Missing Rail Fastener Detection Based on Machine Vision Method

Yongzhi

Min

1*

,

Benyu Xiao

1

, Hongfeng Ma

2

and Biao Yue

1

1

School of Automation and Electrical Engineering, Lanzhou Jiaotong University, Lanzhou, China

2

School of Electronical Information Engineering, Lanzhou Institute of Technology, Lanzhou, China

su_ymin01@qq.com, 13893178455@163.com, 13609345559@139.com, 1440127943@qq.com

Keywords: Fastener missing detection, area positioning, template matching, occlusion removal, machine vision,

minimum distance classifier.

Abstract: Rail fastener missing detection is an important part of railway daily inspection, according to the need of

modern railway automatic detection, a method of rail fastener missing detection based on template matching

is proposed in this paper. Firstly, in order to deal with the interference of environmental light, according to

the basic principle of machine vision, a simple rail inspection car is designed for image acquisition. Secondly,

according to the characteristics of the track image, the rail fastener area is located by using the mutation

information of the image. Then, through the establishment of template, test images are matched with the

template image, when the matching degree between test images and template images is low, it is need to detect

the occlusion area of the test image and if there is a occlusion in the test image, remove the occlusion area

from the test image and sample images to obtain new sample images and test image. Finally, the minimum

distance classifier is used to detect the missing rail fastener. Simulation results show that the correct detection

rate of this algorithm is 93.7% and the average detection time of each image is 385.74 ms, providing a

reference for real-time detection of railway line.

1 INTRODUCTION

With the rapid development of high-speed railway,

how to ensure the safe operation of the train has

attracted more and more attention of the public. Track

fastener is an important component for connecting

rail and track sleeper, playing an important role of

holding on the track gauge and preventing the rail

from vertically and horizontally moving relative to

the track sleeper, once be lost will bring security risks

to the safe operation of the train(Gibert, et al, 2017).

In recent years, many domestic and foreign

scholars have done a lot of research on the detection

of missing track fastener and have obtained some

achievements. Among them, Wang L et al.(2011) use

principal component analysis (PCA) algorithm to

extract the feature vector of the rail fastener nut and

use the minimum distance classifier to detect the

fastener. Yang J et al. (2011) use the orientation field

algorithm and the template matching method to detect

the state of the rail fastener. Jia L H(2014) carries on

processing to the image edge by using mathematical

morphology, intercepts the sub module from the test

images to match with the standard rail fastener image

and uses the support vector machine (SVM) method

to detect the missing fastener. Yan F(2014) extracts

the edge feature of the fastener image, and then

respectively use the BP neural network and fuzzy C

mean clustering method to identify the missing

fastener.

The existing researches mainly focuses on the

case that the track fastener image is not be occluded.

In that case, the local characteristics of rail fastener is

not interfered by the external environment and can be

easily extracted. However, the track fasteners may be

obscured by such as fallen leaves or food bags et al.

in the actual railway lines, causing some of local

features of track fastener be split and cannot be

accurately extracted.

Taking into account the situation that rail fastener

may be obscured by some occlusions, a method based

on machine vision method for the detection of

missing rail fastener is proposed in this paper. Firstly,

the rail fastener area is located by using the position

relationship among components of the track image.

Then, select a track image that contains rail fastener

a track image lacking of track fastener as the sample

images, and the test image is compared with the

sample images. When there is a high matching degree

between the test image and the sample images, the

Min, Y., Xiao, B., Ma, H. and Yue, B.

Missing Rail Fastener Detection Based on Machine Vision Method.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 119-124

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

119

result can be obtained directly, while the difference

between test images and sample images is large, it’s

needed to consider the influence of the may existing

occlusion on the matching result, therefore, it is

necessary to firstly detect the occlusion of the test

image, if there is a occlusion in the test image,

removing the occlusion area to obtain new samples

and test image to minimize the impact of the

occlusion on the detection results. Using the

minimum distance classifier to get the final detection

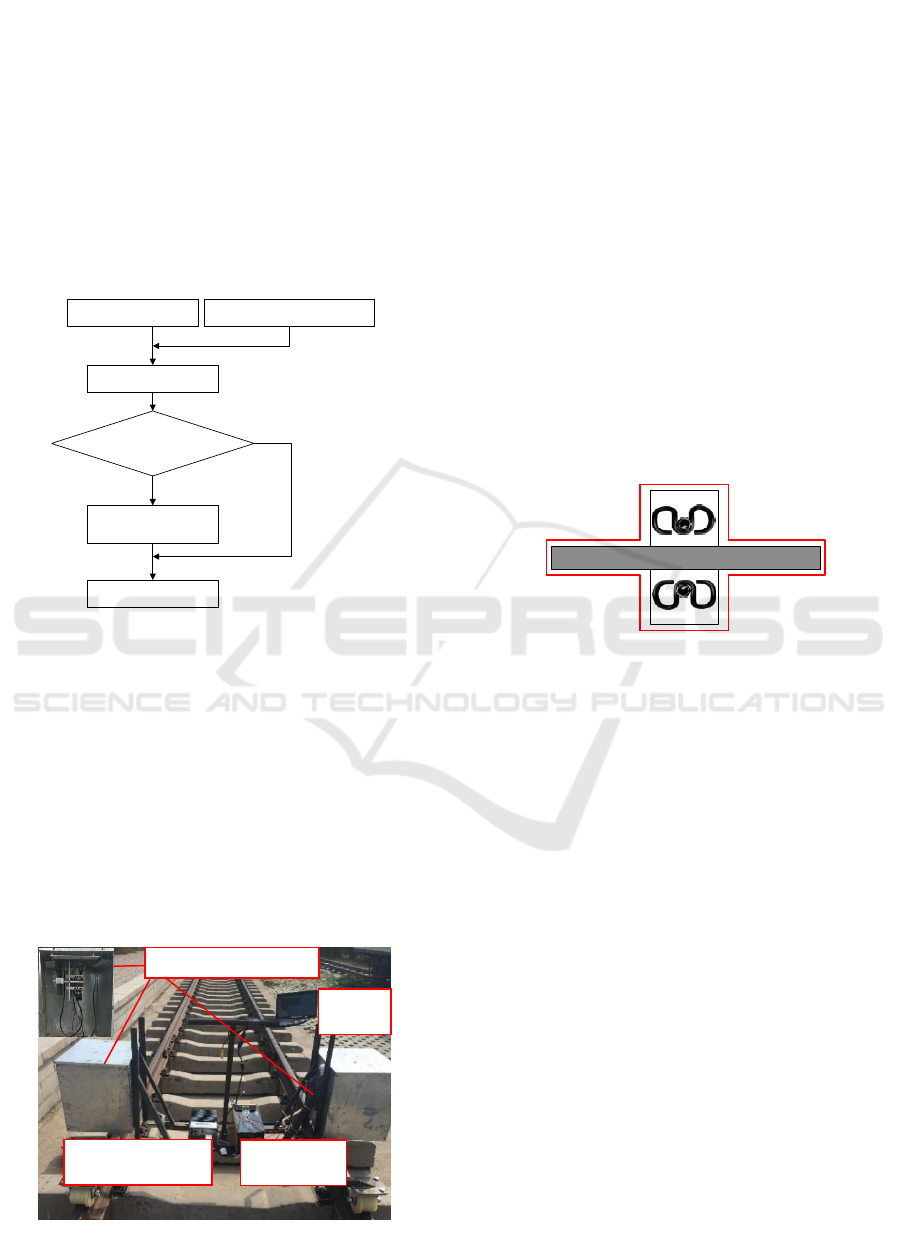

result. The detection flow of the algorithm is shown

in figure 1.

Fastener area positioning

Matching degree between

sample and test image is high?

Detection and removal of

occlusion area

Sample images

Final test result

N

Y

Test images

Figure 1: Schematic diagram of algorithm detection

process.

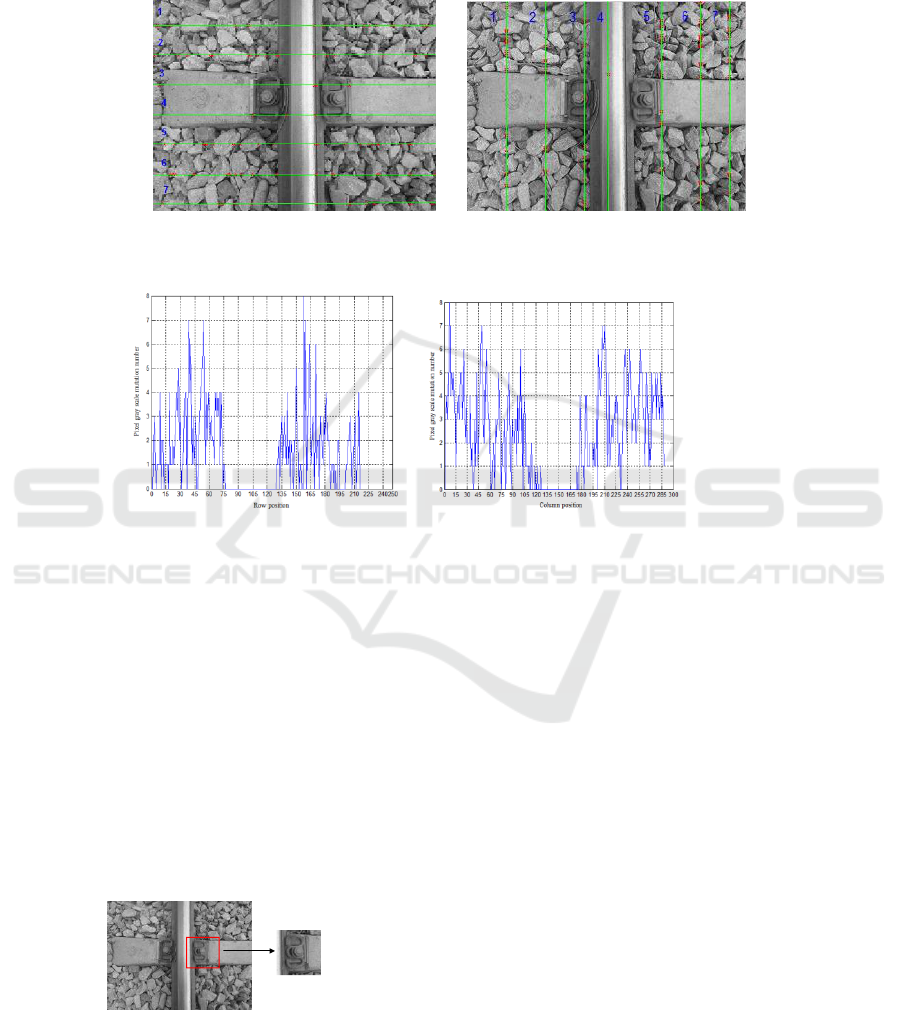

2 IMAGE ACQUISITION

If track images are collected directly in natural

environment, they may be affected by natural light,

making the illumination of images is inconsistent and

the algorithm will be difficult to carry out a unified

process to images (Li, et al, 2010). In order to avoid

the influence of the external light, a rail fastener

detection system is designed and is shown in figure 2.

Figure 2: Rail fastener missing detection system.

A CCD camera is used to meet the requirement of

the system on the acquisition speed and an 8mm lens

is installed to coordinate with the camera. An

industrial control computer and a display screen are

equipped in the rail inspection car to display and

process the images.

3 AREA POSITIONING

The relationship between the track fastener, rail and

track sleeper in a track image is that the track sleeper

and rail intersect vertically, the track fastener is

located on the track sleeper and distributed on two

sides of the rail(Liu J J, et al,2015). The positional

relation of a track image is shown in figure 3.

Therefore, according to the position relation in the

track image, the rail and the sleeper area can be

located firstly, and then the fastener region will be

positioned.

Figure 3: Sketch map of track area structure.

In a track image, there are a lot of edges in the

stone ballast area for a large number of stone ballast

exist in this area, while the rail and track sleeper area

are smoother and have only a small number of edges.

Defined the marker number of gray mutation between

adjacent pixels is as

q

n

:

1, *| ( , ) ( , 1) | | ( , ) ( 1, )|

0, *| ( , ) ( , 1) | | ( , ) ( 1, )|

q

h f i j f i j v f i j f i j T

n

h f i j f i j v f i j f i j T

ì

- + + - + >

ï

ï

=

í

ï

- + + - + <

ï

î

(1)

The gray value of (i, j) is

( , )f i j

and T is a

threshold. In this paper, we set the value of T as 2/3

of the average gray value of image, when we

calculate the gray mutation in the horizontal direction,

take h=0, v=1, while calculate the gray mutation in

the vertical direction, take h=1, v=0.

The statistical value of the gray mutation of k-th

row and k-th column can respectively be obtained by

formula (2) or formula (3):

,

1

=,

J

Hi i j

j

N n i k

=

=

å

(2)

,

1

=,

I

Vj i j

i

N n j k

=

=

å

(3)

I is the row number of image while J is the column

number. k represents the k-th row or the k-th column.

Image acquisition section

Display

screen

Power

Supply

Industry personal

computer

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

120

The number of gray change points in horizontal

and vertical directions of the image respectively is:

H

1

I

Hi

i

NN

=

=

å

(4)

V

1

J

Vj

j

NN

=

=

å

(5)

According to the formula (1)-(5), the gray change

point mark map and the statistical graph are

respectively shown in figure 4 and figure 5.

(a) Horizontal direction (b) vertical direction

Figure 4: Gray change point mark map.

(a) Horizontal direction (b) vertical direction

Figure 5: Statistical graph of image gray mutation.

From figure 4 we can see, the number of gray

change points in the straight line that through the

stone ballast area is more than that in the through

the track sleeper area or rail area straight lines.

Because there are fewer gray abrupt points in the

areas of track sleeper or rail, the bottom is formed in

the statistical chart as shown in figure 5.

The location to the track sleeper area and rail area

can be completed by searching the bottom position in

figure 5, and then the fastener region is positioned by

the position relation in a track image expressed in

figure 3. The coarse positioning diagram of rail

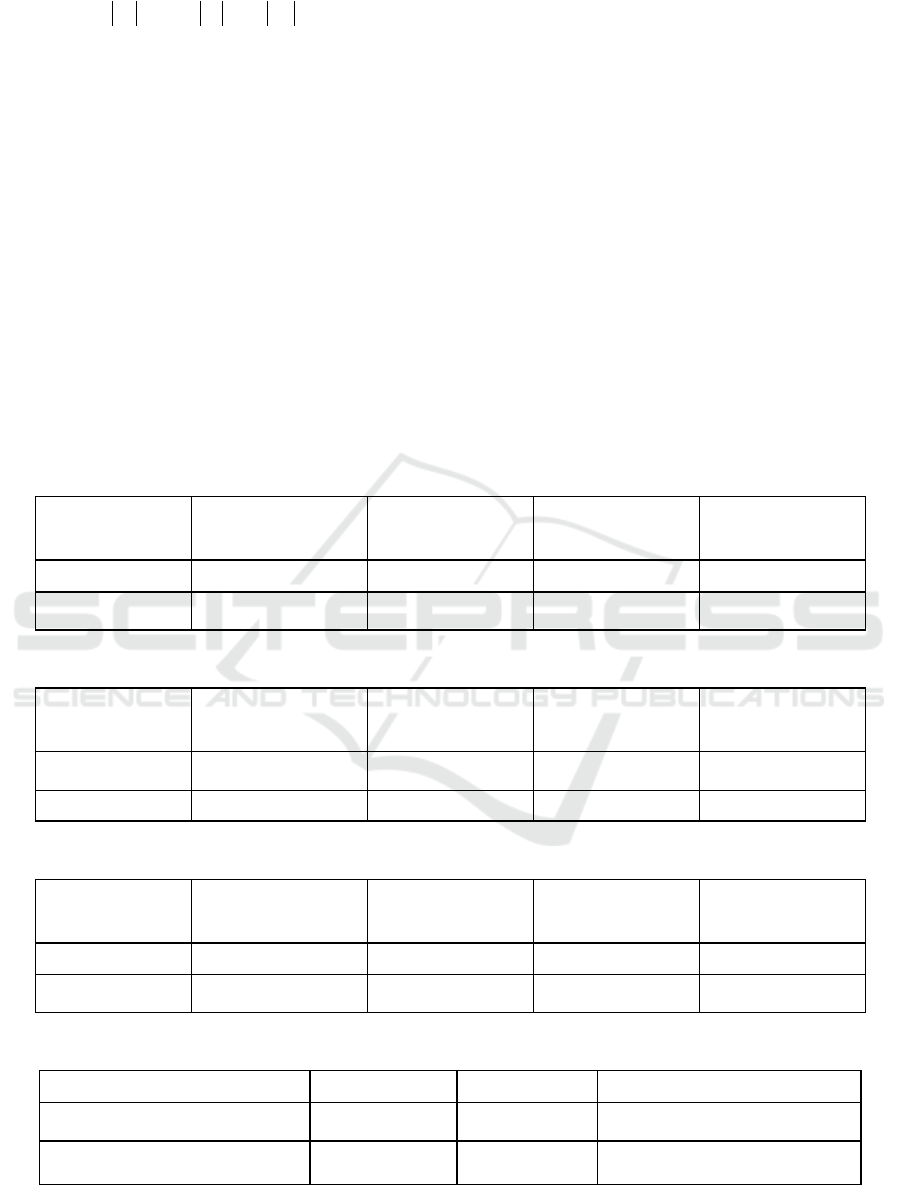

fastener image is shown in figure 6.

Figure 6: Fastener region location and segmentation.

4 DELETION DETECTION

4.1 Image registration

In order to get the difference image between test

images and sample images, it is necessary to register

test images and sample images firstly. Due to test

images may missing rail fastener as well as may be

blocked by occlusion, therefore, in this paper, the

edges of rail and track sleeper are selected as the

image registration features. Even in some occlusion

conditions that shown in figure 7, we can detect at

least one edge line (as shown in figure 8), which is

helpful for us to register the test images and sample

images. Select images shown in figure 9 as sample

images of this paper.

Missing Rail Fastener Detection Based on Machine Vision Method

121

Figure 7: Some of occluded rail fastener images.

Figure 8: Line detection results.

(a) Containing fastener (b)Missing out fastener

Figure 9: Sample images.

4.2 Occluded area detection and

removal

The detection and removal of the occlusion areas is

an important part of the rail fastener detection. Once

the test image is an occluded image, the occlusion

will interfere with the extraction of the fastener

features. The key to the occluded image detection is

to find an effective method to reduce the influence of

occlusion area. This paper presents an improved rail

fastener detection method based on removing

occlusion area. The implementation of this method is

divided into two stages: in the first stage, judging and

detecting the occlusion area in the test image. In the

second stage, carrying out unified treatment on the

occlusion area in the test image and the region that

corresponding to the occlusion area in the sample

images. The specific steps are as follows: ①

According to the comparison result between the test

image and the sample images, get the difference

image between the test image and the corresponding

sample image. ② Compare the gray value of the

difference image with the threshold Y, when the pixel

gray value is larger than the threshold value Y, set the

value of these pixels to 255, otherwise set these pixels

gray value to 0, in this way, we get a new difference

image. ③ Get the removed occlusion images by

subtracting the difference image from the test image

and the sample images respectively.

5 MINIMUM DISTANCE

CLASSIFIER

Compared with the K nearest neighbor method and

the neural network method, the speed of the minimum

distance classifier is faster, therefore, minimum

distance classifier is often chosen for real-time on-

line inspection systems(Liu, 2009). The specific

process of using the minimum distance classifier to

complete the defect detection of rail fastener is as

follow.

Define the modulus of image I as:

11

= ( , )

nm

xy

I I x y

==

邋

(6)

Where n and m are image size of I,

( , )I x y

is the

gray value at (x, y).

Suppose that

F

I

represents sample image

contained with rail fastener and

M

I

represents

sample image of missing rail fastener. The modulus

of image

F

I

and

M

I

respectively are:

FF

11

= ( , )

nm

xy

I I x y

==

邋

(7)

MM

11

= ( , )

nm

xy

I I x y

==

邋

(8)

The modulus of the test image

T

I

is:

TT

11

= ( , )

nm

xy

I I x y

==

邋

(9)

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

122

Compare

T

I

with

F

I

and

M

I

to obtain the

final test results.

6 EXPERIMENTAL RESULTS

AND ANALYSIS

We collected 480 rail fastener images on the spot.

Among them, 467 rail fastener images contain

fastener, 13 images lack of the track fastener. Due to

the small number of the missing fastener images, we

added 20 missing fastener images by using artificial

synthesis method. In this way, the total number of

experimental images is 500. At the same time, in

order to increase the diversity of occluded images, we

randomly selected 20 images from existing images

and add occlusion into these images to obtain 20

occluded images (Cai, et al, 2010).

In order to verify the performance of the

algorithm in different cases, we carried out three

simulation experiments. In experiment 1, all the test

images are all non occluded track images, and this is

the most common experimental method used in

fastener detection algorithms. In order to compare

with experiment 1, in experiment 2, we used occluded

images as the test images. In Experiment 3, the test

image set contains both non occluded and occluded

images, and this is the most consistent with the actual

railway scene. The distribution of sample and test

images of the three experiments are respectively

shown in table 1, table 2 and table 3. It should be

noted that in order to reduce the influence of

occlusion on the test results, the occluded images are

not included in the sample images, the test images

and the sample images are randomly selected in

different experiments. The results of the three

experiments is shown in table 4.

Table 1: Distribution of sample and test images in experiment 1.

Category

Non occluded image

with fastener

Non occluded

image missing

fastener

Occluded image

with fastener

Occluded image

Missing fastener

Sample images

20

10

0

0

Test images

432

17

0

0

Table 2: Distribution of sample and test images in experiment 2.

Category

Non occluded image

with fastener

Non occluded

image missing

fastener

Occluded image

with fastener

Occluded image

Missing fastener

Sample images

20

10

0

0

Test images

0

0

15

6

Table 3: Distribution of sample and test images in experiment 3.

Category

Non occluded image

with fastener

Non occluded

image missing

fastener

Occluded image

with fastener

Occluded image

Missing fastener

Sample images

20

10

0

0

Test images

432

17

15

6

Table 4: Detection result.

Category

Experiment 1

Experiment 2

Experiment 3

Correct detection rate

94.6%

87.5%

93.7%

Per frame Image detection time

367.21 ms

425.58 ms

385.74 ms

Missing Rail Fastener Detection Based on Machine Vision Method

123

It can be seen from the experimental data of table

4 that the detection of occluded images takes a longer

time than that of non occluded images, this is because

there is a process of removing occlusion when

processing occluded images. But in actual scenes, the

proportion of occluded images to the total image is

unlikely to be so high, so, the overall speed of this

algorithm is good, just like the result of experiment 3.

The experimental data also show that the correct

detection rate is less affected by occluded images.

7 CONCLUSION

In view of the possible occlusion problem in defect

detection of rail fastener, this paper propose a method

based on machine vision. The fastener area is

positioned firstly and the template images are

established. The test images are directly matched

with the sample image, accelerating the detection

speed of the algorithm. When the difference between

the test images and the template images is large, by

detecting the occlusion area in the test image and

removing the region corresponding to the occlusion

area from the sample images as well as the test image,

the influence of the occlusion area on the detection

can be effectively reduced and the accuracy of the

detection algorithm is improved. The algorithm

proposed in this paper has higher recognition rate and

strong robustness, it can be used for reference in the

detection of similar occlusions. But the sample image

and the test images used in this paper contains no

track images that acquired in the rain or under strong

sunlight condition, therefore, the sample set is still

failure to fully reflect the actual situation on the rail

line. So, the detection of missing track fasteners for

different weather will be the focus of the next study.

ACKNOWLEDGEMENTS

This research was supported by the National Natural

Science Foundation of China(Grant No.61663022

and No.61461023), the Open Project of Gansu

Province Plateau Traffic Information and Control

Engineering Laboratory(Grant No.20161105), the

Program for Changjiang Scholars and Innovative

Research Team in University(Grant No.IRT_16R36),

and the Postdoctoral Special Foundation of Lanzhou

Jiaotong University(Grant No.2017002).

REFERENCES

Cai C, Zhang M, Zhu J P. 2010. Classification and

identification of weed seeds based on compressed

sensing theory. Scientia Sinica (Informationis),

40(suppl):160.

Gibert X, Patel V M, Chellappa R. 2017. Deep Multitask

Learning for Railway Track Inspection. IEEE

Transactions on Intelligent Transportation Systems,

arXiv:1509.05267(99):1-12.

Jia L H. 2014. Research of the detection algorithm and

design the system on high speed railway fastener based

on DSP. University of Electronic Science and

Technology of China.

Li G, He Y Y. 2010. A new method for pavement crack

detection and classification based on non-uniform

illumination. Acta Photonica Sinica, 39(8):1405-1408.

Liu J J, Li B L, Luo J Q, et al. 2015. Railway Fastener

Detection Algorithm Integrating PHOG and MSLBP

Features. journal of southwest jiaotong university,

50(2):256-263.

Liu X S. 2011. Face recognition based on PCA and SVM

algorithm. Computer & Digital Engineering,

39(7):124-126.

Wang L, Zhang B, Chen X A. 2011. Inspection system for

loss of rail fastening nut based on computer vision.

Computer Engineering and Design, 32(12): 4147-4150.

Yang F. 2014. Research on image detection system of metro

rail missing fasteners. Southwest jiaotong University.

Yang J, Tao W, Liu M, et al. 2011. An Efficient Direction

Field-Based Method for the Detection of Fasteners on

High-Speed Railways. Sensors, 11(11):7364-7381.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

124