Control and Implementation Technology for Horizontal Swivel

Daoping Xie, Dingxu Wen and Zhiwu Xue

(Cccc Wuhan Harbour Engineering Design And Research Co.,Ltd., Wuhan, Hubei, 430070, China)

Keywords: Horizontal swivel method, structural safety, control implementation,Brick wall lock.

Abstract: The horizontal swivel method used in bridge construction can avoid the effect to operation and safety, when we

need to cross the existing railway, highway, bridge and arterial traffic road. This is advantaged than other

construction methods. Through the horizontal swivel of the T-structure bridge of LiMin road, we propose the

corresponding requirements and measures for the construction process, structural safety and construction

control, at the same time, the difference between the brick wall and sand box for temporary locking is analyzed.

According to accurate swivel test data and reasonable control implementation technology, the beam is

accurately swiveled to the design position; this can be used as experience in future similar construction.

1 PROJECT OVERVIEW

The horizontal swivel method install turntable on the

bearing platform of bridge, places the pier shaft and

cantilever beam above it, so that it achieves

gravitational equilibrium. The traction system

provide the moment of couple to rotates around the

center of the turntable.

Liming Road Bridge is located beyond the north

second ring road of Chengdu. The main bridge

crosses the Baoji-Chengdu Railway in s straight line.

The swivel structure incorporates spherical hinges

turning system of slide-way support and central

spherical hinges. T-structure cantilevers are 41+41m.

Angle of swivel is 90 degrees. Total weight of swivel

system is about 68000kN.

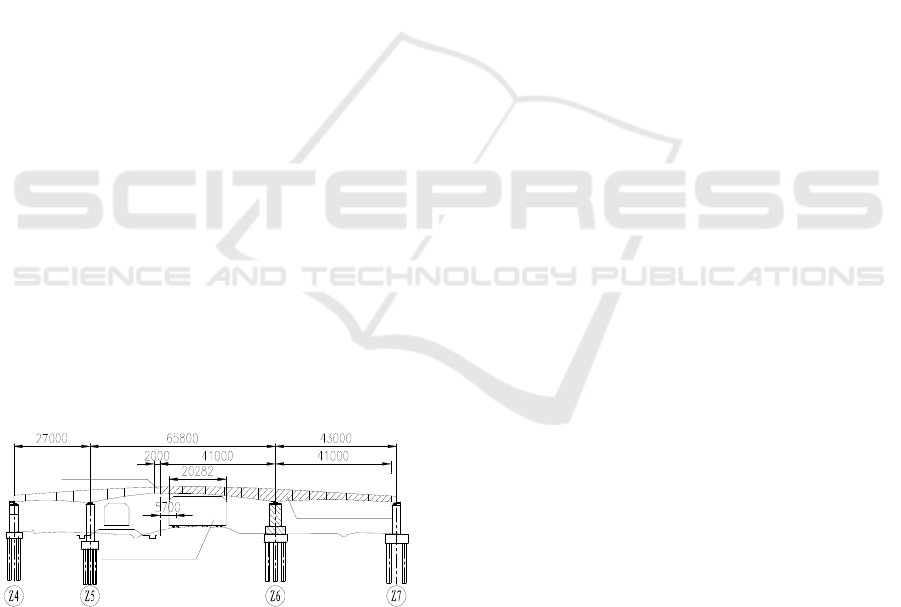

Existing railway

Closure segments

Swivel structure

Fig.1: Swivel Bridge overall arrangement

2 KEY POINTS OF

CONSTRUCTION

The swivel construction implementation control

mainly includes: turntable construction phase and

swivel system construction phase.

Before and after the swivel construction, the

posture of the whole swivel structure is ensured to be

in a controllable range, through various control

measures.

2.1 Turntable construction

Turntable construction primarily involves spherical

hinges and slide-way. They are the key factor to

successful swivel implementation, and also directly

impact the precision. So, the installation accuracy

should be controlled strictly.

(1) The deviation between the central position of

spherical hinges and theoretical center is not greater

than ±1mm.

(2) The error of flatness and concentricity of

spherical hinges is less than ±1mm.

(3) The error of slide-way surface is less than ±

1mm.

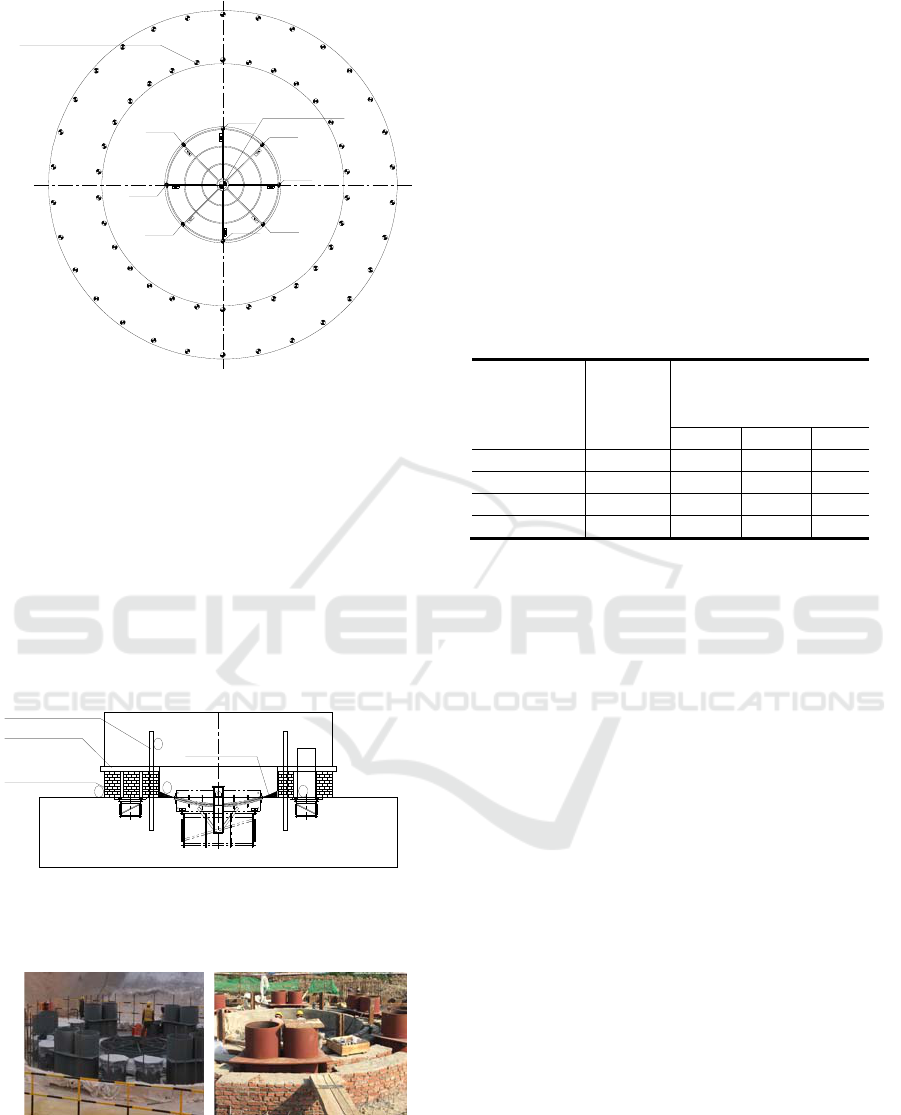

In order to ensure the installation system of

swivel system, the spherical hinges incorporates one

central measure point and eight horizontal measure

points. The slide-way involves 60 horizontal

measure points with 30 points on inside and outside

surfaces. Measuring points are distributed in Fig.2.

Xie, D., Wen, D. and Xue, Z.

Control and Implementation Technology for Horizontal Swivel.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 405-408

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

405

Slide-way

Spherical hinge

Center point

MP 1

MP 2

MP 3

MP 4MP5

MP 6

MP 7

MP 8

Slide measuring point

Fig.2: Measuring points layout of Spherical hinges and

slide-way

In order to avoid swivel and overturn of

turntables before the swivel construction, temporary

locking is installed between the turntables. By

conventional methods, the sand box supports and

screw-thread steel anchors are used to lock at same

time, and the wedge blocks are inserted between

support feet and slide ways to avoid swivel. This

project is supported by the brick wall, and anchored

by six steel rails between the upper and lower

turntables, which can lock together, as shown in Fig.

3.

brick wall locking

Steel rails anchors

1

4

2

3

Mortar bottom

Bottom formwork

Fig.3: The diagram of Brick wall lock

Construction situation of traditional method and

present method is shown in Fig. 4.

Fig.4: Construction situation of traditional method and

present method

2.2 Swivel construction

When the swivel system construction is completed,

the swivel construction can be implemented. Swivel

construction includes test swivel and formal swivel.

Test the swivel before the formal swivel

construction.

Test swivel provides data references to formal

swivel, including the following data: starting force

and time duration for different points, average

distance of beam-end swivel displacement distances

at 3s, 5s and 10s. Relevant data of test swivel

measurement are shown in Table 1.

Table.1: Rotor test results summary of the data

Measurements

number

Traction

force(kN)

When test swivel,the

beam-end moving distance

(

mm

)

3s 5s 10s

1 328 22 29 49

2 315 20 28 48

3 306 19 28 51

Avera

g

e value 316 20 28 49

When test swivel is started for the first time,

greater traction force is 520kN. The subsequent

traction force is relatively uniform stabilize at 316kN.

According to the equation of traction force, the

Friction coefficient of the rotating system is

calculated as 0.034, which less than theoretical

value.

Key points of test and formal swivel:

(1)Based on safety regulations and requirements,

swivel is completed within the limited time.

(2) Observe the gap between support feet and

slide ways; promptly adjust positions of sliding

plates.

(3) Pay extra attention to status and position of

swivel system and lower the swivel speed before

reach the right position to prevent excessive swivel.

The speed and time control of formal swivel:

linear velocity of beam end is 1.2m/min. Angular

velocity is 0.0293rad/min.

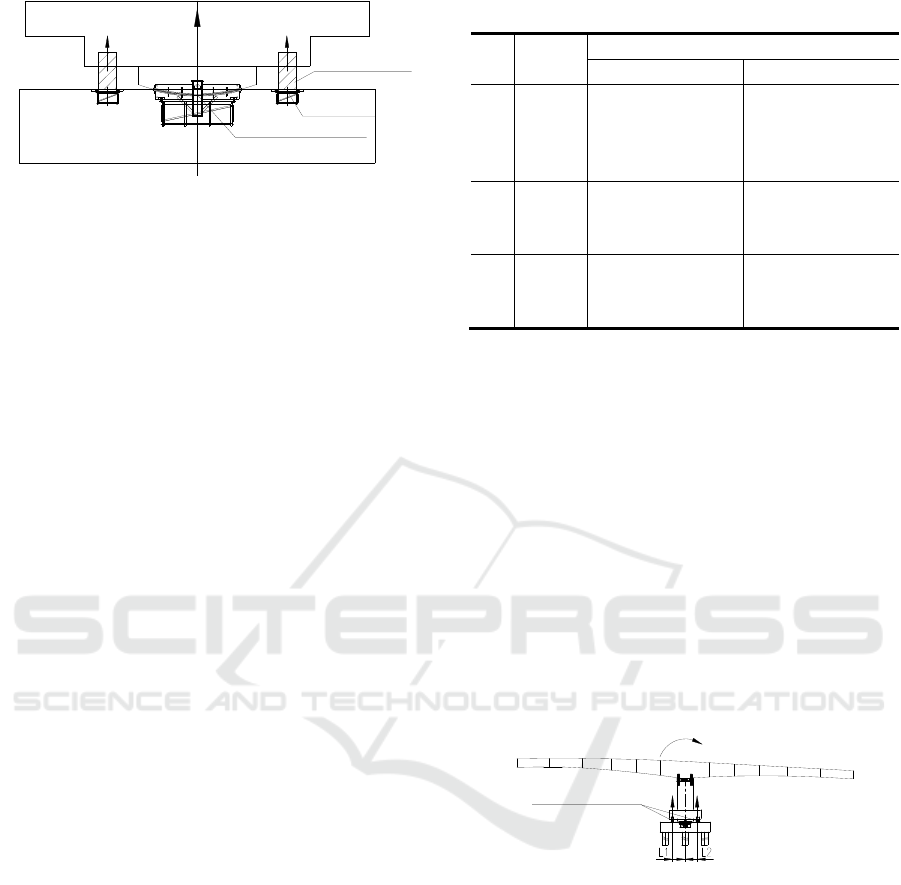

2.3 Turntable status and control

In the process of formal swivel, the ball hinge plays

a major role in support the swivel system. At the

same time, due to the influence of moment force and

other factors, the support feet fall on the Slide-way

usually. These combined to support the swivel

system by three points, so as to ensure the stability

of the whole structure. As shown in Fig. 5.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

406

Spherical hinges

Support feet

Slide-way

Lower turntable

Upper turntable

R

main

R

help

R

help

Fig.5: The weighing jacks layout

The following measures must be taken,

according to the structural characteristics and

operating requirements of the turntable.

(1) The Slide-way surface should be cleaned to

avoid impurities on the Slide-way to hinder the

normal swivel,before formal swivel construction.

(2) Daub lubricating oil on the Slide-way to

reduce the friction coefficient, and ensure the

clearance distance between the support feet and the

Slide-way no more than 5mm, by filling the PTFE

skateboard.

(3) Construct sealing concrete between the upper

and lower turntable as soon as possible, when formal

swivel is completed.

3 CONTROLS OF SAFETY AND

CONSTRUCTION

3.1 Removal of temporary locking

Temporary locking is removed before swivel

construction. The removal process should involve

safety measures to prevent sudden changes of the

stress states. Main measures are stated as following:

(1) Install the steel bracket to support the

turntable. This as a safety support before and after

the temporary locking is removed.

(2) Look at Fig.3; we need symmetrically

demolition temporary locking by the order form one

to four. Brick bottom dies and brace wedges are

removed, anchor tracks are cut off, and mortar

bottom dies are removed lastly.

Sand box locking and brick wall locking are

compared in the following aspects as Table 2.

Table.2: Comparison of temporary locking methods

No Items

Locking mode

Sandbox method Brick wall method

1 Traits

Sandbox bears the

pressure, and

screw-thread steel

bear’s tension.

Brick wall bears

the pressure, and

the track bears

tension

2 Stress

Small

pressure-bearing

surface.

Large

pressure-bearing

surface.

3

Remo

ve

Sandbox is easy

to remove by

unloading sand.

Brick wall bears

pressure. Remove

difficultly.

Both structures meet requirements of temporary

locking. In construction, brick wall structures have

large pressure-bearing surfaces and small stress. But

temporary lock and template are difficult to be

removed and cleaned.

3.2 Weight and balance weight.

It is very important to carry out the weighing

experiment before swivel, which is related to the

balance of the whole swivel system.

The weighing jacks are used for weight

measuring unbalanced moment and frictional

resistance, which installation between the upper

turntable and the lower turntable. The weighing

jacks layout in Fig.6.

Weighing jacks F2F1

Mg

Fig.6: The weighing jacks layout

The principle is: equilibrium between external

lift force, unbalance moment

G

M

and friction

moment

f

M

. This involves two cases: friction

moment is less or larger than unbalance moment.

The actual measurement is that friction moment

is greater than unbalance moment. Left lifting force

1

F

is 2500kN. Right lifting force

2

F

is 4400kN.

The lift arm is

12

LL

=3.3m.

When the

1

F

of the left lifting:

11 fG

F

LM M

(1)

When the

2

F

of the right lifting:

Control and Implementation Technology for Horizontal Swivel

407

22

+

Gf

F

LMM (2)

According to the results of weight, balance

weight and position are determined. 15 00kN.m of

balance moment are needed.

3.3 Swivel process control

During the swivel process, to ensure safe and smooth

operation, the following key points are controlled:

(1) Observe the gaps between support feet and

PTFE skateboard and adjust the position of PTFE

skateboards.

(2) When beam end distance to the design

location is one meter, stop the continuous swivel and

start inching operation, according to the test swivel

result.

(3) The central line and elevation of beam end is

regulated to theoretical position. Continuous jacks

are used to align the central line of beam. Vertical

jacks are used to adjust the horizontal and vertical

gradient and elevation.

4 SUMMARY

After careful preparation, calculation and strict field

control implementation, the formal swivel was

completed within 70 minutes. The precision reached

10mm. The process and key points of swivels are

concluded as following:

(1) This methods of removal temporary locking

can ensure safety of structure, for the temporary

locking use brick wall method.

(2) Test swivel results can be used in formal

swivel, to prevent inadequate or excessive swivel.

(3) Safety and accuracy of formal swivel can be

ensured, by the control implementation technology

of the whole swivel system.

REFERENCES

Zhang J,El-Diraby T E. Constructability analysis of the

bridge superstructure swivel construction method in

China[J].Journal of construction engineering and

management,2006,132(4):353-362.

Ying-jie C. Research and Application of Bridge Swivel

Construction Technique[J].China Municipal

Engineering,2006,2:10.

Jiang L,Gao R. Deformation monitoring during removal of

the supporting of T-type rigid frame bridge constructed

by swivel method[J].Procedia

Engineering,2010,4:355-360.

Qiong Hui Li;Xiang Yang Wang;Li Li Han. Analysis on

Vertical Swivel Construction of Cable-Stayed Bridge

with Steel Arch Pylon[J].Applied Mechanics and

Materials.2013.

Fang Ru Gui.Research on the Monitoring Technology of

Cantilever Construction of Continuous

Girders in Super Large Bridges[J].Applied Mechanics and

Materials,2014,3489(638):1556-1559.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

408