Study on Pulsed Voltage Regulation Technology of Precision Plating

Power Su

pp

l

y

Feng Wang, Yongbin Zhang, Guangmin Liu, Qing Wang and Rangjie Wu

Institute of Mechanical Manufacturing Technology, China Academy of Engineering physical, Mianyang, Sichuan, China

fred110@sohu.com

Keywords: Precision electroplating power supply, Pulse voltage regulation, Current acquisition, Verilog HDL.

Abstract: For the existing precision plating pulse power, in order to achieve the precise control of the voltage, the output

voltage can be adjusted from 0 to 7V by changing the duty cycle of the MOSFET. In the system, Altera's

CycloneIV E-series chips are used as the master chip to design the PWM signal generation module, AD9215

current acquisition module and serial communication module. Verilog hardware language is used to write the

program and Modelsim software is used for PWM simulation. The resulting pulse waveform and AD9215

data collected by the observed signaltap, voltage and current data at different duty cycle are recorded by a

high-precision multimeter. Through the analysis of experimental results, the feasibility and correctness of

pulse voltage regulation are verified.

1 INTRODUCTION

The performance of electroplating power is directly

related to the quality of the electroplated coating,

which is one of the important electrical parameters

that affect the performance of the power supply.

When the current density is low, resulting in a small

cathode polarization, coating coarse crystal, or even

no coating. When the current density is too high, it

will make the crystal along the direction of the power

line to the rapid growth of the electrolyte inside, re-

sulting in coating nodulation and dendrites crystalli-

zation, or even burning. When the current density is

very large, resulting in a strong hydrogen evolution of

the cathode surface, PH larger, metal salt mixed in the

coating, so that the coating black. Therefore, the pre-

cise control of the output current parameters is very

important, which can be obtained by the conversion

relationship between the precision resistor and the

voltage. And the voltage parameters are relatively

easier to control accurately. Therefore, it is necessary

to determine the detailed duty cycle and output volt-

age curve, as well as the pulse equivalent and input

voltage curve of the AD sampling components. The

former is conducive to the determination of the initial

value of duty cycle in the voltage feedback link, so as

to shorten the time of voltage regulation, and the latter

is used to determine the intrinsic nature of the device

itself as a reference standard in the voltage regulation

process. In this paper, the pulse voltage regulation

part of the power supply is studied.

2 PULSE VOLTAGE REGULA-

TION TECHNOLOGY

2.1 System Composition

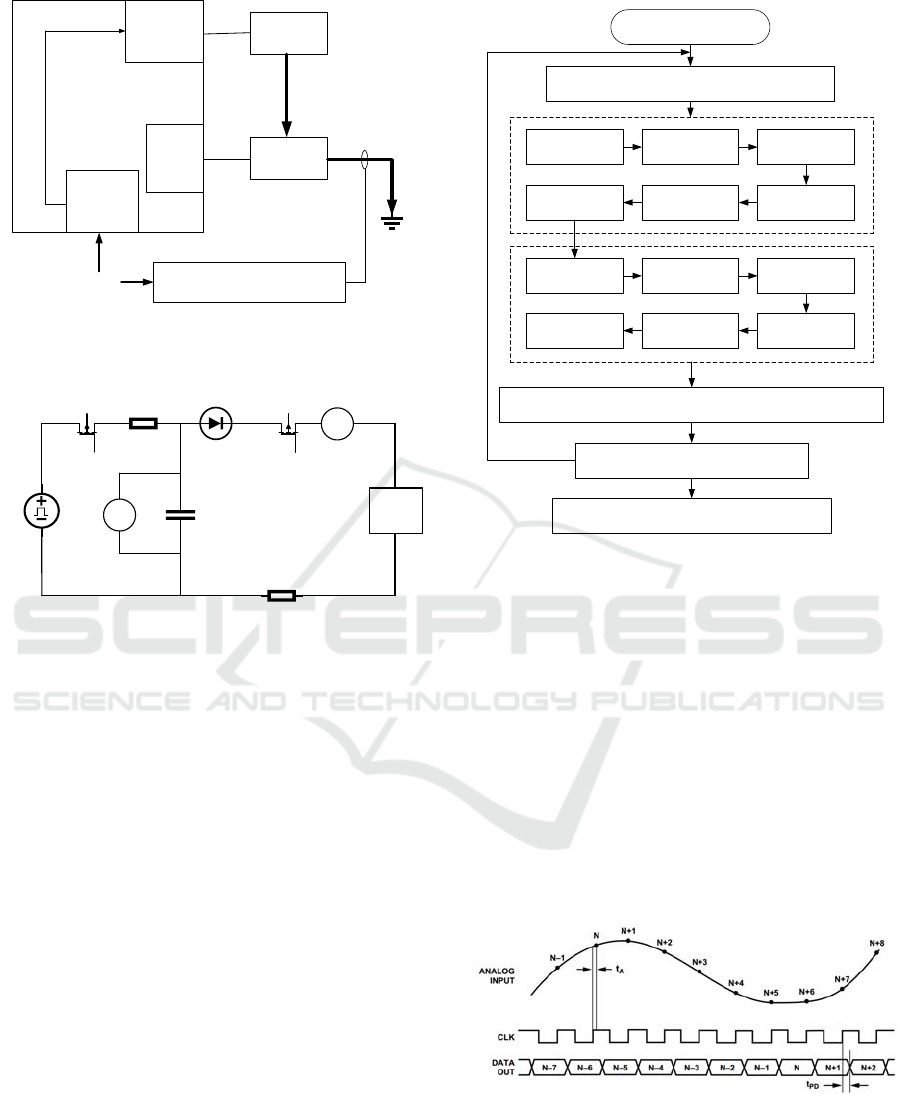

The block diagram of the whole system is shown in

Figure 1. The core of the precision plating pulse

power supply adopts FPGA chip, and the software

module includes the voltage regulation unit, pulse

control unit and current sampling unit, and completes

the functions of PWM pulse voltage regulation, pulse

control and current collection, which AD9215

through the parallel port to the collected data sent to

the FPGA. The system uses closed-loop control, the

feedback current AD sampling results compared with

the set value, according to the size of the difference

between the PWM duty cycle module to produce real-

time adjustment, the driver chip amplification control

Q1 MOSFET, Q2 MOSFET on and off, in order to

achieve Accurate control of the output voltage and

pulse waveform, the circuit diagram shown in Figure

2.

Wang, F., Zhang, Y., Liu, G., Wang, Q. and Wu, R.

Study on Pulsed Voltage Regulation Technology of Precision Plating Power Supply.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 503-509

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

503

FPGA

Software

Module

Pulse

Control

Unit

Q1

MOSFET

Q2

MOSFET

parallel

port

AD9215 sampling circuit

10bit

GND

Current

Sampling

Unit

Voltage

Regulation

Unit

Figure 1: System and software peripheral interface logic

diagram.

load

E

V

Q1

Q2

C

R1

R

A

D

Figure. 2: Schematic diagram of power supply circuit.

2.2 Duty Cycle Pulse Voltage Regula-

tion

The duty cycle in this article is equal to the period

divided by the pulse width in order to be programmed

and applied in practice. Using the Pulse voltage regu-

lation mode, the PWM signal generated by the FPGA

logic circuit is used to control the MOSFET, and then

the output voltage is changed, and the PWM signals

controlled by the Q1 MOSFET are obtained by the

FPGA clock 50M crystal frequency. The experi-

mental flowchart of pulse voltage regulation is shown

in Figure 3. The sampling of duty cycle and the sam-

pling points within each step are based on the princi-

ple that the output voltage is linearly changed during

experiment.

Pulse voltage

regulation

Q1 Duty Cycle x (Period / Pulse Width)

Change every 30s

0<x<=20

x=x+1

20<x<=200

x=x+5

200<x<=1000

x=x+20

3000<x<=5000

x=x+200

1000<x<=3000

x=x+100

1000<x<=3000

x=x-100

3000<x<=5000

x=x-200

5000<x<=10000

x=x-500

Record the serial assistant's duty cycle,

current equivalent, voltmeter value, ammeter value

Draw the duty cycle regulator curve,

analyze the data

Change the pulse width of Q1 and

the duty cycle of Q2

200<x<=1000

x=x-20

20<x<=200

x=x-5

0<x<=20

x=x-1

5000<x<=10000

x=x+500

Figure 3: The experiment flow Chart of pulse voltage

regulation of duty cycle.

2.3 Current Acquisition

The AD9215 is used in a current sampling circuit with

a 10-bit data bit and a high performance sample-and-

hold amplifier and output error correction logic with

a signal to noise ratio of 58dBc. The flexible analog

input range is 1V to 2V, using the single power supply

of 2.7V~3.3V. The data format is an offset binary,

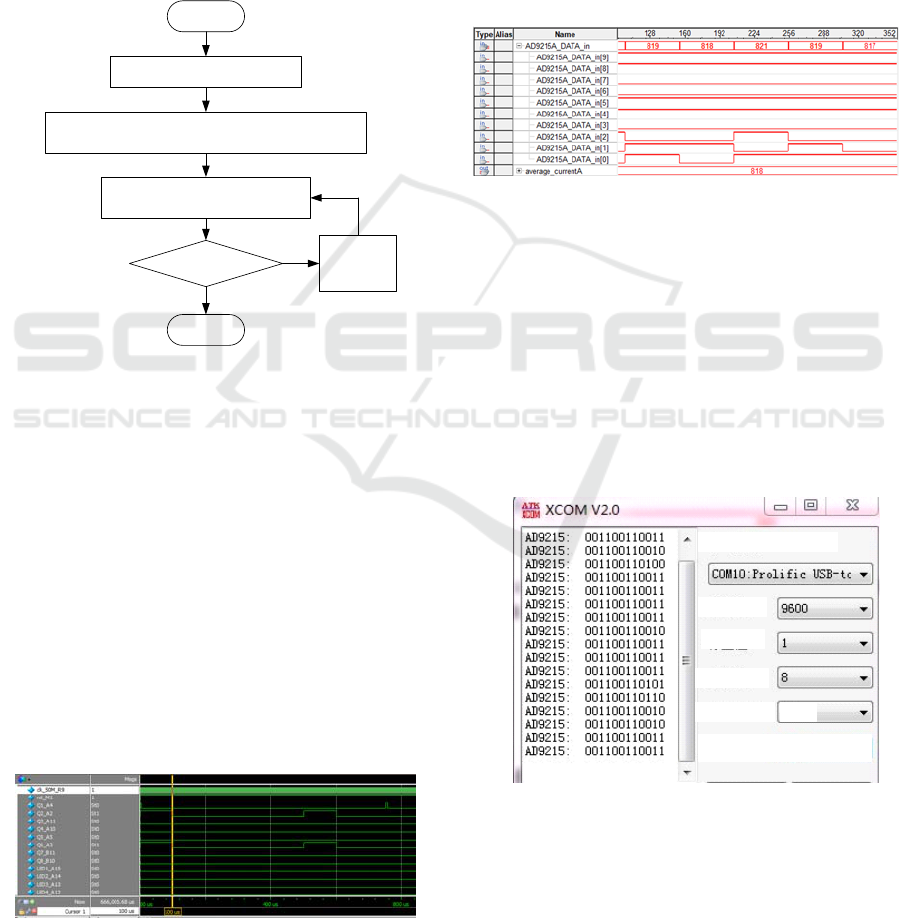

with a clock duty cycle stabilizer. The time sequence

diagram of the AD9215 work is shown in Figure 4. In

this experiment, the sampling clock CLK is obtained

by the 50M crystal oscillator of the FPGA.

Figure 4: AD9215 Work sequence diagram.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

504

Figure 5 is a flow chart using AD9215 to adjust

voltage, the idea is to set the output voltage value,

according to the duty cycle regulating curve measured

in Figure 3, to determine the Q1 initial value of the

duty, and then to calculate the true voltage value by

AD9215 the current and the output voltage

relationship shown in table 4. Compared with the set

value, the real voltage output value and the set value

are within the error allowable range by adjusting the

Q1 duty cycle continuously.

Start

According to the duty cycle curve to determine

the Q1 initial value of the duty cycle

Set the initial voltage

Determine the actual voltage

based on the current value

To set voltage?

Adjust Q1

duty cycle

End

Figure 5: Flow Chart of AD9215 regulating voltage.

3 SIMULATION AND EXPERI-

MENTAL RESULTS ANALY-

SIS

3.1 Simulation Analysis

Modelsim is a powerful simulation software that of-

fers fast, accurate and easy-to-use features. The prep-

aration of the project file simulation, the results

shown in Figure 6. Q1 MOSFET pulse width of 5μs,

duty cycle of 150. Q2 MOSFET pulse width of 100μs,

duty cycle of 5. Modelsim simulation shows that the

design of the pulse generation method is feasible.

Figure 6: Simulation of pulse generating signal.

Signaltap is an embedded logic analysis tool inte-

grated in Quartus II platform. During the early stage

of FPGA design, signaltap inserts the logic analysis

kernel into the system and can capture multiple sig-

nals inside the chip and store the data in the on-chip

memory. Through the JTAG download line to read

data to the PC, simultaneously display multiple sig-

nals on the monitor to verify whether the desired re-

sults. Observed using signaltap, as shown in Figure 7,

where DATA_in is the value taken at 1MHz, aver-

age_current is calculated by averaging 300 values. It

can be seen that the fluctuations are not large and the

acquisition is very stable.

Figure 7: The acquisition value of the AD9215 observed

by signaltap.

The communication method that the serial port

uses is very simple, the serial port is a one-bit send-

ing. Although sending data much slower than a USB

packet, using two different data lines simultaneously

sends and receives data, the maximum transfer speed

is up to 20Kb/s for low-speed data transfer. Serial As-

sistant to collect data at a baud rate of 9600, the binary

value is displayed, converted to about 818 decimal, as

shown in Figure 8, AD acquisition function is normal

and effective.

Baud rate

Serial port selection

Stop bit

Parity check

Data bit

NO

Figure 8: The acquisition value of the AD9215 observed

by serial assistant.

Study on Pulsed Voltage Regulation Technology of Precision Plating Power Supply

505

3.2 Experimental Results Analysis

3.2.1 Relation Between Duty Cycle and Out-

put Voltage

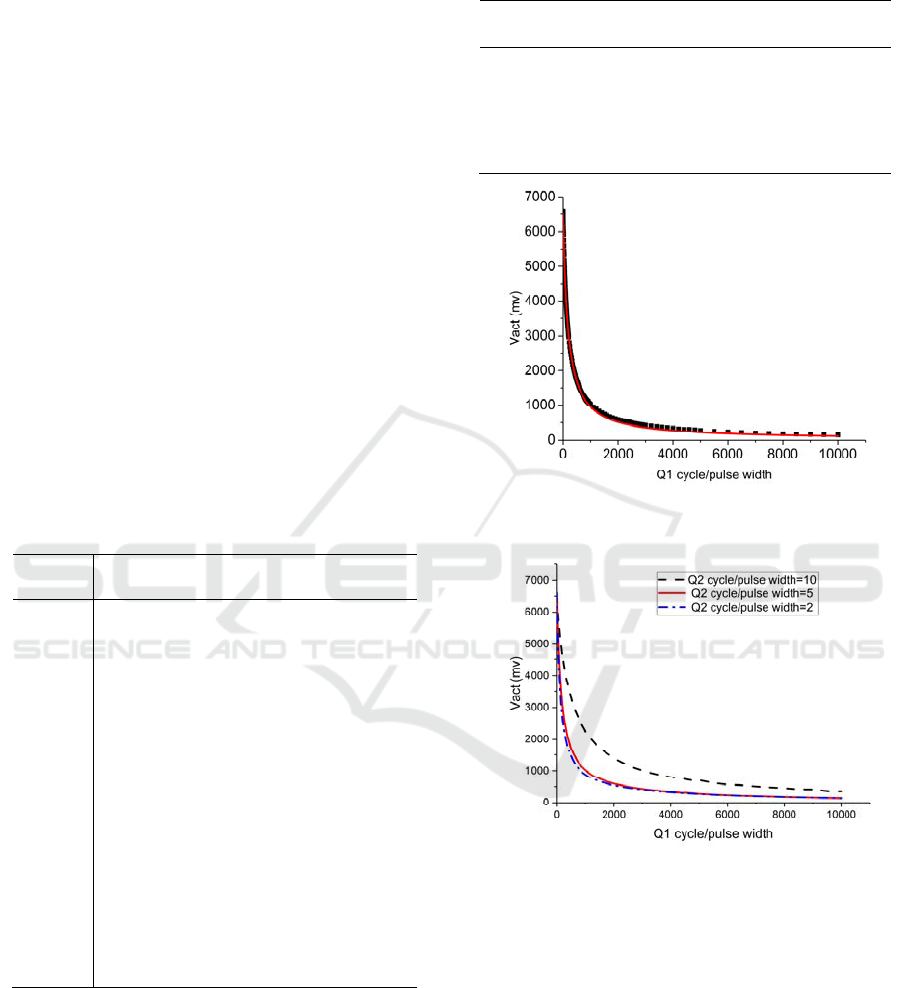

Change the Q1 MOSFET duty cycle according to

the design in Figure 3 and record the voltmeter values

while the voltage is stable, as shown in Table 1, tak-

ing one data point from the measured data at approx-

imately 0.5V each. The experimental order and con-

ditions and the fitting function as shown in Table 2,

the argument x is the duty cycle of the Q1 MOSFET,

the variable y is the voltage across the capacitor C,

Q1 MOSFET duty cycle and measured voltage fitting

curve shown in Figure 9 shows. Since the duty cycle

selected in this paper is the reciprocal of the standard

duty cycle, according to the principle of PWM regu-

lator, therefore, first consider the relationship be-

tween voltage and duty cycle inversely proportional

function. The curve is fitted using Eqs. (1), and the

result c is about zero. From Figure 3, the curve and

the data points can be a good match.

y

= 1 / (ax + b) + c (1)

Table 1: The value of Q1 duty cycle and voltmeter under

four kinds of experimental conditions.

Q1 duty

cycle

V1(mv) V2(mv) V3(mv) V4(mv)

1 6340 6480 6600 6600

30 5890 6000 5590 5370

75 5350 5510 4500 4110

135 4800 5000 3600 3154

200 4350 4550 2970 2548

300 3830 4000 2358 2000

400 3429 3600 1965 1666

600 2861 2983 1490 1258

800 2450 2578 1210 1028

1200 1905 2013 885 770

1800 1432 1520 644 580

3000 965 1010 424 400

7000 470 504 199 196

Table 2: The fitting equation under four experimental

conditions

Q1 pulse

width(μs)

Q2 duty

cycle

fitting formula

50 10 y=10^5/(16.155+0.0318x)

1 10 y=10^5/(15.783+0.0295x)

1 5 y=10^5/(15.286+0.0897x)

1 2 y=10^5/(15.225+0.0116x)

(a) Q1 pulse width 50us, Q2 pulse width 50us duty cycle

10.

(b) Q1 pulse width 1us, Q2 pulse width 50us duty cycle

10,5,2.

Figure 9: The relation diagram of Q1 duty cycle and

voltmeter value.

It can be seen from table 2 that different Q1

MOSFET pulse width and different Q2 MOSFET

duty cycle will cause the change of the voltage value

at both ends of capacitance C at the same duty cycle.

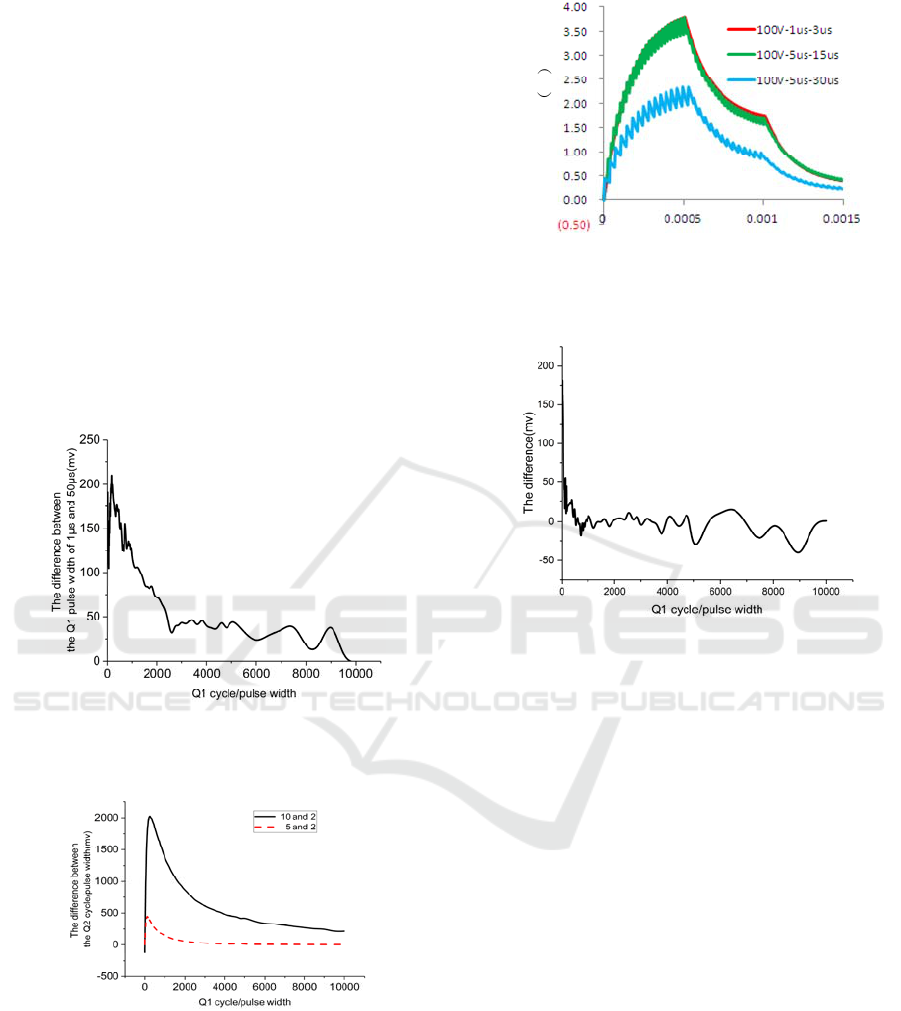

When the pulse width and duty cycle of the Q2

MOSFET are unchanged, the pulse width of the Q1

MOSFET changes from 50 μs to 1 μs, and the voltage

value of the latter minus the former voltage value at

the same Q1 MOSFET duty cycle is shown in Figure

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

506

10(a). According to the principle of PWM voltage

regulation, the change of the pulse width of Q1

MOSFET does not affect the voltage value change of

the capacitor C, and the possible reasons are as fol-

lows: on the one hand, the state of the power supply

has changed under the condition of two energizations;

on the other hand, as shown in Figure 11, the simula-

tion shows that when the pulse period, pulse width

and pulse interval of the processing pulse are rela-

tively large, the ratio of the time constant to the dis-

charge is also relatively large, which will cause the

wide range fluctuation of the average gap voltage and

a slight decrease of the voltage amplitude in a certain

range. As the Q1 MOSFET's duty cycle increases, the

voltage difference decreases. The reason is that as the

duty cycle increases, the proportion of the pulse width

decreases, and the effect of fluctuations on the aver-

age voltage decreases.

(a) Voltage difference curve of Q1 pulse width 1μs and

5μs.

(b) Voltage difference curve of Q2 duty cycle 10 and 2, 5

and 2.

Figure 10: The voltage difference under the same

conditions of Q1 duty cycle.

The average voltage

detected

V

Time (s)

Figure 11: The simulation results of average voltage

detection curve.

Figure 12: Voltage difference curve of Q1 duty cycle from

small to large and from large to small.

The constant MOSFET Q1 pulse width changes

the duty cycle of the Q2 MOSFET resulting in the dif-

ference shown in Figure 9 (b). This change corre-

sponds to a change in the load. The duty cycle of the

Q2 MOSFET increases, indicating a decrease in load.

According to the principle of partial voltage, the volt-

age across the capacitor C rises, as shown in Figure

10 (b), which is Q2 MOSFET duty cycle 10 minus the

difference between 2 and 5 minus 2, with Q1

MOSFET duty cycle Increase, the difference in-

creases first and then decreases. As shown in Figure

12, it is the difference diagram of output voltage be-

tween Q1 MOSFET duty cycle from small to large

and from large to small. It can be seen that within the

error allowable range, the measurement way of Q1

MOSFET duty cycle will not have a great effect on

the result.

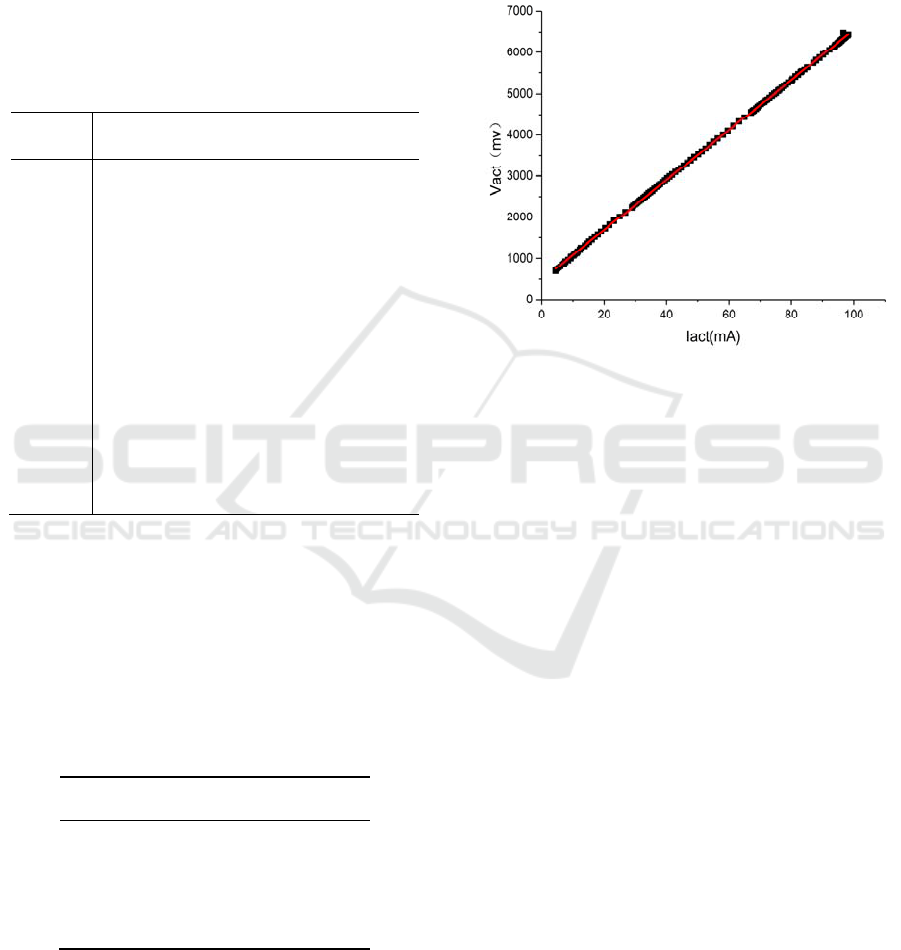

3.2.2 Equivalent Current Value and Output

Voltage

The Q1 MOSFET duty cycle is changed according to

the design in

Figure 3, and the value of Voltmeter and

Study on Pulsed Voltage Regulation Technology of Precision Plating Power Supply

507

Ammeter are recorded at the same time when the volt-

age is stable. Reference Table 1 corresponds to the Q1

MOSFET duty cycle to take data points, the results

shown in Table 3. The experimental sequence, the

conditions and the fitting function are shown in Table

4, the independent variable x is the equivalent current

value (ammeter value * Q2 MOSFET duty cycle), and

the dependent variable y is the voltage value across

the capacitor C.

Table 3: Q1 duty cycle and equivalent current under the

four conditions.

Q1 duty

cycle

I1(mA) I2(mA) I3(mA) I4(mA)

1 95.5 96.7 100.8 101.8

30 89.6 91.0 84 81.4

75 80.6 83.0 66.1 59.4

135 71.5 74.5 51.05 43.9

200 64.2 67.1 40.75 33.92

300 55.5 58.1 30.7 25.16

400 48.6 51.3 24.25 19.64

600 39.2 41 16.6 13.16

800 32.3 34.2 12.2 9.6

1200 23.6 25 7.2 5.72

1800 16.1 17 3.75 3.08

3000 8.8 9.3 1.15 1.08

As the actual work will not be used below 3mA,

the relevant data will be discarded, the equivalent cur-

rent value and output voltage fitting curve are shown

in Figure 13. It can be seen is a clear linear relation-

ship, the fitting function is Eqs. (2), the specific for-

mula shown in Table 4.

y

= a + b * x (2)

Table 4: Fitting relations under different experimental

conditions.

Q1 pulse

width

(μ

s

)

Q2 duty

c

y

cle

fitting formula

50 10 y=474.5+60.4x

1 10 y=475.9+60.7x

1 5 y=476.1+60.8x

1 2 y=474.5+60.2x

From Figure 13, the curve and data points can be

matched well. The slope represents the resistance

value. In this experiment, R is 51Ω. Therefore, the

equivalent resistance of the other devices in the cir-

cuit is about 10Ω, and the voltage drop of the diode

and other devices is about 475mV. It can be seen that

the Q1 MOSFET pulse width is different and the duty

cycle of Q2 MOSFET is different in the range of error

allowances, which does not affect the value of the

equivalent resistance and the equivalent voltage drop.

Figure 13: The fitting curve of equivalent current and

voltage.

4 CONCLUSIONS

In this paper, according to the existing precision elec-

troplating pulse power supply, the program is pro-

grammed by the PWM voltage regulation principle,

and the effectiveness of the pulse generation is veri-

fied on the Modelsim. The data collected by AD9215

are recorded on signaltap and serial assistants, and the

feasibility of AD acquisition is verified. The duty cy-

cle pulse voltage regulation experiment was designed.

The voltage and current data of different conditions

were measured. The duty cycle voltage regulation

curve and the equivalent current and output voltage

curve were fitted. Analyzed the causes of the change,

calculated the equivalent resistance and equivalent

voltage drop in the circuit, which laid the foundation

for the precise control of the output voltage.

ACKNOWLEDGEMENTS

The authors appreciate the support from the National

Natural Science Foundation of China (Grant No.

51475439) and Sichuan Provincial Science and Tech-

nology Department of application-based projects

(Grant No. 2016JY0109).

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

508

REFERENCES

Shusen Wang. Study on Pating copper in Cyanide Free

Bath [D]. Dalian Maritime University, 2009: 50-52.

Hua Liu. Research on digital multi-channel pulse ampli-

tude analyzer based on FPGA and preliminary devel-

opment of digital gamma spectrometer [D]. Donghua

University of Technology, 2016: 20-24.

Zhixiang Dong. Research on Modem for Underwater RF

Communication [D]. Dalian University of Technology,

2016: 20-25.

Yongbin Zhang. Detection of Micro-EDM Discharge

Based on Change of Impedance Between Polar Chan-

nels [C] // National Conference of Specialty Processing.

2017: 231-238.

Xiaoming Wang, Yong Zou. Design and working analysis

of a capacitor-regulated surge power source [J] .High

Voltage Engineering, 2007, 33 (6): 25-29.

Xiaokang Liu, Lifeng. Ultra-short pulse micro-electrolysis

process power supply and process test [J]. Journal of

South University of South, 2008, 36 (8): 75-78.

Study on Pulsed Voltage Regulation Technology of Precision Plating Power Supply

509