Application of TiO2/Bentonite on the Catalytic Pyrolysis of Oil

Sludge

Feifei Wang

1

, Penghui Yang

1

,Xuan Qu

1

, Mingming Du

1

and Chengtun Qu

1,2*

1

College of Chemistry and Chemical Engineering, Xi’an Shiyou University,Xi’an 710065, P. R. China

2

State Key Laboratory of Petrochemical Pollution Control and Treatment,Beijing 102206,P.R.China

Email:xianquct@xsyu.edu.cn

Keywords: Oily Sludge, catalyst (TiO2/bentonite), catalytic pyrolysis

Abstract: Oil sludge is one of the hazardous wastes produced in the processes of petroleum exploitation, refining,

transportation and storage. Implementing the harmless and resource treatment of oily sludge is an urgent

problem to be solved. In this paper, TiO2/bentonite was prepared by sol-gel method, and then was

characterized by scanning electron microscope, X-ray diffraction, Infrared Spectroscopy.The effect of

TiO2/bentonite on improving the yields of oil product was studied. As a result, the oil recovery yield

increased from 86.63%w/w to 95.69%w/w. The oil quality is improved compared with no catalyst after the

TiO2/bentonite was added in the oil sludge.

1 INTRODUCTION

Oily sludge is an oily solid waste which generated

from the oil exploration, transportation, refining, and

oily sewage treatment plants. At present, China

produces about 30 million tons of oil sludge per

year, and hundreds of millions of tons of sludge are

dumped, causing extremely serious pollution to the

soil and groundwater. The main ones are the sludge

and oil sand produced during the petrochemical

industry, which have the characteristics of large

production volume, high oil content, high heavy oil

component, less comprehensive utilization methods,

and difficult processing (Yue and Li, 2010). Oily

sludge generally contains a large amount of benzene,

phenol, hydrazine and other substances, which are

also accompanied by toxic substances and

radioactive elements. If improper treatment of oily

sludge, it will not only pollute the environment,

endanger humans, animals and plants, but also cause

the waste of recyclable resources of the oil sludge

(Liu et al., 2013). Therefore, it is urgent to realize

the resource and harmless treatment of oily sludge.

The common treatment methods for oily sludge

include incineration, conditioning, separation,

solvent extraction, electrochemical treatment, and

pyrolysis. The pyrolysis of the sludge (Wang and

Zou, 2004) as an emerging process technology,

bases on the thermal instability of the organic matter

in the sludge and decomposes the organic matter to

gas, liquid fuel, and carbon under the condition of

the atmosphere without oxygen. Pyrolysis has the

advantages of thorough treatment, better effect of

reducing volume, low secondary pollution, and

energy recovery. It is a treatment method that can

effectively make the sludge resource, reduce, and

harmless (Wang and Zou, 2004). In terms of the role

of mesoporous molecular sieve catalysts in catalytic

cracking of heavy oils , it is proposed that bentonite-

loaded titanium catalysts should be used in the

pyrolysis of oil sludge to explore new ideas for the

influence of pyrolysis temperature, oil recovery rate

and carbon residue during pyrolysis. Yan Li and

other authors have reported:Influencing factors for

catalytic pyrolysis of oily sludge and analysis of

pyrolysis products.

2 EXPERIMENTAL SECTION

2.1 Experimental Reagents

Butyl phthalate. Anhydrous ethanol. Distilled water,

acetic acid. Bentonite. Petroleum ether. The reagents

used were all analytically pure reagents. The

experimental water used was deionized water.

62

Wang, F., Yang, P., Qu, X., Du, M. and Qu, C.

Application of TiO2/Bentonite on the Catalytic Pyrolysis of Oil Sludge.

In Proceedings of the International Workshop on Environment and Geoscience (IWEG 2018), pages 62-67

ISBN: 978-989-758-342-1

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2.2 Preparation of Bentonite Loaded

TiO2 Catalyst

25 mL of anhydrous ethanol and 1mL of butyl

titanate were mixed at room temperature, and stirred

for 1 hour to obtain solution A. 2 mL of glacial

acetic acid was added to 10 mLof absolute ethanol

and mixed thoroughly to form solution B; solution B

was slowly added dropwise to solution A under

magnetic stirring, and solution C was obtained after

homogeneous mixing.2g of bentonite was weighed

into solution C and stirred, then 8 ml of distilled

water was added dropwise, and stirred until the gel.

The gel was washed with deionized water, suction

filtered, dried in an incubator at 80°C, and calcined

at a temperature of 500°C for 3 hours. The resulting

white powder is denoted as TiO

2

/bentonite (1)(

Dong et al., 2013). The amount of butyl titanate is

increased by one times and the other conditions are

unchanged.The resulting white powder is denoted as

TiO

2

/bentonite (2).

2.3 Characterization of Catalyst TiO2 /

Bentonite

Scanning electron microscopy (SEM) with EDAX

; Fourier transform infrared spectroscopy (FTIR)

analysis. The catalyst was subjected to XRD

analysis.

2.4 Catalytic Pyrolysis Experiment of

Oily Sludge

The catalyst and oily sludge were mixed and placed

in a pyrolysis furnace, treated at a certain

temperature for a period of time, the oil recovery

rate was investigated, and the influence of the

catalyst on the pyrolysis was examined. The

experimental conditions were as follows: nitrogen

flow rate 100 mL·min

-1

, temperature 450 ℃ ,

pyrolysis time 4 h, heating rate 10℃·min

-1

, catalyst

TiO

2

/bentonite addition 1%.

The oil recovery rate X is calculated according to

the following formula:

X = W

1

/W × 100% (1

)

In the formula: W

1

is the recovered oil quality, g;

W is the oil quality in the sludge, g.

3 RESULTS AND DISCUSSION

3.1 Features of the Catalyst

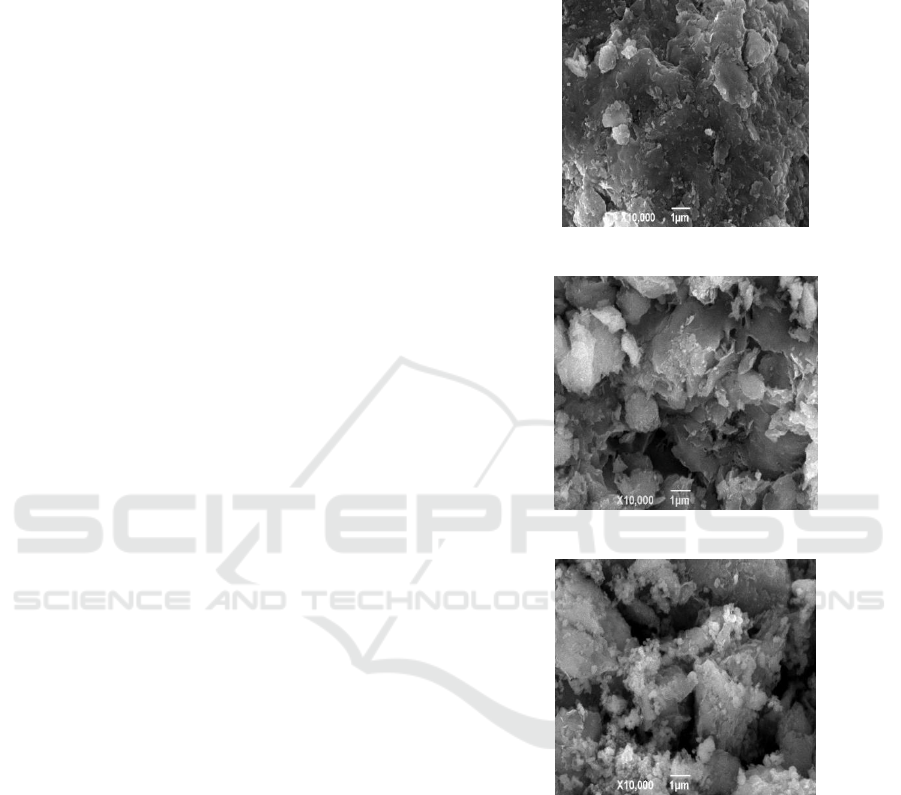

a. Bentonite

b. TiO

2

/ bentonite (1)

c.TiO

2

/ bentonite (2)

Figure 1: SEM image of Bentonite and TiO2 /bentonite.

3.1.1 Morphological Features

Figure 1 is a SEM image of the support bentonite,

the catalyst TiO

2

/bentonite (1) and the TiO

2

/bentonite (2).It is shown that TiO

2

/bentonite and

carrier Bentonite have little change in morphology.

But TiO

2

/bentonite is flaky, this feature can

effectively increase the catalytic specific surface

area.Increase the area of contact with oily sludge to

improve the catalytic effect.

Application of TiO2/Bentonite on the Catalytic Pyrolysis of Oil Sludge

63

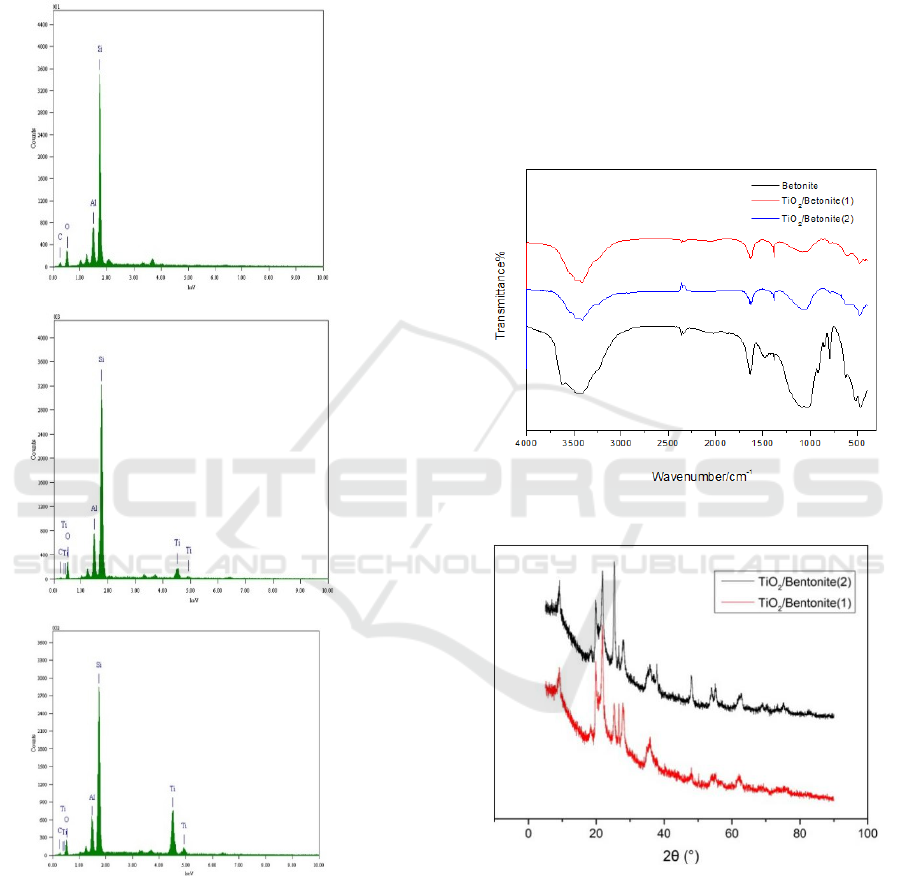

Figure 2 is spectrum elemental analysis diagram

of bentonite, TiO

2

/bentonite (1), and TiO

2

/bentonite

(2).We can see that the samples contain Ti, which

indicates that TiO

2

was successfully supported on

bentonite. In addition, the relative peak value of Si

decreases with the increase of titanium oxide load.

a. bentonit

b. TiO

2

/ bentonite (1)

C.TiO

2

/ bentonite (2)

Figure 2: EDAX of Bentonit and TiO2 /bentonit.

3.1.2 Infrared Spectral Analysis

The infrared spectrum of supported and unsupported

bentonite is shown in Figure 3. It can be seen the

OH stretching vibration of Si-OH-Al in

montmorillonite structure nearby 3630 cm

-1

. It also

can be seen the O-H stretching vibration of adsorbed

water in the interlayer of montmorillonite structure

nearby 3439 cm

-1

. It had stretching vibration band of

O-H near 1642 cm

-1

, and the peak near 1035 cm

-1

is

attributed to the asymmetry bending stretching of Si-

O-Si . The bending vibration absorption peak of Si-

O-Al near 519 cm

-1

, the peak near 1407 cm

-1

is

attributable to the bending stretching of Si-O-Si.

After supported in IR, the peak near 500-700 cm

-1

is

attributable to the bending stretching of Ti-O. The

results revealed that TiO

2

were inserted into

bentonite's layers (Wang et al., 2015).

Figure 3: IR spectrums of bentonite and TiO2 /bentonite.

Figure 4: XRD of TiO2/bentonite.

3.1.3 X-ray diffraction Pattern

Characteristics

A wide-angle XRD spectra of TiO

2

/bentonite (1) and

TiO

2

/bentonite (2) is shown in Figure 4. The anatase

phase of the corresponding diffraction peaks ( 101) ,

( 004) , ( 200) , ( 105) , ( 211) appeared at 2θ = 25.

2°, 37. 8°, 48. 1°, 54. 0° and 55. 2° in both samples.

IWEG 2018 - International Workshop on Environment and Geoscience

64

Rutile phase diffraction peak does not appear.

Shown that the sample has only an anatase phase ,

without rutile phase (Zhang et al., 2014).

TiO

2

/bentonite (1) and TiO

2

/bentonite (2) were

characterized by XRD and the interlayer distance of

them obviously increased. It can be seen from the

figure that the interlayer spacing of TiO

2

/bentonite

(2) is larger than that of TiO

2

/bentonite (1), and the

number of diffraction peaks is increasing. The

results revealed that TiO

2

were inserted into

bentonite's layers.

3.2 Study on Factors Affecting

Pyrolysis of Oily Sludge

3.2.1 Effect of Catalyst Types on the Effect

of Pyrolysis Treatment

The pyrolysis experiments were performed on the

two catalysts at an addition of 1%. The results are

shown in Table 1.

Table 1: Effect of catalyst type

a

.

Catalyst type No

catalyst

TiO

2

/

bentonite

(1)

TiO

2

/bentonite

(2)

Nitrogen flow rate /

(mL·min

-1

)

100 100 100

Temperature

/

℃

450 450 450

Pyrolysis time/h 4 4 4

Heating rate / (℃·

min

-1

)

10 10 10

Oily sludge quality/g 20.07 20.03 20.05

Recovered oil/g 2.85 3.08 3.15

Oil recovery yield/% 86.63 93.90 95.74

Effect of catalyst types on pyrolysis treatment

It is shown from table 1 that the recovery rate of

pyrolysis sludge without catalyst is lower than that

of TiO

2

/bentonite (1) and TiO

2

/bentonite (2). And

the catalytic effect of TiO

2

/bentonite (2) is more

excellent, this is because not only is the titanium

content in TiO

2

/bentonite (2) higher than

TiO

2

/bentonite (1), but also TiO

2

/bentonite (2) is

larger than the surface of TiO

2

/bentonite (1),

increased the contact area of the reaction. This is

consistent with the results of the previous analysis.

3.2.2 Effect of Catalyst Addition on

Thermal Treatment Effect

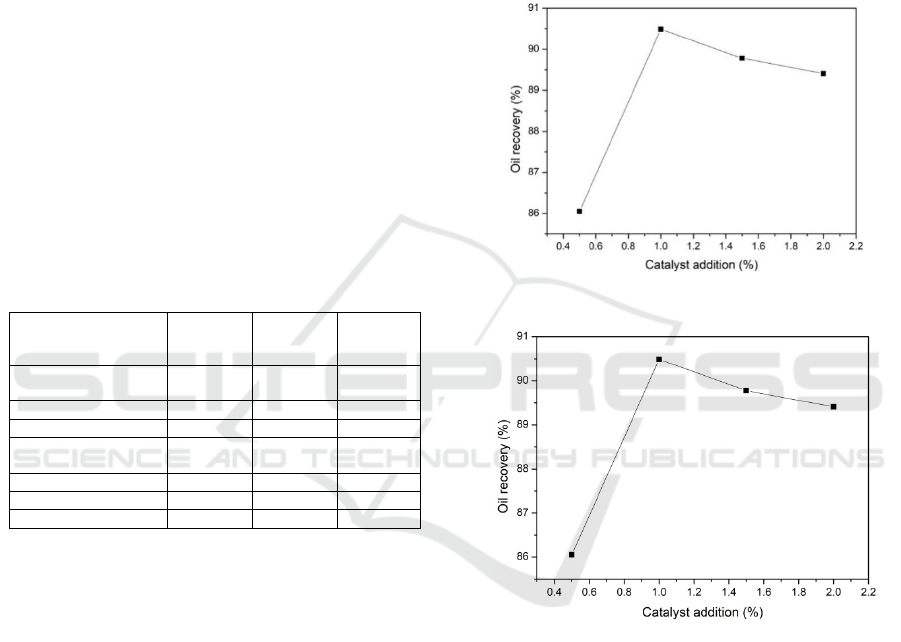

From Figure 5, we can see that the oil recovery rate

increases with the increase of catalyst addition

amount when the catalyst addition is between 0.5%-

1.0%, and it increases from 86.05% to 90.49%;

When the amounts of catalyzer are more than 1%,

the increase of catalyst has little effect on oil

recovery. This is mainly because the oil content of

oily sludge is low, when the amounts of catalyzer

1%, oil recovery rate has reached over 90%, the

activity of the catalyst has been fully played.

Considering the cost of the catalyst, when the

optimum amounts of catalyzer 1%, the oil recovery

rate is the highest.

Figure 5: Effect of catalyst dosage on oil recovery yield.

Figure 6: Effect of pyrolysis temperature on oil recovery

yield.

3.2.3 Influence of Pyrolysis Temperature on

Pyrolysis Treatment

The pyrolysis time was 4 h, the nitrogen flow was

100 mL/min, and the amount of catalyst added was

1%. The effect of temperature on pyrolysis of oil-

containing sludge was investigated. Figure 6 shows

the results.

From Figure 6, we can see that the oil recovery

rate increases obviously with the increase of reaction

temperature when the temperature between 400-420

℃, and it increases from 80.40% to 94.14%, but the

recovery rate of sludge pyrolysis oil decreased when

Application of TiO2/Bentonite on the Catalytic Pyrolysis of Oil Sludge

65

the temperature over 420℃, Because the oily sludge

does not occur pyrolysis reaction at lower

temperatures, when the temperature gradually

increased, macromolecular organic compounds

began to pyrolysis into some small molecules, oil

recovery rate gradually increased, as the temperature

continues to rise, macromolecular pyrolysis reaction

process with many intermediate products will occur

secondary pyrolysis (Li et al., 2006), this results in a

positive proportion of gas production and a gradual

decrease in oil recovery rates. When the temperature

is 420 ℃,and the recovery rate is 10% higher than

that without catalyst. It is indicated that the catalyst

has a strong catalytic effect on the pyrolysis process.

3.2.4 Effect of Time on Catalytic Pyrolysis

of Oily Sludge

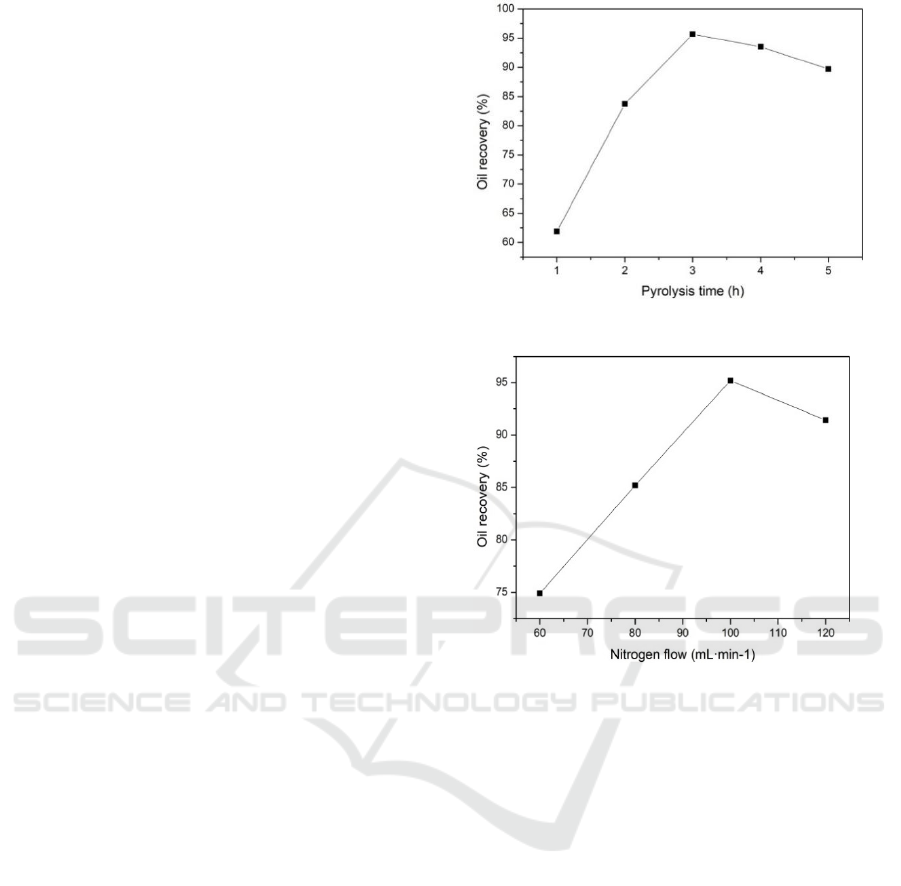

From figure 7, we can see in the process of sludge

pyrolysis, the oil recovery rate increases gradually

with the prolongation of residence time when the

reaction time is between 1-3h, and the recovery rate

increased from 61.9% to 95.69%.When the reaction

time is between 4-5h, the oil recovery rate is

decreasing. The reason is that the pyrolysis reaction

is a parallel reaction, the different depth of the

pyrolysis reaction has a great effect on the

distribution of product yield, which will increase the

residence time of the first reaction product in the

pyrolysis reactor, accelerate the secondary reaction

rates, and increase the gaseous phase products

produced by pyrolysis and the solid products

produced by condensation, it weakens the effect of

reaction time on liquid yield and reaction

conversion. It can also be seen that during the

reaction, when the reaction stays for a short time,

some of the sludge has not reached the current

temperature of the full state of pyrolysis, and when

the reaction time is too long, the oil occurred the

secondary pyrolysis (Li et al., 2006), the formation

of gas to discharge, the collection of oil production

reduced and the recovery rate of the reduction.

Therefore, in order to obtain the higher efficiency

and the shorter processing time, the best reaction

residence time is 3h, The pyrolysis time of catalyst

is 1h shorter than that without catalyst. The

experimental results show that the reaction time is

greatly reduced by adding the catalyst, which

reduces the load of equipment and the energy

required for the experiment.

Figure 7: Effect of pyrolysis time on oil recovery yield.

Figure 8: Effect of nitrogen flow rate on oil recovery

yield.

3.2.5 Effect of Nitrogen Flow Rate on the

Results of Pyrolysis Treatment

At the pyrolysis temperature of 420°C and the

pyrolysis time of 3 h, the effect of nitrogen flow rate

on the pyrolysis of oily sludge was investigated.

Figure 8 shows the results.

It can be concluded that the oil recovery rate

increases with the increase of nitrogen flow rate.

Also, it can reach the maximum value when the

nitrogen flow reaches up to 100 mL/min, but it

would decrease when nitrogen flow increased.

Because the oil and gas products in the pyrolysis

furnace can not be purge out in time when the

nitrogen flow rate is too small, causing the

secondary pyrolysis in the furnace and the oil

recovery rate is lower; there is little no-condensing

products that were purge out in the excessive

Nitrogen flow, resulting in decreasing of oil

recovery yield (Zhao, 1985; Li et al., 2018).

IWEG 2018 - International Workshop on Environment and Geoscience

66

4 CONCLUSIONS

The TiO

2

/bentonite supported catalysts were

successfully prepared, and the catalytic effect was

better with the increase of TiO

2

content. When the

pyrolysis temperature is 420 ℃, the pyrolysis time is

3 h, and the nitrogen flow rate is 100 mL/min, the oil

recovery rate can reach 95.69% by adding the

catalyst, and the addition of the catalyst can improve

the oil quality.

REFERENCES

Chen Shuang, Guo Qingjie, Wang Zhiqi and Liu Huie

2007 Study on pyrolysis kinetics of oily sludge

Journal of China University of Petroleum(Edition of

Natural Science) 04 116-120

Dong Yeshuo, Fei Xuening, Jiang Yuanguang, Xie Liping

and Chen Lei 2013 Effect of calcination stage on the

activity of zeolite-supported TiO

2

catalysts Water

Treatment Technology 39 (12) 41-45

Li Haiying, Zhang Shuting and Zhao Xinhua 2006

Influence of pyrogenation temperture of sewage

sludge on product distribution Solar Energy Journal

08 835-840

Li Yan, Hu Haijie Qu Chengtun and Yu Tao 2018

Influencing factors for catalytic pyrolysis of oily

sludge andanalysis of pyrolysis products Modern

Chemical Industry 38(01) 67-71

Liu Fan, Qu Chengtun, Yang Penghui, Xue Jingli and

Yang Wenjuan 2013 Research progress and prospect

of oily sludge treatment technology at internal and

foreign Liaoning Chemical Industry 42 (08) 999-1002

Wang Qiong and Zou Peng 2004 Pyrolysis treatment of

sewage sludge Renewable Resources Research 04 38-

41

Wang Shanshan, Ma Hong zhu, Wang Jing and Yu Jie

2015 Study on modification of active white soil and its

adsorption of phenol wastewater Silicate Bulletin 34

(01) 84-89

Yue Haipeng and Li Song 2010 Development status,

discussion and prospect of oily sludge treatment

technology in oil field Chemical Technology and

Development 04 17-20

Zhang Guangxin, Wang Bing, Zheng Shuilin and Song

Bing 2014 Effect of H

2

O/HAc on the crystal phase and

properties of TiO

2

Nano-Tio

2

/diatomite composites

Journal of synthetic Crystals 43 (05) 1162-1167

Zhao Guang Mu Free radical reaction Beijing: Higher

Education Press 1985

Application of TiO2/Bentonite on the Catalytic Pyrolysis of Oil Sludge

67