Study on the Purification Process of Arsenic High Iron Wastewater

from Zinc Smelter

Haoen Zuo, Jiankang Wen

*

, Biao Wu, Xinglan Cui, He Shang and Wencheng Gao

National Engineering Laboratory of Biohydrometallury, General Research Insitute for Nonferrous Metals, Beijing 10080,

China.

Email: kang3412@126.com.

Keywords: Wastewater; reducing agent, purification, efficiency, complex salt flocculant

Abstract:

Arsenic high iron wastewater was produced by sulfated roasting-water leaching process from the zinc

smelting industry, high contents of total iron, zinc ion and sulfate ion, were contained, a certain amount of

arsenic ion, copper ion and cadmium ion were also involved. With strict environmental protection, the

comprehensive utilization of wastewater has great economic significance, it is one of the most important

direction that the preparation of iron-salt flocculant with wastewater. It is necessary to pretreat and purify

firstly. In this paper, the sample comes from Chihong Inner Mongolia, China. The concentrations of total

iron, sulfate ion and zinc ion are 24.18 g/L, 91.31 g/L and 5.54 g/L, respectively. The effect of reducing

agent proportion, temperature, stirring speed on the purification of arsenic ion, copper ion, cadmium ion was

researched. The optimal conditions are: reducing agent proportion of 1% of iron powder, 2% of zinc powder,

temperature of 60 ℃, and stirring speed of 800 rpm. Under the conditions, the efficiency of arsenic ion,

copper ion and cadmium ion all reached 99.99%. The concentrations of total iron, sulfate ion and zinc ion in

the wastewater after purification are 55.23 g/L, 126.25 g/L and 39.00 g/L, respectively, which provided the

precondition for the subsequent preparation of iron-salt flocculant.

1 INTRODUCTION

Arsenic high iron wastewater was produced by

sulfated roasting-water leaching process from the

zinc smelting industry(Fu and Wang, 2011)(Zhao et

al., 2012). The main features of this type of

wastewater was high iron content, which was

generally up to 30-60 g/L; strong acidity, pH value

between 1-4; sulfate ion mass concentration up to

thousands of milligrams per liter; at the same time,

contains trace amounts of arsenic ion, copper ion,

cadmium ion and so on(Ozverdi, 2006)(Tang, 2010).

Arsenic high iron wastewater treatment methods

were neutralization precipitation method, sulfide

precipitation method, ion exchange method, iron

reduction method and biological flocculation

method(He et al., 2013; Huisman, 2006; Yang et al.,

2014; Huo et al., 2009; Greenleaf et al., 2006; Liu,

2016). Among them, the industrial application was

still extensively used in the neutralization

precipitation method, which has the advantages of

low cost and simple process The main problem was

the large amount of slag, secondary pollution

problem(Meng and Geng, 2013)(Gao and Sheng,

2015).

The use of arsenic high iron wastewater for

preparation of iron and zinc complex salt flocculant

has good industrial application prospects(Busetti et

al., 2005; Jong and Parry, 2003; Song, 2016).

However, the resource utilization of the kind of

wastewater was limited for arsenic ion, copper ion,

cadmium ion. To prepare iron and zinc complex salt

flocculant by using the wastewater, firstly, it was

necessary to purificate(He et al., 2012)(Li et al.,

2010). In this paper, arsenic high iron wastewater

was used as research object, which come from

Chihong Smelting Plant in In Nei Mongol Province,

China. Iron powder and zinc powder were used as

reduing agent, arsenic ion, copper ion, cadmium ion

and other impurities were purified. Different factors

on the efficiency of arsenic ion, copper ion,

cadmium ion were researched, which included

adding proportion of reducing agent, reaction

temperature and stirring speed.

Zuo, H., Wen, J., Wu, B., Cui, X., Shang, H. and Gao, W.

Study on the Purification Process of Arsenic High Iron Wastewater from Zinc Smelter.

In Proceedings of the International Workshop on Environment and Geoscience (IWEG 2018), pages 189-193

ISBN: 978-989-758-342-1

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

189

2 MATERIAL AND METHODS

2.1 Material

The arsenic high iron wastewater was obtained from

Chihong Smelting Plant in In Nei Mongol Province,

China. The chemical multi-elemental analysis was

detected by ICP-OES, the product model is Agilent

725-ES. The results are shown in Table 1. The

sample contains 46.35 mg/L cadmium ion, 453.74

mg/L arsenic ion, 260.5 mg/L copper ion, 91310

mg/L sulfate ion, 5540 mg/L zinc ion, 24180 mg/L

total iron.

2.2 Experimental Method

Purification experiment was performed in 500 mL

beaker containing 200 mL solution. The content of

arsenic ion, cadmium ion, copper ion, total iron, zinc

ion, and sulfate ion in the solution was measured by

ICP-OES.

(1) Effect of reducing agent proportion

The reactor was set to temperature 60 ℃, time 4

h, stirring speed 800 rpm. The addition amount of

the reducing agent was 3%(ω/ν) of iron, 2%(ω/ν) of

iron and 1%(ω/ν) of zinc, 1.5%(ω/ν) of iron and zinc,

1%(ω/ν) of iron and 2%(ω/ν) of zinc, 3% (ω/ν) of

zinc.

(2) Effect of stirring speed

The reactor was set to temperature 60 ℃, time 4

h, iron 2% (ω/ν) and zinc 1% (ω/ ν). The stirring

speed was 400 rpm, 600 rpm, 800 rpm, 1000 rpm.

(3) Effect of temperature

The reactor was set to time 4 h, stirring speed

800 rpm, reducing agent iron 2%(ω/ν) and zinc

1%(ω/ν). The temperature was 20 ℃, 40 ℃, 60 ℃,

80 ℃.

3 RESULTS AND DISCUSSION

3.1 Effect of Reducing Agent

Proportion

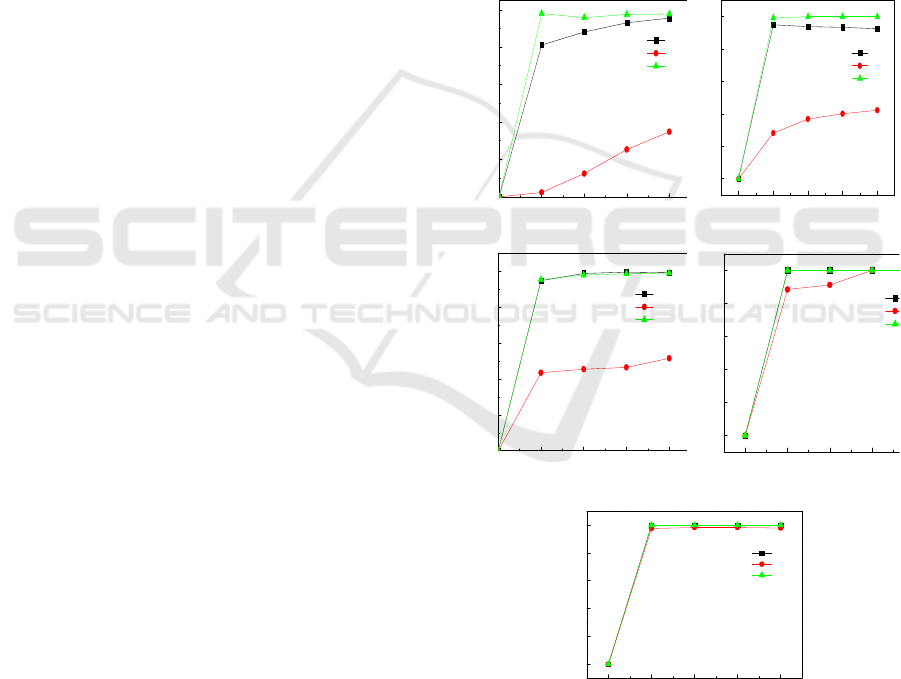

Figure 1 shows the efficiency of arsenic ion, copper

ion, and cadmium ion under different reducing agent

proportion. As shown in Figure 1(a)(b)(c)(d)(e), the

efficiency of arsenic ion, copper ion and cadmium

ion increase firstly then remain stable. Under the

condition of iron powder 3%, copper ion efficiency

was 98.03% in the first hour, finnaly, arsenic ion

and cadmium ion efficiency were 95.64%, 34.81%.

Adding 3%(ω/ν) iron powder has good removal

effect on copper ion and arsenic ion, however

removal effect on cadmium ion was poor with

efficiency of only 34.81%. Under the condition of 2%

(ω/ν), iron powder added with 1% (ω/ν) zinc powder,

the copper ion efficiency was less affected, and the

copper ion efficiency reached 99.24% in first hour, it

increased by 1.21 percentage points compared to

iron 3%, and the addition of zinc powder accelerated

the efficiency of arsenic ion, the efficiency of

arsenic ion was basically identical, the efficiency of

cadmium ion was 42.23%, which was obviously

higher than that without zinc powder, Zinc have a

good impact on the removal of cadmium ion.

01234

0

20

40

60

80

100

(a)

Iron 3%

Removal

efficiency

/

%

Time/h

As

Cd

Cu

12345

0

20

40

60

80

100

R

emova

l

e

ffi

c

i

ency

/%

Iron 2%

Zinc 1%

As

Cd

Cu

Time/h

(b)

0

20

40

60

80

100

Removal

efficiency

/

%

Iron 1.5%

Zinc 1.5%

3

4

As

Cd

Cu

Time/h

1

2

(c)

0123

0

20

40

60

80

100

Removal

efficiency/%

I

Z

Time/h

(d)

01234

0

20

40

60

80

100

Removal efficiency/%

(e)

Zinc 3%

As

Cd

Cu

Time/h

Figure 1: Arsenic ion, copper ion and cadmium ion

efficiency with different iron and zinc addition ratios.

(a) iron powder 3% (b) iron powder 2%, zinc powder 1%

(c) iron powder, zinc powder 1.5%d) iron powder 1%,

zinc powder 2% e) zinc powder 3%.

IWEG 2018 - International Workshop on Environment and Geoscience

190

Table 1: Chemical multi-elemental analysis of arsenic high iron wastewater (concentration, mg/L).

As

3+

Ca

2+

Cd

2+

Cu

2+

TFe K

+

Mg

2+

Na

+

SO

4

2-

Zn

2+

453.74 0.48 46.35 260.5 24180 0.07 0.05 0.02 91310 5540

As shown in Figure 1 (c)(d)(e), the efficiency of

copper ion and arsenic ion have little impact with

the increase of zinc powder addition, copper ion and

arsenic ion efficiency reached 99.99% in first hour,

and the efficiency of cadmium ion was shown an

increasing trend. While the amount of zinc powder

added was 1.5% (ω/ν), the efficiency of cadmium

ion was 51.67%. The addition of 2%(ω/ν) zinc

powder of cadmium ion efficiency reached 99.99%

in the third hour. Cadmium ion efficiency got faster

under the condition of 3% zinc, it reached 99.99% in

the first hour.

As a result, while reducing agent was only iron

powder, arsenic ion and copper ion efficiency was

good, cadmium ion efficiency was poor. With the

increase addition of zinc powder, copper ion

efficiency was less effected, arsenic ion efficiency

can be accelerated to a certain extent. However,

cadmium ion efficiency was effected greatly, the

final efficiency reached 99.99%.

In the selection of addition of iron and zinc

powder, due to the industrial price of zinc is much

more expensive than iron, and combined with the

follow-up preparation of iron-zinc composite salt

flocculant, the agent proportion was iron 2% (ω/ν),

zinc 1% (ω/ ν), the reaction time was 3 h

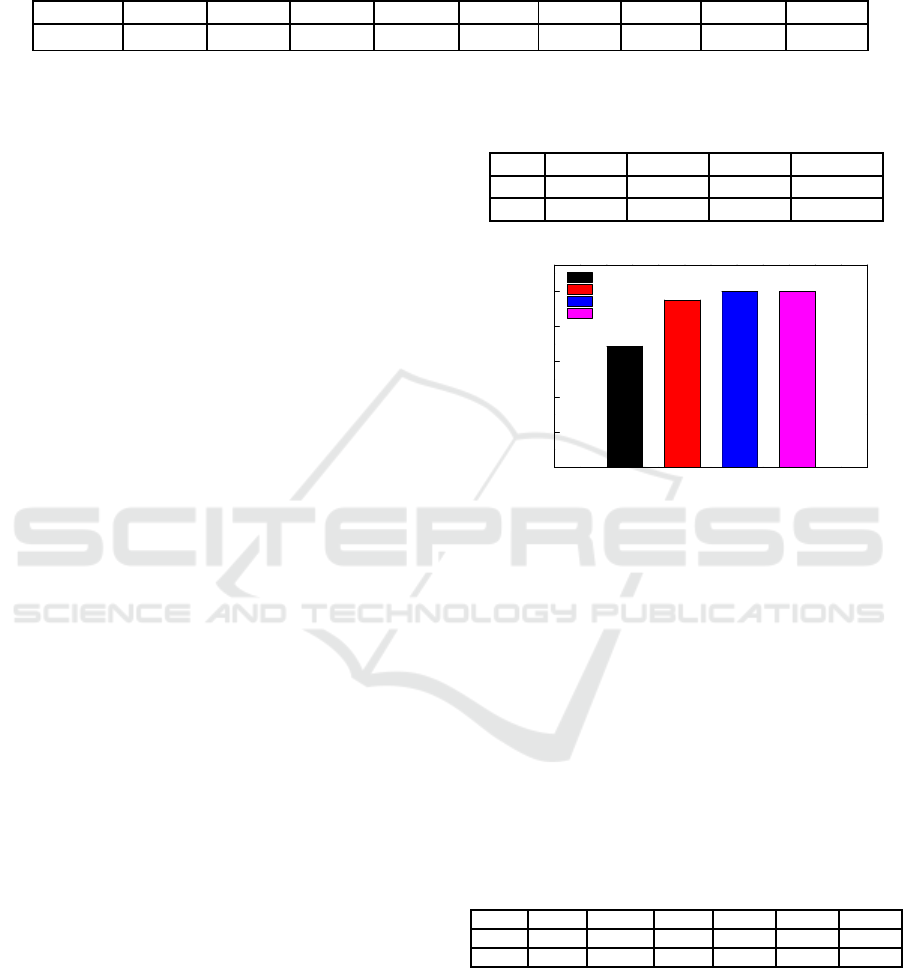

3.2 Effect of Stirring Speed

The effect of stirring speed on the efficiency of

cadmium ion was shown in Figure 2. As can be seen

from Figure 2, with the increase of stirring speed,

the efficiency of cadmium ion was gradually

increased. After the stirring speed was increased to

800 rpm, the cadmium ion

efficiency reached

99.99%. The effect of stirring speed on the

efficiency of copper ion and arsenic ion was shown

in Table 2. It can be seen from that the stirring speed

has little effect on the efficiency of copper ion and

arsenic ion. The increase of stirring speed increased

the removal of cadmium ion, but had no obvious

effect on the efficiency of copper ion and arsenic ion.

In summary, stirring speed was 800 rpm.

Table 2: Effect of stirring speed on copper ion and arsenic

ion efficiency (efficiency/%).

400 rpm 600 rpm 800 rpm 1000 rpm

Cu

2+

99.99 99.99 99.99 99.99

As

3+

99.99 99.99 99.99 99.99

0

20

40

60

80

100

1000

800

600

Cd

2+

removal efficiency/%

400 rpm

600 rpm

800 rpm

1000rpm

400

Stirring speed/rpm

Figure 2: cadmium ion efficiency with different stirring

speed.

The chemical elemental analysis of the purified

solution was shown in Table 3. It can be seen from

Table 3 that the total iron concentration of the

purified solution was significantly increased from

initial iron concentration of 24.18 g/L to final of

45.25 g/L. And the concentration of zinc ion was

31.07 g/L, which was significantly higher than the

initial 5.54 g/L. It was worth noting that the content

of arsenic ion, copper ion, and cadmium ion was

lower after purifying, which meets the National

standards.

Table 3: Chemical multi-element analysis of the purified

solution (concentration, mg/L).

TFe SO

4

2

-

Zn

2

+

Cu

2

+

As

3

+

Cd

2

+

Initial 24180 91310 5540 260.5 453.73 46.35

Final 45250 120090 31070 0.0001 0.0001 0.0001

3.3 Effect of Temperature

The effect of reaction temperature on cadmium

ion removal rate was shown in Figure 3. As was

seen from Figure 3, cadmium ion efficiency

increased with the increase of reaction temperature.

When the reaction temperature was 20 ℃, the

Study on the Purification Process of Arsenic High Iron Wastewater from Zinc Smelter

191

efficiency of cadmium ion was only 76.49%. When

the temperature was increased to 40 ℃, the

efficiency of cadmium ion was increased to 98.12%.

After the temperature was increased to 60 ℃, the

efficiency of cadmium ion reached 99.99%.

The influence of reaction temperature on copper

ion

and arsenic ion efficiency was shown in Table 4.

It can be seen from Table 4 that the reaction

temperature has little effect on the efficiency of

copper ion and arsenic ion. The increase of reaction

temperature increased the removal of cadmium ion

by iron powder and zinc powder, but had no obvious

effect on the removal of copper ion and arsenic ion.

In summary, the reaction temperature was selected

60

0

20

40

60

80

100

Cd

2+

removal efficiency/%

20 ℃

40 ℃

60 ℃

80 ℃

20

40

60

80

Temperature/℃

Figure 3: Cadmium ion efficiency with different

temperature.

Table 4: Effect of temperature on copper ion and arsenic

ion efficiency (efficiency/%).

20 ℃ 40 ℃ 60 ℃ 80 ℃

Cu

2+

99.99 99.99 99.99 99.99

As

3+

99.99 99.99 99.99 99.99

The chemical multi-elemental analysis of the

solution after purification at 60 °C was shown in

Table 5. It can be seen from Table 3 that the

concentration of total iron, zinc ion and sulfate ion

in purified solution were respectively 55.23 g/L,

39.0 g/L and 126.25 g/L. It was worth noting that the

content of arsenic ion, copper ion and cadmium ion

in the purified solution was relatively low, which

also meets the National standards.

Table 5: Chemical multi-element analysis of the purified

solution(concentration, mg/L).

TFe SO

4

2

-

Zn

2

+

Cu

2

+

As

3

+

Cd

2

+

Initial 24180 91310 5540 260.5 453.73 46.35

Final 55230 126250 39000 0.0001 0.0001 0.0001

4 CONCLUSIONS

Adding iron powder as reductant without zinc,

arsenic ion, copper ion efficiency was good, the

removal rate reached 99.37%、99.17%, however,

cadmium ion removal rate was poor, the removal

rate of only 51.67%. cadmium ion removal rate can

be greatly improved by adding zinc powder , which

reached 99.99% under the condition of 1% zinc;

The best purification conditions are: iron powder

1%, zinc powder 2%, reaction temperature 60 ℃,

stirring speed 800 rpm. Under this condition, arsenic

ion, copper ion, cadmium ion content comply with

national emission standards;

After purification, the concentrations of total

iron, sulfate ion and zinc ion were 55.23 g/L, 126.25

g/L and 39.00 g/L, respectively, which provided the

precondition for the subsequent preparation of iron

and zinc complex salt flocculant.

REFERENCES

Busetti F, Badoer S, Cuomo M, et al. 2005Occurrence and

Removal of Potentially Toxic Metals and Heavy

Metals in the Wastewater Treatment Plant of Fusina [J].

Industrial & Engineering Chemistry Research 44(24)

9264

Fu F, Wang Q 2011 Removal of heavy metal ions from

wastewaters: a review[J] Journal of Environmental

Management 92(3) 407

Cao X L, Sheng Y X 2015 Research Progress in

Biological Treatment of Wastewater Containing

Sulfate Heavy Metals[J] Environmental Science and

Technology s2 181

Greenleaf J E, Lin J C, Sengupta A K 2006 Two novel

applications of ion exchange fibers: Arsenic removal

and chemical-free softening of hard water[J].

Environmental Progress 25(4) 300

He Y C, Li X Z, Zhou Q J. 2013 Practice of treatment of

copper-containing acidic wastewater by sulfide

precipitation method[J] Sulfuric Acid Industry 06 51

He Z, Li Y, Yu G, et al. 2012 Preparation of polyferric

aluminum sulfate from pyrite wastewater treatment

sludge[J] Chinese Journal of Environmental

Engineering 6(7) 2437

Huisman J L S G 2006 Biologically produced sulphide for

purification of process streams, effluent treatment and

recovery of metals in the metal and mining industry.[J]

Hydrometallurgy 83 56

Huo J X, Guo Y, Wang Z 2009 Review and Prospect of

Arsenic (III) Water Treatment Technology[J]

Environmental Science and Technology 11 102

Jong T, Parry D L 2003 Removal of sulfate and heavy

metals by sulfate reducing bacteria in short-term bench

IWEG 2018 - International Workshop on Environment and Geoscience

192

scale upflow anaerobic packed bed reactor runs[J].

Water Research 37(14) 3379

Li Y, Xu M X, Lin C M 2010 Process for preparing iron

black pigment from pyrite wastewater[J] Chemical

Industry and Engineering Progress 29(1) 168

Liu Z C 2016 Research on resource utilization technology

of pickling waste liquid in iron and steel enterprises [D]

Xiangtan: Xiangtan University

Meng B, Zhai C Z 2013 Research progress in the

treatment of arsenic-containing wastewater by

microbial treatment[J] Water Treatment Technology

39(11) 5

Ozverdi A E M 2006 Cu

2+

, Cd

2+

and Pb

2+

adsorption from

aqueous solutions by pyrite and synthetic iron

sulphide.[J] J. Hazard. Mater 137 626

Song J 2016 Preparation and properties of novel organic-

inorganic flocculants [D] Tianjin: Tianjin Polytechnic

University

Tang Z Y 2010 Study on wastewater treatment of heavy

metals and arsenic [D] Lanzhou: Lanzhou University

Yang Z C, Zhu L J, Liu R P, et al. 2014 Treatment method

and economic evaluation of strong acid high

concentration arsenic wastewater[J] Journal of

Environmental Engineering 06 2205

Zhao J Y, Wang J S, Zheng J 2012 Current Status of

Treatment and Disposal Technology of Arsenic-

Containing Wastewater and Waste Slag[J] Journal of

Beijing Normal University(Natural Science) 48(3) 287

Study on the Purification Process of Arsenic High Iron Wastewater from Zinc Smelter

193