Research on Gasoline Engines Health Monitoring and Fault

Dia

g

nosis based on Vibration Si

g

nal Anal

y

sis

QiuqinYue

1

and Jielin Zhou

2

1

Chongqing College of Electronic Engineering, Chongqing, 401331, China

2

Chongqing University, Chongqing,400044, China

yqq622@163.com

Keywords: Engine Health Monitoring, Fault Diagnosis, Vibration Signal Analysis, Wireless Acceleration Sensor, Fast

Fourier Transform.

Abstract: Aiming at research on engine health monitoring and fault diagnosis based on the characteristics of the

surface vibration signals measured from the engine, a measured method by using wireless acceleration

sensor is proposed in this paper. The basic characteristics of engine vibration signal taking the Chevrolet

Epica 2HO automotive engine as an example was measured in this paper. The original measured data was

pre-processed using the Fast Fourier Transform (FFT) to suppress abnormal interference of noise, and avoid

the pseudo mode functions. Finally, the vibration signals of automotive engine are analyzed and the results

show that the method is feasible and effective in feature extraction and condition evaluation of engine health

monitoring and fault diagnosis.

1 INTRODUCTION

More and more importance of health monitoring and

fault diagnosis has been realized, which is no longer

a supplementary accessory to the system, but a

necessary and essential element to ensure reliability

and productivity in an effective and cost-efficient

way (Jin, 2014). Gasoline engines, as one of the key

equipment in a variety of applications, have always

been popular as the subject of condition health

monitoring. Engine contains abundant fault

messages. Thus the gasoline engine health

monitoring and fault diagnosis technique based on

the characters of engine vibration signal is adopted

to enhance the operation reliability and reduce the

blindness of the maintenance work. Actually, engine

is a complicated mechanical system with various

vibration excitations and different corresponding

excitation mechanisms. For instance, automotive

engine is chosen as an illustrative case study. In

normal condition, the gas pressure and inertia force

are the most common and immediate excitation

sources of the automotive engine. They act on the

automotive engine with their own effect rule and

frequency and cause a wide variety range of

vibration signal. Specifically, the gas pressure acts

mainly on the cylinder head and the frequency band

covers from tens to thousands Hz; but the inertia

force acts on the cylinder block and manifest a slow

frequency harmonic oscillations. So the accurate

extraction of vibration signals is very important to

the engine health monitoring and fault diagnosis

(Chandroth, 1999; Taglialatela,2013; Gravalos,

2013; Geng, 2003).

Recently, In order to monitor engine health and

further diagnose faults in gasoline engines, various

successful methodologies have been developed. S. P.

Mitchell Lebold et al intensively investigated several

different methods to analyse faults based on injector

signal, vibration signal, and speed encoder signal.

Misfire faults have been successfully identified

using time domain, frequency domain and order

domain analysis tools. Signals of each category of

every method were presented to show the difference

between normal and faulty condition, and the

quantization of the difference is later formulated. All

the approaches had the ability to identify the faulty

cylinder location (Jin, 2014). Mollazade et al.

presented a fault diagnosis method for external gear

hydraulic pumps based on a fuzzy inference system

(FIS)

(2009). Sakthivel et al. used decision tree and

other machine learning algorithms for fault detection

of mono-block centrifugal pump. Ahmadi and

Mollazade investigated fault diagnosis of an electro-

pump in a marine ship using vibration analysis

(2010). Muralidharan and Sugumaran presented a

440

Yue, Q. and Zhou, J.

Research on Gasoline Engines Health Monitoring and Fault Diagnosis based on Vibration Signal Analysis.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 440-443

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

procedure for mono-block centrifugal pump fault

diagnosis based on vibration signals (2013).

However, few of research works are designed

and researched based on the actual vibration

circumstance in practical applications. In order to

research on engine health monitoring and fault

diagnosis based on the characteristics of the surface

vibration signals measured from the engine, a

measured method by using wireless acceleration

sensor is proposed in this paper. Firstly, for

convenience, the paper measures and analyzes the

basic characteristics of engine vibration signal

taking the Chevrolet Epica 2HO automotive engine

as an example. Secondly, the original data is pre-

processed using the Fourier transform to suppress

abnormal interference of noise, and avoid the pseudo

mode functions. Finally, the vibration signals of

automotive engine are analyzed and the results show

that the method is feasible and effective in feature

extraction and condition evaluation of engine health

monitoring and fault diagnosis.

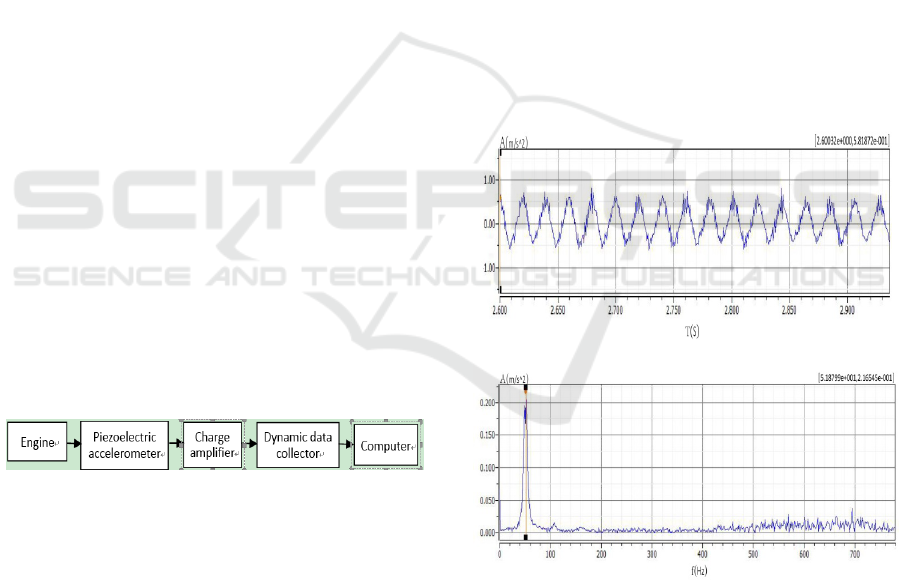

2 MEASUREMENT OF ENGINE

VIBRATION SIGNAL

To elaborate on basic characteristics of engine

vibration signal and emphasis on the need to

incorporate real vibration environment, the paper

take the Chevrolet Epica 2HO automotive engine as

the monitoring content and records the vibration

signals on the cylinder head in both time and

frequency domains. The engine vibration collection

system is provided by YMC PIEZOELECTRIC INC

and the schematic is shown in Figure 1.

Figure 1: The schematic of the engine vibration test

system

Vibration signals are collected in normal and no-

load running conditions and vary from seven

different speeds, as summarized in Table 1. All the

data are taken from the z-axis, which is normal to

the deck (C. Polonowski, 2007).

As shown in figure 1, the vibration signals on the

cylinder head of engine are measured by the

piezoelectric acceleration sensor (accelerometer).

But this signals are too small to show in the

measured instruments, so the measured signals are

amplified by feeding into the charge amplifier, and

the amplitude of signal are enhanced. Moreover, the

noise signal is suppressed by using dynamic data

collector. Finally, the vibration data are transmitted

to the computer by wireless communication method.

The vibration signals are measured at the condition

of the lowest 800 rpm and highest 4000 rpm for

engine speed.

3 ANALYSIS OF THE

MEASURED DATA

Vibration analysis is the most successful and cost

efficient group of condition monitoring methods.

Vibration analysis is a promising technique which is

particularly used for some time as a predictive

maintenance method and as a support for machinery

maintenance decisions (Ahmadi H, 2009). In the

proposed health monitoring system, the vibration

signals in Z direction on the cylinder head of the

engine are analysed by using the Fast Fourier

transform (FFT) in detail as follows. The plots of

vibration signal at the lowest 800 and highest 4000

speed are given in Figure 2 and 3, respectively.

(a) Time domain

(b) Frequency domain

Figure 2: The acceleration amplitude of vibration signal in

Z direction on the cylinder head of the engine at the lowest

800 rpm of speed

Research on Gasoline Engines Health Monitoring and Fault Diagnosis based on Vibration Signal Analysis

441

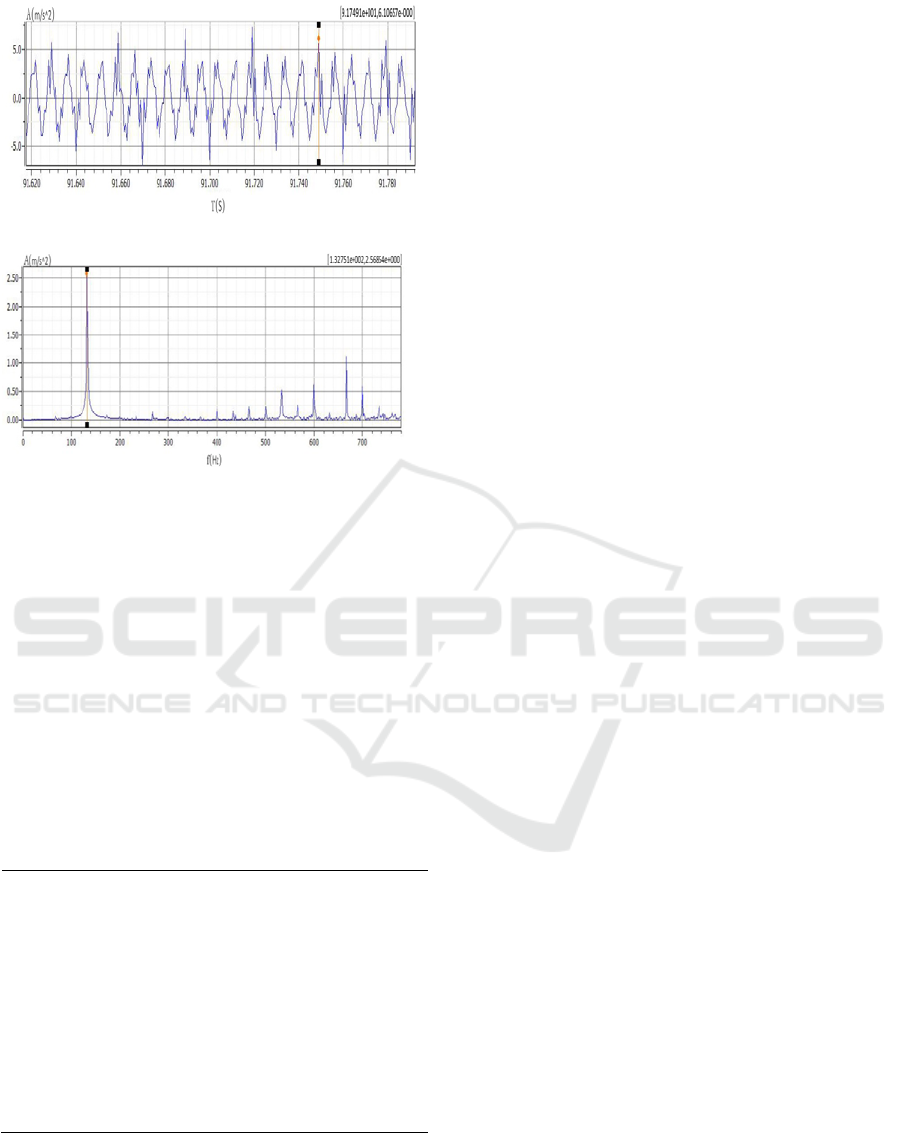

(a) Time domain

(b) Frequency domain

Figure 3: The acceleration amplitude of vibration signal in

Z direction on the cylinder head of the engine at the

highest 4000 rpm of speed.

Although the time domain wave forms of

vibration signals in Figure 2 and 3 are bewildering,

periodic gas force excitation can be observed

obviously, which is consistent with theoretical

analysis in previous. In addition, the FFT results

demonstrate the gas force’s prompted vibration is

laid on low frequency band and the value of the

frequency is apparently positively related to engine

speed, which is also confirmed in Table 1.

Table 1: The values of vibration signal in Z direction on

the cylinder head of the engine

Speed

(r/min)

Acceleration

amplitude (m/s

2

)

Acceleration

frequency (Hz)

800 -0.49 ~ 0.58 51.88

1500 -0.76 ~ 0.98 53.41

2000 -1.63 ~ 1.76 74.77

2500 -2.30 ~ 2.32 94.60

3000 -3.45 ~ 4.60 111.39

3500 -5.97 ~ 5.95 129.70

4000 -6.67 ~ 6.10 132.75

Such these characterizations provide practical

performance requirements for the design of the

engine health monitoring and fault diagnosis used in

the particular application (B. Badawi, 2006).

Adapted for engine vibration conditions under

different speeds, the designed vibration structure

should work in withstand accelerations of 7m/s

2

and

extract the electrical response in around 50 to 130Hz

frequency range.

4 CONCLUSION

In order to research on engine health monitoring and

fault diagnosis based on the characteristics of the s

from the engine, this paper proposed one method of

measuring vibration signals of engine by using

wireless acceleration sensor. The original measured

data was pre-processed using the Fast Fourier

transform (FFT) to suppress abnormal interference

of noise. The vibration signals of automotive engine

are analyzed and the results show that the method is

feasible and effective in feature extraction and

condition evaluation of engine health monitoring

and fault diagnosis.

ACKNOWLEDGEMENTS

The authors thank Chongqing Research Program of

Basic Research and Frontier Technology (Grant No.

CSTC2015jcyjA40017)

REFERENCES

Jin C., Zhao W., Liu Z., Lee J., He X. (2015) 2014

International Conference on Prognostics and Health

Management, PHM 2014, art. No. 7036371.

Chandroth, G. O., Sharkey, A. J. C., & Sharkey, N. E.

(1999). Cylinder pressures and vibration in internal

combustion engine condition monitoring. In

Proceedings of Comadem, 99.

Taglialatela, F., Lavorgna, M., Mancaruso, E., &

Vaglieco, B. M. (2013). Determination of combustion

parameters using engine crankshaft speed. Mechanical

Systems and Signal Processing, 38(2), 628–633.

doi:10.1016/j.ymssp.2012.12.009.

Gravalos, I., Loutridis, S., Moshou, D., Gialamas, T.,

Kateris, D., Tsiropoulos, Z., & Xyradakis, P. (2013).

Detection of fuel type on a spark ignition engine from

engine vibration behavior. Applied Thermal

Engineering, 54, 171–175.

doi:10.1016/j.applthermaleng.2013.02.003.

Geng, Z., Chen, J., Barry Hull, J. (2003). Analysis of

engine vibration and design of an applicable

diagnosing approach. International Journal of

Mechanical Sciences 45, 1391–1410.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

442

Mollazade K, Ahmadi H, Omid M, (2009). An intelligent

model based on data mining and fuzzy logic for fault

diagnosis of external gear hydraulic pumps. Insight

2009; 51(11): 594–600.

Sakthivel NR, Sugumaran V and Babudevasenapati S.

(2010).Vibration based fault diagnosis of monoblock

centrifugal pump using decision tree. Expert Syst.

Appl.2010; 37:4040–4049.

Muralidharan V and Sugumaran V. Feature extraction

using wavelets and classification through decision tree

algorithm for fault diagnosis of mono-block

centrifugal pump. Measurement 2013; 46(1): 353–359.

C. Polonowski, V. Mathur, J. Naber, J. Blough, (2007).

Accelerometer based sensing of combustion in a high

speed HPCR diesel engine. SAE Technical Paper

2007-01-0972.

Ahmadi H and Mollazade K, (2009). Fault diagnosis of an

electro-pump in a marine ship using vibration

condition monitoring. Insight 2009; 51(8): 431–438.

B. Badawi, M. Shahin, M. Kolosy, S. Shedied et al.,

(2006). Identification of diesel engine cycle events

using measured surface vibration. SAE Technical

Paper 2006-32-0097.

Research on Gasoline Engines Health Monitoring and Fault Diagnosis based on Vibration Signal Analysis

443