

recovery ratio of heavy oil after entering multiple

rounds of steam huff and puff (Zhang et al., 2012; Li

et al., 2007; Tian, 2015), it has conducted the

relevant indoor and field study in the field.

Zhang Liehui etc have proposed foam flooding

empirical model. Compared with other models, the

model except adds a surface active agent flowing

equation, the model does not require any additional

large amounts of data. This feature makes this model

widely used in the software customization

(Zhang et

al., 2000; Fan et al., 2009; Rossen and Zhou 1994);

Liao Guangzhi, Chen Guo etc have established a

mathematical model to describe polymer alkali

active agent and foam fluid combination flooding

(Chen et al., 2001; Zhang et al., 2012; Malcolm,

2004). Aimed at the second north block in Shengli

oil field, and launched a pilot test to improve

recovery ratio of injecting nitrogen foam. It is found

that technology of nitrogen foam can effectively

supplement layer capability in this block and

improve swept volume (Zhou et al., 2006; Cao et al.,

2013; Cao et al., 2006). With the effect of weak gel

profile control rapid decline, liaohe oil field has

established laboratory test of nitrogen foam profile

control. According to laboratory findings, confirmed

a series of field nitrogen foam injection scheme. It is

demonstrated that inject nitrogen foam can

effectively plugging tall permeation high capacity

channel of oil layer, enhance swept volume, and

improve effect of water injection (Yang et al., 2004;

Islam et al., 1989). Aimed at the needs of Daqing

Zhang, J., Li, Q., Chen, X., Lu, G. and Liu, L.

Nitrogen Foam Profile Control Improves Steam Huff and Puff Development Effect.

In Proceedings of the International Workshop on Environment and Geoscience (IWEG 2018), pages 223-232

ISBN: 978-989-758-342-1

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

223

Sabei oil field development, and launched pilot test

of nitrogen foam flooding in the Beiding well and

xing well. It is confirmed that availability of

nitrogen foam flooding in the field is good, and

foam combination flooding can improve oil

recovery 30% than water flooding (Zhang et al.,

2001; Wang and Zhang, 2007; Islam, 1989).

After XQ-45 block entering the high cycle of

steam huff and puff, distribution of remaining oil is

complex, and the effect of steam huff and puff is

getting worse. Due to the heterogeneity of reservoir

layers, steam overlapping and steam enthalpy occur,

which leads to steam escaping along the high

permeability zone, making the steam sweep

efficiency small, greatly reducing the effective

steam sweep area and affecting the efficiency of

steam huff and puff. Aiming at this issue, in order to

further study the effect of nitrogen foam profile to

improve the development of steam huff and puff, the

block wells are divided into five types of remaining

heavy oil wells, potential of these five remaining oil

wells is analyzed and nitrogen profile study of the

most potential inter-layer differential wells is

conducted. Parameters of optimal nitrogen foam

injection are optimized, and effect of nitrogen foam

profile control inter-layer differential wells

development is confirmed.

2 BLOCK OVERVIEW

2.1 Reservoir Geological Features

XQ-45 block is located in the north east direction of

the Xinzhuang complex fault block in the northern

slope of the Biyang depression. This part of strata is

mainly composed of three different oil groups and

unconformity contact of angle in the third system.

The whole area contains oil-bearing horizon

group Ⅱ. The main oil layers are H3Ⅱ2 oil layer,

H3Ⅱ3 oil layer, H3Ⅱ5 oil layer and H3Ⅱ6 oil

layer, and effective thickness of oil layer is 0.8-10.4

meters. Buried depth of reservoir is 75 ~ 245m, the

average of oil layer assemble thickness is 8.2m, and

the pure gross thickness ratio is 0.5-0.99. Reservoir

lithology mainly consists of linen rudstone, glutenite

and siltstone. Cementing materials are dominated by

earthy material. Type of cementation is generally as

pore cement. Oil reservoir has better physical

properties with average porosity of 30.44% and

mean permeability of 2209.4×10

-3

µm

2

. Relative

density of ground crude oil between 0.9361 cm

3

and

0.9666g/cm

3

, content of gummy asphalt is 6.3%~

33.43%, paraffin content is 2.87%~9.06%, sulfur

content is 0.03%~0.12%, solidifying point is -2℃

~7℃, viscosity of degassed crude oil is 11258~

20876mPa·s, which belongs to particularly heavy oil

reservoir.

2.2 Steam Huff and Puff Development

Process

XQ-45 block has been put into large scale

development since 2005. After five years of steam

huff and puff, by the end of April 2011, a total of 76

oil wells have been put into production, with

cumulative liquid production is 110.23×10

4

t,

combined water content is 85.7% and cumulative

oil-gas ratio is 0.23.

Since June 20, 2011, due to infancy of steam

flooding is not effective and oil-gas ratio is poor.

XQ-45 block implements injection and production

parameters adjustment, nitrogen foam assists steam

flooding and other measures, it is found that steam

flooding production wells gradually effective, daily

oil production and oil-gas ratio increase year by

year. By the end of December 2015, a total of 72 oil

wells have been devoted to development and 58

wells as open wells. The average single well

throughput is 10 cycles, daily fluid production is

523.6t, daily oil production is 32.1t, and water

content is 93.9%. Cumulative oil production is

22.7049×10

4

t, degree of reserve recovery of

producing reserves is 23.3%, cumulative steam

injection volume is 94.6038×10

4

t, and cumulative

oil-gas ratio is 0.24.

2.3 The Main Problems in the

Development Process

With increase of the number of throughput cycles,

development effect of the block gradually

deteriorated. At present, the average steam huff and

puff cycle has reached more than 10 cycles and the

average of degree of reserve recovery is about

18.6%. The average single-well daily production is

only 0.6t and oil-gas ratio is about 0.13. After the

development of high cycle throughput and steam

flooding, following problems mainly restraint the

effect of development and the increase of recovery

ratio: (1) Section plane heterogeneity is strong, and

degree of utilization is disproportionation. (2) After

high cycle of steam huff and puff, pressure is low,

IWEG 2018 - International Workshop on Environment and Geoscience

224

and daily liquid production of single well is low.

Oil-gas ratio is low and the effect of development is

poor. There are many low production wells and

invalid production wells. In the XQ-45 zone, the

average steam cycle has reached 10 cycles, the

formation pressure has dropped to 0.8MPa-1.2 MPa,

and the pressure maintenance level is only about

40%.At present, the average daily production of

single well is 9t, daily oil production is 0.6t , water

content is 93.3%, oil-gas ratio is 0.13, which has

poor development. Among them, there are 10

normal production wells with daily production of

more than 1.0t and 49 low-efficiency wells with

daily production of less than 1.0t. (3) Remaining oil

distribution is complex, and the realization of

tapping potential is difficult. The remaining oil

recognition method is only the logging interpretation

method and the reservoir engineering method, and it

is limited to single well points and small layers. The

remaining oil potential is difficult to recognize and

evaluate, and it restricts the fine adjustment and

potential tapping of the reservoir in the later period.

3 CLASSIFICATION AND

POTENTIAL ANALYSIS OF

REMAINING OIL TYPES IN

HEAVY OIL WELL

3.1 Remaining Oil Classification of

Five Heavy Oil Wells

Combining actual production data of liquid

producing capacity, gas injection volume and water

content of each well, and based on the data of

geologic analysis and well logging interpretation.

According to different parameters such as remaining

oil saturation and degree of reserve recovery, 79

wells in XQ-45 block are measured to establish the

classification criteria.

There is edge water in the small layers of block,

and area of edge water block is unequal. With the

continuous of the process of pressure releasing and

producing, edge water along the high permeability

zone with better physical property advances into the

well. At this time, oil productive capacity rapid

decline, water production rapid increase. As a result,

layers around oil wells are not evenly used, and they

are identified as oil wells affected by edge water.

The block is mainly controlled by faults, and the

radius of oil drainage is significantly affected by

faults. The value of remaining oil saturation nears

the fault is relatively high, and degree of reserve

recovery is relatively low. So that, oil wells in this

block are confirmed fault screened heavy oil wells.

The criteria for dividing inter-layer differential

type of remaining oil is: the value of average

remaining oil saturation difference between H3II2,

H3II3, H3II5 and H3II6 four layers are≥0.12.

The criteria for dividing intra-layer differential

type of remaining oil is: the value of remaining oil

saturation difference in the three small layers of

H3II31, H3II32 and H3II33 are≥0.08.

According to the distribution of the remaining oil

saturation field, except for the types of remaining oil

wells above, which the remaining oil wells are still

rich at the end of the recovery, are divided into the

interwell enrichment remaining oil wells.

On the basis of the results of the five types of

remaining oil, the single well controlled geological

reserves are calculated according to the volumetric

method, and the degree of reserve recovery of the

five type of remaining oil type wells are analyzed.

The average degree of reserve recovery of interwell

enrichment wells is 22.9%, the average degree of

reserve recovery of intra-layer differential remaining

oil wells is 28.1%, the average degree of reserve

recovery of inter-layer differential remaining oil

wells is 24.5%, the average degree of reserve

recovery of edge water affected wells is 21.7%, and

the average degree of reserve recovery of fault

screened oil wells is 8.23%.

3.2 Potential Analysis of Five Type

Remaining Oil Wells

According to the degree of reserve recovery of the

five type remaining oil wells, the remaining oil

potential classification evaluation is performed. The

remaining oil potential evaluation criteria are: the oil

wells with less than 10% degree of reserve recovery

have the high potential of remaining oil, the oil

wells with degree of reserve recovery of 10%-25%

have the medium potential of remaining oil, the oil

wells with more than 25% degree of reserve

recovery have the low potential of remaining oil. It

is concluded that the order of the production of five

types of heavy oil wells is as follows: intra-layer

differential type > inter-layer differential type >

interwell enrichment type > edge water effected

type>fault screened type.

According to the evaluation criteria for

remaining oil potential, the remaining geological

Nitrogen Foam Profile Control Improves Steam Huff and Puff Development Effect

225

reserves of the five remaining oil types are

calculated. The order from high to low is as follows:

inter-layer differential type> edge water effected

type> fault screened type> interwell enrichment

type> intra-layer differential type.

According to the above analysis, the remaining

oil potential of the five heavy oil wells is as follows:

inter-layer differential type> edge water effected

type> fault screened type> interwell enrichment

type> intra-layer differential type. It is can be seen

that the inter-layer differential type remaining oil is

the high potential of the remaining oil in the five

heavy oil wells, so the analysis its causes.

3.3 Analysis the Development of Inter-

Layer Differential Type Remaining

Oil Wells

The formation and distribution of inter-layer

differential type remaining oil are mainly affected

by interlayer barrier, inter-layer heterogeneity and

perforation interval. The virgin formation oil layers

in the same wells generally maintain characteristics

of the native reservoir, and a high remaining oil

distribution in the local zone is formed. The

temperature loss of barrier limits the effective range

of steam flooding, so that more remaining oil is

formed in the upper part of barrier to form a high

remaining oil enrichment zone. The inter-layer

thermal interference makes high permeability layers

communication transform to form steam

communication, so that the relatively low

permeability layer or disconnected layer form high

remaining oil.

4200 well in the block is selected to analysis. For

H3II3 layer, the value of porosity is 32.96%, the

value of permeability is 1660×10

-3

μm

2

, and the

value of remaining oil saturation is 0.41. For H3II5

layer, the value of porosity is 39%, the value of

permeability is 479×10

-3

μm

2

, and the value of

remaining oil saturation is 0.54. For the two layers

mentioned above, the difference value of

permeability is 1181×10

-3

μm

2

, and the difference

value of remaining oil saturation is 0.13. Conflicts

between layers is large, thus inter-layer differential

type of remaining oil is formed.

4 STUDY ON NITROGEN FOAM

PROFILE CONTROL INTER-

LAYER DIFFERENTIAL TYPE

OIL WELLS

According to the inter-layer differential type

remaining oil wells, on the basis of actual

production data such as the potential productivity of

single-layer remaining oil, the effective thickness of

oil layer, the cumulative oil production and the

degree of reserve recovery. The representative 4003

well and 4502 well are selected to optimize design.

Due to the difference heterogeneity of reservoir

layers, steam overlapping and gas channeling occur.

It is results that the steam rushes into the high

permeability zone, makes sweep efficiency of steam

small and greatly reduces the effective area of

steam, thus affects the efficiency of steam huff and

puff. Aiming at the high degree of reserve recovery

of layer in inter-layer differential type oil wells, the

nitrogen foam profile control measures are adopted

to adjust the gas injection profile and mode of two

layers commingled production. The nitrogen foam

profile control parameters and steam injection

parameters are optimized, including nitrogen foam

injection volume, gas fluid ratio (nitrogen: foam

liquor), foam concentration and cycle steam

injection volume. Using the numerical simulation

method and combining with the economic benefit

analysis under the current low oil price, the best

solution is obtained by obtaining the maximum

crude output and the economic limit oil gas ratio

greater than 0.2 as the evaluation standard.

4.1 Geological Modeling

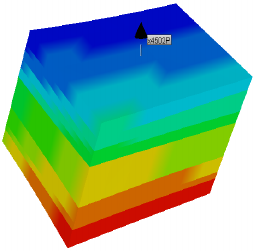

Figure 1: The geological model of 4502 well.

IWEG 2018 - International Workshop on Environment and Geoscience

226

From the actual geological model in XQ-45 block, a

single-well geological model of the new 4502 well

is extracted (Figure 1). According to the single well

reserves control range, the model plane size take

half the well spacing is delineated (40m).

The oil production of each small layer of well

4502 is calculated, and the volume method is used to

separately calculate the single wells geological

reserves. The utilization of reserves in each layer is

analyzed, the results show that H3Ⅱ5 layer and

H3Ⅱ6 layer are imperforate into production, and the

single layers of H3Ⅱ2 layer and H3Ⅱ3 layer have

higher degree of reserve recovery of 71.08% and

76.73%. The total degree of reserve recovery of two

layers is 74.35%. Since the cycles of steam huff and

puff of H3Ⅱ2 layer and H3Ⅱ3 layer in Well 4502

have reached more than ten cycles, and on June 20,

2011, it turns to steam flooding, they are currently in

a state of high water cut stage well shutdown. The

average temperature of H3Ⅱ2 layer is 50.3℃. The

average temperature of H3Ⅱ3 layer is 51.45℃. The

temperature of oil layer is higher, the nitrogen foam

profile the higher degree of reserve recovery of

H3Ⅱ2 layer, H3Ⅱ3 layer is took at first, and then

two layers of steam huff and puff production method

is combined , in this way the volume of nitrogen

foam and steam is optimized.

4.2 Nitrogen Foam Profile Control

Experiment Design

In the study, there are many programs parameters

design, if we conduct a comprehensive test, the test

scale is very large and difficult to implement, so we

can take orthogonal test method for multi-factor test,

using part of the test to replace the full test, through

the analysis of some of the test results, thus we can

find the test rules.

The optimization program of nitrogen foams

includes that the gas liquid ratio, foam

concentration, the total amount of nitrogen foam

injection and the steam injection. The gas liquid

ratio of the four levels of 1:1, 2:1, 3:1 and 4:1 was

selected, the concentration of foam was 0.3%, 0.4%,

0.5% and 0.6%.The injection volume of being

selected four levels of nitrogen foam is 0.1PV,

0.15PV, 0.2PV and 0.25PV, the steam injection

quantity of being selected at four levels of 80t/m,

100t /m, 120t/m and 140t/m, carrring out the

orthogonal experiment design of four factors and

four levels L16 (4

4

), the pore volume is calculated

according to the profile control radius of 30m. The

porosity volume is calculated through each small

layers and the effective thickness, according to the

profile volume multiplier to calculate the layered

profile volume, to further determine the specific

parameters of profile control (Table 1).

Table 1: L16(4

4

) The optimization parameter table of

orthogonal experiment.

Leve

l

factors

A

Input

B

Gas/liqui

d ratio

C Cycle steam

injection

volume t/m

D Foam

concentr

ation %

1 0.1PV 1:1 80 0.3

2

0.15

PV

2:1 100 0.4

3 0.2 PV 3:1 120 0.5

4

0.25

PV

4:1 140 0.6

According to the four factors and the four levels

L16 (4

4

) to design nitrogen foam profile test, a total

of programs are 16.Using CMG thermal numerical

simulation software to simulation and calculation

the program, there are two ways to simulate foam

flooding in CMG's STARS thermal simulator; the

one is a semi-empirical approach, which simply

reflects the foam's presence by modifying the

relative permeability of the gas phase. The other is

the mechanism method, the use of total balance

model to simulate the formation of foam、burst、

merger 、 transport and other mechanisms. This

method uses the liquid film as a component of the

gas phase, its concentration determines the flow

characteristics of the gas phase, the form of the total

balance model is similar to the material conservation

equation, it divides the unobstructed foam by the

density of the flowing bubbles and the density of

stationary bubbles [the number of bubbles per unit

volume], and affects the apparent viscosity of the

foam by the density of the bubble, considers the

influence of foam on the relative permeability of gas

phase and the apparent viscosity. The static foam

liquid film prevents the pore throats of flowing of

gas; the characteristics of flowing foam are

controlled by such mechanisms as foam rheology,

foam formation, trapping, and merging.

The total balance model: amount of bubble

increase = influx - outflow + net increase of bubble

+ source and sink items.

Nitrogen Foam Profile Control Improves Steam Huff and Puff Development Effect

227

rg g g

gff g f f g f g f g f f

gc

(1 ) ( )

t144

kk M g Z

s

xn s x n p nq x s G C

g

ρ

φφ φ

μ

⎡⎤

∇

⎛⎞

∂

⎡⎤

+− =∇ ∇− ++ −

⎢⎥

⎜⎟

⎣⎦

∂

⎢⎥

⎝⎠

⎣⎦

(1

)

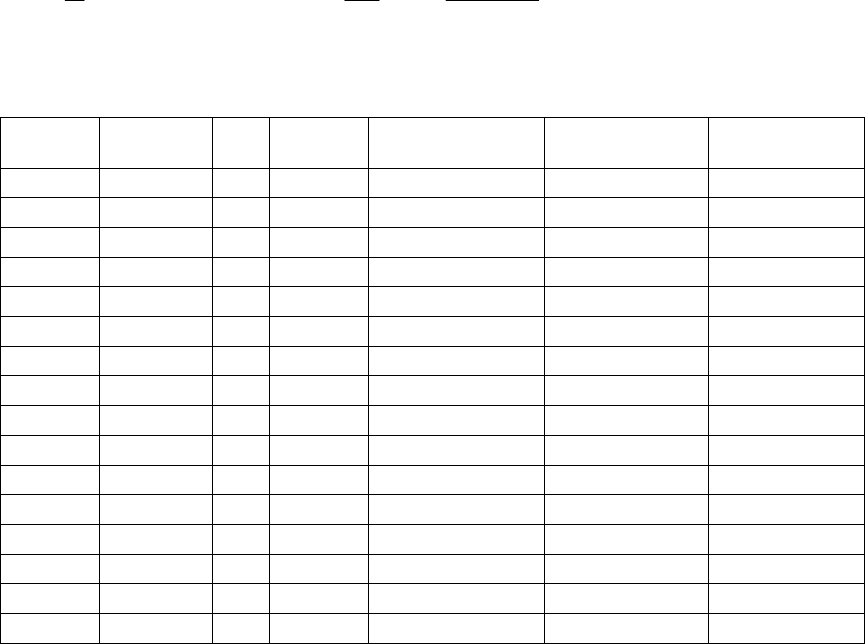

Table 2: Results table of orthogonal experiment.

Scheme Group of

horizontal

PV Gas/liquid

ratio

Cycle steam

injection volume t/m

Foam concentrate-

ion %

Cumulative oil

production t

1 A1B1C1D1 0.1 1:1 80 0.3 593.27

2 A1B2C2D2 0.1 2:1 100 0.4 1035.78

3 A1B3C3D3 0.1 3:1 120 0.5 1270.65

4 A1B4C4D4 0.1 4:1 140 0.6 1362.08

5 A2B1C2D3 0.15 1:1 100 0.5 1356.51

6 A2B2C1D4 0.15 2:1 80 0.6 1343.37

7 A2B3C4D1 0.15 3:1 140 0.3 1104.77

8 A2B4C3D2 0.15 4:1 120 0.4 1067.93

9 A3B1C3D4 0.2 1:1 120 0.6 1422.73

10 A3B2C4D3 0.2 2:1 140 0.5 1414.77

11 A3B3C1D2 0.2 3:1 80 0.4 1283.16

12 A3B4C2D1 0.2 4:1 100 0.3 1097.98

13 A4B1C4D2 0.25 1:1 140 0.4 1409.77

14 A4B2C3D1 0.25 2:1 120 0.3 1418.99

15 A4B3C2D4 0.25 3:1 100 0.6 1302.68

16 A4B4C1D3 0.25 4:1 80 0.5 1221.82

n

f

is the average density of flow bubbles. n

s

is the

average density of still bubbles. x

f

is the fractional

flow of flow gas. x

s

is the fractional flow of

captation gas. G

f

is the bubble production speed. q

g

is the gas injection or output rate. Φ is the porosity.

s

g

is the gas saturation. u

g

is the Darcy flow velocity.

The total balance model is a more

comprehensive description of the various

mechanisms in the process of foam seepage, with

high accuracy. In this study, the mechanism model

was used to simulate the orthogonal experimental

scheme and the following experimental results were

obtained (Table 2).

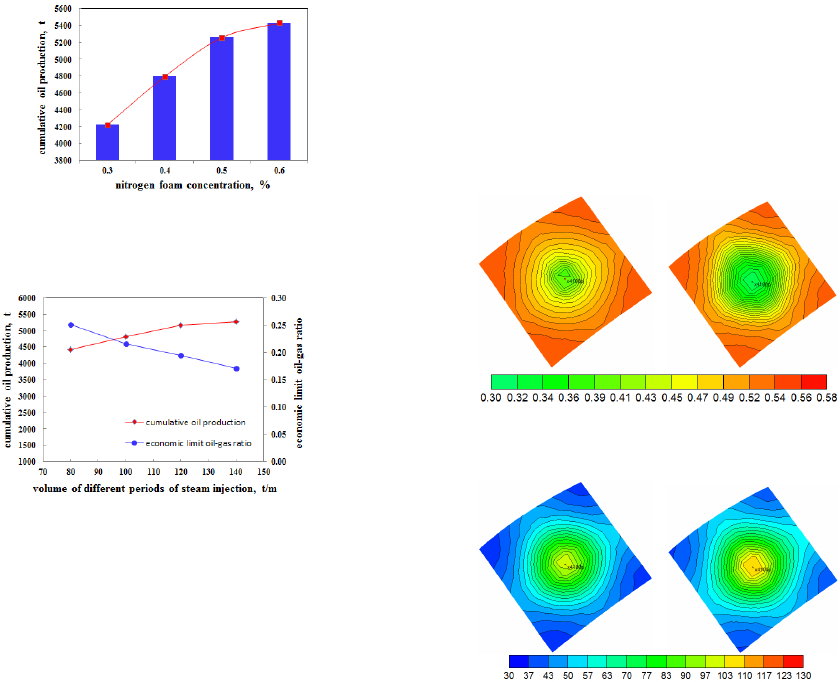

It can be seen from figure 2. With the nitrogen

foam volume increasing, the cumulative oil

production increasing, and the economic cost of

nitrogen foam also continue to increase. When the

nitrogen foam volume is 0.2PV, the trend of

cumulative oil production tends to be flat. When

nitrogen foam volume continued to increase to

0.25PV, the increase of cumulative oil production is

relatively small, so that determines the optimal

nitrogen foam injection is 0.2PV.

It can be seen from figure 3. With the continuous

increase of the gas liquid ratio, the cumulative oil

production increases first and then decreases. When

the gas liquid ratio is small, the amount of foam

produced is less and the foam system is unstable,

which does not fully display the function of profile

control. When the gas liquid ratio is 2: 1, the foam

plugging drive and the function of nitrogen to help

discharge are best. When continue to increase the

proportion of gas liquid ratio, due to poor stability of

the thin foam liquid film, and large doses of nitrogen

easily lead to steam channeling. It is resulted that oil

production is low and the effect of degree of reserve

recovery is poor. So that determines the best gas

liquid ratio is 2: 1.

IWEG 2018 - International Workshop on Environment and Geoscience

228

Figure 2: Effect curve of nitrogen foam injection on

cumulative oil production.

Figure 3: Effect curve of nitrogen foam gas liquid

ratio on cumulative oil production.

Table 3: Optimal case table of 4502 well nitrogen foam profile control.

Layer

Effective

thickness

Pore

volume m³

0.2PV

Bubble

underground

volume(m³)

N2

underground

volume m³

Foam

concentrati

on t

N2 above

ground

volume m³

H3Ⅱ2 4.4 4251.32 850.26 283.42 566.84 1.42 33273.51

H3Ⅱ3 6.6 5822.01 1164.40 388.13 776.27 1.94 45567.05

Total 11 10073.33 2014.66 671.55 1343.11 3.36 78840.56

Table 4: The statistics table of nitrogen foam profile control measures effect.

Cycle

Cycle oil

production (t)

Cycle steam

injection volume(t)

Average daily oil

production (t)

Cycle oil-

gas ratio

1 242.88 1100 2.70 0.22

2 350.49 1100 3.89 0.32

3 313.58 1100 3.48 0.29

4 273.79 1100 3.04 0.25

5 250.50 1100 2.78 0.23

total 1431.23 5500 3.18 0.26

According to the curve between cumulative oil

production and nitrogen foam concentration (Figure

4), with the increase of the concentration, the

cumulative oil production increases. When the foam

concentration is greater than 0.5%, with the foam

concentration continues to increase, the increase of

the cumulative oil production slowed down. As the

foaming agent advances in the strata, the foam

system of the adsorption loss on the rock surface is

occurred, and the liquid film damaged in the process

of profile controlling and oil driving. The stability of

the low-concentration foam system is poor, the

disintegrate speed of liquid film is rapidly, and the

profile controlling and oil driving effect of low-

concentration foaming agent is poor. With the foam

concentration continues to increase, the stability of

the foam system continues to increase. When the

foam concentration reaches 0.5%, the formation of

liquid film has been stable enough. On the basis of

continuing to increase the foam concentration, the

increase of oil production is not obviously.

Nitrogen Foam Profile Control Improves Steam Huff and Puff Development Effect

229

Therefore, the optimum concentration value of

foaming agent is 0.5%.

It can be seen from figure 5. We can find that in

the case of nitrogen foam profile control measures,

when the cycle steam injection volume is between

80t/m-100t/m, the economic limit oil-gas ratio is in

the range of 0.25-0.22. The cycle steam injection

volume is above 120t/m, the economic limit oil-gas

ratio is less than 0.2. Therefore, when the cycle

steam injection volume is 100t/m, the economic

limit oil-gas ratio can be maintained above 0.2 and

the maximum oil production can be obtained at the

same time. So, the cycle steam injection volume of

100t/m is optimized.

In summary analysis, the optimum nitrogen foam

injection parameters are as follows: nitrogen foam

injection volume is 0.2pv, foam concentration is

0.5%, gas-liquid ratio is 2: 1, and cycle steam

injection volume is 100t/m.

Figure 4: Effect curve of nitrogen foam under

concentration on cumulative oil production.

Figure 5: Different periods of gas injection cumulative

oil production, economic vapor ratio curve.

4.3 Development Effect of Nitrogen

Foam Profile Control

According to the optimized optimal nitrogen foam

injection parameters, the nitrogen subsurface usage

is converted to ground consumption according to the

Clapeyron equation. The calibration equations are:

11 1

ZRPV n T= (2)

22 2

ZRPV n T= (3)

According to the 40℃ wellhead temperature, the

surface atmospheric pressure of 0.1MPa, the

subsurface temperature of 100℃, the subsurface

pressure of 7MPa and other data turn to calculation.

That is, the amount of ground nitrogen is equal to

58.7 of the amount of underground nitrogen.(Table 3)

It can be seen from table 4. The oil production

peak of 4502 well was 4.8t in the second rounds,

and after that the daily oil production gradually

decreased with the increase of the profile control

round.

According to the curve of oil saturation variation

and curve of temperature variation(Figure 6-Figure

7), we can find that after 5 rounds of profile control,

the oil saturation value of H3Ⅱ2 oil layers

decreases from 0.43 to 0.37. The oil saturation value

of H3Ⅱ3 oil layers decreases from 0.45 to 0.35. The

average temperature of H3Ⅱ2 oil layers increases

from 50.3℃ to 60.38℃. The average temperature of

H3Ⅱ3 oil layers increases from 51.45℃to 78.41℃.

It is shows that the production measures of nitrogen

foam effectively play the role of profile control and

oil displacement. Meanwhile the production

measures make the steam fully heat the oil layer to

achieve the ideal sweeping effect.

Figure 6: The remaining oil saturation field before or

after profile control.

Figure 7: The temperature field before or after profile

control.

IWEG 2018 - International Workshop on Environment and Geoscience

230

5 CONCLUSIONS

The actual production data of liquid producing

capacity, gas injection volume and water content of

each well are combined. Based on the data of

geological analysis and logging interpretation, 79

wells in XQ-45 block are measured according to the

different parameters such as the remaining oil

saturation and the degree of reserve recovery

establishes the five types remaining oil classification

criteria.

Based on the degree of reserve recovery of the

five type remaining oil wells, the remaining oil

potential evaluation criteria are: the oil wells with

less than 10% degree of reserve recovery have the

high potential of remaining oil, the oil wells with

degree of reserve recovery of 10%-25% have the

medium potential of remaining oil, the oil wells with

more than 25% degree of reserve recovery have the

low potential of remaining oil. It is concluded that

the remaining oil potential of the five heavy oil

wells is as follows: inter-layer differential type>

edge water effected type> fault screened type>

interwell enrichment type> intra-layer differential

type.

According to the inter-layer differential type

remaining oil, the representative well is selected,

and single well geological model is established. The

production status of each layer is combined and the

remaining oil potential is analyzed, the production

plan is designed in layers. Orthogonal test method is

used to carry out the orthogonal experiment design

of the relevant parameters of oil well production

measures. At the same time, the numerical

simulation method is used to carry out numerical

simulation and optimize injection and production

parameters. In this way, combining with the

economic benefit analysis under the current low oil

price, the best solution is obtained by obtaining the

maximum crude output and the economic limit oil

gas ratio greater than 0.2 as the evaluation standard.

Aiming at the high-level intervals in the oil wells

with different layers, then take nitrogen foam profile

control measures to adjust the suction profile, and

optimize the optimal nitrogen foam injection

parameters are: volume of nitrogen foam injection is

0.2pv, foam concentration is 0.5%, gas-liquid ratio

is 2: 1, cycle steam injection volume is 100t/m.

The results show that the oil production is the

largest in the second round of profile control, the

average daily oil production is 3.89t, and the cycle

oil-gas ratio reaches 0.32. On this basis, continue to

increase the profile control round, after the profile

control 5 rounds, the average daily oil production is

3.18t, the average oil-gas ratio is 0.26, the cycle of

cumulative oil production is 1431.23t, and the

program implementation effect is getting better. It

shows that nitrogen foam profile control can

obviously reduce the ineffective and inefficient

channeling of steam in the low remaining oil

saturation zone and improve the development effect

of steam huff and puff.

ACKNOWLEDGEMENTS

This paper is supported by "Thirteenth Five-Year

Plan" National Science and Technology Major

Project (2016ZX05015-002).

REFERENCES

Cao Yanbin, Liu Dongqing and Wang Shantang, et al.

2013 3D physical simulation of steam flooding and

applications in ultra-heavy oil reservoirs of Shengli

oilfield Acta Petrolei Sinica 34(04) 733-739

Cao Zhengquan, Ma Hui and Jiang Na, et al. 2006

Application of nitrogen foam profile control technique

in thermal recovery well in Gudao Oilfield Petroleum

Geologyand Recovery Efficiency 05 75-77+108

Chen Guo, Liao Guangzhi and Niu Jingang 2001 Foam

flow equivalent mathematical model in porous media

Petroleum Geology & Oilfield Development in Daqing

02 72-74+138

Fan Zhicheng, Liu Huiqing and Zhang Hongling, et al.

2009 Laboratory study of nitrogen-foam agents profile

control technology at heavy oil reservoir in Jinglou

Oilfield[J] Oil Drilling & Production Technology

31(02) 74-78

Huseyin Onur Balan 2013 Dynamics of Foam Mobility in

Porous Media The University of Texas at Austin

Islam M R 1989 Mechanics of foam flow in porous media

and applications The Journal of Canadian Petroleum

Technology 12(8) 88-96

Islam M R, MacDonald T A and Farouq S M Ali, et al.

1989 Experimental and numerical study of foam flow

through porous media[A]. Proc. Of the Thrid

International Symposium on EOR Maracaibo,

Venezuela 144-163

Li Zhaomin, Li Binfei and Xu Yonghui, et al. 2007 Study

on the flow-diversion characteristics of foam and its

application Journal of Xi’an Shiyou University(Natural

Science Edition) 02 100-102+106+179

Malcolm Greaves 2004 Air injection-improved oil

recovery strategy for the UK continental shelf The Oil

& Gas Review 34(3) 118-121

Nitrogen Foam Profile Control Improves Steam Huff and Puff Development Effect

231

Rossen W R and Zhou Z H 1994 Modeling Foam Mobility

at the Limiting Capillary LA, Sept. 26-28

Tian Xin 2015 Study on microscopic mechanism and

factors affecting the sealing characteristics for nitrogen

foaming flooding Bulletin Of Science and Technology

31(03) 93-96

Wang Binyu and Zhang Jun 2007 Application of nitrogen

foam profile control technology in saibei oilfield Sino-

Global Energy 04 63-67

Yang Guanglu, Lin Yuqiu and Liu Jialin, et al. 2004 Study

on adaptability of nitrogen foam flooding to heavy oil

reservoir in liaohe oilfield Xinjiang Petroleum Geology

02 188-190

Yang Lei 2014 The research and application of nitrogen

foam conformance treatments optimal design method

Yangtze University

Zhang Liehui, Hu Yong and Tu Zhong, et al. 2000 Foam

flooding experience model and its application Journal

of Southwest Petroleum Institute 03 50-52+3-2

Zhang Sifu, Liao Guangzhi and Zhang Yanqing, et al.

2001 Experimental study on Daqing oilfield foam

compound flooding pilot mine Acta Petrolei Sinica 01

49-53+5-4

Zhang Zhongping, Liu Xiaobo and Li Changheng, et al.

2012 Nitrogen foam improves steam huff and puff

development research on numerical simulation

technology Sino-Global Energy 17(01) 61-65

Zhang Zhongyi, Zhou You and Shen Dehuang, et al. 2012

Physical modeling experiments on steam nitrogen

foam flooding for a vertical and horizontal well

combination Acta Petrolei Sinica 33(01) 90-95

Zhao Renbao, Yue Xiang’an and Ke Wenqi, et al. 2009

Study on influence factors for stability of nitrogen

foam system Acta Petrolei Sinica 30(01) 84-87+91

Zhou Guohua, Song Xinwang and Wang Qiwei, et al.

2006 Application of foam combination flooding in

Shengli Oilfield Petroleum Exploration and

Development 03 369-373

IWEG 2018 - International Workshop on Environment and Geoscience

232