Research of Thin Film Thermocouple Based on MEMS for

Temperature Measurement on Spacecraft Surface

ZhenWei Li, ZeYuan Liu, Chang Liu and Fang Han

Beijing Institute of Spacecraft Environment Engineering, Beijing 100094, China

13502836@qq.com

Keywords: MEMS (Micro-Electro-Mechanical-Systems), thin film thermocouple, the measurement of spacecraft

surface transient temperature, physical test.

Abstract: The paper introduces the technology of MEMS and its advantages in the manufacture of aerospace sensors.

According to the requirements of spacecraft surface temperature measurement, a K-type (NiCr/NiSi) thin

film thermocouple is designed. The graphic process design of thin film thermocouple is studied, including

thermal junction and thin film lead wires. The test shows that the response time of the thin film

thermocouple is shorter and the relative error is smaller compared with the traditional thermocouple.

1 INTRODUCTION

The MEMS (Micro-Electro-Mechanical-System) is

based on the micron/nanometre technology, and was

applied to the design, processing, manufacturing,

measurement and control of micron/nanometre

materials. It’s an intelligent extension of integrated

circuit technology. The MEMS has the advantages

of miniaturization, integration, low energy

consumption, low cost, high accuracy, long life and

dynamic properties(Zhu,2013). With the above

advantages, the MEMS becomes the ideal device in

space application field. In the future, the space

exploration will focus on the cost and goal of task.

In order to save cost, the future trend will be the

MEMS devices replace the heavy weight devices on

the space carrier, the actual loads on the

communication and navigation platform.

Furthermore, it will replace the complete subsystems,

such as attitude sensor, attitude controller, phased-

array antenna, earth sensor and optical switch.

Compared with the traditional solutions, the size and

quality of MEMS devices can be significantly

decreased. Some of the MEMS devices(Wu, 2012)

which have been used in space are displayed in

Table 1.

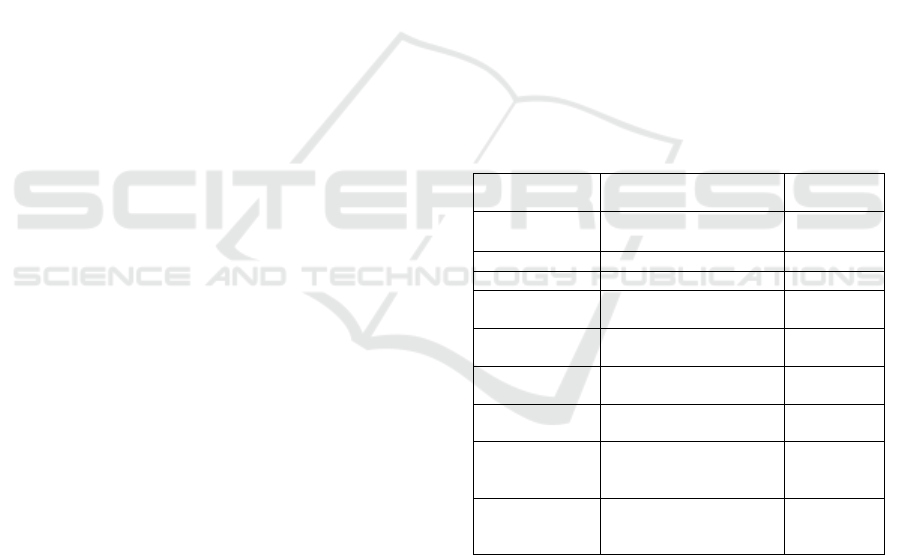

Table 1: The MEMS devices used in space and its

technical maturity.

MEMS device

name

Flight mission

Technical

maturity

Accelerometers

, gyroscopes

NASA regular flight High-level

Pressure senso

r

Rocket normal fligh

t

High-level

Magnetomete

r

Cube satellite fligh

t

High-level

Atomic force mi

cro-scope

The "Phoenix" mission

of NASA in 2008

Advanced-

level

Solar sensor

The "Delfi 3C" mission

in 2008

Advanced-

level

Microfluidic

senso

r

The "GeneSat" satellite

mission of NASA

Middle-

level

Bolometer

The "Planck" mission of

ESA in 2009

Middle-

level

Thermal

controller

The task of "Space

Technology 5"of NASA

in2006

Middle-

level

Micro optical

electromechanic

al syste

m

Used in Jame Webb

Space Telescope in 2013

Intermediat

e-level

With the rapid development of deep space

exploration, hypersonic vehicles and space shuttle

vehicles in China, the transient temperature

measurement of the spacecraft surface is better

required(Zhang,2013). Especially, in the process of

returnable spacecraft re-entry flight, the

aerodynamic heat effect of high speed friction will

make the temperature of spacecraft surface rise

fast(Manoj,2015). The surface temperature can

better reflect the thermal characteristics of the

spacecraft and its structures. It also can provide the

reference data for the verification of spacecraft's

522

Li, Z., Liu, Z., Liu, C. and Han, F.

Research of Thin Film Thermocouple Based on MEMS for Temperature Measurement on Spacecraft Surface.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 522-528

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

thermal protection system. At present, the ordinary

thermocouples were generally used to measure the

surface temperature of spacecraft during its thermal

test and flight. However, for the hypersonic and

space shuttle spacecraft, the surface temperature is

changed sharply. Due to the structure, heat capacity

and installation mode of the ordinary thermocouples,

the measurement results were obviously hysteresis

and inaccurately. It can’t meet the measurement

requirements of the spacecraft surface transient high

temperature.

To solve the above problems, the MEMS process

of thin film thermocouples is researched in this

paper, which can be used to measure the spacecraft

surface transient high temperature. In present, the

temperature sensor based on thin film thermocouple

has been used in the measurement of the bullet

ejected bore, the wall of internal-combustion engine,

the heat flux distribution of the laser beam, and the

working cutting tool successfully(Zhao,2012).

However, due to the special structure of spacecraft,

the thin film of thermocouple can’t be pasted on the

surface of test object directly. Therefore, the needle-

type structure of thin film thermocouple is proposed

in this paper. The high temperature resistant ceramic

material is selected as the structure substrate and K-

type material is selected as thermoelectric material

for this type of thermocouple. Then, the thin film

thermocouple was prepared on the structure

substrate by magnetron sputtering technology. The

thickness of this thermocouple’s thermal junction is

micron scale, and its capacity is much smaller than

the traditional thermocouple. It can be effectively

fitted to the surface of the test object, and the

transient temperature up to 800℃ is measured

quickly and accurately. These properties make the

sensor better meet the measurement requirements of

the hypersonic vehicles and space shuttle vehicles.

2 WORKING PRINCIPLE AND

STRUCTURE DESIGN OF THIN

FILM THERMOCOUPLE

In 1821, the German physicist Thomas Johann

Seebeck found the thermocouple phenomenon,

which describes that the junction of two different

materials can generate voltage with the temperature

changing. For the same type of thermocouple, the

thermoelectric potential generated by thermocouple

is proportional to the temperature difference

between two thermal junctions. The relationship

between the thermoelectric potential and

temperature difference is described in equation (1).

ΔV=α

s

*ΔT (1)

In equation (1), the ΔV is the thermoelectric

potential generated by thermocouple, the ΔT is the

temperature difference between two thermal

junctions, and the α

s

is Seebeck coefficient, whose

unit is μV/K.

In the long term industrial practice, several

standard thermocouples have been gradually formed,

such as B-type (PtRh30-PtRh6) thermocouple, S-

type (PtRhl0-Pt) thermocouple, R-type (PtRhl3-Pt)

thermocouple and K-type (NiCr-NiSi)

thermocouple. These thermocouples are different at

thermoelectric material. In consideration of the

working temperature range, the measurement

accuracy and the economic cost, this paper selects

the K-type thermoelectric material which conforms

to the national standard to research the MEMS film

technology.

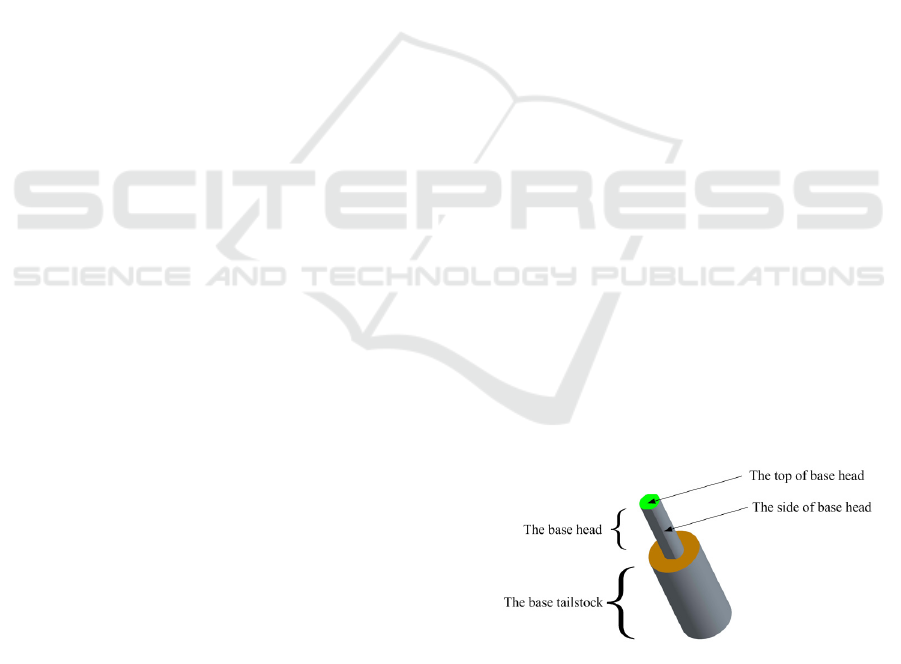

In order to fit the actual conditions of the

transient temperature measurement on spacecraft

surface, the style of thin film thermocouple structure

was designed as needle-like. As shown in Figure 1,

the thermocouple structure substrate is divided into

the base head and the base tailstock. First, Al

2

O

3

insulation film was deposited on the surface of the

thermocouple substrate that the material is high

temperature resistant ceramic material. Then, the K-

type thermocouple thin film was deposited on the

top of substrate base head by magnetron sputtering

technology. Finally, the Al

2

O

3

insulation film is

deposited on the thermocouple film. This insulation

film can protect thermocouple film from falling off

and breaking, caused by friction, scour, impact and

corrosion. At the same time, it can also provide the

well electrical insulation and physical protection for

thermocouple film.

Figure 1: The structure diagram of needle-type thin film

thermocouple.

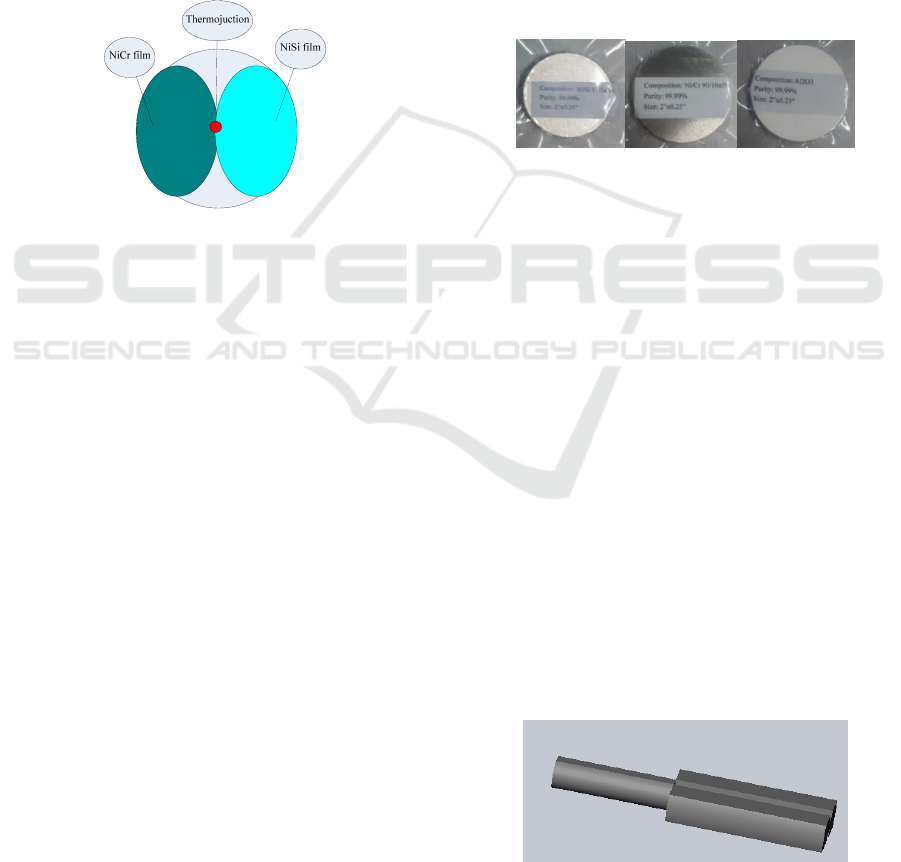

The thermal junction of thermoelectric material

is located at the top of base structure’s head. As

shown in Figure 2, the NiCr film and NiSi film were

Research of Thin Film Thermocouple Based on MEMS for Temperature Measurement on Spacecraft Surface

523

prepared on the left and right semicircular surfaces

on the top of base head by the magnetron sputtering

technology. The thermal junction is the core of the

sensor. The thickness of the thermocouple film is

about 2μm. The diameter of the isothermal surface is

50 times more than thermocouple film’s thickness,

while, the geometric area of thermal junction is

much less than the isothermal surface. Therefore, the

specific heat capacity of the thermal junction is

much smaller than that of the traditional

thermocouples. It can achieve the measurement of

transient temperature easily. The thermal junction of

the thin film thermocouple is good performances.

But, the preparation process of the thin film

thermocoupleis difficult.

Figure 2: The thermal junction diagram of thin film

thermocouple.

3 THE FABRICATION PROCESS

OF THERMOCOUPLE

The k-type thin film thermocouple studied in this

paper is processed by MEMS process. The MEMS

microprocessing technology is an extension of

traditional microelectronics technology. In the

substrate selection from the traditional silicon

material, expanded to ceramics, glass, plastic and

other materials. MEMS microprocessing technology

enables the chip processing method from 2D to 3D,

through electroplating, mold, laser, corrosion and

other processes. A series of MEMS processes, such

as photolithography, stripping and sputtering, are

used during the processing of k-type film

thermocouples. The substrate of thermocouple is

nonplanar substrate, with greatly processing

difficulty. The special fixture is designed in this

paper, and the fabrication of MEMS process, such as

photolithography and sputtering of 3D unit, is

realized.

3.1Target material

The electrode materials of the k-type thin film

thermocouple are prepared by sputtering, and the

sputtering equipment is KJLC LAB18. Sputtering

particles of energy (ions, neutral atoms or

molecules), such as argon ions, are used to bombard

the target surface. Atoms and molecules near the

target surface will get enough energy to escape from

the target surface, and then deposit on the substrate

of thermocouple. The purity of target material will

affect the composition of the thermocouple electrode

and the temperature measurement precision of the

thermocouple. In this paper, the targets of Ni

90

Cr

10,

Ni

97

Si

3

and Al

2

O

3

with purity of 99.99% were

prepared according to the atomic weight ratio, which

were shown in Figure 3.

Figure 3: Sputtering targets

3.2 The technology process

Fabrication process of needle-type thin film

thermocouple includes ceramic substrate production,

lead wire production, thermal junction production,

and the encapsulation of the lead terminal etc. In the

process, each step is carried out in order.

3.2.1 Selection of the substrate material

The substrate is the basic component of the thin film

thermocouple structure. Because the maximum

temperature range of the film thermocouple reaches

800℃, it is necessary for the substrate material to

have a high temperature resistance. In addition, in

order to avoid the influence of the thermocouple

temperature from the substrate, that is required to

having low thermal conductivity for the substrate.

This paper uses the Al

2

O

3

ceramic with high heat

resistance and low thermal conductivity as substrate

material. As shown in Figure 4 as the substrate

structure.

Figure 4: The structure of substrate

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

524

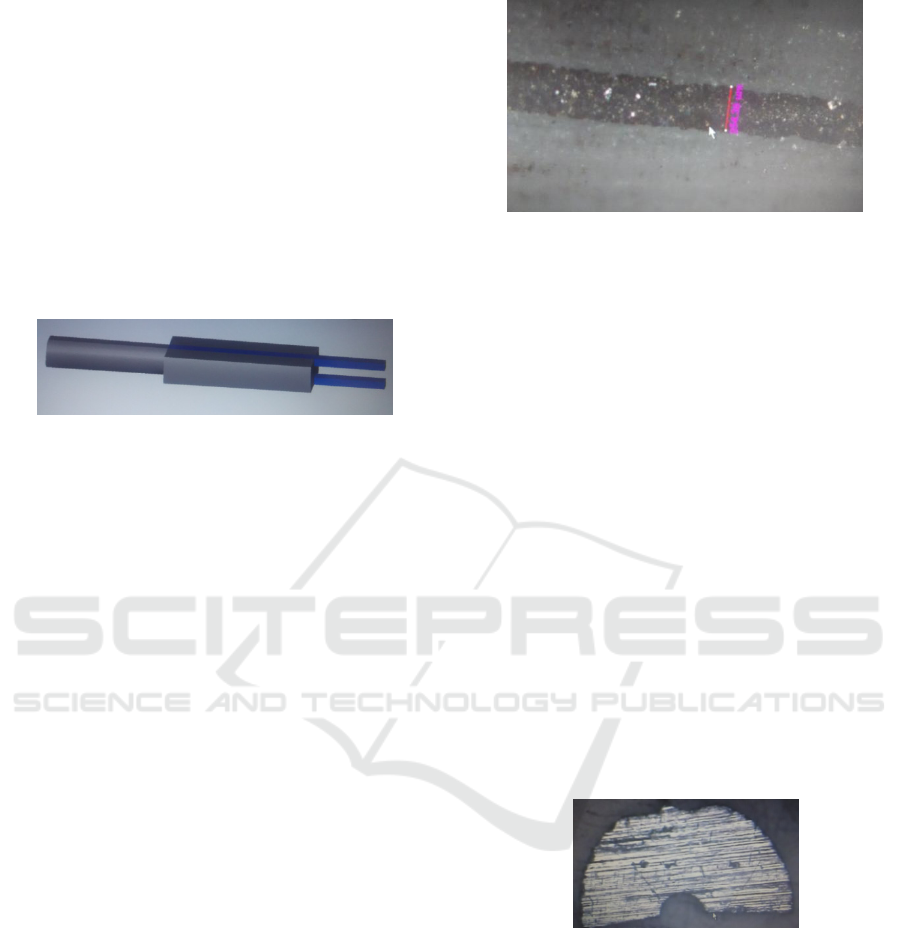

3.2.2 The lead terminal making

According to the thermocouple homogeneous

conductor's law, if the third material in the

production of lead terminals was inducted, it may

cause the thermal potential of two leads different,

and then cause the measurement errors. In this

paper, the electrode leads are made by the same

target materials as the two thermoelectric materials

of the thermocouple, and then bonded to the grooves

on the side of the base with high temperature

ceramic glue. The surface of the electrode leads

needs to be planed and polished. As shown in Figure

5 as the lead terminal making.

Figure 5: The lead terminal making

3.2.3 Preparation of lead wire

The commonly used methods for making the thin

film lead of thermocouple are peeling and etching

respectively. Special aluminum foil tape is used as

the mask in the peeling method, and the design

pattern of the thin film lead is transfered to the mask

by stamping or laser etching process. Using the NiCr

and NiSi target sputtering, film thickness is 1μm.

The mask is removed to form thermal electrode film

pattern. However, the change of the temperature in

the sputtering process causes the change of the

adhesive force between the mask and the substrate,

resulting in the distortion of the mask pattern.

In order to solve the above problems, this paper

uses laser etching method to make thin film. The

surface of the ceramic substrate is covered by

sputtering thickness of 1μm NiCr/NiSi film. The

film parameters design is directly input into the laser

controller to control the movement of the laser spot,

and the excess film is melted away. The etching

laser is produced by a 1064nm wavelength fiber

laser with a moving precision of 1μm, which can

ensure the high precision of lead figure. As shown in

Figure 6, the width of the film lead is designed to be

250μm, and the measured width is 254.30μm.

Figure 6: Thin film wire

3.2.4 Preparation of the thermal junction

The thermal junction is the most important part of

the thermocouple measurement circuit, which is

directly contacted with the surface of the

thermometric object. The heat capacity of the

thermal junction is very small, and it can quickly

reach the same temperature as the surface of the

thermometric object. By measuring the

thermoelectric power signal produced by the

Seebeck effect, surface temperature can be

calculated. As we can see from Figure 2, the region

of the interaction between NiCr film and NiSi film

forms a thermal junction, with a diameter of 200μm

and a thickness of 2μm. The mechanical mask and

exposure mask methods were studied and analyzed

in this paper before preparing the thermal junction.

If the mechanical mask method is adopted, the

SUS304 stainless steel sheet will be handled

according to WEDM process of making the mask, as

shown in Figure 7. Due to the edge roughness of the

mechanical mask relatively large, the figure of the

thermal junction is not regular enough.

Figure 7: The mechanical mask

In order to further insure the accuracy of the

graphics, a special exposure mask method is

developed in this paper. First, the design

diagram is

transferred (copied) to the film. Then, photosensitive

ink or hot pressing dry film was coated on the top of

the ceramic substrate. The film mask is placed on

the top of ceramic column, and then exposed with

UV lamp. It is melted into the developing liquid.

Then the top shape has been transferred to the top of

ceramic column. After the sputtering is completed,

the ceramic column is put into the stripping solution

Research of Thin Film Thermocouple Based on MEMS for Temperature Measurement on Spacecraft Surface

525

or acetone solution to dissolve the ink or dry film.

Finally, as shown in Figure 9, only the thermal

junction film is left on the top of the ceramic.

Figure 8: Thermocouple junction design

4 PHYSICAL VERIFICATION AND

RESULT ANALYSIS

In order to verify the overall performance of the thin

film thermocouple which was designed in this paper,

a thermocouple performance testing system was

developed firstly(Li,2017). As shown in Figure 9,

the system consists of control computer, measuring

instrument, programmable power supply, infrared

lamp array, copper plate of constant temperature and

graphite carpet etc. During the actual test, 8 K-type

ordinary thermocouples and 2 K-type needle thin

film thermocouples were installed equably

on

φ

200mm circle on the copper plate. The

temperature of the copper plate must maintain

constant in order to ensure that all thermocouples

were in an uniform temperature field. The copper

plate was heated by the infrared lamp array, and its

target temperature was set as the average

temperature value of 8 ordinary thermocouples. The

thermoelectric potentials of ordinary thermocouples

and needle thin film thermocouples under the same

temperature field were read, and then converted into

the temperature values. Comparison and analysis of

the temperature measurement values between thin

film thermocouple and ordinary thermocouple, the

results of two thermocouples fit well, we can

conclude the measurement performance of the film

thermocouple under the conditions of high

temperature impact and transient temperature was

verified.

Measurement and

control computer

Programmable

power supply

Data acquisition

instrument

Infrared

lamp array

Constant

temperature

copperplate

Thin film

thermocouple

Graphite felt

Figure 9: Performance test system for thin-film

thermocouple.

In this paper, eight K-style ordinary

thermocouples were named by 1# to 8#,and two

K-type needle thin film thermocouples were named

by 9# to 10#. In order to verify up to 800℃working

temperature of the thin film thermocouple , the

copper plate for the performance test system was

heated up to 850℃. The excess of 50℃is used to

verify the reliability of the film thermocouple. The

test results of measurement points were shown in

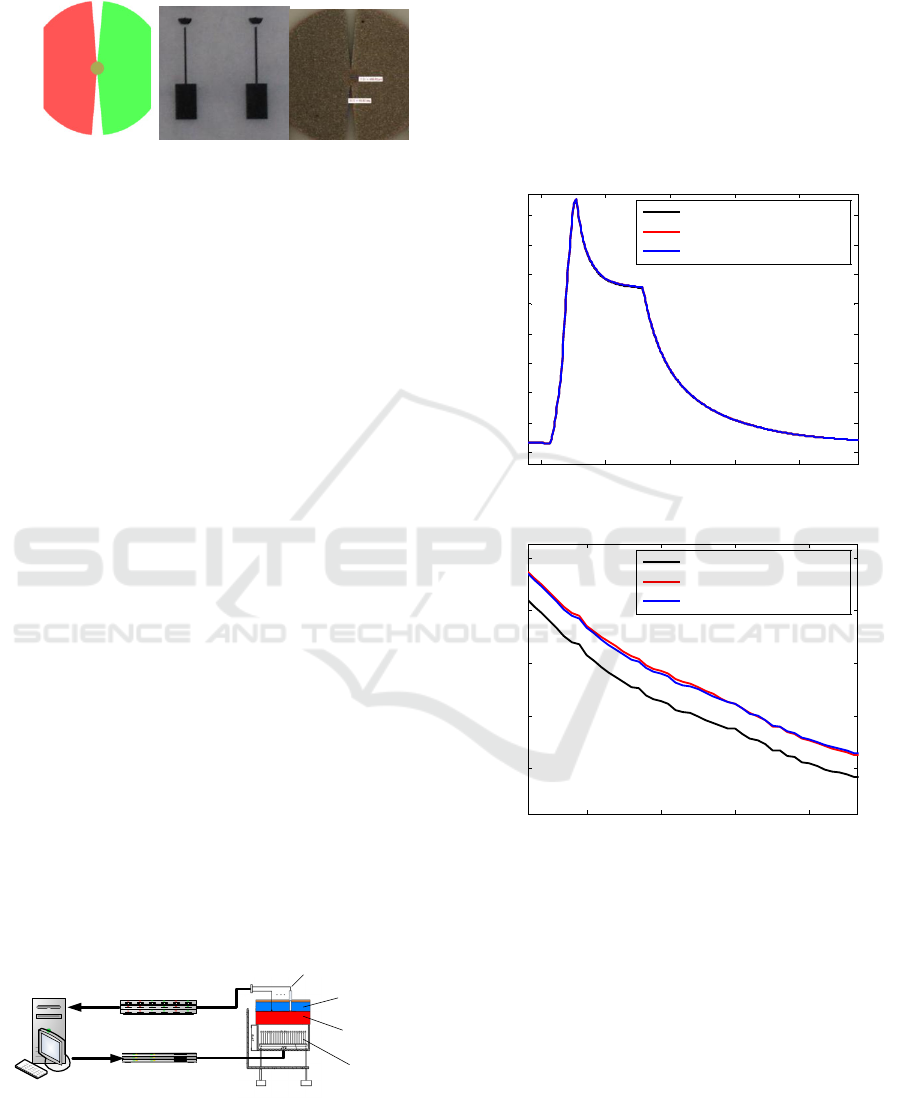

Figure 10 and Figure 11.

a: global curve

b: partial enlarged curve

Figure 10: Temperatures of the copper plate and needle

thin film thermocouples

The average temperature value of eight ordinary

thermocouples and two thin film thermocouples

were shown in the Figure 10. We could see from

figure 10 that the copper plate was begun to heated

at about 107min. And then, the temperature values

of all thermocouples increased rapidly, and reached

about 850 ℃ at about 127min. Among them, the

average temperature value of eight ordinary

thermocouples rose from 29.6℃ to 850.1℃ in 20

minutes, and its average temperature rise rate was

100 150 200 250 300

0

100

200

300

400

500

600

700

800

Time/min

Temperature/

the average from 1# to 8#

9#

10#

160 165 170 175

555

560

565

570

575

Time/min

Temperature/

the average from 1# to 8#

9#

10#

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

526

41.2℃/min, and its maximum temperature rise rate

was 78.8 ℃/min. The temperature of needle thin

film thermocouples rose from 29.6℃ to 853.2 ℃ in

20 minutes, and its average temperature rise rate was

41.2 ℃/min, and its maximum temperature rise rate

was 78.9 ℃/min.

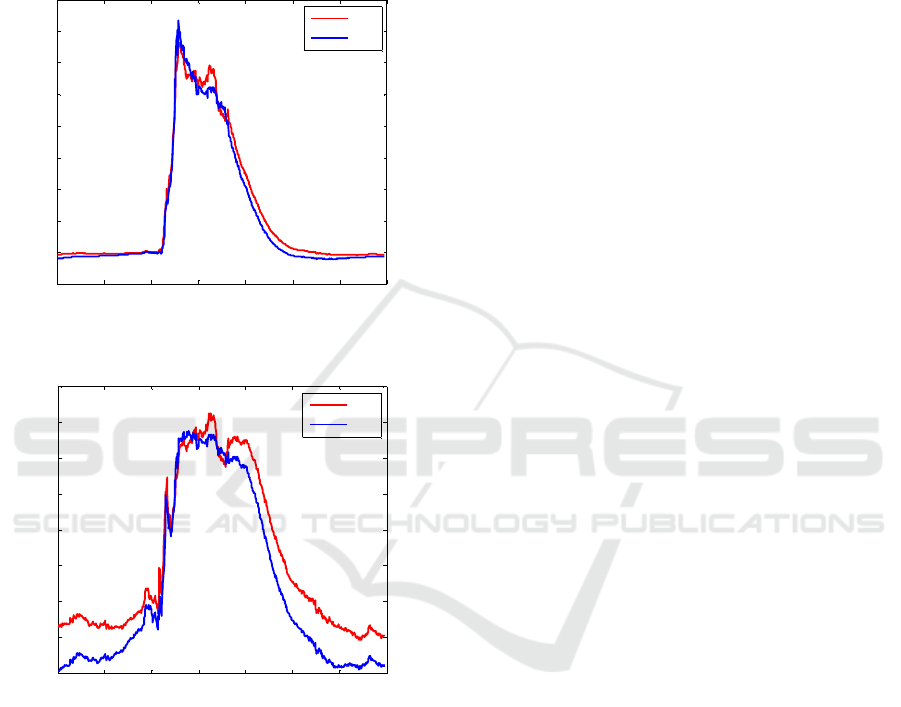

a: absolute errors

b: relative errors

Figure 11: Temperature measurement errors of thin-film

thermocouples

For the purpose of analysis of the validity and

accuracy of temperature value for the needle thin

film thermocouples, the temperature values of 9#

and 10# thin film thermocouple were compared with

the actual value of the copper plate (the average

temperature of eight ordinary thermocouples). The

absolute error and relative error of 9# and 10# thin

film thermocouple were shown in Figure 11. We can

see that the film thermocouple can response the

temperature change of the copper plate excellently,

and the response time is short. Among them, the

maximum absolute error of the needle film

thermocouple is 3.67 ℃, and the maximum relative

error is 0.47%.

Based on the analysis of experimental results, it

is shown that the thin film thermocouple based on

MEMS technology has a smaller heat capacity, and

shoter response time than the ordinary

thermocouple. Furthermore, the maximum absolute

error of the thin film thermocouple can be less then

±4 ℃, and its relative error is less than 0.5%. The

performance of the thin film thermocouple meets

well the design goals.

5 CONCLUSIONS

In this paper, a needle thin film thermocouple for the

measurement of high transient temperature on the

surfaces of hypersonic vehicle and shuttle vehicle

has been researched. The substrate of the thin film

thermocouple is made of high temperature resistant

ceramic material, and the K-type thermocouple film

was deposited on the surface of base top by

magnetron sputtering technology. The fabrication

process of the thermocouple film lead terminal and

thermal junctions were mainly studied and

optimized. The performance of the thin film

thermocouple was verified by the test system. The

test results show that the needle thin film

thermocouple owns excellent performance,

including short response time, and the relative error

of less than 0.5%. It can meet the measurement

requirements in the field of transient temperature on

surfaces of hypersonic vehicle and shuttle vehicle

completely.

ACKNOWLEDGEMENTS

The work is supported by key project of the advance

research field fund provided by the Ministry of

Equipment Development (NO. 6140923020301).

REFERENCES

Li Z W, et al. 2017. Development of thin-film

thermocouple for measuring transient temperature of

spacecraft surfaces. Spacecraft Environment

Engineering.

Manoj K S and Dewal M L. 2015. Simulation of thin film

thermocouple for high temperature measurement

applicable to missiles. Defence Science Journal.

0 50 100 150 200 250 300 350

-0.5

0

0.5

1

1.5

2

2.5

3

3.5

4

Time/min

Absolute errors/

9#

10#

0 50 100 150 200 250 300 350

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0.5

0.6

Time/min

Relative errors/%

9#

10#

Research of Thin Film Thermocouple Based on MEMS for Temperature Measurement on Spacecraft Surface

527

Wu X D. 2012. Application and prospects of MEMS

devices for space. Micronanoelectronic Technology.

Zhang S Y, Ma Y H, Zhao X J. 2013. The experimental

study of heat-flux identification technology for

hypersonic aerothermodynamics[J]. Journal of

Experiments in Fluid Mechanics.

Zhao Y S and Yang L H. 2012. Research progress of thin

film thermocouple temperature sensor. Transducer

and Microsystem Technologies.

Zhu X X and Zhou X W. 2013. Temperature sensor.

Electronic Test.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

528