A Quick Detecting Method Based on The Least Square Method for

Missing and Damage of Manhole Cover

Jie Qiao

1

, Jing Song

2

and Junwei Zhao

3

1

Chang’an University, Xi’an, China

2

Chang’an University, Xi’an, China

514366153

@qq

.com, 871325569

@qq

.com

Keywords: CCD cameras, Least square method, Rectangular degree, manhole cover cracks.

Abstract: In this paper, a high-speed condition based on the least square method covers defects and damage detection

methods, this method can through visual road surface shape characteristics, fracture characteristics of the

cover quickly identify and make analysis and processing.The road image in front of the detection vehicle is

obtained at high speed through the two CCD cameras fixed at the top of the locomotive.The image acquisition

card converts analog signal to digital signal transmission to the upper computer. The processing center uses

the algorithm to preprocess the image and the least square ellipse fitting of the processed image to realize the

shape feature recognition, using the calculated pixel area, pixels horizontal and vertical projection, calculation

methods of rectangular degree, realize the manhole cover crack identification;The location of the well cover

can be indirectly reflected by rotating encoder and GPS location detection vehicle.This method is simple, fast,

safe and cost effective for the existing well cover detection technology. It can effectively recognize the loss

and damage of the surface well cover and provide support for road safety.

1 INTRODUCTION

With the development of urban transport system and

vehicle ownership continuing increasing

sustainability, more and more people pay attention to

road traffic safety. In the method of investigating the

condition of the damaged road manhole cover, the

most widely used method are manual visual

inspection and installing the sensor in the manhole

cover, but they are time-consuming and inefficient.

The number of manhole covers is large, the method

of installing the sensor in the every manhole cover

costs hugely and is error-prone, there is a certain

degree of instability in this method. There is not an

ideal method for detecting of damaged road manhole

covers automatically (Xinyu Kou, 2002). The method

should be able to identify a variety of road covers,

including manhole covers' cracks and missing, etc,

under various driving speeds and environmental

conditions (Jain A.K, 1989).

At present, there are many kinds of road condition

detection vehicles which are mainly for road damage,

roughness, rutting and other road safety hazards

detection of highways, municipal roads, airport

runways , but there is not the study for vehicle type

on the detection of damage and defect of the manhole

cover on the road surface. In this paper, a method of

detecting missing and damage of high-speed on-

board manhole covers based on image processing is

proposed (M.Mendelsohn, 1968).

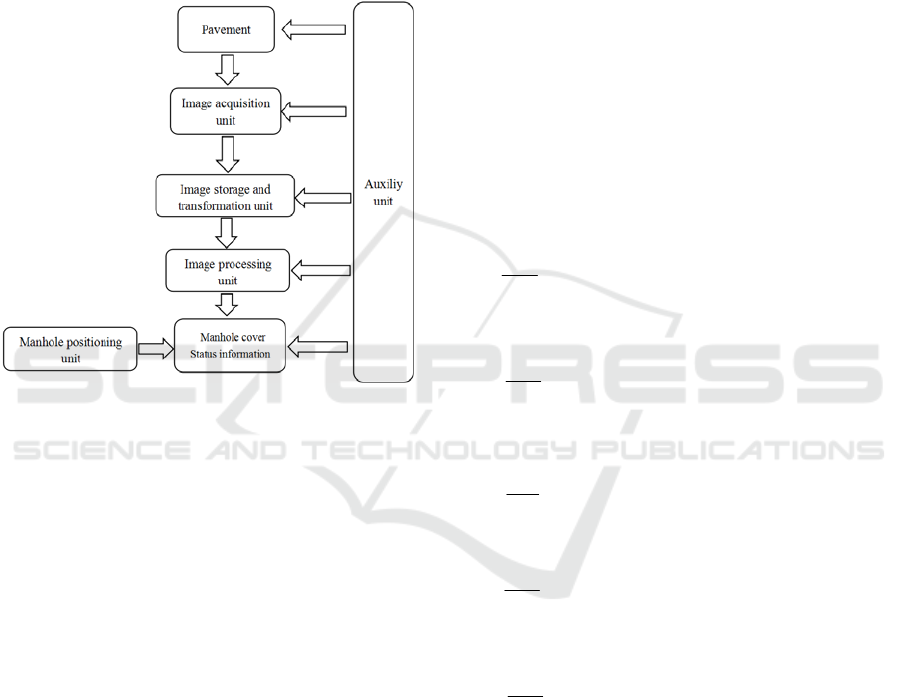

2 OVERALL FRAMEWORK

The whole system includes image acquisition unit,

image storage and transformation unit, image

processing unit, manhole cover positioning unit and

auxiliary unit. The image acquisition unit comprises

two parts of image acquisition and auxiliary

illumination. Image acquisition part is two CCD

cameras which were fixed in front of the top of the

detection vehicle and used to obtain road

images.Auxiliary lighting part is the auxiliary

lighting which is fixed on the bracket and located in

the middle of the two cameras and it is used to provide

uniform lighting conditions to ensure the image

quality ; image storage and transformation converts

analog signals into digital signal transmission to the

computer for the next step through the image

acquisition card (Jain A.K, 1989). The image

processing unit uses the image processing technology

to preprocess the image by the algorithm program and

196

Qiao, J., Song, J. and Zhao, J.

A Quick Detecting Method Based on The Least Square Method for Missing and Damage of Manhole Cover.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 196-199

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

analyze and judge the processed image to realize the

identification of the shape characteristic of the

manhole cover, the identification

of the fracture characteristic of the manhole cover,

and the evaluation of the manhole cover

condition. Manhole cover positioning unit reflects

the specific location of the manhole indirectly

through the rotary encoder and GPS positioning

detection vehicle position.Auxiliary unit includes

testing vehicles, support and power supply and other

auxiliary equipment.

Figure 1: Chart of system’s untis

3 MANHOLE COVER FEATURE

IDENTIFICTION

It is necessary to preprocess the image of the road

ahead which is collected by the CCD camera in order

to identify the characteristics of manhole covers.The

preprocessing includes grayscale processing,

filtering, edge detection and binarization (

Zhang

Xuegong, 2000

).

In the image, the object to be recognized has a

target feature.Target feature is its unique attributes

which is the basis for distinguishing the target type

(

E.R. Darvis, 1968). These characteristics may be the

natural properties of the object such as geometric

features. It can also be attributes provided for the

convenience of computer processing such as

statistical properties. Target feature extraction is the

category of image analysis (

Radim H, 1998). Target

feature extraction is a technique of changing data

from image, that is, the input form is the image

form .A set of data that reacts object attributes and

characteristics are output.The target feature

extraction is used to digitize the target information in

the image, which can describe the target feature more

accurately and objectively and lay a foundation for

the target recognition (Qu Wen-tai, 2005).

Because there is a certain angle between the

camera and the road, the manhole cover will be taken

to the oval state,the ellipse fitting is performed by the

least square method.The following is the

identification of the manhole cover feature step:

(1) Use the least squares method for ellipse

fitting,the general equation of the ellipse is:

0

22

feydxcybxyx

(1)

b, c, d, e, f are fitting parameters.

(2) Use the least squares method, the variance of

the coordinates of the edge points on the image is:

2222

)( feydxcyybxxs

vtvvvv

v

(2)

(

vv

yx ,

) Is the coordinates of the ellipse

boundary point.

(3) Solve the partial differentials of b, c, d, e, f :

(3)

(4)

(5)

(6)

(7)

(4) Use the Gaussian elimination method to solve

the above equations (16) - (20), then obtain value of

b, c, d, e, f . The fitting elliptic coefficient is obtained.

(5) For the ellipse, the variance of the coordinates

of each edge point (

2

s

) is very small, If

2

s

≤T

(threshold value),it can be judged that the image is

an ellipse.Then the manhole cover is recognized in

the image.

v

vvvvvvv

eydxcyybxxx

d

s

22

2

(2

0)

f

v

vvvvvvv

eydxcyybxxy

c

s

222

2

(2

0)

f

v

vvvvvvvv

eydxcyybxxyx

b

s

22

2

(2

0)

f

v

vvvvvvv

eydxcyybxxy

e

s

22

2

(2

0)

f

v

vvvvvv

eydxcyybxx

f

s

22

2

(2

0)

f

A Quick Detecting Method Based on The Least Square Method for Missing and Damage of Manhole Cover

197

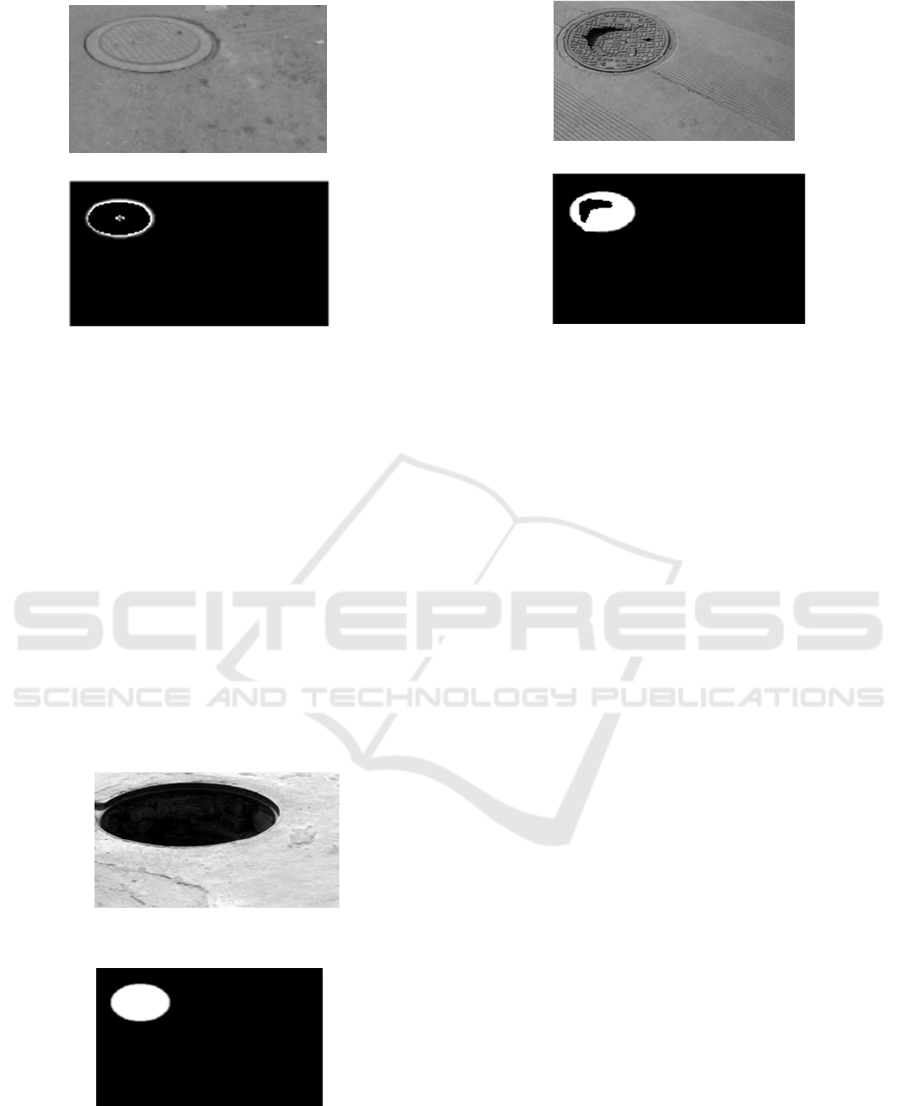

(a)

(b)

Figure 2: Ellipse recognition result

4 TO DETERMINE WHTERMINE

WHETHER A MANHOLE

COVER MISSING AND

BROKEN

After locking the manhole cover area. When the

manhole cover is missed and broken, the gray value

on the image is not the same as the gray value when

the manhole cover exists or complete. Through the

gray value of the size, set a reasonable threshold and

the manhole cover missed and broken can be judged.

As shown in Figure 3 and Figure 4, it’s the test result.

(a)

(b)

Figure 3: Manhole cover loss detection results

(a)

(b)

Figure 4: Manhole cover rupture test results

5 WELL COVER CRACK

IDENTIFICATION

(1) Judge the existence of cracks in the manhole cover

surface.If there is a crack, there is a need to further

determine the type of fracture. It can judged whether

there are cracks on the cover by calculating the crack

pixel area, the calculation of the fracture area is

actually calculating the number of the cover area f (i,

j) = 0, that is the number of pixels whose gray value

is 0.

(8)

W represents the crack pixel area, f (i, j)

represents the crack binary image, and P and Q denote

the total number of rows and columns of the image

respectively. When X = 0, there is no crack in the

manhole cover (Qu Wen-tai, 2005).

(2) Transverse longitudinal crack identification:

according to different geometric shapes and direction

of the cracks, and these differences in the horizontal

and vertical projection are fully reflected:

1,......1,0),()(

1

0

PijifjY

Q

j

(9)

(10)

X represents the horizontal projection, Y

represents the vertical projection, f (i, j) represents the

manhole cover binarization image. Pixel value of the

crack part of the 0, the rest is 255, P is the total

1

0

1

0

),(

P

i

Q

j

jifW

1,......1,0),()(

1

0

QijifjY

P

j

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

198

number of manhole covers the region, Q is the total

number of covers area.

The projection value of the crack image is

integrated into the data parameter,set the parameters

are:

(11)

(12)

When

S

X

is larger and

S

Y

is smaller, this is a

longitudinal crack, when

S

X

is smaller and

S

Y

is

larger, this is a transverse crack.

(3) Network crack identification: Because the

contour of the crack is determined, the minimum

circumscribed rectangle of the crack portion can be

obtained.Calculate the maximum and minimum

values of the boundary coordinates of the fracture in

the horizontal and vertical directions respectively, to

obtain a range of horizontal and vertical spans. Solve

the rectangle of the crack what is the ratio of the area

of the cracked pixel to the area of the smallest

circumscribed rectangle, representing the proportion

of the object in its minimum circumscribed rectangle.

Let A be the squareness, S be the area of the crack

pixel, S1 be the minimum circumscribed rectangular

area of the crack portion.

(13)

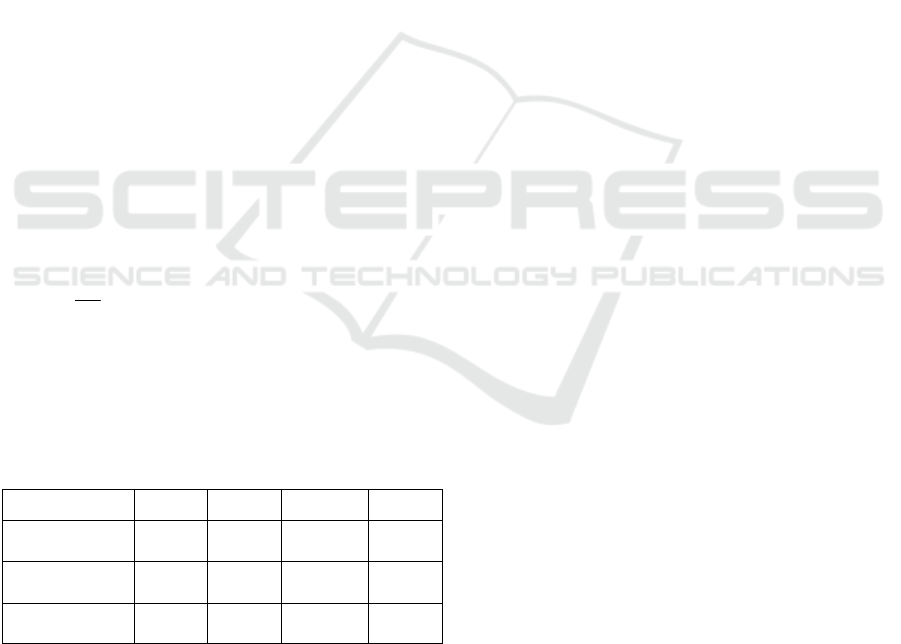

When

16.0 A

, this is a mesh crack. The

characteristic parameters of the three cracks are

shown in Table 1

Table 1: Comparison of characteristic parameters of three

types of fractures.

Type of fracture W

S

X

S

Y

A

Lateral cracks smaller smaller larger smaller

Longitudinal

cracks

smaller larger smaller smaller

Mesh cracks larger modera

te

moderate larger

6 CONCLUSION

In this paper, the identification method based on

visual analysis of the loss and damage of the well

under high speed condition is proposed. On the basis

of image processing, the method of ellipse fitting by

least square method is introduced, which can

effectively identify the area of manhole cover in the

image. Judge whether the lack of cover and a wide

range of rupture clearly by setting a reasonable

threshold; the existence of the cracks on the cover

shape can be intelligently identified, locate covers

with missing or damaged conditions simultaneously

and summarize the situation by calculating the pixel

area method, pixel vertical projection method, the

calculation of rectangularity and other methods

(Haykin s, 2011).

Experiments show that this method has a strong

practicality.This method can detect the hazardous

situation of road covers in advance and provide data

support to the relevant departments. Compared with

the existing manhole cover detection technology, this

method is simple, fast, safe, cost-effective and

provide support for road safety.

REFERENCES

Xinyu Kou, ZhongWang a Full Automatic Algorithum for

Reign of Interest location in camera calibration, optical

Enginnering, V0141, NO6, June 2002, to be published.

Jain A.K.Fundmental of Digital Image processing [M].

prentice Hall International.Inc., 1989.

M.Mendelsohn ,B.Mayall.J.Prewitt.Digital Transformation

and computer Analysis of Microscope Image,Advances

in optical and Electron Microscopy, Academic press ,

1968.

Zhang Xuegong. Statistical learning theory and support

vector machines [J]. Acta Automatica Sinica,

2000,26(1):32-41.

Qu Wen-tai. Chord Midpoint Hough Transform Based

Ellipse Detection Method[J]. Journal of Zhejiang

University: Engineering Science, 2005, 39(8): 1132-

1135.

E.R. Darvis , Finding Ellipses using the Generalished

Hough Transformation and computer Analysis of

Microscopy, Academic press,1968.

Radim H, Jan F. Numerically Stable Direct Least Squares

Fitting of Ellipses[C] Proc. of WSCG’98. Plzen-Bory,

Czech Republic: [s. n.], 1998.

Haykin s. Neural Networks and learning machines 3rd

Edition[M]. Translated by Shen Furao, Xu Ye, Zheng

Jun, Chao Jing. Beijing. China machine press, 2011.

2

0

|)1()(|

Q

i

s

iXiXX

2

0

|)1()(|

P

i

s

iYiYY

10

1

A

S

S

A

A Quick Detecting Method Based on The Least Square Method for Missing and Damage of Manhole Cover

199