Development of an Assembly Consistency End-of-Line Inspection

System for Corn Harvester

Bingzhong Peng, Du Chen, Dong Sun, Shumao Wang

College of Engineering, China Agricultural University, Beijing 100083, China;

1

Beijing Key Laboratory of Optimized Design for Modern Agricultural Equipment, Beijing 100083, China

bingzhong @cau.edu.cn, tchendu @cau.edu.cn

Keywords: Corn Harvester, Assembly Consistency, Vibration, Transmission.

Abstract: Nowadays, along with the application of intelligent equipment and new technology, automation degree of

manufacturing becomes more and more advanced. While corn harvester, as one of the most important

agricultural machineries, the assembly quality was still inspected by traditional method depending on workers’

experience in China. Transmission is the core part of corn harvester, which is also the vibration source of

whole machine. Detecting and keeping transmission assembly consistency can reduce the vibration degree

and increase the mean time to failure, and improve the performance of whole machine. In this paper, a

transmission assembly consistency inspection system was designed and a method for judging the assembly

consistency was proposed. The proposed approach included two parts, the vibration signals analysis, which

was processed based on six bands method to calculate the energy of six bands; and the consistency comparison,

which was used to judge the assembly consistency intuitively through the chart. In the last we chose the corn

harvester pulverizer as an analysis object. According to result, the third and the fifth are incongruous.

1 INTRODUCTION

Corn harvester, as one of the most complex

agricultural machinery, is mainly embodied in the

complexity of the transmission system. On the one

hand, the transmission system of corn harvester

consists of various transmission forms, including belt

drive, chain drive, gear transmission, cam drive and

so on. On the other hand, for the corn harvester, the

harvest process requires long time, and the

transmission system need to withstand interfere of

dust, straw, clods and other debris while working,

which increase the reliability and durability

requirements of transmission system. Therefore it is

necessary to inspect the assembly quality of corn

harvester to ensure its reliability. At present, the

inspection of assembly quality is still in a traditional

way, without automation. Inspecting with an

automated way can control assembly quality well.

At present, studies on assembly quality focus on

process quality control strategies and techniques.

Suzuki et al. (2001) aiming at the reliability of

assembly workshop, put forward a method (AREM)

of assembly reliability evaluation, in which, the

assembly failure rate was quantitatively studied by

designing factors and workshop factors. According to

this study, it can improve the reliability level of

assembly by controlling influence factors. Kurt et al.

(2000) used the AQM and DFA to evaluate the

assembly quality of the products, so as to improve the

assembly quality in design stage. Milberg and

Wisbacher (1992) analyzed noise of the assembled

products and assembly process, and then controlling

the assembly quality of products by using the noise

spectrum diagram. Su S. developed a marine diesel

engine assembly quality information management

system based on management system model, which

can extract diesel engine configuration information

and generate assembly quality inspection cards

suitable for specific diesel engines. Kong F.

established the prediction model of assembly quality

defect rate, it can be used as the monitoring means of

assembly quality, and can also be used as the basis for

product design and assembly process adjustment.

According to the references, we know that most of the

studies focused on design stage or components

assembly. However, there is no end of line assembly

quality evaluation method.

Specifically speaking, in order to ensure assembly

reliability of corn harvester and raise automation

degree of inspection, we proposed an end of line

assembly quality evaluation method. The rest of the

652

Peng, B., Chen, D., Sun, D. and Wang, S.

Development of an Assembly Consistency End-of-Line Inspection System for Corn Harvester.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 652-656

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

paper is organized as follows: Section 2 provided

method and materials in this work. Section 3

determined the proper sensor. In Section 4 the results

and discussion are presented and Section 5 gave some

conclusions.

2 METHOD AND MATERIALS

In the shop, the assembly quality of corn harvester is

inspected in an artificial way (Yi and Wang, 2009). To

make it automatic, we designed an inspection system,

which can acquire vibration signal and analyze

assembly quality with it. The inspection system

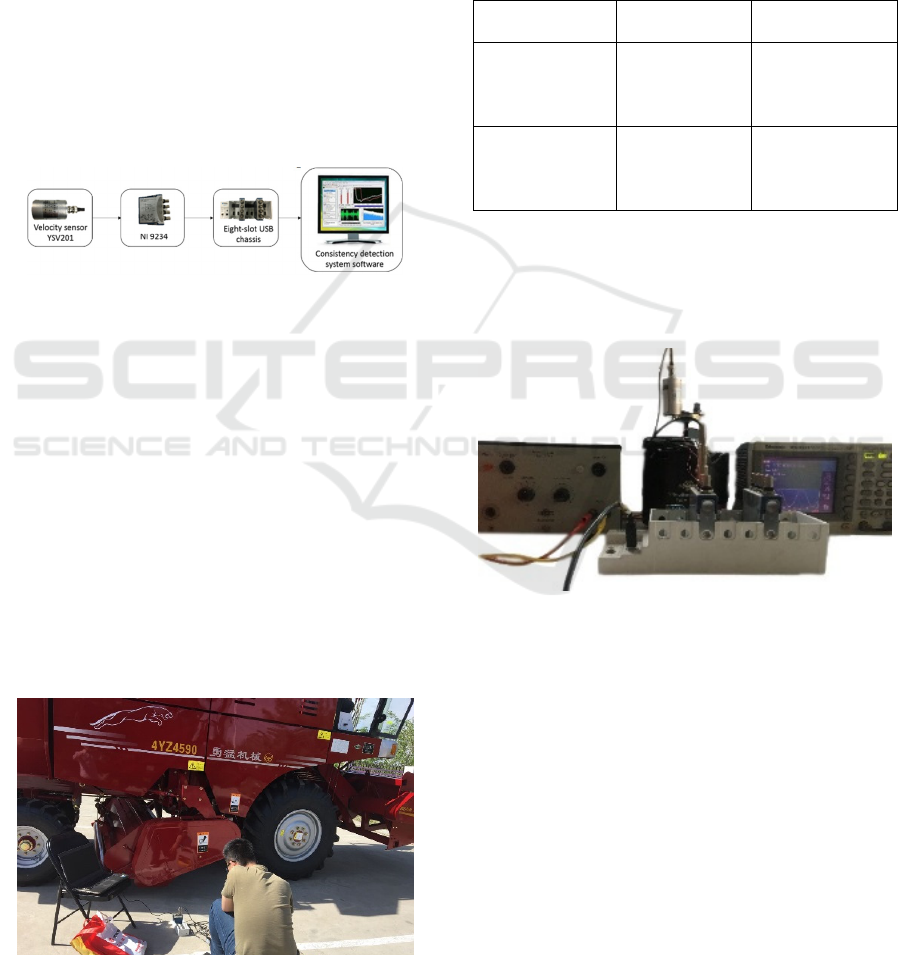

includes velocity sensor, NI-9234 AD input module,

NI cDAQ-9172 eight-slot USB chassis, and a signal

analysis software. The specific composition and flow

chart of measurement is shown in Figure 1.

Figure 1: The specific composition and flow chart of

measurement.

With the inspection system, to acquire vibration

signal, we designed a set of experimental scheme and

carried out in Tianjin Yongmeng Machinery Co. Ltd.

The whole detection flow chart mainly included five

steps, namely frequency pre-estimation, signal

acquisition and processing, band division, data

analysis, and results presentation. Type 4YZ4590 was

selected as experiment object. And selecting four key

vibration parts in a corn combine harvester, namely

header, engine, pulverizer and rear bracket to test.

Total 8 corn harvesters were tested. Each part tested 3

times. The sampling rate is set to 10 kHz. The

harvester worked both in idle rotational or maximum

rotational speed conditions. Figure 2 is the picture

taken while we were doing experiment.

Figure 2: Doing experiments.

3 DETERMINATION OF THE

PROPER SENSOR

In this paper, a preliminary experiment was carried

out to determinate the proper sensor between velocity

sensor and accelerometer, both using piezoelectric

principles. Important parameters of the two sensors

are shown in table 1.

Table 1: Main parameters of sensors.

Name

Performance

index

Technical

p

aramete

r

Type YSV201

Velocity sensor

range

response

frequency

sensitivit

y

185mm/s

4~1000Hz

27mV(mm/s)

Type

ULT2035V

Accelerometer

range

response

frequency

sensitivity

50g

1-12000Hz

98.24mV/g

All experiment materials comprised function

generator, power amplifier, vibration exciter, velocity

sensor, accelerometer, NI-9234 AD inputs module, NI

cDAQ-9172 eight-slot USB chassis, and a computer

with Signal Express software. Experiment installation

is shown in figure 3.

Figure 3: Experiment installation

In this experiment, according to the vibration

frequency range of corn harvester, which belongs to

low-frequency stage (Lin et al. 2015), it is better to

use velocity to reflect vibration features based on

vibration theoretical background. Therefore, velocity

peak-peak value are measured to make a performance

contrast. Data were acquired at the operational

condition of sinusoidal signal from frequency 4Hz to

44Hz. And to get velocity values, the data acquired

with accelerometer was processed in single

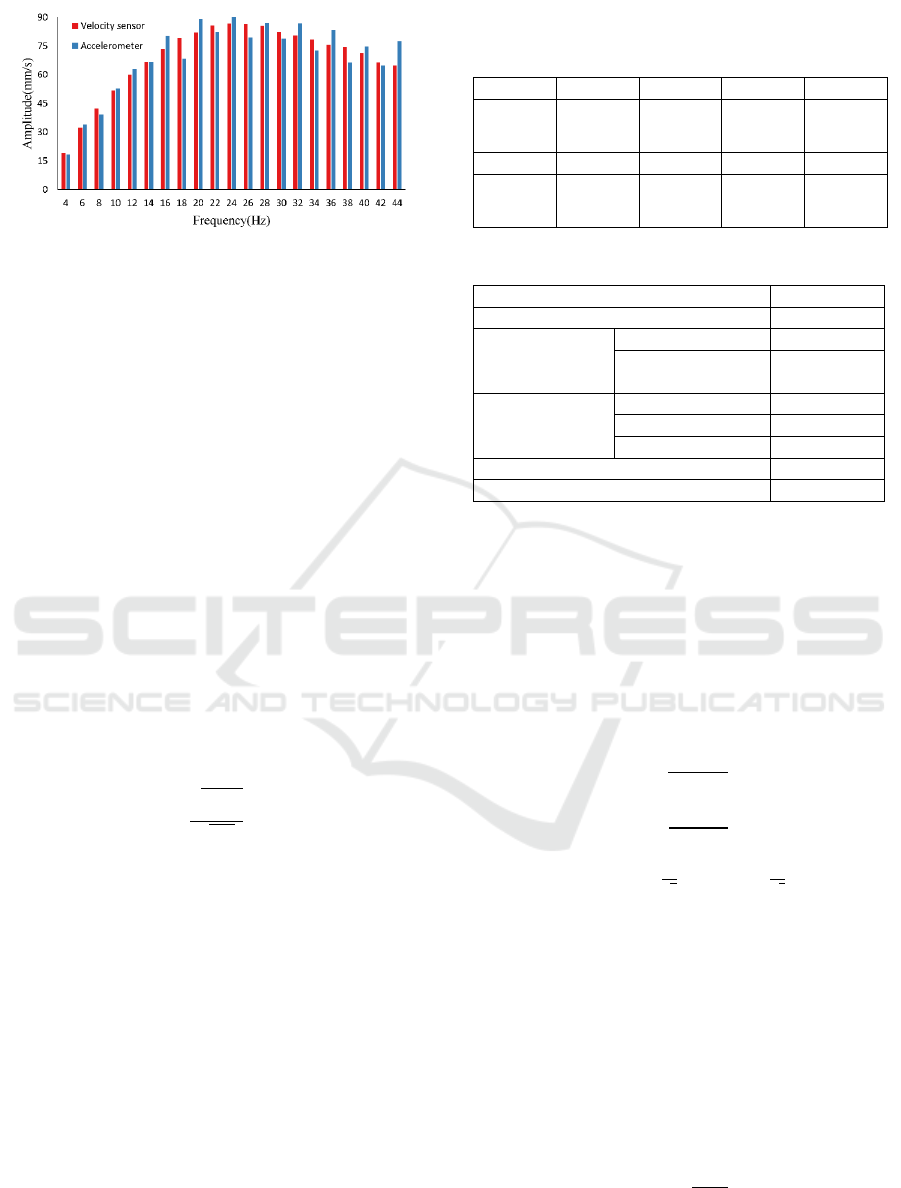

integration algorithm. In Figure 4, measured data are

shown.

Development of an Assembly Consistency End-of-Line Inspection System for Corn Harvester

653

Figure 4: Peak-peak value contrast histogram between

velocity sensor and accelerometer

From Figure 4, the two histograms are closed to

each other from frequency 4Hz to 14Hz, when the

frequency exceed 14Hz, they are alike in the tendency,

but the result tested by accelerometer fluctuate

tremendously. So the comparison leads to the

conclusion that the velocity sensor is better while the

frequency belongs to low-frequency stage. It is

correspond to what we know that the accelerometer is

suitable for frequency over 1000Hz. In a conclusion,

from the stability perspective, measured with the

velocity sensor is better.

4 RESULTS AND DISCUSSION

To judge assembly consistency, frequency band

energy is a most commonly used parameter. The total

energy generated by all the peaks in the band is

calculated by the following formula:

E=

∑

F

i

2

n

i=1

N

BF

(1)

Where the n is number of spectral lines in

frequency band,

is the spectrum value, and

is noise bandwidth of the selected window function.

According to the carried out experiment, corn

harvest pulverizer was chose as analysis object. In

order to analyze the test result, two kinds of data

processed methods were used. One is statistical

analysis. Total energy of corn harvester from

frequency 0 to 500Hz was calculated in level and

vertical directions. As we tested 3 times on each corn

harvester, then made an average of total energy. Table

2 showed the sum of averaged level and vertical total

energy. According to the data in table 2, first we verify

that it obey the normal distribution. Because the

sample is 8, we use the method of non-parametric test

with the statistical analysis software SPSS. Result is

shown in the following table 3:

Table 2: Total energy of frequency band.

Table 3: Single sample Kolmogorov-Smirnov test.

p

arameters energy

N8

Normal

parameter a, b

Mean value 537.4300

Standard

deviation

306.62526

Extreme

difference

A

b

solute value 0.335

Positive 0.335

Negative -0.210

Kolmogorov-Smirnov Z 0.947

Progressive significance(

d

ouble side) 0.332

a. the distribution of test is normal distribution.

b. calculated according to the data.

The progressive significance is 0.332>0.05, so it

obeys the normal distribution.

As it is verified obey the normal distribution, and

the total mean value, variance are unknown, we can

use T test and calculate the confidence interval of

consistency, of which the confidence is 95%. The

sample average, standard deviation and confidence

interval are calculated with the following formulas:

X

=

(x

1

+…+x

n

)

n

(2)

S=

∑

(x

i

-x)

2

n

i=1

n-1

(3)

(X

-t

α

2

(n-1)

S

√

n

,X

+t

α

2

(n-1)

S

√

n

) (4)

Where the n is sample,

is sample average, S

is variance, and α is significance level.

The calculated result is X

=537.43,S=306.63, and

confidence interval is (281.58, 793.28). According to

the confidence interval, the third and fifth corn

harvests are incongruous. A reference index value K

can be calculated. K=793.28/281.58=2.82. If the K

value calculated less than 2.82, then the assembly is

consistent, otherwise, it is incongruous. K value

calculation formula:

K=

P

281.58

(5)

Where the P is the total power.

No 1 2 3 4

Total

power

290.43 305.61 1148.42 437.24

No567 8

Total

power

863.42 471.82 333.26 449.24

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

654

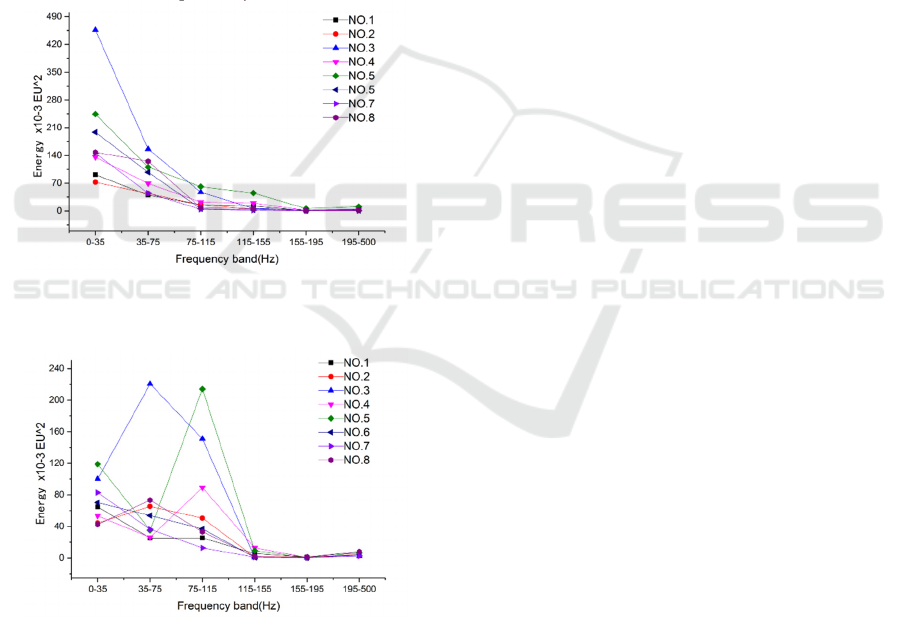

Six bands spectrum is an effective way to analyze

vibration signals by dividing the frequency domain

signals into six frequency bands. On each band, it

reflects correspond faults. Usually the first frequency

band is less than 1 times working frequency, second,

third, fourth and fifth frequency band contain 1times,

2 times, 3 times and 4 times, sixth band contains 4 to

12 frequency doubling (James, 1990). As the engine

speed of tested corn harvesters is 2400rpm, so for the

corn harvest pulverizer, its major energy focuses on

the frequency from 0 to 500Hz, we divide it into 6

frequency band, first is from 0 to 35Hz, second is 35

to 75, and the increment is 40 from the second to the

fourth, the last frequency band is from 195 to 500Hz.

On each band, energy was calculated and made an

average with 3 times. Figure 5 and figure 6 show the

frequency band of 8 corn harvesters in level and

vertical directions, respectively.

Figure 5: The energy of line chart in level direction.

Figure 6: The energy of line chart in vertical direction.

From the line chart, it is easy to discern the third

corn harvest and the fifth is incongruous with the

others both in level and vertical direction. According

to the knowledge of mechanical vibration fault

diagnosis, we know rotary machine exist rotor

unbalance if it is abnormal in working frequency, and

if it is unusual in 2 times working frequency indicates

rotor misalignment. The pulverizer is a kind of

rotating machine, from figure 4 and figure 5, we can

judge the third one with fault of unbalance and the

fifth one exist misalignment.

Statistical analysis and six bands can judge

assembly congruous of corn harvester both well. The

statistical analysis makes a judgment quantitatively,

while six bands judges more intuitionistic, which can

also reflect specific fault.

5 CONCLUSIONS

In this work, it demonstrates an assembly consistency

inspection system and a method of consistency

judgment about corn harvest transmission system.

The result using vibration signals corroborate its

efficiency. The use of frequency bands energy help to

separate the energy of different corn harvests in

different bands, which make the corn harvest, whose

assembly is incongruous, remarkable and easy to

distinguish form the chart. It gives us an intuitionistic

judgment.

This method proves to be extremely useful in

cases where the vibration signals are the most

important information for the complicated corn

harvests. And it make the inspection of consistency

more scientific, efficient and automatic, which can

guarantee the whole performance of corn harvests

well before they start working.

ACKNOWLEDGMENTS

This work was financially supported by National

Science & Technology Pillar Program during the

thirteenth Five-year Plan Period (2017YFD0700204).

The corresponding author is Du Chen.

REFERENCES

Suzuki, T. et al. 2001. Assembly Reliability Evaluation

Method. International Symposium on Assembly and

Task Planning Soft Research Park, Fukuoka, Japan May

28-29, 2001.

Kurt, A. et al. 2000. Assembly quality method: a tool in aid

of product strategy, design, and process improvements.

Design Engineering Technical Conferences Baltimore,

MD September 10-13, 2000.

Milberg, J. & Wisbacher, J. 1992. Acoustic Test Procedures

—A Powerful Method for Quality Assurance and

Process Monitoring in Assembly [J] CIRP Annals -

Manufacturing Technology. 41(1):25-28

Development of an Assembly Consistency End-of-Line Inspection System for Corn Harvester

655

Yi, K. & WANG, M. 2009. Analysis and countermeasures

for Chinese agricultural machinery product quality [J].

Chinese Agricultural Mechanization, (5): 07~10

Lin, J. et al. 2015. Status of Maize Harvesting Machinery

and Its Development Trend in China [J]. Agricultural

Science & Technology and Equipment(6)

James, E, Berry. 1990. How to Specify Machinery

Vibration Spectral Alarm Bands. Sound and Vibration.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

656