Design of the Wire Repair Tool for the Maintenance Robot with

Electrification Used in Substation

Gang Dong

1

, Xu Dong

2

,Qiang Chen

2

and Yan Zhang

2

1

State Grid Shandong Electric Power Company ,Jinan,China

2

Shandong Luneng Intelligence Technology Co. Ltd. Jinan,China

dxengineer@163.com

Keywords: Open-type Substation, Wire repaired, Worm and Gear, Remote Control.

Abstract: The power transmission lines in open-type substation which long-term exposure to the outdoor environment

easily occurs in the phenomenon of wire breakage in the harsh environment of wind and sun .The broken

wire in lines would appear the phenomenon of vibration breakage due to the role of external forces when

working. The further expansion of the steel core aluminium strand would lead to a decrease in the

mechanical strength of the line, and then resulting in a safety accident. The wire repair tool is the special

operation tools for the maintenance robot with charged used in substation, which is clamped by the

mechanical arm installed at the end of the robot. The wire repair tool with power transmission mode of the

worm and gear and the remote control mode to repair the damage wire of the power transmission line in the

open substation, and then reduces the danger level effectively.

1 INTRODUCTION

As the scale of substation expands gradually, the

stability of transmission lines in substations will

directly affect the reliability and stability of users.

The power transmission lines in open-type

substation which long-term exposure to the outdoor

environment, under the bad environment and the

external force, prone to broken phenomenon. If the

wire is not repaired in time, it will not only affect the

transmission efficiency for a long time, but also

affect the mechanical strength of the line. Power

transmission and transformation line carries the risk

of breaking, and then cause the safety accidents.

According to the relevant provisions, it can be seen

that the loss of damage of the wire at the same place

exceeds 5% but less than 17% of the total tensile

force and the cross-sectional area does not exceed

25% of the total cross-sectional area of the

conductive part, repairing with a repair tube. In the

current stage, the work of wire repair is mainly

repaired by artificial repair, the use of wire crimping

pliers as a crimping tool and the use of repair pipe

on the broken wire repair. The work of artificial wire

is high in strength, low in efficiency, unable to be

charged and a low degree of automation, there is a

certain security risks. There are certain safety

hazards. Researchers of State Grid Shandong

Institute of Electrical have improved the wire

hydraulic plier, and the control mode is changed

from manual to remote controlled operation, as

shown in Figure 1, which is used for 10kV

distribution network operations. The Quebec Water

Research Institute in Canada developed the wire

crimping repair tool is mainly used for overhead

lines, only applies to the line inspection robot,

cannot be used in the substation power transmission

line. At present, there is no related research about

the wire repair tool which is used in substation for

the electric maintenance robot of substation.

Fig.1 The wire hydraulic plier

In order to solve the problems existing in the

above research, overcome the difficulties and

Dong, G., Dong, X., Chen, Q. and Zhang, Y.

Design of the Wire Repair Tool for the Maintenance Robot with Electrification Used in Substation.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 131-135

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

131

limitations of the wire repair operation in the

substation, improve the efficiency of the wire repair

work, reduce the labor intensity of the operator,

improve the mechanical strength of the damaged

wire, and ensure the stability of the power supply of

the substation. According to the repair requirements

for damaged line of 220kV and below the voltage

level substation and the operating requirements for

the substation electromechanical operation of the

robot, a wire repair tool is designed to conduct the

repair mission which is used for the maintenance

robot with charged used in substation.

2 DESIGN OF MECHANICAL

STRUCTURE

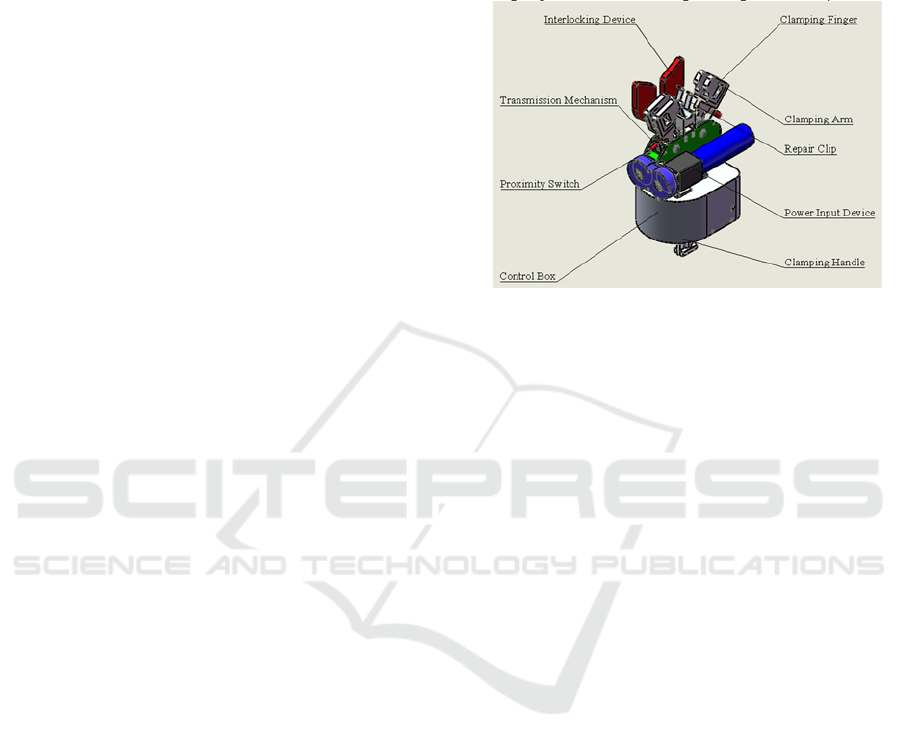

The wire repair tool is mainly composed of a repair

clip, a pair of clamping fingers and clamping arm,

the interlocking device and transmission mechanism,

the power input device, the proximity switch, control

box and clamping handle. The schematic diagram of

the wire repair tool is shown in Figure 2. The repair

clip is made with material of aluminum, which

thickness is 2mm. The material of aluminum sheet

can make the repair clip has good ductility and

mechanical strength, and it cannot spread the

aluminum strand of the broken wire. The main role

of the interlocking device is to loose stranded strand

straight and close the wire to repair clip clamping

easily, and then improve the repair efficiency. The

interlocking device uses POM which is the

insulating material to prevent the tip discharge from

occurring during contact with the wire. The

clamping fingers are the executing agencies at the

end of the tool and make the repair clip to produce

the deformation to achieve the purpose of wire

repair in the operation of the clamping arm. The

clamping fingers are also made by POM. A

miniature camera is installed in the center of the

repair clip and the position of the wire can be

observed in real time. Both ends of the clamping

arm are equipped with proximity switches to control

the travel of the clamping arm. The transmission

mechanism using worm gear drive mechanism, with

the advantages of single-stage speed ratio of worm

gear mechanism to transfer power to the clamping

fingers for operation. The power input device is the

power source of the wire repair tool, and the motor

drive mode is adopted to facilitate precise control,

and the actuator is connected to the transmission

mechanism by the decelerating mechanism of the

servo motor. The clamping handle is the manipulator

clamping part of the tool, the main body of the

clamping handle is made of hard aluminum alloy,

and the anti-wear material is used in the clamping

part with the handle in order to achieve the purpose

of the use of lightweight and ease of use. The

clamping handle can be replaced periodically.

Fig.2 The schematic diagram of the wire repair tool

3 DESIGN OF CONTROL

SYSTEM

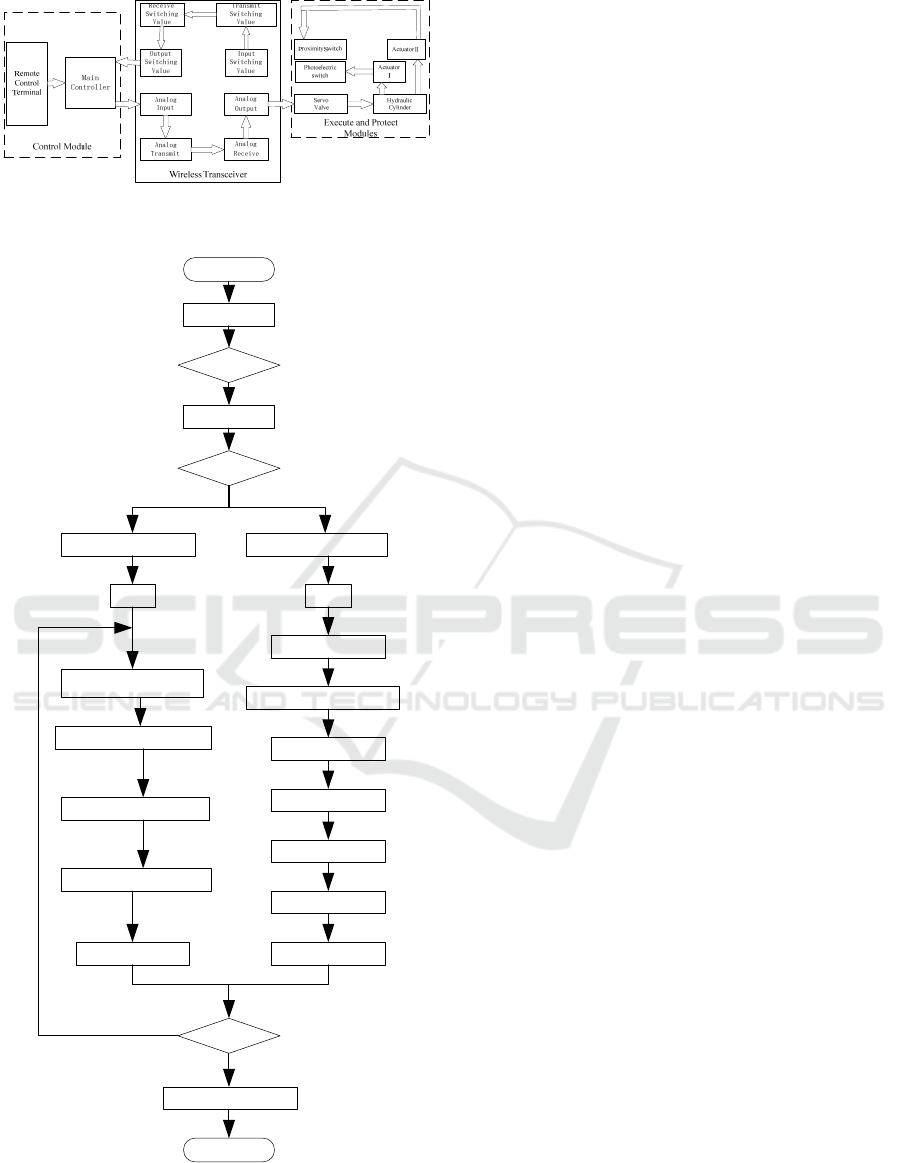

The control system of the wire repair tool is mainly

composed of the remote control terminal, the

wireless transceiver, motor and actuator and Beckoff

control system. The block diagram of control system

for the wire repair tool is shown in Figure 3. The

remote control terminal sets the start-stop and status

button, respectively corresponding to the motor's

start-stop and state control. The communication

between remote control terminal and Beckhoff

controller through WIFI wireless, Beckhoff

controller according to the collected key information

output corresponding to the digital to EL2024 digital

output module when press the button. Digital output

module connected with the transmitter so that the

transmitter can automatically send the corresponding

signal to the receiver, and the receiver connected

with the motor. So that the motor could start and

stop, forward and reverse by the remote control

terminal. The control flow diagram is shown in

Figure 4.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

132

Fig.3 The block diagram of control system for the wire

repair tool

Start

Initialization

Button

Click

Read key value

K1/K2/K3…K10

D / I ?

K1/K2/K3…K8

Km Kn

Input Switching Value

Analog Input

Transmit Switching Value

Receive Switching Value

Main Controller Processing

Analog Transmit

Analog Receive

Main Controller Processing

Motor Driver

Servo Motor

Operating ToolsActuator

End

Proximity Switch

Location?

D

I

Yes

No

Fig.4 The control flow diagram

(1) Motor control

The remote control terminal output a continuous

control signal (set to "-127 ~ 127") ,and the remote

terminal communicates with Beckhoff controller

through WIFI wireless, and the receives the signal (-

127 <X <127) at the same time, and then output a 0

to 5v analog signal to EL4104 after DA conversion.

The EL4104 module is connected with the analog

wireless transmitting device and outputs the analog

signal to the transmitting device, the wireless

transmitting device and the wireless receiving device.

The wireless receiving device outputs the "0-5V"

analog signal. The wireless receiving device are

connected with the motor driver "IN1", and then the

analog signal is outputted to the "IN1" port to

complete the control of the motor.

(2) Limited control

The proximity switch would be triggered when

the clamping finger moved to the limit position, and

the proximity switch outputted a voltage signal of

5V. The proximity switch outputted signal is

connected to the wireless transmitter, and the

voltage signal is inputted to the wireless transmitter.

Since a wireless transceiver can only transmit two

signals, the limit position of one clamping finger is

detected and the other is synchronized. The wireless

transmitting device communicates with the wireless

receiving device, the wireless receiving device

synchronously outputs a voltage signal (12V) to the

wireless receiving device. The output of wireless

receive device is connected with the EL1144 module

and outputs the signal to the one of the channel. The

controller corresponds to receiving the high and low

voltage signal to control the motor's start-stop when

the proximity switch corresponds to the high and

low voltage signal.

4 THE PROCESSING OF

REPAIRING

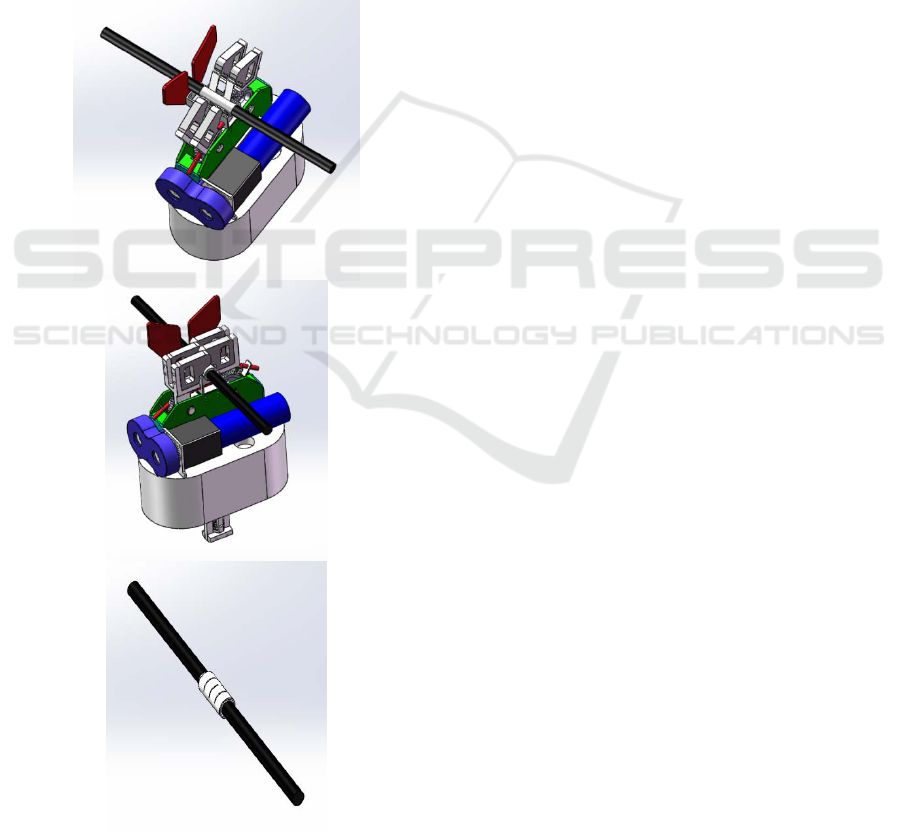

The wire repair tool is held by the mechanical arm

and the repair process is shown in Figure 5. The wire

repair tool is clamped by the mechanical arm, and

the mechanical arm holds the wire repair tool to

enter from the undamaged side of the wire. The

mechanical arm clamps the wire repair tool slowly

moves from the damaged side to the undamaged side,

in order the clamping fingers could align the wire

through videos from the camera on the wire repair

tool. The broken wire is closed under the action of

the interlocking device. The mechanical arm stops

Design of the Wire Repair Tool for the Maintenance Robot with Electrification Used in Substation

133

moving when the center position of the repair clip is

on the broken wire through the camera to observe,

and then the motor of the wire repair tool is

controlled by the remote controller to conduct the

repair work. The proximity switch on the wire repair

tool can detect the position of the clamping arm to

control the travel of the work. When the job is

completed, the clamping arm is rotated in the

opposite direction under the action of the motor, and

the position of the clamping arm is detected by the

proximity switch, and then the motor would stopped

after the clamping arm fully opened. The mechanical

arm holds the wire repair tool to move directly

below the wire after the repair clip is clamped in 3

times (the repairing work), and the wire repair tool is

pulled out of the wire.

Fig.5 The repair process of the wire repair tool

5 CONCLUSIONS

The work of wire repair in open type substation is of

great significance to the safe and stable operation of

substation. At this stage, the repair work in the

substation is mainly in the stage of manual with

power failure, which is in a low degree of

automation and poor economic efficiency. This

paper designs a wire repair tool for the maintenance

robot with charged used in substation, which can

repair the damaged wires in the substation without

power failure. The wire repair tool adopts the

transmission mode of the worm and gear and the

control mode of the remote control operation to

repair the power transmission line which is broken

in open type substation. The design of the wire

repair tool for the maintenance robot with charged

used in substation can improve the operation of

automation, reduce the number of blackouts, and

improve economic efficiency at the same time.

ACKNOWLEDGEMENTS

Key Technology and System Research of Robot for

Operation and Maintenance of Grid Equipment

(Technology project of China Southern Power Grid

Co., Ltd. No. 090000KK52150073)

REFERENCES

Guo Hui Ma Jing.Application of charged Wire Repair

Method of Double Circuit Tower with High-pressure

Line Getting into Strong Electric Field[J]. Journal of

Henan Science and Technology, 2015,Vol.567(7):144-

146.

ZHU Difeng, XU Yangyong, WU Kunxiang, LIU

Hongxin. New Type of Pre-Twisted Splice Bar

Application on EHV/UHV Transmission

Lines[J],2017,35(2):79-81.

CHE Li-xin YANG Ru-qing GU Yi. Design of High-

voltage Hotline Sweeping Robot Used in 220/330kV

Substation [J],ROBOT ,2005,27(2):102-107.

C.Y.G.Design of substation equipment HV hot-line

sweeping robot[J]. Robot. 2005,27(2):102-107.

F. Research of hot-line sweeping robot mobile carrier[D].

Shang Hai:Shanghai Jiao tong University, 2008.

Caccavale F, Natale C , Siciliano B, et al. Integration for

the next generation:embedding force control into

industrial robots[J]. IEEE Robotics and Automation

Magazine, 2005(9): 53-64.

Shouyin Lu, Peisun Ma and Hui Qi. Research on high

voltage electric power live line working robot.

Automation of Electric Power Systems, 2003(17).

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

134

A.Santamaria, R.Aracil and A.Tuduri. Teleoperated

Robots for Live Power Lines Maintenance

(ROBTET) . In: Proc of 14th International Conference

and Exhibition on Electricity Distribution,

1997,3(31):1-5.

K. Study and design of control system ultra-high voltage

hot-line sweeping robot[D]. Shang Hai: Shanghai Jiao

tong University, 2008.

Design of the Wire Repair Tool for the Maintenance Robot with Electrification Used in Substation

135