Technical Development and Analysis of Four-Wheel Aligner for

Automobiles

Sheng Yu, Fuzhou Zhao

1

a

, Yunming Zhang and Xukai Huang

School of Mechanical Engineering, Ningbo University Of Technology,Ningbo, Zhejiang Province, China, 315211

1

Department of Automobile Engineering, Changshu Institute of Technology,Changshu, Jiangsu Province, China, 215500

{ xjz2020@163.com }

Keywords: Four-wheel aligner, technical development, automobile.

Abstract: The development status of four-wheel aligner for automobiles is reviewed in this paper at first. Then the key

technology of developing four-wheel aligner is analyzed. Measuring Datum and positioning mode are the

base of the aligner model. Measuring principle and its theoretical error are illustrated to enhance the

measurement accuracy. Finally this paper gives an outlook to the research of four-wheel aligner.

1 INTRODUCTION

Vehicle wheel alignment parameters which mainly

include the kingpin inclination angle, the caster

angle, the camber angle, the toe-in angle and the

thrust angle reflect the relative position relation

between wheel, steering knuckle and front/rear axle.

They have important influence on vehicle's handling

stability. According to the design requirements, the

wheel alignment parameters need to be adjusted in

advance, but they will change after a period of

driving. Wheel positioning angle deviation from the

design value will result in a series of adverse

consequences such as abnormal tire wear, fuel

consumption increase, and even the car steering

difficulties and path offset. As a special equipment

for detecting wheel alignment parameters, the four-

wheel aligner plays an important role in vehicle

maintenance and fault detection.

2 DEVELOPMENT STATUS OF

FOUR-WHEEL ALIGNER

With the continuous improvement of the accuracy

requirements of the wheel alignment parameters in

modern automobile performance testing, the

research of four-wheel aligner has been flourishing.

At present, there are two kinds of measurement

methods for four-wheel aligner used at home and

abroad, static measurement and dynamic

measurement. Static measurement refers to the mode

of detecting the vehicle wheel alignment in the

stationary state according to the geometrical relation

of the reference point on the center of the wheel. The

equipment with this mode mainly includes leveling

wheel aligner, pull-line wheel aligner, laser wheel

aligner and CCD wheel aligner. The leveling wheel

aligner is simple in structure and easy to carry, but it

has low precision and can not measure the toe-in

angle and the thrust angle. The typical levelling

wheel aligner such as Japan's 900A, WAT2000 and

domestic GCD-I, and is only suitable for the

detection of the front wheel about non-independent

suspension trucks (XU Guan, 2009). The pull-line

wheel aligner adopts the micro-computer to control

the angular displacement sensor to analyze the data,

and then realizes the visual display of the data.

However, the operation complexity and low

precision are still its main drawbacks (LV Xiaojun,

2011). Laser wheel aligner adopts the cooperation of

the lasers and wheel mounted jigs to capture signals.

It can neither be used to accurately measure nor

rapidly detect because of the narrow beam and the

limited range, therefore laser wheel aligner has been

abandoned in the developed countries of the

automotive industry. As an advanced wheel aligner,

CCD wheel aligner integrates with a new type of

semiconductor integrated optoelectronic device,

which makes it wide utilization and high precision.

Whereas there are also disadvantages such as high

manufacturing cost and complex maintenance (DAI

Renqiang, 2013). At present, this type of wheel

aligner manufacturers mainly include HUNTER,

Yu, S., Zhao, F., Zhang, Y. and Huang, X.

Technical Development and Analysis of Four-wheel Aligner for Automobiles.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 555-559

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

555

JBC, BEISSBATH, CORCHID, Three Jay Yi , and

so on.

Dynamic measurement refers to the method of

measuring the vehicle wheel alignment in the

moving state. The toe-in angle, track width, the

wheelbase and the inclination angle are all directly

when the vehicle is driving while they are distorted

in the stationary state, which are influenced by many

factors such as rim distortion, chassis clearance,

suspension deformation and heavy load. Thus, the

dynamic measurement becomes the mainstream

measurement method with higher precision. The 3D

wheel aligner is one of the most widely used

measurement equipment in the market, which is

attributed to its use of three-dimensional dynamic

measurement and the fast algorithm to achieve a

qualitative leap in principle, precision and real-time,

such as the JBC-V3D of the United States, the

German BOSCH-FWA4510, etc. The device has

many advantages such as high measurement

efficiency, accurate measurement and low failure

rate.

3 KEY TECHNOLOGY OF

DEVELOPING FOUR-WHEEL

ALIGNER

3.1 Measuring Datum and Positioning

Mode

There are two important rotating axes that affect the

four-wheel alignment, the steering axis of steering

wheel when turning and the rolling axis of the

wheel. Among them, the kingpin inclination angle

and the caster angle are the two-dimensional angle

of the steering axis, the camber angle and the toe-in

angle are two dimensional angles of the rolling axis

(ZHANG Mei, 2008). In addition, the four-wheel

positioning datum also comprises a OXY plane of

vehicle coordinate system, a geometrical centreline

and a thrust line.

The OXY plane refers to a plane formed by the

center of the front and rear axles, and the thrust line

is an imaginary line obtained from the intersection

of the two rear wheels plane and the OXY plane

(ZHAO Qiancheng, 2013). The positioning method

of the coordinate relation between the four wheels

and the suspension in the direction of X, Y and Z

axes is called the four-wheel alignment of the thrust

line, which takes the angular split line of the toe-in

angle of the rear wheel as the body Motion Center,

regardless of the body center offset (WEN Dong,

2009). Using the thrust line positioning, the first step

is to determine the position of the thrust line by

measuring the rear wheel, and then the thrust line is

used as reference to adjust the toe-in angle of the

directive wheel. When the thrust line does not

coincide with the geometrical centerline, the four

wheels deviate from the geometrical centerline,

which means that the deviation direction and

abnormal wear of the tires will appear when the

vehicle is running in a straight line.

The geometric centerline is the connection line

of the midpoint of the front and rear axle of the

vehicle, and it can be used as a reference to adjust

the toe-in angle of the wheel. When the rear wheel is

in the correct position, the adjustment of the front

wheel to the geometric centerline and the thrust line

coincide, the positioning effect is the best. Once the

rear wheel position is offset or the geometrical

centerline is not coincident with the thrust line, the

steering performance of the vehicle will be affected.

Therefore, the rear wheel alignment will be ignored

when the front wheel is adjusted with the geometric

centerline as the datum.

For modern four-wheel aligners, most of them

have the ability of complete four-wheel alignment.

The positioning method of the coordinate

relationship between the four wheels and the

suspension in the direction of X, Y and Z axes which

takes the wheel thrust line as the Body Motion

center line is called the complete four-wheel

alignment (WEN Dong, 2009). The specific

operation is to take the geometric centerline as the

datum, and realize the change of the relative position

between the thrust line and the geometrical center

line by adjusting the thrust angle continuously.

When the thrust line is coincident with the

geometrical centerline, the thrust line or the

geometrical centerline is used as reference, and the

wheel alignment is accomplished by adjusting the

toe-in angle of the directive wheel. Once the four

wheels are adjusted, the direction of each wheel is

parallel to the geometric centerline, at which time

the vehicle has the best running performance. This

method is by far the most ideal adjustment for four-

wheel alignment(XU Guan, 2009).

3.2 Measuring Principle of Typical

Four-wheel Aligners

The traditional four-wheel aligners ,such as pull-line

aligner and laser aligner, all use inclination sensors

to measure the kingpin angle and the camber angle

directly, and the steering wheel is positioned in the

center position before measuring. The measuring

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

556

beam which forms a closed approximate rectangle

around the wheel is emitted by the measuring head

of the wheel mounting clamp, and the toe-in can be

measured according to the rectangular shape. The

kingpin is a virtual axis without a measurement

reference and is in a general position in space. The

wheel needs to be rotated at a certain angle on the

angle plate. Indirect measurements of kingpin angle

are made using the measured values of two tilt

sensors perpendicular to each other inside the

measuring head and then derived by approximate

linear equations. The standard stipulates that the

accuracy of the camber angle and the toe-in angle

measured by the four-wheel aligners is ±2 ', but the

accuracy of the kingpin inclination is ±6 '(XU Guan,

2007).

The 3D wheel aligner is currently the most

advanced four-wheel alignment equipment, and the

main components include computer, high-resolution

camera, target board and corner plate. The

commonly used target board is mainly planar form,

and the traditional high-precision optical electronic

sensor is replaced by the reflector as a target. The

3D wheel aligner generally adopts the method of

measuring trolley marching, which is divided into

three steps (ZHAO Qiancheng,2013). First of all, the

wheel of the vehicle is fitted with a target board with

a certain pattern, so that it can synchronize with the

wheel movement. Secondly, 2 high-resolution

cameras are used to capture the image information

presented on the target board. Finally, the computer

uses the image collector to analyze the wheel's

stereo posture, and obtains the position relation of

each wheel relative to the measuring datum. The

measuring method is simple and rapid, and the non-

contact measurement is realized by the four-wheel

aligner with the principle of perspective, but it has

strict requirements on the shape and sharpness of the

image on the target board. The following is the

mathematical derivation model of 3D wheel aligner

(ZHANG Qixun, 2014).

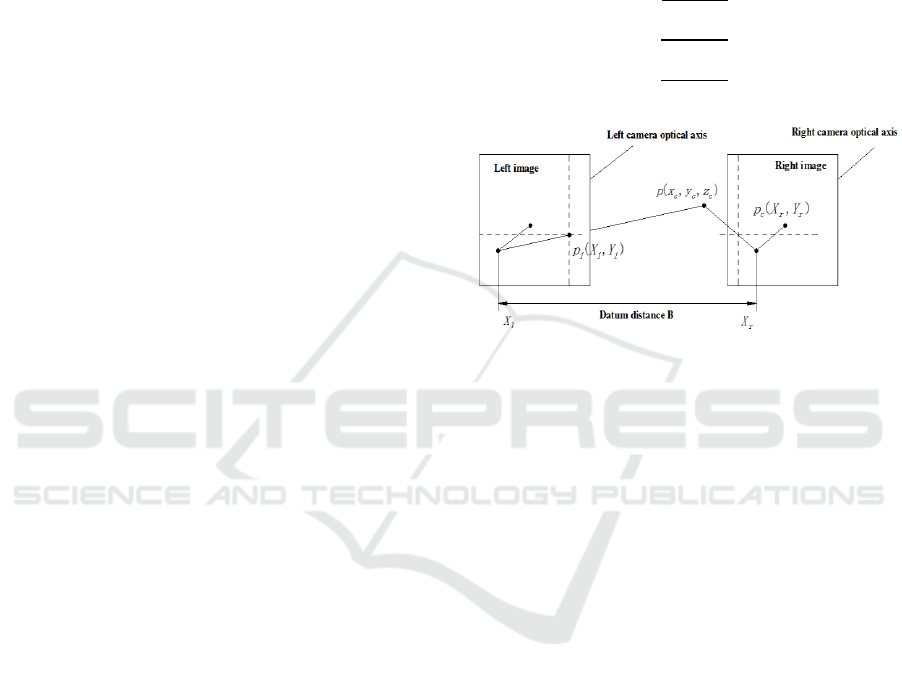

As shown in Figure 1, the optical axis of the left

camera and the right one is a pair of parallel axes,

and the distance between the two cameras is

recorded as baseline B. When the left and right

camera simultaneously observe the same point P, the

coordinates of point P are recorded as p

l

(X

l

,Y

l

) and

p

r

(X

r

,Y

r

) respectively. Assuming that the image

information collected by two cameras is on the same

plane and the focal length is f, the mathematical

relationship can be derived as follows:

(1)

The space coordinates of point P can be derived

by using the formula (2) in the camera coordinate

system:

(2)

Figure 1: 3D stereoscopic imaging principle

3.3 Error Analysis

As a measuring equipment, the precision of four-

wheel aligner is the main criterion to determine its

application value. Based on the above analysis, it is

concluded that the camber angle and the toe-in angle

can be measured directly, so there is no theoretical

error and can achieve extremely high precision.

However, when measuring the kingpin angle, the

approximate linear formula can only be deduced by

establishing the space geometry model, and then the

wheel alignment parameters are calculated by

combining the data obtained by the inclination

sensor and the approximate linear formula.

However, the linear formula does not reflect the true

motion state. Thus, different mathematical models

will cause different errors, as well as the actual

detection errors, which constitute the main error of

the four-wheel aligner. The following deduction is

taken as an example of measuring the kingpin

inclination angle by using a four-wheel aligner with

inclination sensor.

Taking the left front wheel as an example, when

the wheel turns left or right to , the

relationship between the kingpin inclination angle

and measurement angle is deduced as follows:

(3)

Technical Development and Analysis of Four-wheel Aligner for Automobiles

557

The formula (3) indicates that the kingpin

inclination angle is times that of the

actual measurement angle

. Using the

relationship of times to set the four-wheel

aligner can directly measure the kingpin inclination

angle , then formula (3) is a linear model of the

four-wheel aligner with inclination sensor.

However, in the derivation of formula (3), the

measurement result of the four-wheel aligner is

biased with the real value due to the approximate

treatment of the small angle. When considering the

effect of the small angle on the result, the following

relationships can be obtained:

(4)

(5)

(6)

Among them, the b

1

,c

1

,b

2

,c

2

are all related to the

caster angle , the kingpin inclination angle and

the horizontal rotation angle .

From the above, it can be seen that the

measurement angle

is the function of the

caster angle , the kingpin inclination angle and

the horizontal rotation angle , and the kingpin

inclination angle is obtained by

measurement angle

, so the kingpin inclination

angle is influenced by the caster angle . However,

the linear model of the four-wheel aligner with

inclination sensor does not consider the caster angle

, so it has theoretical error to measure it (XU Guan,

2006).

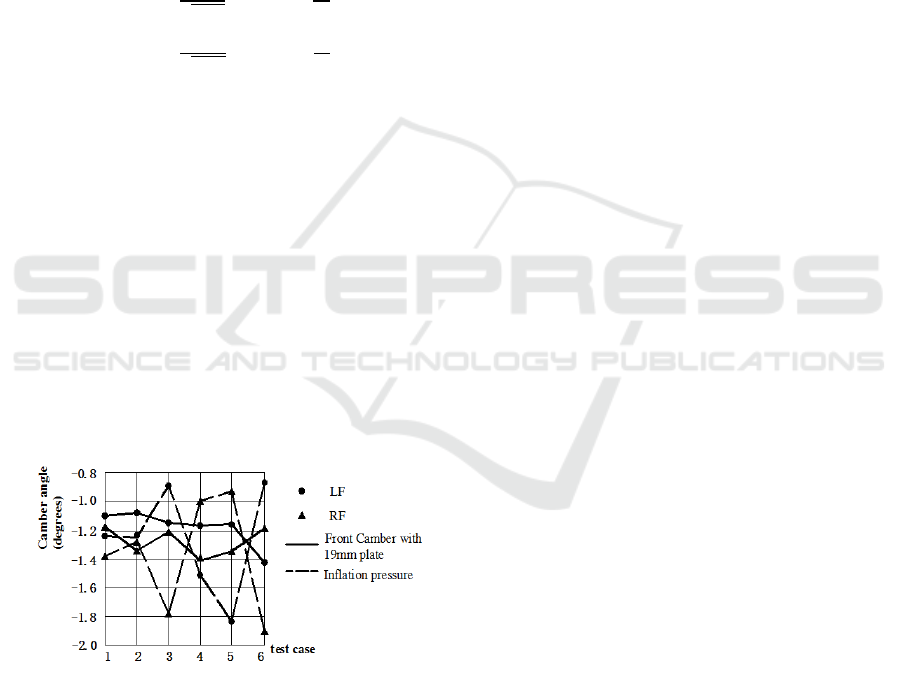

Figure 2: two factors impact on Front Tire Camber

4 CONCLUSION AND

DEVELOPMENT TREND

We found that the static wheel alignment

measurement is not strongly affected by many of the

variables tested. These included, equipment

accuracy, suspension preload, and operator.

However, the largest effects on wheel alignment

accuracy that can be expected to arise in a plant or

wheel alignment shop are caused by levelness of the

platform and errors in tire pressure (Patel H, 2016)

(see Figure 2). Therefore, the four-wheel aligner

based on static measurement will pay more attention

to the levelness of the platform and tire pressure in

the future, while increasing the degree of automation

to reduce human participation.

In addition, the four-wheel aligner based on the

computer vision measurement technology brings

great reform to the traditional wheel alignment (LV

Xiaojun, 2011), and the detection equipment with

3D image as the mainstream is gradually replacing

the traditional four-wheel aligner. However, while

pursuing accurate wheel alignment parameters, other

problems also arise. Among them, the diagnosis of

large amount of information and uncertain factors

are the disadvantages of electronic computing. For

the existing four-wheel aligner, the calibration is still

subject to artificial adjustment, so it is very

important to operate conveniently while ensuring its

stability and reliability. In the future market, people

no longer only focus on the accuracy of measuring

instruments but require as few steps as possible,

which aims to reduce the incidental error caused by

human operation and shorten the training time of

technicians. In this era of rapid development of

automobiles, the automobile industry is gradually

forming more complete information resources. For

the four-wheel aligner, in order to solve the above

problems from the root, I believe that the global

empirical database will be formed in the near future,

at that time automakers and four-wheel aligner

manufacturers will work together to develop the best

data and upload it. At the same time, in order to

achieve the most authentic positioning effect, the

four-wheel aligner can be loaded in the car body.

When the vehicle is running, the four-wheel aligner

will monitor the wheel state in real time and use the

network to compare directly with the standard in the

database. If the result is outside the standard range,

the four-wheel aligner automatically adjusts the

wheel to the proper position when the vehicle stops,

which realizes the integration of detection and

adjustment.

In addition, the new four-wheel aligner can be

added to the active safety system. Such a proposed

active safety system is a lane departure warning

where an driver support system acts as a copilot to

monitor lane –keeping performances, and warn the

driver when a lane departure is predicted (SG Barhe,

2016). Therefore, the invention of a humanized and

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

558

intelligent four-wheel aligner based on computer

vision measurement technology and ergonomics will

become the common goal of future.

ACKNOWLEDGEMENTS

This work is supported by grant 201611058009 of

National Training Program of Innovation and

Entrepreneurship for Undergraduates.

REFERENCES

XU Guan. Research on vision system of vehicle wheel

alignment parameters and calibrating method[D]. Jilin

:Jilin University, 2009.

LV Xiaojun. Verification device of 3D four-wheel aligner

and Its optimization design[D]. Jilin:Jilin University,

2011.

DAI Renqiang, WANG Mengjun. Research on automobile

Four-wheel aligner and calibration device[J].

Public Communication of Science

& Technology, 2013, 5(8):101-105.

ZHANG Mei, HUANG Rujun. Influence of four-wheel

aligner on vehicle driving performance[J]. Journal of

Chongqing University of Science and Technology (

Natural Sciences Edition ), 2008, 10(3):56-60.

ZHAO Qiancheng, HUANG Dongzhao,YANG

Tianlong,et al. Research on the key techniques of 3D

computer vision four-wheel aligner[J]. Chinese

Journal of Scientific Instrument, 2013, 34(10):2184-

2190.

WEN Dong. 2009 Positioning New Perspective[J]. For

Repair & Maintenance, 2009, (5):28-29.

XU Guan,SU Jian,PAN Hongda,et al. Research on

verification technology of four-wheel alignment

instrument for automobiles[J]. Measurement

Technique, 2007,(8):44-47.

ZHANG Qixun, SHAO Chenghui,ZHANG Zhongyuan, et

al. Research on the key detection technology of 3D

four-wheel alignment calibration device[J].Chinese

Journal of Scientific Instrument, 2014, 35(9):1979-

1989.

XU Guan. Study on the Calibrating Method and

Apparatus of Four-wheel Aligners[D]. Jilin : Jilin

University,2006.

Patel H, Casino M, Noakes D, et al. Suspension Variables

Influencing Static Vehicle Wheel Alignment

Measurements[J]. 2016, 9(2):551-559.

SG Barhe, BG Gawalwad. Measurement of Wheel

Alignment using IR Sensor[J]. 2016, 4(2): 158-161.

Technical Development and Analysis of Four-wheel Aligner for Automobiles

559