Application and Simulation

of Atkinson C

y

cle En

g

ine for the Ran

g

e Extender

Limian Wang

1

, Zhenghe Song and Shumao Wang

College of Engineering,China Agricultural University, Qinghua East Road, Haidian District Beijing,China

1

Faculty Secretary Office, Beijing Automotive Technician College, Caiyu Town, Daxing Beijng, China

wlmjt2003@126.com, { songzhenghe, wangshumao }@cau.edu.cn

Keywords: Atkinson cycle engine, Range extender, Simulation.

Abstract: The range extender can effectively improve the driving mileage of the electric vehicle, which is equipped

with an engine and a generator. The characteristics of the Atkinson engine are evaluated in this paper.

Additionally, Cruise software is used to simulate the performance of the range extender which is composed

of an Atkinson cycle engine and a generator. The study has illustrated that the Atkinson cycle engine if used

in the range extender can greatly reduce fuel consumption.

1 INTRODUCTION

The range extender is composed of a generator and

an engine. It is arranged in a straight line with the

battery pack and the transmission system. The

traction device of the range extended electric vehicle

is made up of three parts: the engine device, the

generator device and the motor device. When the

vehicle is running, the engine drives the generator to

produce electricity, then the controller transfers the

generated electricity to the battery or traction motor,

and finally drives the vehicle through the

transmission system (Zhu Longfei, 2012).

Though the electric vehicle is evolved from the

traditional vehicle, the operation mode of the range

extended electric vehicle is different from the

traditional vehicle. It operates mainly in all-electric

mode, with the extended range mode only serving as

a supplement. The driving mileage is effectively

improved by this mechanism. As the core of the

range extended electric vehicle, the range extender

works only when the power battery is insufficient. In

this way, it always works in the high efficiency zone

when activated. The system configuration of the

current range extender is similar, but the power

source of the generator varies. It is essential to

choose an engine which is stable, efficient and

environment-friendly.

2 CHARACTERISTIC ANALYSIS

OF THE ATKINSON CYCLE

ENGINE

Atkinson cycle is the working cycle of the internal

combustion engine with high compression ratio and

long expansion strokes. It is designed with only one

flywheel to drive the crank connecting rod

mechanism to achieve 4 strokes (Mehedad Ehsani,

2010).

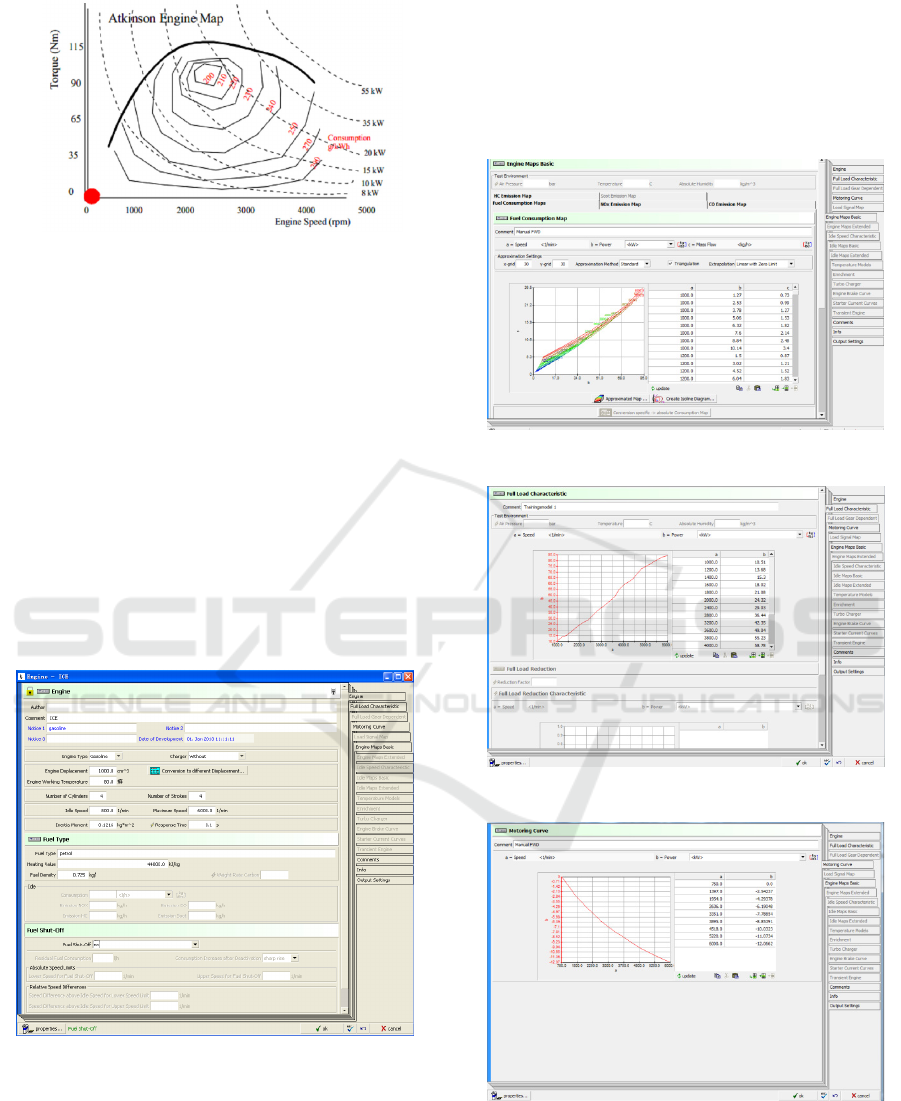

The implementation of Atkinson cycle

technology can greatly improve the fuel economy of

the engine. The oil consumption of the gasoline

Atkinson cycle engine can reach as low as

200g/kWh, as shown in figure 1. The thermal

efficiency of the conventional engine is

approximately 30% (250g/kWh) while the thermal

efficiency of the Atkinson cycle engine is as high as

36% (200g/kWh), saving about 25% of the oil. The

saving credit attributed to compression ratio increase

from 10 to 13 is about 15%, while the remaining

saving credit attributed to reduction of oil pumping

loss is about 10%. If it is used as a utility model

engine, the objective of ultra low fuel consumption

and low emission can be realized effectively.

584

Wang, L., Song, Z. and Wang, S.

Application and Simulation of Atkinson Cycle Engine for the Range Extender.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018) , pages 584-587

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure1: Map of the typical Atkinson cycle engine

3 APPLICATION AND

SIMULATION OF THE

ATKINSON CYCLE ENGINE

FOR THE RANGE EXTENDER

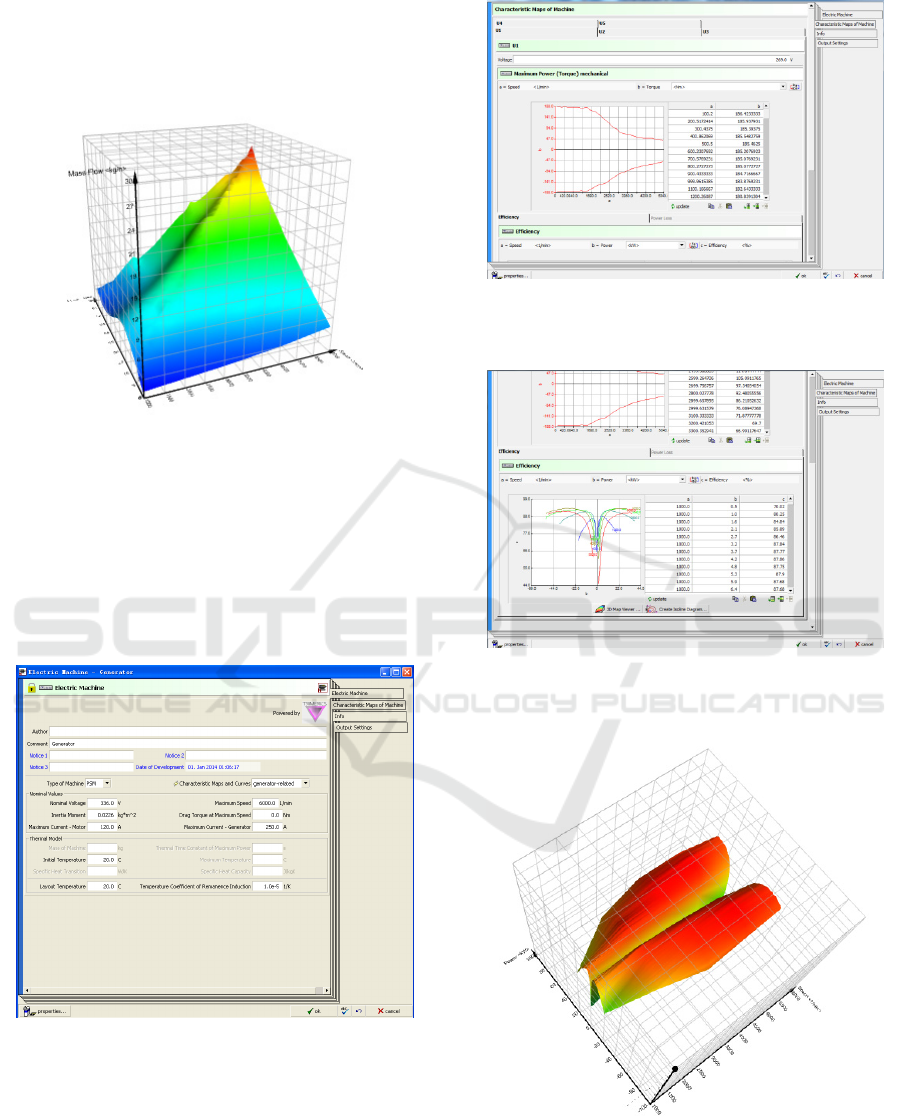

In this paper, a small Atkinson gasoline engine and a

generator are used as the range extender. The engine

performance data is obtained from the bench test.

The engine model and the generator model are

established in the Cruise, which ensures the high

precision of the simulation.

3.1 Engine Model

Figure 2: Input interface of basic parameters of the engine

module

The parameters that need to be set under the engine

module mainly are: engine type, displacement,

normal working temperature, cylinder number, idle

speed, maximum speed, moment of inertia and fuel

parameters (type, calorific value, density) (Dong

Xinyang,2012). The input interface of basic

parameters of the engine module is shown in figure

2. The engine characteristics are specified by

following parameters: engine external characteristic

data, engine universal characteristic data, anti-drag

characteristics, fuel consumption and emission

performance, as shown in figure 3 through figure 5.

Figure 3: Efficiency diagram of the engine

Figure 4: External characteristics of the engine

Figure 5: Anti-drag characteristics of the engine

After torque calibration by bench test and

emission test, the map of the internal combustion

engine of the range extender is generated, in addition

to three-dimensional table containing engine load,

Application and Simulation of Atkinson Cycle Engine for the Range Extender

585

speed and fuel consumption rate, as shown in figure

6. The function model of the engine is formulated by

putting it into the corresponding module of the

Cruise.

Figure 6: Map of the engine

3.2 Generator Model

The built-in motor module in the Cruise is used as

the generator (Zhao Jinlong, 2014), and the input

interface of the generator parameters is shown in

figure 7 through figure 10 below.

Figure 7: Input interface of the generator parameters

Figure 8: External characteristics of the motor

Figure 9: Universal characteristics of the motor

Figure 10: Efficiency map of the generator

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

586

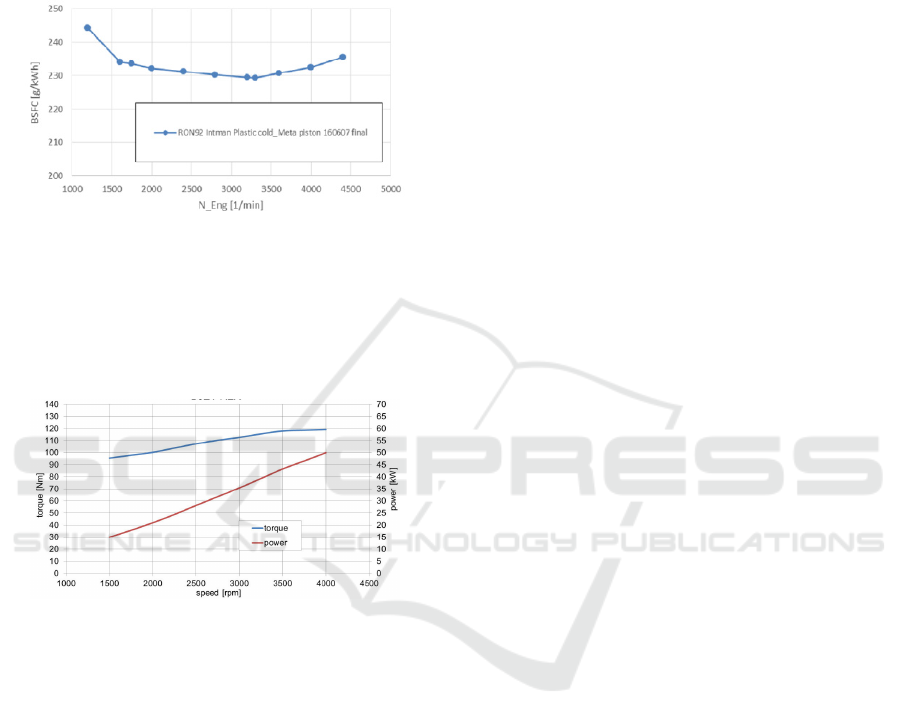

4 SIMULATION ANALYSIS

After the simulation test, the fuel consumption curve

of the Atkinson engine is obtained as shown in

figure 11. It can be seen that the minimum fuel

consumption can reach 230g/kWh.

Figure11: Fuel consumption curve of the engine

The external characteristic curve is generated as

shown in figure 12 by taking data from the best

efficiency working points of the engine (the low fuel

consumption point) and setting up the engine

working conditions.

Figure 12: External characteristic curve of the engine

The comprehensive fuel consumption per

hundred kilometres (L) (GB/T 19753-2005) is less

than 1.9, which is obtained by operating the range

extender according to the Atkinson cycle optimal

curve.

5 CONCLUSIONS

The study shows that applying the Atkinson engine

to the range extender can reduce the fuel

consumption, so that the comprehensive fuel

consumption per 100 km can reach 1.9 or less by

running the engine at the optimal efficiency points.

REFERENCES

Zhu Longfei. Parameters design and performance

optimization of the power system of the range

extended electric vehicle [D], Hefei, Hefei University

of Technology, 2012.

Dong Xinyang. A study of control strategy design and

optimization for the powertrain of the range extended

electric vehicle [D], Hefei, Hefei University of

Technology, 2012.

Zhao Jinlong. Parameter matching and control strategy

research of powertrain system for Range-extended

electric vehicle [D],ChongQing University, 2014.

Mehedad Ehsani, Yimin Gao, Ali Emadi. Modern electric

vehicles, hybrid electric vehicles and fuel cell vehicles

-- basic principles, theories and designs (second

edition of the original book) Translated by Ni

Guangzheng, Ni Peihong and Xiong

Suming[M].Beijing, Machine Press, 2010.

Wang Da, Wang Bo. Research on Driving Force Optimal

Distribution and Fuzzy Decision Control System for a

Dual-motor Electric Vehicle [A]. Chinese Control

Conference[C]. Hangzhou: Institute of Electrical and

Electronics Engineers, 2015.

Zhang Xiaoling. Simulation and analysis for the power

system of the extended range electric vehicle[J],

Journal of Chinese Agricultural Mechanization, 2017,

37(6).

Wang Peng. A Study on powertrain matching and

optimizing for Range -extended electric vehicle[J],

Computer Simulation, 2016,33(8).

Application and Simulation of Atkinson Cycle Engine for the Range Extender

587