Application Study of Hydraulic Turbochargers in Landfill Leachate

Treatment Systems

Tong Liu

1

, Yunguang Ji

1

, Hongtao Li

1

, Shu-qi Xue

1*

, Mike Oklejas

2

and Shouzhi Yang

3

1

College of Mechanical Engineering, Hebei University of Science and Technology

,

Shijiazhuang 050018

,

China

2

Oklejas Turbo Solutions LLC, Ann Arbor, MI 48103, USA

3

Shijiazhuang Haikuojieneng Technology Co., Ltd

,

Shijiazhuang 050018

,

China

*Corresponding author e-mail:

x

ueshuqi@hebust.edu.cn

Keywords: Landfill Leachate Treatment, Pressure Energy Recovery, Hydraulic Turbocharger, Energy Consumption, Seal.

Abstract: Based on the two-thousand-ton per day landfill leachate treatment process, a new system with energy

recovery device was designed by using a hydraulic turbocharger to replace the circulation pump of the

existing system. Energy consumption and equipment failure rate was decreased and system stability was

improved by using hydraulic turbocharger. This study can provide a good reference for design and integration

of energy recovery systems in landfill leachate treatment process.

1 INTRODUCTION

Landfill leachate is one kind of complex organic

liquid produced in the process of landfill garbage

storage, and it will cause serious environmental

pollution if it is not treated before discharge. With

the change of filling ages, the BOD/COD5 value and

pH value of landfill leachate will increase and it is

difficult to use biochemical method merely to meet

the emission standards for the treated liquid. Reverse

osmosis (RO) process is little influenced by the

factors such as composition and temperature, and it

ensures the stability of water quality and has great

advantages in the treatment of landfill leachate with

high concentration of salt (

ZHANG Lina, 2016), so

biochemical treatment and/then RO process has

become the mainstream technology in landfill

leachate treatment. However, in the usually used disc

tube reverse osmosis (DTRO) treatment system, the

pressure energy is wasted because that the high

pressure brine is discharged through pressure release

valve directly after the first stage RO process. In this

paper, a hydraulic turbocharger is used to replace the

electric circulating pump in existing DTRO system

to recycle the brine pressure energy, which may

provide a reference for design and configuration of

energy recovery systems in landfill leachate

treatment process.

1.1 Existing Landfill Leachate DTRO

Treatment Process

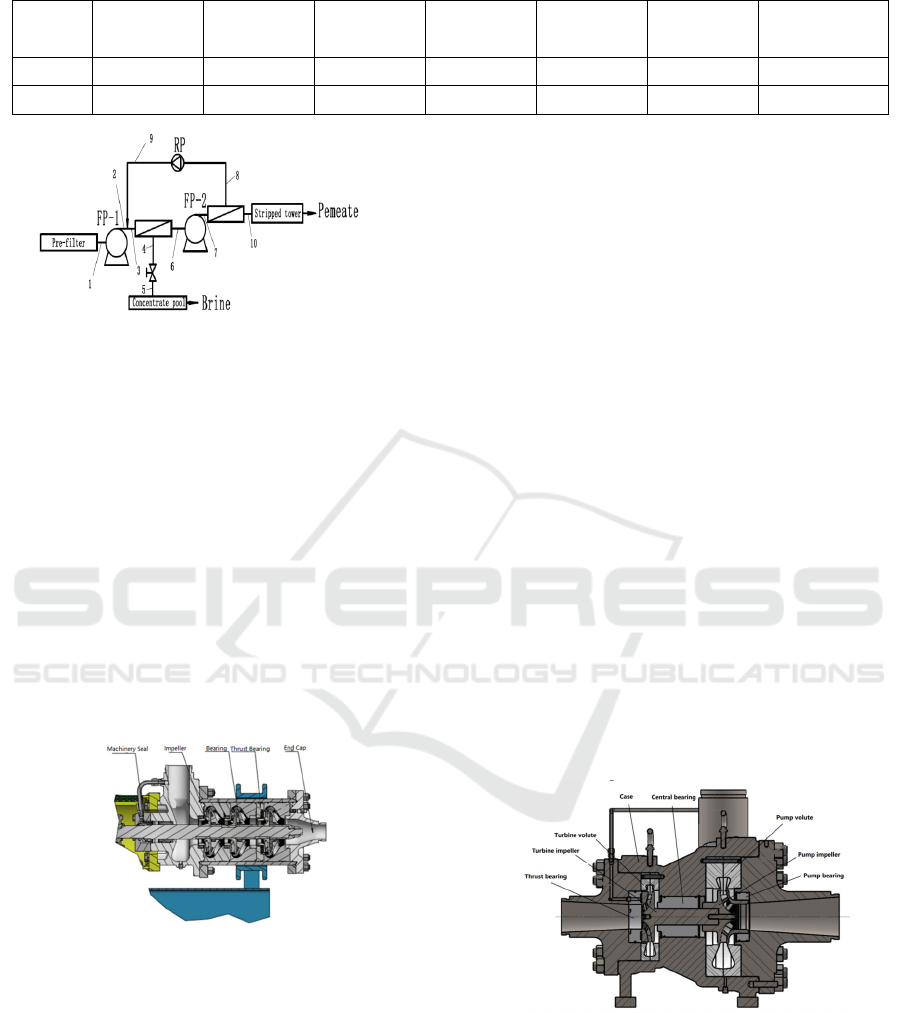

As shown in Figure 1, in the current landfill

leachate treatment process, after pre-treatment,

landfill leachate is pumped through the first stage

DTRO membrane and the left brine will be

pressure-reduced by a pressure release valve and

returned the concentrated tank; the filtered liquid by

the first stage DTRO membrane is then pumped

through the second stage DTRO membrane and the

left brine in this stage will be returned back and then

pumped through the first stage membrane again.

Liquid filtered by two-stage DTRO membrane may

enter the stripping tower and tank, and can be

discharged if its quality meets the emission standard

requirements. This process has been applied in a

waste landfill of China and the measured liquid

quality data of the inlet and outlet of the system are

shown in Table 1. The operation data show that the

recovery rate of the first and second stage DTRO

membrane is 77% and 90% respectively and the

overall recovery rate of the system is 75% (

ZUO

Junfang, et al., 2011

).

Landfill leachate treatment process has high

fresh water recovery rate and low flowrate and high

pressure with the circulation brine, but the pressure

energy is not recycled and reused, and it requires

high sealing performance for circulating pumps.

110

Liu, T., Ji, Y., Li, H., Xue, S-q., Oklejas, M. and Yang, S.

Application Study of Hydraulic Turbochargers in Landfill Leachate Treatment Systems.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 110-113

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Table 1: Water quality parameters of landfill leachate treatment systems.

COD

(mg.L-1)

BOD5

(mg.L-1)

SS

(mg.L-1)

NH3-N

(mg.L-1)

TN

(mg.L-1)

pH value conductivity

Inlet ≤20000 ≤6000 ≤1000 ≤2000 ≤2500 6~9 ≤20000

Outlet ≤100 ≤30 ≤30 ≤25 ≤40 6~9 -

Figure 1: The existing landfill leachate treatment process

(numbers refer to positions in Table 3).

1.2 Circulating Pump Used in the

Existing System

In the existing process, the circulating pump shown

in Figure 2 is used to pressurize the second stage

brine to return to the first stage DTRO membrane

and its inlet port pressure is 35bar, outlet pressure is

65bar, head is 300m. The high pressure of the inlet

put strict requirements for the mechanical seal of the

pump shaft connecting with the motor. High pressure

mechanical seal is expensive, and the maintenance

cost is high in the operation due to its low mean time

between failures (MTBF).

Figure 2: Internal structure of the circulation pump.

2 STRUCTURE OF HYDRAULIC

TURBOCHARGER AND ITS

APPLICATION IN DTRO

PROCESS

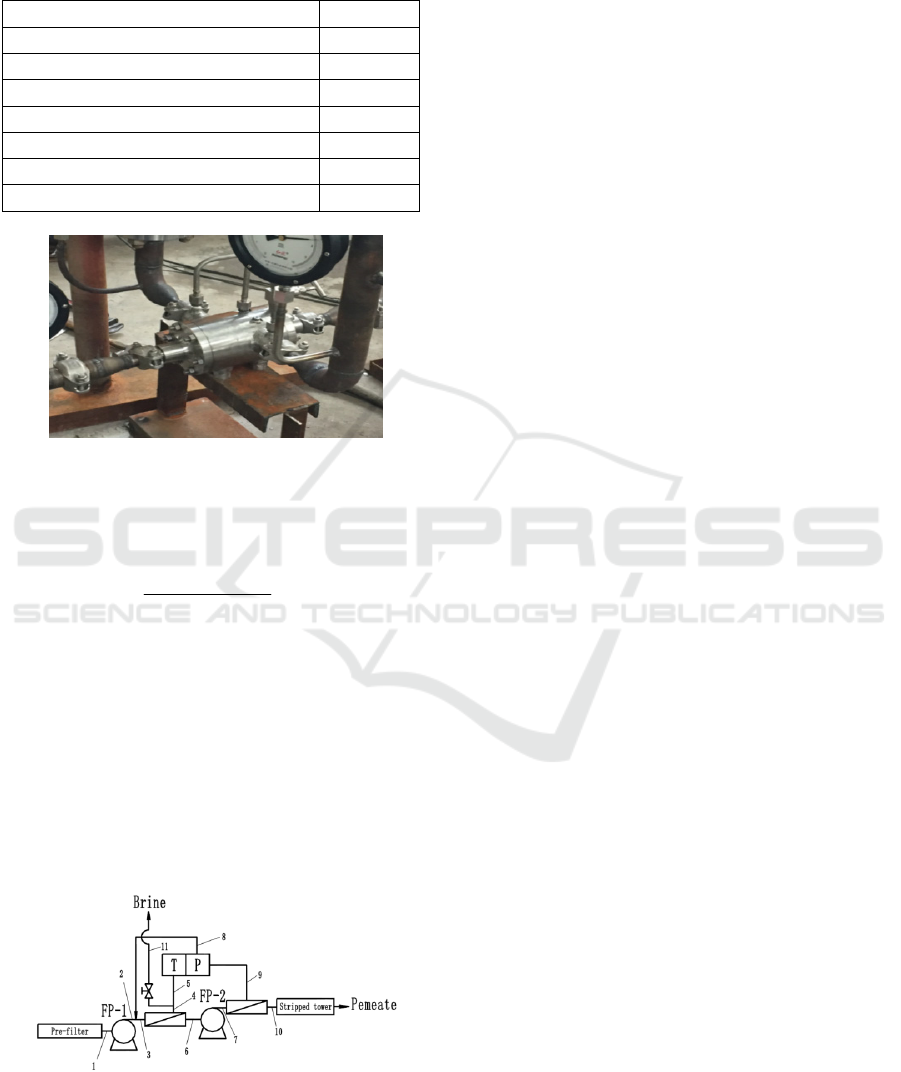

2.1 Structure of Hydraulic Turbocharger

As shown in Figure 3, structure of hydraulic

turbocharger is similar to that of automotive engine

turbocharger, where turbine section and pump

section are connected by a central shaft. It can be

used for pressure recovery and is widely applied in

RO desalination system. Compared with the

existing booster hydraulic turbine, hydraulic

turbocharger has the advantages of simpler structure,

higher efficiency, less leakage, and then higher

reliability and longer operation time. The

flow-through parts of the turbocharger are

calculated by one dimension method firstly, and

then key parameters are optimized by CFD

numerical simulation, finally design efficiency is

verified by experiments and testing (JI Yunguang et

al., 2017). The central bearing in pump section

bearing provides radial support, and the thrust

bearing on the turbine section is used to balance the

axial force between the turbine section and the

pump section pressure difference which points to

the turbine section. The bearing is self-lubricated so

as has more compact and simple structure. Figure 4

is the hydraulic turbocharger prototype.

In the landfill leachate treatment system, in

order to adapt to the corrosiveness of the high

salinity medium, stainless steel SS2205 is used for

the impellers and case of the turbocharger, and

polyether ether ketone (PEEK) material is used for

the thrust bearing.

Figure 3: Internal structure of the hydraulic turbocharger.

2.2 Design Parameters and Energy

Recovery Efficiency of

Turbocharger

Table 2 is the design parameters of the hydraulic

turbocharger for a two thousand ton landfill leachate

Application Study of Hydraulic Turbochargers in Landfill Leachate Treatment Systems

111

treatment system.

Table 2: Parameters of the turbocharger used in a

2000-ton/day landfill leachate treatment system.

Parameters Values

Turbine Section Flowrate, Q

T

11.3 m

3

/h

Inlet pressure of turbine section, P

t,in

6 MPa

Outlet pressure of turbine section, P

t,out

0.5 MPa

Pump section flowrate, Q

p

6.75 m

3

/h

Inlet pressure of pump section, P

p,in

3.5 MPa

Outlet pressure of pump section, P

p,out

6.5 MPa

Overall-energy-recovery-fficiency,

η

32.6%

Figure 4:The prototype of the hydraulic turbocharger.

The energy recovery efficiency of the hydraulic

turbocharger can be calculated by the following

equation:

)(

-

,,

outP,inP,P

outTinTT

PPQ

PPQ

−

=

)(

η

(1)

2.3 Energy Recovery Process of

Hydraulic Turbocharger

As shown in Figure 5, in the new process the

circulating pump is replaced by hydraulic

turbocharger cycle, and the discharge pipeline is

connected to the turbocharger. The pressure energy

of the first stage brine then can be recycled and

pressure of second state can be boosted by the

hydraulic turbocharger.

Figure 5 : Landfill leachate treatment process with a

turbocharger.

Different from the RO desalination system, the

flowrate of the first state is larger than that of the

second stage in landfill leachate treatment process,

and the available flowrate in the turbine section is

greater than that needed for the pump section.

Therefore, only a part of pressure energy in first

stage brine is used to provide pressure for the

second state circulating, then a pressure relief valve

is designed to adjust the flowrate of turbine section.

Compared with the existing system, the new system

does not require a motor to provide mechanical

energy, where the energy exchange between the first

stage and second stage brine can be performed by

the hydraulic turbocharger.

3 COMPARISON OF ENERGY

CONSUMPTION

Hydraulic turbocharger energy recovery system is

widely used in RO seawater and brackish water

desalination,, petrochemical and other

industries(Alisha Cooley, 2016). In this study,

application of hydraulic turbocharger energy

recycling device in landfill leachate DTRO

treatment system is firstly proposed in China.

Table 3 lists flowrate and pressure on each

position in the process of 2000-ton/day landfill

leachate DTRO treatment system. The energy

consumption the whole process is that of the pumps

for providing pressure:

g

Q

TH

W

=

(2)

where W is energy consumption of high pressure

pump per hour (kWh), Q is flowrate (m

3

/h), T is

time (H), H is pump lift (m), g is gravity constant.

Effective work W1 of high pressure water pump

FP is

WTHQW 147.17kg

111

==

ρ

(3)

Effective work W

2

of boosting pump FP-2 is:

WTHQW 75.49kg

222

==

ρ

(4)

Effective work W

3

of circulating pump RP is

WTHQW 5.68kg

333

==

ρ

(5)

Total energy consumption per hour of the

existing system is

kWWWWW

new

292.5///

332211

=++=

η

η

η

(6)

where η

1

is the efficiency of the high pressure pump

FP; η

2

is the efficiency of boosting pump of FP2, η

3

is the efficiency of the circulation pump FP3.

Table 4 shows the flowrate and pressure of the

landfill leachate DTRO treatment system with a

hydraulic turbocharger.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

112

Table 3: Flowrate and pressure of existing landfill leachate treatment process.

Position 1 2 3 4 5 6 7 8 9 10

Flowrate/

m

3

· 83.3 83.3 90.3 20.77 20.77 69.5 69.5 6.95 6.95 62.6

Pressure/MPa

0.1 65 65 60 0.5 0.1 40 35 65 0.5

Table 4: Flowrate and pressure of landfill leachate treatment process with hydraulic turbocharger.

Position 1 2 3 4 5 6 7 8 9 10 11

Flowrate/m

3

h

-

1

(

m3/h

)

83.3 83.3 90.3 20.77 11.35 69.5 69.5 6.95 6.95 62.6 20.77

Pressure/M

P

0.1 65 65 60 60 0.1 40 35 65 0.5 0.5

Energy consumed by the new system is

WWWW 278.32k//

2211new

=+=

η

η

(7)

Electricity power saved every hour

WWW 14.2k-

new

=

(8)

It is seen from the calculated results that

hydraulic turbocharger used in the new process

reduces the energy consumption by 14.2 kW or 5%

compared with the existing landfill leachate DTRO

treatment system.

4 CONCULUSIONS

A new system with energy recovery device is

presented by using a hydraulic turbocharger to

replace the circulation pump of the existing landfill

leachate system. Calculation shows that the new

system has lower energy consumption and failure

rate, and higher operation stability due to no

mechanical dynamic seals in the turbocharger. This

study can provide a good reference for integration of

hydraulic turbocharger energy recovery systems in

landfill leachate DTRO treatment system.

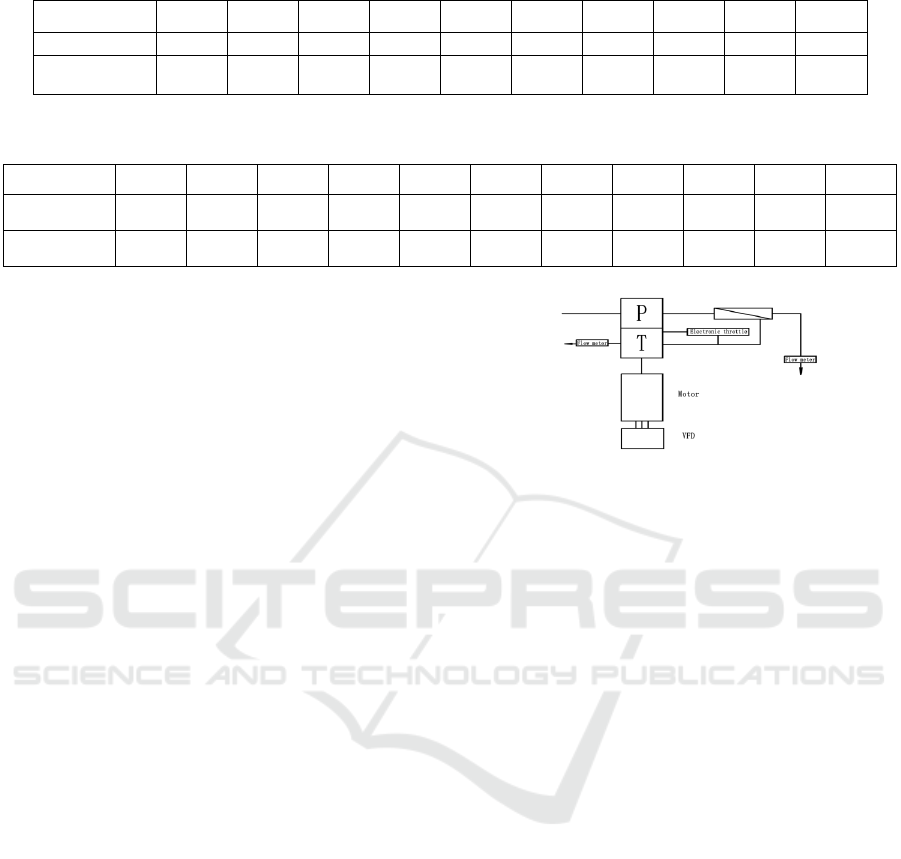

However, the pressure energy is not recycled

completely by the hydraulic turbocharger because

the flowrate of the second stage brine is relative low

in the two-stage landfill leachate treatment system,

in this case a electricity generator may be integrated

in the turbocharger as shown in Figure 6 (Tamer A.

EI-Sayed et al., 2016), where the extra energy can be

recycled and transformed to electricity power, which

will be presented in the future research.

ACKNOWLEDGMENTS

This work was financially supported by key project

of science and technology research of Hebei higher

Figure 6: Hydraulic turbocharger with generator.

education institutions (ZD2015090); science and

technology project of Hebei province, China

(17394505D); 100 Talents Program of Hebei

province, China (E2016100006); and introduction

of foreign intelligence project of the year 2017 of

Hebei province, China.

REFERENCES

ZHANG Lina, 2016. Process design of two-stage DTRO

system for landfill leachate treatment. China Water,

32 (16): 59-62 (in Chinese)..

ZUO Junfang, et al., 2011. Application of DTRO

technology in the treatment of landfill leachate.

Membrane Science and Technology, 2011,31 (02):

110-115 (in Chinese).

JI Yunguang, et al., 2017. Application study of fluid

pressure energy recycling of decarbonization

process by C4H6O3 in ammonia synthesis systems

by hydraulic turbochargers. Modern Chemical

Industry, 37 (11): 158-161 +163 (in Chinese).

Alisha Cooley, 2016. Turbocharged cost savings in RO

systems. World Pumps, 6:36-41.

Tamer A. EI-Sayed et al., 2016. Performance of hydraulic

turbocharger interated with energy management in

SWRO desalination plants. Desalination, 379:

85–92

Application Study of Hydraulic Turbochargers in Landfill Leachate Treatment Systems

113